Installation features

When building from cellular plastic, it is recommended to take into account its properties and follow the installation rules:

- The stiffening ribs of the panels are arranged vertically. Condensation that accumulates inside the channels must flow freely out. If this is not provided for, water that gets into the cells will rupture the thin walls of the material when it freezes.

- A gap is left between the sheets for thermal expansion. Since polycarbonate increases in linear dimensions when heated, lack of free space leads to destruction of the panel.

- Holes for fasteners are drilled 2 mm wider than the diameter of the bolt or self-tapping screw. This measure is necessary to compensate for changes in the size of the plastic due to temperature fluctuations.

- When attaching sheets, do not use excessive force. Thin partitions are damaged when screws are screwed in with pressure. Over time, moisture, insects and fungi continue to degrade, leading to premature deterioration of the material.

Although cellular polycarbonate panels are considered strong and durable, improper installation can significantly shorten their service life.

What and how to cut

When cutting material, the main danger is crushing and damage to the edges of the cut with the tool, so you should not use a hacksaw for processing polymer.

A high-quality smooth edge is formed when cutting:

- a stationery or construction knife;

- angle grinder (“grinder”);

- jigsaw;

- hacksaw for metal;

- circular saw.

For professional purposes, CNC milling machines and laser equipment are used.

Work on cutting polycarbonate is carried out in the following sequence:

- Draw a polycarbonate gazebo on paper to scale.

- A smooth sheet of plywood, chipboard, fiberboard is laid on a clean and level area.

- The plastic panel is placed on the base with the laminated, mirror or UV coating facing up. The film is not removed until cutting is completed.

- Transfer the markings from the drawing to the polymer sheet. Use a tape measure, ruler and marker.

- Place 40 mm thick boards along the cutting line on both sides. They will act as supports and prevent cutting through the substrate.

- Use a sharp tool to cut out the material using a rule or ruler.

To process sheets up to 6 mm, use a construction knife or scissors. Thick panels are cut with a more powerful power tool at high speeds. First you need to practice on unnecessary trimmings. When working with a grinder or jigsaw, wear safety glasses. It is advisable to remove shavings from the channels with a vacuum cleaner with a narrow nozzle before installation.

How to attach

When building a polycarbonate gazebo with your own hands, you need to properly prepare the panels:

- follow the location of the stiffeners - vertically with a pitched roof, parallel to the bends - with an arched one;

- attach protective sealing tapes to the edges;

- Install an end profile along the bottom edge;

- orient the sheet outward with a UV layer that protects the polymer from ultraviolet radiation; lamination is usually marked by the manufacturer.

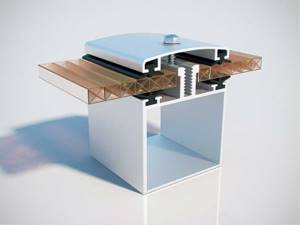

Attaching polycarbonate to the frame is done:

- self-tapping screws and bolts with thermal washers;

- special polymer or aluminum profiles;

- galvanized steel strips.

The sequence of work when attaching plastic to a metal frame made of a 40x60 mm profile:

- Apply sealing tape to the top surface of the steel structure.

- Place the edges of two polycarbonate sheets on the supporting profile, maintaining a gap of 8-10 mm.

- The protective film is folded back from the edges of the panels, and an aluminum profile with sealing contours is mounted on top of the joint. They are inserted independently into the grooves intended for this purpose.

- Holes with a depth of at least 36 mm are drilled through the aluminum profile, and self-tapping screws are screwed in with a pitch of 500 mm.

With this fastening, cellular polycarbonate is not subject to drilling. Seals create a reliable barrier against moisture penetration and compensate for temperature deformations of the polymer in the assembly.

Installation technology

The frame is made of stainless or galvanized steel. Polycarbonate gazebos have a fairly simple design, which is highly reliable and durable.

The installation of the structure takes place using a certain technology, the main stages of which should be specified in more detail:

The polycarbonate gazebo canopy must be firmly fixed in the ground. This will prevent it from tipping over in strong winds. Therefore, the load-bearing supports must be buried to a level of 50 - 80 cm in the ground. To do this, you need to make holes using a hand drilling tool. With a small gazebo area, 4 holes will be enough. If the length of each side exceeds 3 meters, then the holes should be made in increments of 1.5 - 2 meters;

To securely fix the support pillars in the ground, you need to fill them with concrete mortar. When preparing it, you must use cement grade M 500 and fine-grained sand. You can mix the cement mixture yourself. Since large volumes are not required, there is no need to order a construction mixer;

Having placed the metal profile from the recess, they should be filled with a solution prepared in advance. In this case, the supports must be kept level to prevent an incorrect angle of inclination. The supports must be positioned strictly vertically at right angles.

As a rule, gazebos and canopies made of metal are finished products. Therefore, when concreting pillars, the structure itself is actually being installed. No additional actions are required. However, it is recommended to carry out floor installation work.

How to make a floor in such a gazebo

Canopies and gazebos made of polycarbonate require the installation of a floor. Otherwise, in rainy weather it will be impossible to stay inside the building due to dirt. The floor can be made in two main ways:

Using a board. To do this, the product design must include corners welded to the frame. They will be an excellent base for laying boards. Horizontal metal elements will need to be welded to such corners. These elements will serve as a lag. It is already necessary to lay wooden boards on them. In this case, the boards must be treated with special compounds that prevent rotting. Otherwise, the wood will quickly lose its color and strength in the open air. Such compositions simultaneously color the wood, giving it an attractive appearance;

Through concreting. This is the most durable option. Concreting allows you to get a very durable floor surface that can last indefinitely. Carrying out concrete work will require the creation of a level platform. It is necessary to remove a layer of soil 20 cm deep. The bottom of the resulting small pit should be covered with 10 cm of sand. The sand cushion should be watered until it is as hard as possible. This cushion will prevent cracking of concrete and prevent it from sinking during seasonal changes in soil density. Formwork needs to be done around the perimeter of the pit. To do this, you can use sheets of plywood, boards and similar materials at hand.

The concrete mixture can be prepared at home using a portable concrete mixer. Its power is enough to produce in one day a volume of concrete sufficient to fill the site. You can raise its level above the ground by 20 - 30 cm. This will be quite enough.

It is necessary to wait until the concrete hardens, which occurs within 20 days. To prevent the floor surface from cracking, in hot weather it is necessary to moisten the concrete with water.

The result is a flat floor on which paving slabs can be laid.

Another option for installing a floor in a polycarbonate gazebo would be a terrace board. This material is resistant to moisture and tolerates temperature changes and heat well. At the same time, the terrace board will last more than 20 years without losing its color saturation and functional qualities.

Closed gazebo made of polycarbonate photo

Gazebo with brick supports

A gazebo with a polycarbonate canopy can have supports not only made of metal profiles or round pipes. Brick supports can be used. They will serve as an additional decoration for the site and the gazebo itself. Especially if you use colored bricks or line the supports with artificial stone.

To obtain the required strength, a thickness of one brick will be sufficient. In this case, a brick load-bearing support will require a foundation buried half a meter. It is created using the technology described above. They are completely similar to the structure of the base for metal supports.

Since the polycarbonate gazebo canopy does not have much mass, it is not necessary to make brick pillars.

Thus, a polycarbonate canopy will be an ideal solution when building a gazebo in a garden or summer cottage. It has universal qualities and is suitable for a frame made of any material.

Such a canopy will withstand temperature fluctuations, heating from sunlight and precipitation. It can be firmly fixed to a metal base or to wood. Strong steel bolts and nuts are used for fastening.

Selection of location and base material

The material for making the base of a polycarbonate gazebo can be wood, metal or stone. Options with other types of materials are possible, but these three are the most commonly used.

Each of them has both a number of advantages and certain disadvantages.

- Wooden frames are made from timber. This is a completely accessible and inexpensive material. Its undeniable advantage is its environmental friendliness and naturalness. In addition, wood has a beautiful natural structure. The disadvantages of this design include fragility, instability to weather conditions and difficulty in maintenance.

- The metal base is a frame made of a profile or corner. Such gazebos are very durable, reliable, and have a long service life. But they also have their disadvantages: high cost, complexity of assembly, requiring welding.

- Stone frames are made of natural stone, brick, concrete. Stone bases will last a very long time, in addition, they are distinguished by their naturalness and aesthetic appeal. At the same time, they are quite heavy, their construction will require a lot of time, and replacement will create a lot of difficulties.

It is best to choose a flat, dry surface. Ideally, it will be located at a slightly higher elevation so that moisture from precipitation does not collect in the area of the building. Choose a place in the shade, with no drafts. It will be convenient if the building is located as close to the house as possible. If there is a body of water, then it is good to place a gazebo near it; this will give additional freshness and coolness during the summer heat.

Step-by-step instruction

When choosing a place in the garden to build a canopy, it is necessary to take into account the presence of unevenness and slopes on the surface of the earth. Before starting construction, it is recommended to carefully level the site.

Also pay attention to wind speed and direction. An open arched gazebo that will be constantly blown by the wind is unsuitable for its intended use.

For this reason, try to cover the structure with a wall, fence or even plants. It is worth noting that the proximity of dense bushes and tall trees negatively affects the technical characteristics of polycarbonate. During strong gusts of wind, plant branches scratch the roof of a building.

A garden gazebo, which will be used as a summer kitchen, should be close to the house. The close location of the dacha and gazebo will allow you to organize family tea parties and dinners in the fresh air.

The frame of the structure can be made of wood or metal. Wooden beams and boards are susceptible to rotting and therefore require periodic treatment with antiseptics and fire retardants. Iron is strong, reliable and durable. You can prevent the appearance of rust on the surface of a metal profile by treating it with special anti-corrosion agents.

In the process of erecting a canopy made of metal profiles and polycarbonate coating, you will need the following tools and materials:

- polycarbonate sheets;

- sealing tape for processing the end of polymer plastic;

- self-tapping screws and thermal washers;

- steel pipes with a diameter of 50 mm for the manufacture of supports;

- metal corner measuring 40x40 mm for the manufacture of rafters, strapping and frame fencing;

- metal screws and brackets;

- electric jigsaw, hacksaw or saw for cutting polymer;

- building level, twine and wooden pegs;

- soil drill and hammer;

- container for mixing concrete, shovel;

- screwdriver, electric drill with attachments of various diameters;

- pliers;

- hacksaw for metal;

- welding machine, grinding machine.

To create a gazebo you will need a tool

Measurements and calculations

The preparatory stage of constructing a summerhouse involves the development of a drawing plan. A diagram thought out to the smallest detail will help you make correct calculations and avoid common mistakes during construction. You can draw up a drawing yourself. To do this, you need to draw a sketch of the future structure, calculate its dimensions and select the material.

If you do not have drawing skills, it is recommended to seek help from specialists who will help you construct a drawing and draw up a detailed plan for the construction of the project.

Foundation

The construction of a stationary gazebo in the courtyard of a personal plot begins with marking the site and pouring the foundation:

- Clear the garden area of plants and various debris. Level the area.

- Determine the first corner of the frame. Place a wooden peg in this place.

- Using a building level, mark the other three corners of the canopy. Stretch the twine by connecting four points around the perimeter.

- Dig a pit 25–30 cm deep. Compact the soil and check the evenness of the horizontal and vertical lines. Fill the hole with sand and gravel.

- Using a soil drill, drill holes 70–100 cm deep in the corners. Now you need to install, secure and concrete the metal support pipes. Straighten the supports.

- Weld the metal corners to the supports.

Frame

Assembling the metal frame of a garden gazebo is easy if you follow the step-by-step instructions:

- Weld crossbars to the support posts.

- Make the top trim of the frame. Test it for strength.

- Assemble the rafters and other floor members on the ground. Raise the welded structure to the top and weld the roof to the support posts.

- Treat the metal profile with anti-corrosion agents.

Glazing

At the last stage of assembling the garden gazebo, you need to cover the structure with polycarbonate.

267212844ea2c49b48c5844a49bf5855.jpe

eb87fd93af2ca6bcfcc70b8728cdb3d1.jpe

Polycarbonate sheets are cut on a flat horizontal surface. Then you need to treat the ends of the canvas with sealing tape. When sheathing the frame, leave a small gap for thermal expansion of the canvas. You need to work with polycarbonate carefully and carefully.

Do not remove the protective film from the surface of the panels until the glazing of the structure frame is completed. Otherwise, scratches and cracks may remain on the polycarbonate.

What components are needed for polycarbonate buildings?

For your convenience and durability of the building, the Polycarbo company also offers components for installation. These include various types of profiles, thermal washers, and sealing tapes. What are they?

A profile for polycarbonate is a flexible narrow part designed for reliable and convenient connection of sheets to each other. Profiles can be corner, end, wall, ridge, detachable and one-piece, so it will not be difficult for you to choose the appropriate option for any type of connection and design option. They, like polycarbonate, are manufactured in different versions and are matched to the material itself in terms of thickness and color.

A correctly selected profile reliably seals the joints of polycarbonate sheets, protecting the structure from the destructive effects of the external environment.

Thermal washers are used to seal the places where polycarbonate is attached to the frame and also perform a number of important functions:

- protect holes from moisture and prevent rust on fasteners;

- reliably insulate the internal part of the structure when polycarbonate expands under the influence of direct sunlight and contracts in cold weather;

- eliminate the cold bridge, thereby helping to retain heat;

- prevents plastic from cracking.

High-quality sealing of joints and fasteners not only improves the appearance of the structure, but also prolongs its life.

As for the sealing tape , it is designed to insulate the ends of the polycarbonate and protect them from dust, dirt and moisture (and, accordingly, the formation of mold). Thanks to the sealing tape, cellular polycarbonate will last much longer and retain its original appearance and color.

Construction of structures: first steps

A gazebo for a summer house made of polycarbonate is available in open or closed form. Use material for walls and partitions - you will erase the visual boundaries between the pavilion and the beauty of the surrounding landscape. It is necessary to begin work by designing the location of the product.

Where to put the gazebo?

The low weight of the structure ensures its stability on any soil. Experts recommend choosing a place for garden gazebos made of cellular polycarbonate as follows:

- place the structure next to the house or build a long canopy that will connect the adjacent part with the pavilion;

- An excellent solution is a flat and dry area on an elevated place;

- It is preferable to install the product near a pond or in the shade of trees. This will slightly reduce the influence of sunlight that the honeycomb material attracts.

Make a drawing of a simple product with an arched roof, taking into account the standard parameters of cellular (2.1x6 m) or monolithic (2.05x3.05 m) material. On the diagram, take into account the direction of the wind, uneven ground, type of building and its total mass.

How to choose the type of gazebo?

There are many options for beautiful polycarbonate gazebos that will appeal to the owners of country houses:

- Depending on the presence of walls, there are open and closed buildings. The first type of garden gazebos, made of polycarbonate, will create the effect of unity with nature, and the second will protect from rain;

- Depending on the installation method, products can be stationary or portable. Mobile ones will allow you to play with landscape design, but a stationary gazebo with your own hands requires a reliable foundation;

- the complexity of the design determines the configuration of the polycarbonate canopy for the gazebo - on supporting pillars or fantasy.

The product can be equipped with a barbecue, barbecue or left in its original form.

Pavilion Design Ideas

Any little thing can influence the style of a stylish gazebo made of cellular or solid polycarbonate intended for a summer residence. The design idea will be a photo from the Internet, but you can use ready-made options:

- Create an attractive canopy using corrugated polycarbonate. Keep it in a trendy eco-style by building a frame made of wood;

- play with the drawing by choosing an unusual gazebo shape - place one sheet close to the ground, and leave the second open;

- a domed greenhouse with open walls is a great opportunity to relax in environmentally friendly and comfortable conditions;

- Profile and polycarbonate structures give a classic look. It will be a little pretentious, but a solemn solution for a site in a landscape or Versailles style;

- connoisseurs of maximum comfort will like arched structures with glazing, pavilions near the pools, complemented by forging or a domed roof.

Build an extension to the house by making a polycarbonate canopy for your gazebo in the form of an extension of the roof. Organize your exit from the inside of the yard. Such an arbor will be warm even in winter.

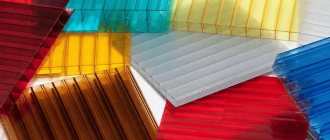

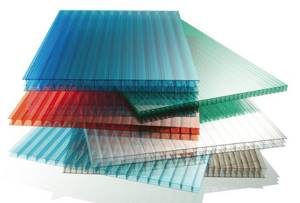

Material selection

In order for a polycarbonate gazebo to be built technologically correctly with your own hands, consider the following criteria for choosing a material:

- The width of a honeycomb or monolithic sheet. In the first case, this figure is 2.10 m, and in the second – 2.05 m.

- Length of profiles. Monolithic ones are produced in lengths up to 6 m, and cellular polycarbonate plastic - up to 12 m. Cutting of plates can be ordered from the manufacturer.

- Translucency. The throughput of the monolithic type of material is higher, and the cellular type transmits 88% of the rays.

- Insulation performance. The cellular type of polycarbonate has a higher level of noise and heat insulation.

Both types of polymer plates have safety edges and do not crack or chip. Practical gazebos and durable canopies made of various polycarbonates can have a functional or decorative value.

Selecting a frame

To make a polycarbonate gazebo with your own hands, you will need to decide on the type of supporting frame. Wood and metal are popular materials for decking polycarbonate sheets. Metal parts will be strong and reliable, but wood is easier to install. During operation, the structure requires maintenance: the metal is periodically painted, and the wood is treated with anti-rot impregnations.

What kind of roof can you build?

Single-pitch

The simplest, cheapest and most popular option. The gazebo is covered with several sheets, which are attached to the roof at an angle and provide reliable and practical protection.

This option is far from those aesthetic architectural masterpieces of expensive gazebos, but it is quite applicable for almost any building.

Single-pitch option

Gable

A relatively simple structure that will not be difficult to build on your own

It will be important to correctly select the angle of inclination on both sides, which should be at least 6 degrees so that the entire structure looks harmonious

Gable

Four-slope

This option belongs to a more complex type. You will have to invest a lot of time in disassembling the structure and installing sheets on the rafter system.

a9a7d3eefd53ab2a7e5fa81a1c0d712e.jpe

bf4429fb78576d02cce8ed1254739b60.jpe

The process of erecting a “steeper” hip roof looks even more complicated, but possible. If you follow the instructions and do not skimp on materials and quality of construction, then everything will turn out better.

Four-slope

Hexagon

In this case, difficulties already arise with the polycarbonate itself, which needs to be correctly measured and cut. There will be problems with the construction of the roof, since it will be difficult to make it even on all edges (but possible!).

This option can also be implemented with your own hands without any special knowledge and experience.

Hexagonal (hexagonal)

Arched

In the case of an arched shape, you will have to bend the polycarbonate to attach to the rafters.

Here it is important to understand the specifics of polycarbonate - it gains the greatest rigidity when it is curved downward in honeycombs, and condensation does not accumulate in them due to this direction. Otherwise, when bending, you can simply ruin the material

Arched

Dome (round)

The pinnacle of architectural thought in this publication is the domed shape of the carbonate roof. Few summer residents dare to use a similar roof format, since this process is quite complex and risky.

However, if you decide to sculpt a similar form from polycarbonate, follow the instructions of experienced builders, otherwise by the end of construction you will have neither a roof nor building material left :).

Dome blue

Examples of beautiful polycarbonate gazebos

Polycarbonate is a flexible and affordable building material that makes excellent gazebo options. They convey aesthetics and beauty. This material is used as an addition to the main extension, and not as a base. This could be a roof covering, a partition, or just a shelter.

A small gazebo with a semicircular polycarbonate roof on a log base

Compact gazebo with a gable roof for outdoor dining

There are many options for the structure. One of the simplest and most popular is awnings. This is simply a roof on support pillars, which can act both as the main element and as an addition to the house, like an extension.

376ac298b5e911e56006d6deab09f066.jpe

A very original solution - a polycarbonate canopy placed on gabion poles

Garden gazebo made of polycarbonate in the shape of a geological dome

To make the structure more monumental and impressive, it is made on a rafter system. Gazebos with decorative forging are another option that is considered not only expensive, but also impressive and of high quality. Polycarbonate practically protects the entire structure from bad weather.

Beautiful wrought iron gazebo with an original shaped roof

Quite a simple gazebo on a frame made of profile pipe

The shape can be different: multifaceted, round, square, arched - all to your taste and budget. To add zest to your design, polycarbonate can be chosen in different colors - it looks very beautiful and aesthetically pleasing. If your home is in a classic style, a bronze shade would be perfect.

Advantages of self-construction of a gazebo for a summer residence

If you dream of a closed gazebo, then, as a rule, you have to turn to specialists for help. They develop the design, purchase materials, and carry out construction manipulations.

Closed gazebo made of polycarbonate for a summer residence

Have you learned how to make a polycarbonate gazebo for your garden with your own hands? Such knowledge will allow you to get significant savings:

- You can draw up a project yourself, without having to pay for the services of a designer.

- The foundation is laid very simply, so there is no need to hire special equipment.

- Polycarbonate can be cut perfectly without the use of special tools, which eliminates the need to purchase expensive equipment.

Self-assembly of a polycarbonate gazebo

Building a gazebo yourself will allow you to choose any solutions that attract you. You can create a simple design. However, it is possible to choose the most sophisticated style that fits perfectly with the greenhouses located on the site.