What are the differences between a high-quality and a bad hacksaw? Low quality can be seen by poorly sharpened teeth. Sometimes manufacturers cheat and make the teeth seem sharp, but after a few jobs they become dull. A good hacksaw, on the other hand, is made of steel that will hold its edge for a long time. The review contains a rating of the best hacksaws for woodworking, indicating the features of choice and functions.

| Category | Name | price, rub. | Short description |

| Popular models of wood hacksaws | Gross Piranha 24106 450 mm | 900 | The model is equipped with a fixed handle. Features hardened teeth and Teflon coating. |

| BLACK+DECKER BDHT0-20169 500 mm | 600 | Equipped with a fixed handle. Only wood is processed with a 500 mm long blade. | |

| STANLEY JETCUT 2-15-595 450 mm | 1000 | Fine teeth allow you to make the cut as accurately as possible. | |

| BISON Professional 15154-250 250 mm | 450 | Can process laminate, wood and plastic. | |

| Vira 800240 400 mm | 450 | Suitable for smooth and precise operation. Designed for wood processing only. | |

| STANLEY JETCUT 2-15-281 380 mm | 950 | Belongs to the category of new products. Cutting direction: longitudinal-transverse. | |

| Kraftool Katran Precision Cut 1-15194-18-22 185 mm | 720 | Performs cutting of wood, plastic and laminate. There is also a 3D sharpening function. | |

| JCB JSW002 550 mm | 600 | The fixed handle with a rubberized insert ensures comfortable work. | |

| Gross Piranha 24100 450 mm | 1100 | Processes wood, plastic and laminate. The set includes one canvas. | |

| STANLEY Fatmax 0-20-556 | 1200 | A miniature hacksaw will be indispensable in tourism and farming. The length of the entire tool is 302 mm. | |

| Bahco 2600-16-XT11-HP | 1500 | Friction during operation is reduced by the low friction coating. This protective layer reduces the degree of heating of the canvas and also protects against corrosion. |

Top best hacksaw models

When choosing a hand saw for wood, there are many factors to consider. First, the purpose for which the tool will be used. Secondly, the components of a hacksaw: saw blade, size and shape of teeth, handle (it should be comfortable). The saw should be user-friendly and sharp. Below is a list of the best hand tools for woodworking , according to parameters and according to customer opinions.

STANLEY JET CUT SP 2-15-288

Carpenter's saw, blade size - 50 cm, teeth suitable for longitudinal and transverse cuts. Gross weight - 0.5 kg.

BISON "EXPERT"

Woodworking devices from the ZUBR company are represented by the following models:

- EXPERT 15071-45: cross-cut saw, blade length - 45 cm, tooth pitch - 3.5, weight - 0.34 kg.

- EXPERT 15071-40: cross-cut saw, length - 40 cm, pitch - 3.5, weight - 0.33 kg.

- EXPERT 15073-45: cross-cut saw, length - 54 cm, pitch - 5, weight - 0.34 kg.

STANLEY OPP 1-20-089

Carpentry tool, blade length - 38 cm, hardened teeth. Gross weight - 0.5 kg.

BAHCO 396-LAP

The length of the canvas is 19 cm, folds, has an anti-corrosion coating, and is fixed in the closed and open state. Gross weight - 0.215 kg.

Encore Wolf 9858

For cross-cutting wood, blade size is 40 cm, tooth pitch is 4 mm, sharpened at three angles, which is a big plus for speed of work. Gross weight - 0.35 kg.

Anchor Beaver 9857

Metal blade made of high-strength steel, for longitudinal and cross cuts, length - 50 cm, teeth sharpened at two angles, therefore quite versatile. Gross weight - 0.5 kg.

IZHSTAL 030108-050

For carpentry work, blade size - 50 cm, pitch - 6.5 mm, designed for two types of cutting. Gross weight - 0.46 kg.

Criteria for choosing a hacksaw for wood

When choosing a hacksaw for wood, you need to rely on the following characteristics:

- blade length;

- shape and size of teeth, as well as pitch;

- steel quality;

- the type, size of the handle, as well as what material it is made of.

Hand hacksaws for wood can be used both for gardening and generally intended for the garden.

Popular models

The best new wood hacksaw models are presented below.

Gross Piranha 24106 450 mm

High-quality hacksaw at an affordable price. It can be purchased for 900 rubles. The model is equipped with a fixed handle. Features hardened teeth and Teflon coating.

Has the following advantages:

- 3D sharpening.

- Processes wood, laminate and polystyrene foam.

- Rubberized handle.

The length of the canvas is 450 mm, and the pitch is 11-12.

Gross Piranha 24106 450 mm

BLACK+DECKER BDHT0-20169 500 mm

One of the cheapest hacksaws for wood. Its cost is about 600 rubles. The teeth are hardened and their pitch is 11. Equipped with a fixed handle. Only wood is processed with a 500 mm long blade. The saw with hardened teeth received a longitudinal-transverse direction. There is also a 3D sharpening function.

BLACK+DECKER BDHT0-20169 500 mm

STANLEY JETCUT 2-15-595 450 mm

Fine teeth allow you to make the cut as accurately as possible. Also processes wood. Teeth pitch 11 points. The hardened teeth received a longitudinal-transverse direction. The fixed handle adds reliability during operation. The length of the blade is 450 mm. The price is within 1000 rubles.

STANLEY JETCUT 2-15-595 450 mm

BISON Professional 15154-250 250 mm

Great option for hiking. The length of the canvas is 250 mm. This is optimal for small jobs. Can process laminate, wood and plastic. It will cost only 450 rubles. Ideal option for tourists.

BISON Professional 15154-250 250 mm

Vira 800240 400 mm

A fixed handle and 3D sharpening function are typical characteristics of modern hacksaws. Suitable for smooth and precise operation. Designed for wood processing only. The 400 mm long blade is suitable for small and medium-sized jobs. The direction is transverse. Price 450 rubles.

Vira 800240 400 mm

STANLEY JETCUT 2-15-281 380 mm

Belongs to the category of new products. Cutting direction: longitudinal-transverse. Hardened teeth process the wood. The length of the canvas is 380 mm. The price is within 950 rubles. Teeth pitch 7 points.

STANLEY JETCUT 2-15-281 380 mm

Kraftool Katran Precision Cut 1-15194-18-22 185 mm

Performs cutting of wood, plastic and laminate. There is also a 3D sharpening function. The length of the canvas is 185 mm. The price starts from 720 rubles. The direction of the saw is longitudinal-transverse. Suitable for hiking or trimming small branches in the garden.

Kraftool Katran Precision Cut 1-15194-18-22 185 mm

JCB JSW002 550 mm

This model is equipped with the longest blade of the models presented in the rating. Its length is 550 mm. The fixed handle with a rubberized insert ensures comfortable work. Can process materials of sufficiently large diameter and thickness. Tool steel prevents possible spring actions. Such a tool will cost 600 rubles.

JCB JSW002 550 mm

Gross Piranha 24100 450 mm

Processes wood, plastic and laminate. The set includes one canvas. Its length is 450 mm. The longitudinal direction of the saw is provided by hardened teeth. The fixed handle and the possibility of 3D sharpening play an important role. The tooth pitch is 7-8 points. The cost of a copy is 1100 rubles.

Gross Piranha 24100 450 mm

STANLEY Fatmax 0-20-556

A miniature hacksaw will be indispensable in tourism and farming. The length of the entire tool is 302 mm. Outwardly it resembles an ordinary knife, but differs in the presence of teeth. The reliable rubberized handle prevents slipping in the hand. Best for cutting drywall or thin plywood. The price is in the average range for such a tool. It will cost 1200 rubles.

Types of hand saws

Depending on the hacksaw blade for wood, the saw can be of the following types:

- classical;

- narrow;

- thorny.

The classic tool is a saw that can make longitudinal and cross cuts. This type of hand saw is also called a regular or wide one. It is not designed for precise carving. It leaves a lot of shavings, the cut will not look beautiful. The teeth are triangular in shape, and the pitch is 1.5-6.5 mm.

Narrow or circular saw - designed for accurate cutting. In most cases, the saw has teeth on both sides. With such a hacksaw you can make beautiful patterns and carefully cut out various parts from the material.

A tenon saw is necessary for a beautiful, neat cut. The teeth are presented in the form of an isosceles triangle with a pitch of 1-1.5 mm. The saw is used only for transverse threads. With this tool you can cut beautiful details from wood.

Specifications

The technical characteristics of a hand hacksaw include:

- hacksaw type;

- what material can it cut;

- weight;

- length and material of the canvas;

- the material from which the handle is made;

- size, shape and pitch of teeth;

- what kind of sawing it is intended for (longitudinal, transverse, mixed);

- whether the canvas is folding or not.

Thanks to all these characteristics, the buyer will be able to decide which tool is the best in quality.

It is best to buy a hacksaw in person, because... When choosing, you need to evaluate the weight of the tool and the handle, which should fit comfortably in your hand. If the saw is uncomfortable for any reason, you should not buy it, despite the fact that all the characteristics will be excellent.

The device of a bow saw for wood

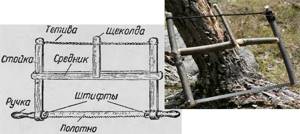

The modern “onion” includes:

- Frame made of rolled profiles. Depending on the size of the saw blade - and they are usually standard: 350 mm, 530 mm or 760 mm, the frame can be made in the form of an oval trapezoid (for longer blades) or an oval triangle (for shorter ones).

- A handle whose profile prevents sudden injury to the worker’s fingers.

- Saw blade.

- Devices for tensioning saw blades.

- Fastening the canvas to the frame.

The frame of a bow saw for wood has special requirements - it must be rigid and at the same time light, so as not to increase physical stress during sawing. A special tubular profile with a very small width satisfies the task. This makes it easy to bend it during the manufacturing process to the required frame configuration without losing the strength of the part, providing the saw with the necessary mobility.

One of the main differences in the design of modern bow saws for wood is the principle of saw blade tension. For example, the Gardena or Proline brands use a handle with an eccentric for tensioning: by using it, changing the angle of inclination of the handle relative to the longitudinal axis of sawing, you can thus adjust the tension force.

Manufacturers of saws from Bahco Stanley have taken a different path: there a special screw mechanism for tensioning the saw blade is mounted in the handle. The choice is determined by ease of use, however, the presence of a screw mechanism provides increased tension accuracy, and does not depend on random movements of the user, when the position of the handle during sawing can randomly change. Therefore, it is recommended to use a rotary tension mechanism if you have some experience working with a bow saw.

To fasten the saw blade to the opposite part of the “string” (frame), removable cotter pins or wing screws are used. The latter are more reliable, since the cotter pin, usually made of mild steel, wears out over time and can spontaneously come out of the mounting hole.

Fabric material

The best material from which a tool should be made is steel. The saw blade can be presented in the following types:

- mini-hacksaw, length no more than 35 cm, has a large number of small teeth;

- standard hacksaw, no more than 55 cm, teeth are at an average distance from each other;

- wide hacksaw, no more than 60 cm, teeth with increased pitch.

When choosing a size, you need to be guided by the main purpose for which the hacksaw will be used.

It is also worth considering that there are saws with replaceable blades . They cost more, but they are much more convenient to use in everyday life.

Teeth parameters

The teeth are divided according to the following criteria:

- form;

- step;

- type.

The form is as follows:

- for longitudinal sawing (in the form of oblique triangles);

- for cross cutting (in the form of an isosceles triangle);

- for mixed sawing (teeth alternate).

The pitch is indicated in mm and has the designation TPI, followed by a number indicating the number of teeth per 24.5 mm of length.

Type of teeth: hardened and unhardened (regular). Hardened ones cannot be sharpened after they are worn out, but unhardened ones can.

Operating rules

In order to carry out cross-cutting with maximum convenience, the wood blanks must extend beyond the edge of the stationary support. Experts try to start sawing, focusing on the nail of the largest finger on the hand, which will hold the beam. As soon as the canvas “bites” into the material, it is carefully placed on the thumb itself. But for better cutting accuracy, it is best to use special templates.

A bow saw for wood is perfect for longitudinal cutting. For this process, the canvas must be secured at an angle of up to 90 degrees from the horizontal rack. The pressure here will be much less than with a cross cut, so this procedure will take a little longer.

This cut is made with both hands. Professionals advise placing the board horizontally and working the saw towards you, holding the handle and stand firmly to the side.

If you need to make a curved cut, then you should stock up on a narrower blade so that its width does not exceed 8 mm. Blades for this kind of slots can be found with rectangular teeth and a significant spread - almost up to 2.5 denominations of the thickness of the blade itself. If you need to saw a material that is too thick with many knots, it is better to select the widest blade - up to 5 cm. It is better that it has a not very large spread, but significant thickness. It is not worth making a cut like a figured or curved one on such material.

Saws for any type of cutting may differ in the shape of the teeth. For cross cutting, the teeth will be in the form of a regular triangle with equal sides. For cutting lengthwise, use a slightly oblique triangle in the shape of a wolf tooth. On hiking trips, you will not need to saw wood along the grain. The main task here is to collect dead wood and cut it into a certain number of logs.

The effort you will have to spend on sawing will depend on the accuracy of sharpening and the correct alignment of the teeth of the product. When sawing, the teeth will become dull - their edges usually become rounded. The tip of the tooth will be the most dull. Sawing with such a product with blunt teeth is pure torture. Before using the saw, inspect it visually and carefully. Blunt teeth will immediately have a noticeable light stripe along the edge; a well-sharpened tooth will not have such an edge.

Read also: Cutting attachment for drill

It is worth taking a closer look at how to properly sharpen this kind of product. If it is quite old and the height of the teeth seriously distinguishes one from the other, then you need to align them with a special file. The teeth are made straight before the sharpening process, but only after the setting has been carried out. Sharpening of products is done using a file in the shape of a small triangle. These are not very difficult manipulations, but they will require special patience. The tool blade will need to be clamped in a special vice. If you don’t have these, you need to secure the saw to some solid base - on the edge of a chair or stool.

Sharpening of the teeth must be done alternately through the tooth, first on one side, and then on the reverse side. A piece of metal, such as a chamfer, will be removed from two sides of the tooth, positioned at an angle of 60 degrees to the blade, which will match the angle of the file itself, which has 3 sides. It is necessary to remove a little more metal from the tip of the tooth than from its base. You can press on the sharpening tool only with a sharp “throw” forward. The tool will go back a little more freely so that the file comes off the surface of the blade a little.

You should not try sharpening by pressing your finger on the teeth - then the file may slide on the fatty film that you left on the metal with your touch.

Owner reviews

To understand which hand saw is more profitable to buy, what characteristics are better, on the Internet you can look at all kinds of reviews from bloggers, authors, and also read customer reviews.

The article presented the best range of hand saws for wood. Each differs from each other in certain characteristics. You need to choose depending on the purpose for which the saw is intended.

All the hacksaws presented above are made of high-quality materials, the saw blades are made of steel, the handles are comfortable, the teeth are of high quality, the weight is standard so that the tool is not too heavy. All characteristics are good, but each buyer should proceed from the main purpose of the saw and their own preferences.

The article reviewed the best wood hacksaws and their characteristics, and also provided a general description of hand hacksaws, which can help in choosing a quality tool. If you liked the article, don't forget to share the link on social networks. We are also waiting for your comments about the advantages and disadvantages of the article and the site as a whole; we will definitely read your wishes and take them into account.