Who among the owners of dachas or country cottages does not dream of having their own swimming pool on the site? And don’t think that this is an extremely expensive structure that requires a lot of effort during construction and operation. With minimal skills in working with building materials and some expenses, you can build an inexpensive pool.

In this article we will tell you how to make a pool at your dacha with your own hands from various materials (concrete, frame, film), and also demonstrate video and photos.

Pools may vary. For some, an inflatable container installed in a suitable place and filled with water from a hose will be enough. If you want to build a solid stationary reservoir that can last for many years, you will have to work.

First of all, you need to choose a suitable location. It should be kept away from beds and trees. The less debris that falls into the water, the less maintenance effort will be required. In addition, you need to think about the water supply and drainage. It is better to choose a simple shape of the pool, without sharp corners: in the form of an oval, circle, square or rectangle.

The simplest and cheapest way to install a pool is to cover the hole in the ground with a special film. However, this structure cannot be called reliable and durable. More often, owners prefer to build pools from concrete or polymer materials.

Frame

A frame pool is considered a fairly simple structure, quite suitable for independent construction. Its peculiarity is its design, which consists of a frame “skeleton” made of metal pipes. The bowl is lined with three layers of PVC film. Inside it has a special mesh made of nylon, which gives the material additional tensile strength. The metal frame holds the water pressure.

It is placed with some depression in the ground or simply on the surface. The area for the pool must be prepared: remove all vegetation, and level the bottom of the shallow pit and fill it with sand or gravel. In some cases, even a concrete pad is poured.

Then the entire surface is lined with heat and waterproofing. Penofol or folitep are best suited here. These are modern thermal insulation materials made of foamed polyethylene covered with aluminum foil. The mats are laid end to end and the seams are taped with construction tape.

After this, the pool itself is assembled according to the instructions included with the kit. The only necessary tool for the job is a screwdriver.

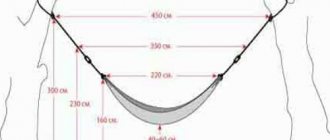

Preliminary calculations - sizing

The width and length are determined based on the purpose of the pool. If it is intended for swimming, then choose a rectangular shape, making the bowl elongated. If for relaxation, splashing and resting the whole family, then it is more convenient to communicate in round bowls.

A more important criterion is depth. It is believed that in order to feel free, swim easily, turn around under water and jump from the side, you need a depth of one and a half meters (and no more!). But ski jumping requires a deeper bowl - at least 2.3 m. However, it is enough to make such a depth in the diving area, creating a smooth transition from the main size (1.5 m).

If the construction of a swimming pool at the dacha is intended exclusively for children's recreation, then the depth of the bowl should not exceed half a meter. This is enough for fun games and wallowing without risk to health.

The most complex design is a combined pool in which everyone will swim. In this case, different depths are created for the children's and adult zones, and both zones must be separated by a strong partition that starts from the very bottom. This will ensure that children do not accidentally enter the adult area.

Important! In any pool that has several different depths, it is necessary to make the bottom flat and smoothly transition from one size to another. Sudden changes in depth are unacceptable for safety reasons. A person, walking along the bottom, can gape and miss the boundary beyond which another depth begins, and in a panic, when his legs instantly go down, the risk of choking is very high.

Concrete

When constructing a concrete pool, work also begins with digging a pit. In this case, the entire bowl is sunk into the ground. When calculating the dimensions of the pit, do not forget to add approximately 0.4 m to the wall thickness. The shape of the pit should follow the contours of the pool itself. The optimal depth can be considered 1.4 m. To make the recess as reliable as possible, its walls need to be given a slight slope to the outer sides, about 5°.

Concrete bowl

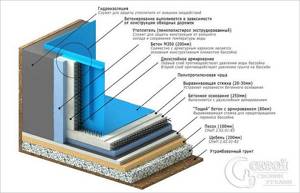

The finished pit of the desired shape must be carefully leveled, the soil compacted and a sand cushion about 30 cm thick laid on the bottom. Then the pool is waterproofed, everything is covered with waterproofing material (roofing felt with bitumen mastic) in several layers and the formwork is installed. Liquid concrete is poured into the gap between the wooden panels and the earthen wall. Additionally, the walls are reinforced with double metal mesh. It simultaneously counteracts the water pressure in the pool and the ground pressure.

Section of a concrete pool bowl diagram

Note!

Concrete grade – no less than M350.

The bottom of the future pool is also reinforced with mesh and filled with a layer of concrete of at least 20 cm. When the solution hardens, the formwork is removed and the entire surface is rubbed with “cement laitance” - a liquid solution of cement and water without adding sand. This process is also called ironing. It allows you to remove microcracks on the frozen surface and prevent their occurrence in the future.

Pool equipment

At the final stage, the walls and floor of the pool bowl are finished with a decorative coating. Usually these are ceramic tiles. However, it is first necessary to install a ladder, nozzles, waterfalls and underwater lights, equipment that makes it easier to maintain the pool.

We invite you to see a photo report of the construction of a concrete pool:

Preparing the site

Pit

Concreting

Finishing and installation of equipment

Result

Permanent pool in the garden - step by step instructions

First things first, stock up on tools.

- Master OK;

- Meter;

- Level and plumb;

- Shovel;

- Construction tape;

- Sharp knife;

- Hacksaw;

- Container for mixing concrete;

- Construction mixer.

If available:

- concrete;

- cement;

- sand;

- plasticizer;

- roofing felt;

- fittings;

- boards for formwork;

- wire;

- sealant;

- bars;

- hydrophilic rubber;

- plaster mortar;

- facing tiles or other material;

- then start construction. Building a pool in the garden with your own hands is not difficult, the main thing is to follow the sequence in construction:

- We dig out a pit of the shape corresponding to your project. Dimensions - 20 cm larger than designed.

- Depth - from one and a half to 2.5 meters.

- Use a level and a plumb line - since the bottom should be tilted towards the drainage hole or drain (slope - 4 cm per 1 meter).

- Fill the bottom with sand and tamp it down.

- We fill in a layer of gravel and tamp it down.

- We cover it with two layers of roofing material and strengthen it with mastic.

- We concrete the bottom, at the same time it is advisable to start concreting the walls.

- For concreting the walls, install formwork.

- Pour the concrete evenly, allowing it to set.

- Then wipe with a water-concrete solution and dry again.

- When concreting, leave holes for pipes, communications, drains, etc.

Experts, when building a pool in the garden with their own hands, recommend using concrete grades M350 - M400, frost resistance rating F200, and water resistance rating W6. To model a concrete pool bowl with your own hands, use heavy concrete with plasticizers and hydrophobic additives from well-known brands.

Then select the pool bowl - that is, the surface with which you will come into contact while swimming. Options:

- Ceramic tiles;

- Plastic frame;

- Polypropylene;

- Composite materials.

Your choice will be based on the price of melon materials, and in terms of color and texture, the market offers a huge number of types and color solutions. When choosing a pool bowl material, you need to consider:

- Reliability (polypropylene comes first in this indicator);

- Water resistance (composite materials);

- Durability (polypropylene);

- Environmental friendliness;

- Tightness;

- Immunity to temperature changes;

- Frost resistance;

- Easy to install.

Depending on your financial capabilities and priorities, you will make the right choice.

Also don’t forget about the steps, which can be:

- Concrete and built together with the base of the pool.

- Hanging stairs - when building a concrete bowl, the places where such steps will be attached are taken into account.

The simplest version of a hanging ladder for a pool will cost you 2,100 rubles. Stainless steel staircase - 5,000 rubles.

Film pool

Finishing with waterproofing film

Due to its versatility of use, PVC film is widely used for arranging swimming pools. It is used:

- to create a pool in the ground;

- for arranging frame pools;

- for sealing the concrete base of the pool bowl;

- as a repair kit for an old pool.

Note!

PVC film has a thickness of 0.5–2 mm. The thinnest one is suitable only for small pools with minimal load. It is best to use a film no thinner than 1.5 mm with a reinforcing layer of fabric.

Pool in the ground

Pool made of film in the ground

If you want to make a pool quickly and relatively inexpensively, then in this case you can dig a pit with gently sloping walls, which will be the base of the pool. Carefully remove plant roots and compact the soil. Make sure that there are no sharp stones left anywhere, as they can damage the canvas.

The entire bottom of the pool is covered with sifted sand, in a layer of at least 3 cm, and leveled. You can lay a layer of mineral wool as a thermal insulation material, but it is better to spread roofing material, as it is not afraid of moisture. Spread a non-woven cloth over this cake and only then a film. After this, you can weld the seams.

Note!

Before you start welding the seams, you need to practice on scraps of material so as not to spoil the fabric intended for sealing the pool.

In order to secure the edges of the sheet, you can use a special mounting angle to which the film is welded. A simpler option is to dig in the edges of the film. In this case, a decorative stone edging is often made around the pool.

Concrete pool

Concrete film pool

We will not dwell in detail on creating the design of the pool itself - it should be a reinforced container. The main advantage of using PVC film is that it does not require waterproofing. If the surface is not perfectly smooth, then it would be correct to use a substrate, which can be geotextiles or the same roofing felt. The actions with the film are similar when arranging a pool in the ground.

All that remains is to choose a method for attaching the film to the edges of the pool (it is better if it is a special mounting corner) and you can use the product.

Repairing an old swimming pool

Application of liquid rubber

It is no secret that a permanent pool can lose its tightness or even crack over time. If the crack is constantly expanding, then no sealing, even applying liquid rubber, will help. In this case, you can, just like for a concrete pool, use PVC film, having previously sealed the cracks and leveled the base.

What does it cost us to build a pool?

Many people, before deciding to have their own pool in the garden, are afraid of the prices - they say, we won’t be able to bear such a financially heavy burden. These fears must be put aside. After all, you can build a swimming pool in the garden with your own hands in economy mode - a pit version with concreting and tiling. This will not require much money, and will be of high quality and reliable. The only thing is that it will require hard work, attentiveness, accuracy and meticulousness from the owners. After all, before construction it is necessary to delve into all the nuances and not miss the main thing. Therefore, the first thing to do is:

- Sketch a pool project - shape, dimensions, appearance.

- Select a location for the pool:

- Sunny side;

- At least 4 sq. meters;

- Distance from buildings and fences;

- Proximity to communications: water supply, drainage;

- Convenient for moving around the garden;

- Without removing the necessary plantings.

- The choice of pool texture - seasonal or stationary.

- Decide on the overall design: do you need a roof, a fence, a seating area around the pool, etc.

- Choose the desired depth - if with diving - then at least 2.5 meters, if diving into the water on a ladder - 1.5-2 meters.

ADVICE!

To reduce the entry of dirt into the pool, experienced experts advise placing the bowl above the surface of the ground. Otherwise, when it rains, water along with sand and dirt will fall into your pool.

Polypropylene

A polypropylene pool also requires a pit and pouring a concrete bowl. The polymer allows you to solve the main problem when constructing swimming pools - providing reliable waterproofing. Polypropylene is an extremely durable material and can take any shape. Pools from it are made in two ways:

- buy a ready-made bowl of the desired size and shape;

- sheet polypropylene is purchased and a bowl is made from it.

Note!

The cost of both methods is approximately the same.

Welding of sheets is carried out using a thermal welding machine - an extruder.

Polypropylene bowl - concreting

After installing the polypropylene bowl and installing all communications, concrete is poured on top again and decorative material is laid.

It is polypropylene pools that are most suitable for installation in a summer cottage. They are not afraid of temperature changes and weather vagaries.

Before construction

Before you build a swimming pool in your garden with your own hands, take a close look at your plot and answer the questions:

- Is there enough space for the pool you are planning to build?

- Will he deprive you of valuable land for planting vegetables and fruits?

- What type of pool is right for your site?

- Round;

- Oval;

- Square;

- Arc-shaped;

- Other unusual shape.

If children are running around the area, then decide on the fence:

- Mesh metal;

- Mesh fabric;

- Monolithic polypropylene;

- From a different material.

Please note that installing a fence will require a certain amount of space. Make sure that the pool doesn’t “eat up” the entire area of the garden.

Also, immediately decide whether the pool will be closed: in the summer - to protect the water from excess debris and insects, in the autumn - from numerous leaves, in the winter - from snowdrifts. If you decide that you need a roof for the pool, then choose the type:

- Pavilion;

- Reclining;

- Rolling back;

- Static - in the form of a canopy.

The cost of a roof for swimming pools in various variations:

| Pool awning | from 790 to 4730 rub. |

| Polycarbonate visor | from 2000 rub. |

| Polycarbonate canopy | from 4000 rub. |

| Sliding pavilion | from 155,500 rub. |

| Sliding dome | from 250,000 rub. |

Installation of a swimming pool with a finished bowl

Let's look at how to make a swimming pool at your dacha using a factory-made bowl.

Site marking

- We carefully measure the bowl delivered to the site.

- We mark the location of the future pit on the ground using pegs and rope. We drive pegs into the corners of the future bowl, and stretch the rope between them. The more irregular the shape of the pool, the more often you drive in the pegs.

- We step back a meter from the stretched rope and make marks along the entire perimeter (cut off the soil, hammer in new pegs, etc.). It is from this marking that you will begin to dig the pit. This reserve is needed to make it easier to lower the bowl, insulate its walls and create a solid foundation.

- We remove the internal markings and start digging a pit.

Excavation

The pool pit must have a flat and stable bottom, so it is concreted

The pit should be half a meter deeper than the size of the bowl itself. Now we create a base on which we will place the bowl:

- Spread the bottom with a 20-centimeter layer of coarse sand and compact it.

- We lay a metal mesh over the sand for a fortress and pour concrete mortar over it, 25 centimeters thick. We wait until it dries.

The concrete layer used to fill the bottom must be reinforced so that it does not crack when the soil moves

After this we insulate the pool:

- We lay geotextiles over the entire concrete base, and three-centimeter slabs of expanded polystyrene on it. They will insulate the bottom of the pool from the cold ground.

- Lay a thick, durable film over the insulation.

- While the bowl is at the top, its walls should be insulated. The outer surface of the walls is “packed” in polystyrene foam and insulated with polyethylene.

The outer walls of the bowl are insulated with polystyrene foam to insulate them from cold ground