Cultivated plants can be grown without the use of soil, using aeroponics. This is a type of hydroponics. The technology requires the presence of a nutrient solution and substrate.

Vegetables, berries, and herbs are grown using aeroponics. To apply a new method of crop production, it is necessary to purchase special equipment. What is aeroponics? How to use it?

Aeroponics, what kind of technology is this?

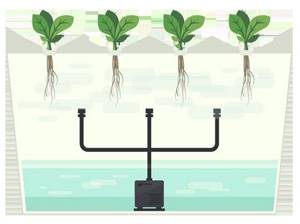

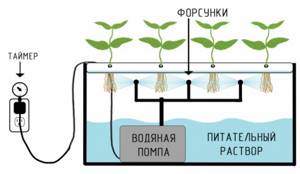

Aeroponics is one of the technologies that can make the farmer’s work easier and increase productivity in limited conditions, when there is not enough moisture and a minimum of technological space. This is a method of growing plants without the use of aggressive chemicals with a minimum of fertilizers and all this thanks to the active saturation of the roots with oxygen. “Watering” is carried out using special nozzles, spraying water and nutrients dissolved in it in the form of mist directly into the root zone of plants.

What is aeroponics?

Explanatory dictionaries define aeroponics as agricultural technology in which soil is not used in the process of cultivating plants. Translated from Greek, “aero” means air. It is this environment that is working. The roots grow without a substrate in the open air, receiving water and nutrients through aerosols.

For the first time, the aeroponic growing method was tested by a Russian scientist, Professor Artsikhovsky. Then, in 1911, oxygen saturation technology did not receive a response from the public. However, several decades later, an American-born scientist named Went developed and patented a new method of growing plants without soil. It was thanks to Vento that the technology received the name “Aeroponics”.

Also, recently, a hybrid technique that has absorbed the best from different technologies has become popular among professional farmers: aero-hydroponics. The method consists of enriching plants with oxygen supplied to the nutrient solution by an air pump.

What is the difference between aeroponics and hydroponics?

Using hydroponics, plant roots are located in aqueous solutions or special substrates supplied with nutrients. Under such conditions, algae often appears, which adds additional problems for the care and maintenance of equipment.

With aeroponics, the plant and its roots hang in the air, so it receives a sufficient amount of oxygen. Nutrition occurs by spraying an aqueous solution onto the roots. The yield of this method is so high that there is no need to use additional growth stimulants, fruiting accelerators and, accordingly, toxic pesticides. This means that the products will be much cleaner and more environmentally friendly, and will be suitable for feeding children, adults and people who are forced to adhere to strict diets.

Ultrasonic aeroponics

You can spray a solution of nutrients not only through nozzles, but also using ultrasound. Any household fog generator (humidifier) is suitable for this. With its help, you can obtain a cloud of fine particles of the nutrient solution. But there are pitfalls here. The steam has a temperature of about 40 degrees, which is very high for the root system of plants. Therefore, the steam must be cooled, which gives the installation additional volume.

Craftsmen offer a lot of ways to grow useful plants at home.

Aeroponics will quickly, reliably, and economically help you obtain any amount of herbs and vegetables you need. This is an excellent solution if traditional cultivation methods do not live up to expectations, or the climate of the region does not allow you to grow the plants you need in open ground.

Types of aeroponic installations

- With a water pump,

an aeroponic installation works like this: first, a nutrient solution is prepared in a special tank, and air is also supplied there from an air compressor to saturate the liquid with oxygen. Using a pump that turns on strictly according to a schedule, the liquid is supplied through tubes to the nozzles and the solution is sprayed directly onto the roots. - Ultrasonic aeroponics

is a method that uses ultrasound to turn a nutrient solution into a mist, creating a humid environment. And this mist is fed into the root zone of the plants, feeding them with everything they need.

Other aeroponics options

Another, most unusual option for aeroponics is ultrasonic. The role of the fog production device is performed by an ultrasonic air humidifier. It creates a cloud of small droplets, the only drawback of which is the high temperature, which is destructive for plants, so an additional cooler must be used in combination with the system.

It is based on the ability of a sound wave to pierce a nutrient solution, thereby creating bubbles. When released into the air, they burst and the solution falls on the rhizome. To create ultrasound, piezoceramic parts in the form of a membrane or disk are used. Features of the technology allow the use of mixtures of low concentration.

For indoor plants

Anyone can cultivate flowers, vegetables and herbs. The most common version of aeroponics consists of a small vessel, the bottom of which is covered with a solution, a lid made of dense material in which plants are fixed, part of the root system of which touches the feeding liquid. To assemble such a structure you will need:

Maintenance in this case will consist of periodically adding a solution.

For seedlings

To plant seedlings, you must use the following instructions:

For crops with large root systems

A good, dense root system requires large boxes for planting. The structure is constructed in the same way as for ordinary seedlings, however, the lower container is chosen deeper so that the roots develop freely.

Advantages and disadvantages of aeroponics

As with any other growing method, aeroponics has its pros and cons. Pros:

- If one plant is infected, it does not infect the entire soil and all its “neighbors”. It is removed quickly and painlessly. Diseased roots are immediately noticeable, they are easier to quickly treat;

- There is no need to use a substrate, because of this the room is clean and tidy;

- Minimum pests, no need to disinfect the soil and control them;

- Oxygen saturates the roots of plants much better than in other growing methods, due to which they grow faster and produce higher yields;

- It is easy to grow plants from other climate zones. For example, strawberries can be grown all year round, yielding crops up to three times a year;

- The solution contains all the necessary substances at once; its composition can be changed if such a need arises;

- There is no need for aggressive chemical treatments, resulting in an environmentally friendly product without harmful impurities;

- Even if growing space is limited, you can easily place boxes with plants in several tiers on top of each other;

- Harvests can be harvested several times throughout the year;

- The system is easy to maintain. Even in preparation for the next season, you only need to carry out the necessary disinfection and clean the trays and system.

- Most operations can be automated: watering at certain intervals, there is no need to dig, cultivate and fertilize the soil.

Minuses:

- There is an opinion that vegetables and herbs grown in this way have a low level of vitamins and sugars that can only come from the ground, but this has not been proven;

- Constant monitoring of the quantity and composition of the solution is important;

- The equipment is quite complex, you have to buy special devices - pumps, filters, tanks, nozzles, lamps, fans and other accessories necessary for growing indoors;

- It is important to ensure timely troubleshooting, since any malfunction of the equipment may cause the plants to die;

- With exposed root systems, plants must be kept in sterile conditions because any viruses can damage or even kill them.

The future of aeroponics

Using air to create a stunning indoor garden is not the only thing aeroponics offers.

Some experts believe this is the wave of the future for locals and urban farmers, especially in areas where land is precious and there are many mouths to feed. If you've seen those futuristic photos of green landscapes growing on the sides of skyscrapers, you've got an idea.

It's also interesting to note that aeroponics is important to the space program, where NASA is working hard to plan ways to efficiently grow crops during manned space travel or where humans may land in the future, including the Moon and Mars.

Until we start adding a planetary prefix to our zip codes, aeroponics can be a powerful and effective tool for the inner gardener right here on Earth.

15.09.2019

Examples of growing crops using aeroponics in an apartment

At home, this method is suitable for those who are limited by space, but who want to get a good, guaranteed harvest several times a year. You can even grow strawberries, although they will need such additional things as a constant air temperature in the room (18-25 degrees, if it’s lower than that you won’t be able to get berries), lighting (more than 12 hours a day, since this is a light-loving berry) and a special solution with fertilizers (nitrogen, potassium, phosphorus, as well as magnesium, calcium, sulfur, they must be added to the solution).

The main difference between strawberries and other plants grown in the same way is that they require a change in nutrition at each stage of growth. Germination from seed, seedlings, vegetation, pre-blooming, flowering, fruiting, rest. There are a huge number of strawberry varieties that can be grown aeroponically: Asia, Albion, Vivara, Murano, etc.

Strawberry crops can be harvested in winter and summer, all year round.

Aeroponics: paradise for plants

Aeroponics is the process of growing plants in air without the use of soil or substrates, in which nutrients are delivered to the roots in the form of an aerosol. With this method, the plant sits in mineral wool. The method does not require a large area, eliminates the appearance of weeds, and most importantly, it is an environmentally friendly product that does not contain nitrates or pesticides.

With aeroponic technology, there is a great saving of water and fertilizers, and the risks of crop loss are minimized. It allows you to grow produce all year round. The growing season is shortened, so you can get from 4 (cucumbers, tomatoes) to 12-14 (lettuce, greens) harvests per year.

The vertical growing method saves space, so any premises, even basements and warehouses, are suitable for a greenhouse. You can create in-depth greenhouses, which are built 3 meters deep into the ground, which significantly saves money on heating and cooling.

We talked with two companies that are developing aeroponics in Ukraine and learned some of the intricacies of this business.

The first of them, Green Garden Group, is probably the only company today that grows lettuce using the aeroponic method on an industrial scale, and the second, Cybergrow, is a technology company that provides equipment for growing using aeroponic technology, and is also involved in this promising area of aeroponic business like vertical gardening.

Vadim Tsirul, owner of the Green Garden Group company, shared his experience of growing lettuce on an industrial scale:

Vadim, how did the idea of organizing an aeroponics greenhouse come about?

We started it all as an experiment, then we realized that we were succeeding and began to move on. I read a lot on this topic, collected information, visited greenhouses in Europe and was surprised by the low level of their technology. You could say it's Stone Age there. Dutch companies are more advanced, but they work more using the hydroponics method. Of course, Europe also has high-tech enterprises, but it would be wrong to say that all its agriculture is computerized. In any case, this applies to lettuce, in the cultivation of which they are not leaders in advanced technologies. Only England and the USA demonstrate a high level.

There is also no salad consumption culture in Ukraine, so the market is absolutely free. Today in the country no more than 5 enterprises grow greens year-round. In percentage terms, this is no more than 15% of the market. Ukraine still imports the remaining percentage.

We started growing salads using aeroponics more than two years ago, in February 2021. At the moment we have two greenhouses, which have already fully paid for themselves. The construction of one greenhouse costs about $150 thousand. We are currently preparing a third greenhouse and plan to build two more.

We are also engaged in the construction of greenhouse complexes using the aeroponics method on a franchising basis. One such complex has already been built and launched in Novi Petrivtsi. This year we plan to build two more franchise complexes.

We are currently developing in the Kyiv region and plan to expand to the Odessa region, which is interested in the active development of tourism and, accordingly, increased demand for greens.

What is special about the technology of growing salads using the aeroponic method?

The first stage of growing lettuce using the aeroponic method is growing it on the table. We cut the mineral wool into 3x3 cm cubes, place them on the tables and begin sowing. While the plant is on the table, which is from 3 to 10 days, we feed it with a concentrated organic solution, which contains all the micro- and macroelements necessary for the normal development of the plant.

When the plants sprout roots, they are ready to be planted in a cup and placed in a pipe. The pipe has nozzles through which aerosol pollination of the roots is carried out. Thanks to this aeroponic arrangement, the roots of the plant are constantly in the air and enriched with oxygen. Aerosol drip irrigation starts every hour and continues for 60 seconds. Thus, the plant is constantly in an oxygen environment, due to which it grows much faster and does not accumulate unnecessary impurities.

When we transplant the plant into pipes, we slightly increase the concentration of nutrients. We use only organic substances.

Growth in aeroponics happens very quickly, right before your eyes. It only takes 30–35 days to grow lettuce, and even less in the summer—20–25.

How is watering carried out? How much water does it take?

The water is collected and settled for several days in three barrels of 3000 liters each. After this, a solution is prepared in barrels. We mix fertilizers in large batches of 10 liters per 3000 liters of water. After this, the solution is supplied to barrels located in greenhouses. Already from these barrels through the pipes all plants are pollinated. Please note - these are drainage pipes: we watered, the water drained and returned back to the barrel. Thanks to this, only one cubic meter of water is enough for us for two weeks. This is much more economical than regular watering. The water temperature is within 20°C.

We have our own laboratory, and every morning we take water tests, look at how the salt concentration has changed, and adjust the solution.

Do you provide additional lighting to your plants?

Yes, in winter there is additional lighting, we use LED lamps, they automatically turn on and off.

What fertilizers do you use?

We use only organic fertilizers. We approach their choice very responsibly, we do not skimp on this, we mix the solution ourselves. Low-quality fertilizers can clog the nozzles due to the fact that some salt has not dissolved, and there are two thousand such nozzles in only one greenhouse, so cleaning them is a very labor-intensive process.

How are the plants arranged in the pipe, how many fit per square meter? What is the yield per cycle?

We have two greenhouses, each 480 m2. In one greenhouse we grow salads and herbs using horizontal aeroponics; in another, arugula and basil grow in vertical aeroponic pipes.

The lettuce greenhouse is divided into two parts: the first zone is 50 m2 for germinating seeds, and the second zone is 430 m2 for growing sprouted lettuce.

In the first zone there are four tables measuring 1x2 m, each of which has 1800 seats.

The second lettuce planting zone features 432 horizontal aeroponic tubes, each with 36 holes. Thus, there are 15550 holes in total. Two lettuce seeds are planted in one hole. Each cell produces 120–160 g of finished product.

Thus, the lettuce yield will be: 432 (pipes) x 36 (holes, seats) = 15550 (holes) x 140 g (average weight of lettuce in the hole) = 2177 kg.

The holes in the pipe are located in such a way that the lettuce grows normally, there is enough space for it, there is air circulation and the lettuces do not interfere with each other. We plant lettuce in horizontal pipes because they have fewer holes and they feel more comfortable, but they fall out of vertical pipes under their own weight.

In the second greenhouse we grow purple and green basil and arugula using the vertical method. The greenhouse is also divided into two parts: the first zone for germinating seeds occupies 120 m2, the second zone for growing sprouted plants has 360 m2.

In the first zone there are 15 tables measuring 1x2m, each of which has 1800 seats.

The second zone contains 432 vertical aeroponic pipes, each with 70 holes. Total 30240 holes. If you calculate the arugula harvest, then 20–30 arugula seeds are planted in one hole. The duration of the season from planting arugula to its ripening, depending on the time of year, ranges from 35 to 45 calendar days. Each hole produces 70–100 g of finished product.

Thus, the arugula harvest will be: 432 (pipes) x 70 (cells, seats) = 30240 (holes) x 80 g (average weight of arugula in the hole) = 2410 kg.

Basil is planted with 5–9 seeds per hole. The duration of the season from planting to ripening, depending on the time of year, ranges from 30 to 40 calendar days. Each hole produces 25–40 g of finished product.

The yield will be: 432 (pipes) x 70 (holes, seats) = 30240 (holes) x 30 g (average weight of basil in the hole) = 910 kg.

What kind of lettuces do you grow?

We grow such salads as Lollo Rossa, Lollo Bionda, two types of Romaine - red and green, and Friese lettuce. We also have varieties such as Gauguin and Boston. We started growing oakleaf endive. We make trio mixes, which include oakleaf lettuce, Lollo Rossa and Lollo Bionda. The so-called vitamin sets that we form from dill, parsley, basil and spinach are also flying off with a bang.

We are constantly experimenting, trying different growing options. For example, we grow three lettuces in one pot - Lollo Rossa, Lollo Bionda and oakleaf. As an experiment, we grow rosemary, strawberries, raspberries, and blackberries. Surprisingly, one strawberry bush bears fruit all year round.

We sell greens with mineral wool, thanks to which they are stored fresh for a long time and do not lose their beneficial properties. We are also trying, and quite successfully, to grow blackberries and raspberries. We planted small shoots of these plants, and after 2 months they grew into mature bushes. They are now a year old. Just like strawberries, they bloom and bear fruit continuously. It happens that they rest for two weeks, and then they produce the harvest again. To be honest, this is very surprising.

As an experiment, we grow tomatoes, eggplants, and zucchini, which also produce a good harvest. Thus, you can grow anything using aeroponics.

Alexander Kandul and Sergey Pribura, co-founders of Cybergrow, talked about how the company helps clients organize an aeroponics business, what kind of crops tomatoes and cucumbers can produce, and why vertical aeroponic gardening is promising and in demand in Ukraine.

A few words about your company, how many years have you been involved in aeroponics?

Our activity began as an experiment, a hobby, which quickly grew into a commercial project. Since 2009, we have been testing different crops - from ornamental ones for vertical gardening, such as vines, bananas, palm trees, to agricultural crops: hot and sweet peppers, low and tall tomatoes, cucumbers, zucchini. Our task is to help the maximum number of farmers and greenhouse growers organize efficient cultivation.

What yield can tomatoes and cucumbers produce using the aeroponic growing method?

The yield of tomatoes, with the work of a qualified technologist , can be about 6 kg per bush in one growing cycle, which is approximately 80 days. 6 bushes grow per 1 m2 - that’s 36 kg/m2 per cycle. There are 4 such cycles a year, which means we can get 144 kg of tomatoes per square meter per year.

The yield of cucumber under the same conditions can be about 4-5 kg per bush per growing cycle, which lasts 65–68 days. 6 bushes/m2, 5 cycles per year - that’s 150 kg/m2 per year.

To further speed up the aeroponics growing technology, you can grow a plant not from a seed, but from a cutting. We did this with tomatoes. We cut off the stepson and root it in mineral wool, so we preserve it for about a month.

Many plants can be grown using aeroponics. But in order to perfect the technology for a particular plant, it is necessary to “test” more than one cycle on it. In order to understand how many cycles a plant can produce per year using aeroponics, you need to grow it for a year. Only research can show how many kilograms per square meter can be obtained. For example, they ask us, is it possible to grow this or that? We answer: it is possible to grow almost everything, the question is how much demand there is for it.

Tell us about the direction of vertical gardening.

For our country, the issue of fresh air may not be so pressing, but in hot countries, where everyone is in air-conditioned rooms, there is a catastrophic lack of fresh air. In this case, a good solution might be to install an aeroponic greenhouse on the roof of this building, in which oxygen is produced and then supplied to the premises. An aeroponic greenhouse, unlike a conventional soil greenhouse, does not weigh down the building, so such solutions are becoming increasingly in demand.

In countries where, unfortunately, there is no such luxury as the climate of Ukraine, but there is money, there are our potential clients who are already ordering and are ready to order vertical green installations.

Moreover, vertical gardening can be a solution for an asthmatic person. He can order a vertical green wall measuring 2.5 x 4 meters with plants that draw the air that is in this room through them, and the person will feel much better. Due to its lightness, such vertical gardening can be offered even on yachts. Therefore, in the direction of vertical gardening, we see great opportunities for growth and development.

Oxygen and water are non-renewable resources, so the niche of clean air will increasingly enter the market. Breathing fresh air and eating organic products is vital, and this is what the aeroponics method can provide.

Nadezhda Lyadetskaya,

Equipment needed to create an aeroponics installation with your own hands

- Containers for storing nutrient solution and plants.

- Reservoir for storing clean water.

- Tubes and hoses for supplying solution to the roots. They should be chosen exclusively opaque to prevent the appearance of microorganisms and do not forget that they must be connected hermetically using special fittings. The hoses must be flexible so that they can be brought to any place if necessary.

- Water pump.

- Spray nozzles.

- Timer for irrigation automation. There are mechanical and electronic. Mechanical ones are more reliable, but their minimum interval is 10 minutes, which is too long for young plants and seedlings; electronic ones are more accurate, but the cost is higher.

Containers for plants and nutrient solutions

Containers or trays for growing plants must be designed in height so that the root system of plants does not touch the bottom and does not tuck under. It is for this reason that the height of some containers is usually greater than when growing using hydroponic methods. It is recommended to use food plates that do not transmit light. It is mandatory that these containers have a lid so that the nutrient solution sprayed by the nozzles does not fly out.

The reservoir for nutrient solutions is calculated according to the volume of the plants to provide them with full nutrition. The recommended material for containers is food grade plastic. Plastic does not react with liquids, which does not create problems during operation. The tanks must be light-proof and preferably white on the outside to reflect the light that is valuable to us. The system can be built either for one single plant or in several tiers on top of each other. The container should have a lid on top to protect it from dust and debris and be opaque.

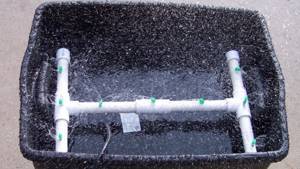

Pumps, compressors and pumps

The aeroponics pump must be of sufficient power. For home and homemade projects, you can take a compressor from a car for windshield washer, but its power is only capable of providing pressure to one or two nozzles.

It is preferable to buy high-pressure pumps at a specialized equipment store, but this is only the case if there are several sprayers and there is more than one plant.

It is recommended to apply a pressure of more than 1 atmosphere and as quiet as possible. If the system is located far from living rooms, in a barn or basement, then you can ignore the noise.

Sprayers and nozzles

The most important requirement for nozzles that can be used in aeroponics is:

- They should spray liquid rather than pour in streams;

- Nozzles must be resistant to oxidation when interacting with nutrient solutions;

- The size of the “drop” should be suitable for your plants; the more delicate the plant’s root system, the smaller the drop should be.

- The size of the hole should be of such a diameter that it works as long as possible and does not become clogged;

- The nozzle must be dismountable to allow for maintenance and cleaning.

How to assemble equipment yourself

If you assemble the entire system yourself, then you must adhere to the rule, the simpler the better. There is nothing complicated about this, the design of aeroponic systems is not complicated and it is not at all difficult to assemble such a device from scrap materials. Show some imagination or learn from our experience.

The most important thing is to ensure an uninterrupted supply of nutrients to the plants and choose the most reliable nozzles or sprayers.

It is necessary to take into account the growth of the roots, they will become larger, and the capacity for them will be required more and more, it is important to take this into account during manufacturing.

Types of Aeroponic System

Aeroponics systems can be of several types. They are divided depending on the way in which the liquid for feeding the roots is converted into an aerosol:

High pressure pump system

Provides spraying of roots at certain intervals. This type of system has the following characteristics:

Aeroponic system with air compressor

It works like this:

Ultrasonic aeroponics

The principle of its operation is similar to climate control units:

Important! The mist obtained using ultrasonic aeroponics has a too high temperature of 40 C. While crops require a temperature of no more than 20 C. For this reason, it is necessary to pre-cool the liquid.

Due to its features, this method is good for growing seedlings or young greens.

Preparing a solution for aeroponics

First of all, you should take care of the quality of the water; it should not be as clean as possible. Ideal water is distilled water. Tap water can be used, but only after preliminary analysis or cleaning. Also, such water must be allowed to settle in an open container to get rid of Chlorine for a day or even two.

There are various solution formulations that vary depending on the condition of the plant and its needs. Its composition can be changed if the need arises. The concentration of nutrients, frequency and duration of watering must be changed throughout plant growth.

Everything is pre-dissolved in water in dark, airtight containers. By and large, a solution for aeroponics is no different from solutions for hydroponics, only the requirements for cleaning from large impurities and debris are higher. It is not recommended to use nutrient solutions without purification and filtration in aeroponics.

Nutrient solution

Here I also spent a long time studying alternatives. I thought about ready-made solutions and about making them myself. In the end, I decided to take a risk: first I made a mixture of fertilizers, but everything turned out so inconvenient, complicated and with an uncertain result that I found a chemical supplier. reagents, bought pure substances and gradually arrived at the current three-component concentrated composition. Unfortunately, I don’t know how good it is: I would like to do a foliage analysis to check what is missing/missing, but I don’t yet understand where and how to do this. Several times I almost killed the bushes with my suboptimal composition and incorrect acidity, but nothing happened.

I mix the solution itself using distilled water, which I buy. To be sure of the composition, the solution is not reused; the drain is immediately disposed of. By the way, since this is aeroponics, I use a solution with an EC around 400 mS/cm3 (TDS - ~200 ppm on a 0.5 scale). Moreover, there is a suspicion that this is too much. For comparison, the TDS of my tap water is about 130 ppm.

Necessary materials

What is needed to assemble aeroponics yourself? You will need the following components:

- A special container designed for nutritional mixture.

- A flat container (be sure to use an opaque one) with a tight-fitting lid. One of the conditions for high-quality soilless cultivation is the absence of sunlight, so that weeds and algae do not form in the mixture.

- Hoses. When choosing, it is important to take into account their diameter and the dimensions of the accompanying fittings, so that during assembly all connectors and connections are without gaps, and all joints are sealed.

- Depending on the type of crops grown, a sprayer is selected. For example, when watering a powerful root system, heavy watering with large drops would be appropriate. But spray nozzles are usually used when water enters in the form of a fine suspension. In this case, along with watering, nutrients will be better absorbed.

- Powerful pump. Ideally, special equipment made for factory aeroponic installations would be suitable (costs about 2,000 rubles), but you can also use a car compressor; a pump for washing windshields would also be a good option. The main thing is not to use very low-power aquarium equipment, as this is one of the common mistakes of novice gardeners.

- High quality timer. There are two types of this equipment that are suitable for soilless growing methods. The first are mechanical timers, which are considered more durable. But their main drawback is the minimum watering interval of more than ten minutes, while the root systems of most crops require a continuous supply of moisture at intervals of five minutes at the initial stage. Only in the future (as you grow) will the interval increase to 20 minutes. Therefore, it is better to use electronic timers, which are considered more accurate.

Air compressor system

When assembling a soilless system, the pump used to deliver the nutrient mixture can be replaced with an air compressor (external) . All joints when connecting such equipment to a container are carefully sealed to ensure the necessary pressure in the container with the nutrient solution. Most often, installations using an air compressor are used for cultivating various greens.

In order for the installation to function perfectly, it is equipped with a pressure gauge, and high-quality dispersion of nutrients is ensured by solenoid valves.