A canopy is an almost integral part of any country house, allowing you to protect gazebos, playgrounds and other areas from rain. In the last decade, canopies made of metal profiles have become very popular, which is explained by the low cost of construction, as well as reasonable cost. What types of such canopies are there, as well as their advantages, we will consider further.

An example of a metal profile canopy for parking

Functions and advantages of a metal profile canopy

The main function that a metal profile canopy performs is protective. It is installed in places where there is a need to create a roof that protects from precipitation.

Metal profiles have become so widespread for a number of reasons:

- Fire resistance. Compared to plastic and tiles, metal profiles have a high fire-resistant level, without causing ignition when exposed to open fires.

- Environmental friendliness. The roofing material fully complies with all standards and requirements, without violating the permissible limits.

- Availability. The price of the material allows it to be used by absolutely all segments of the population without fear for the family budget.

- High quality. A durable and at the same time easy to install metal profile will last at least 10 years without requiring any necessary repairs.

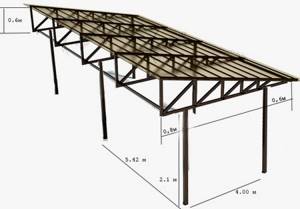

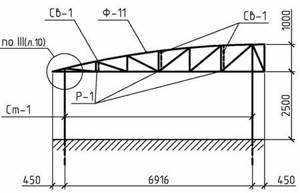

Diagram of the device with the dimensions of the canopy made of metal profiles - Resistant to temperature changes. Due to the fact that the metal profile has a fairly dense structure, it is not subject to freezing, and also does not cause chips and cracks during sudden temperature changes.

- Attractive appearance. A variety of colors and sheet shapes allows you to select a metal canopy in accordance with the individual wishes of the client. During operation, the metal profile does not fade, completely retaining its original color, and also does not require constant painting.

This list can serve as a basis for choosing a metal profile as a roofing material for a canopy, since it has excellent technological characteristics that are ideally combined with affordability.

Benefits of use

Many people prefer a canopy for several reasons:

- It is faster to build compared to a permanent structure;

- Little materials and time are required compared to building a garage or shed from foam blocks;

- There are many types of awnings, so there is a variety of choices;

- The appearance of the canopy attracts attention.

Guided by these advantages, people give preference to structures that will protect and at the same time will not create clutter on the site. This is especially true when a person has a small plot of land. In addition, building a full-fledged, permanent building is not always necessary, since saving things or a car requires a short amount of time.

Construction of a canopy made of corrugated sheets for a parking lot

This design meets all the necessary requirements not only for storing items: it can become an excellent place to relax outdoors in any weather.

Types of canopies made of metal profiles

When building canopies, it is necessary to focus on their shape and spatial position.

Semicircular profile canopy

In accordance with these criteria, the following main types of canopies are distinguished: single-pitched, gable, arched.

Single-pitch canopy

This type of canopy is very convenient because it has the shape of an inclined plane located at an angle. This design provides maximum protection for the area and also has a natural drainage system. Water and other precipitation are not able to linger on the inclined plane, thus protecting roofing materials from premature deterioration.

If you want to make a lean-to canopy from a metal profile with your own hands, you need to take into account several features. First, determining the angle of inclination is key. If it is too steep, then there is a risk of unwanted moisture getting under the canopy, and there is also a high probability of damage to the metal under the influence of strong gusts of wind.

Single pitch carport

Secondly, it is imperative to consider the organization of the drainage system, since the constantly rolling liquid will turn into a water flow capable of eroding soils.

Thirdly, the choice of slope direction should be based entirely on statistical data on the predominance of air masses, or more precisely, their direction.

To obtain such data, you can use the services of meteorologists, or independently note the wind direction for six months.

And fourthly, additional strengthening of the canopy should not be neglected, especially in regions characterized by frequent gusts of wind. A lean-to canopy made of metal profiles will perfectly protect not only from precipitation, but also from excessive sun, which is extremely convenient for all seasons. Most often it is used not as a separate structure, but as an extension.

Detailed diagram with dimensions of a lean-to canopy

Gable canopy

In those regions where it is difficult to determine the prevailing wind direction, a gable canopy made from a profile is more often in demand. It differs from a lean-to roof by an additional plane; this design looks like a regular house roof, but has a slightly different structure.

Such a canopy has many more advantages, since its area allows it to cover much more territory than in the first case. To achieve maximum effect, as well as make the structure reliable, it is necessary to use a more serious fastening system that requires additional profile supports.

Multi-slope awnings

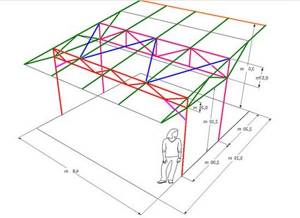

It is most convenient to equip exhibition centers, playgrounds and car parks with multi-slope canopies, which look like a cascade of gable canopies.

A multi-level arrangement allows you to maximize the area covered, but the installation process will take much longer.

This is due to several needs:

- measurements and drawings (in order for the multi-slope canopy to be durable and fully perform its functions, it is impossible to do without accurate measurements and design skills);

- selection of suitable material;

- mandatory arrangement of drainage and stormwater systems.

You can often find a multi-slope canopy in a private house, which plays the role of an extension of the garage, serving as an excellent option for protecting vehicles from precipitation.

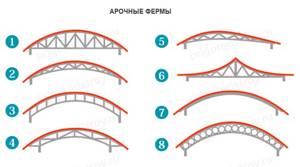

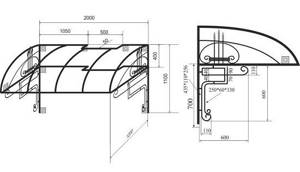

Arched canopies

For those for whom a canopy is not only a means of shelter and protection, but also a decorative element, an arched canopy is ideal.

Option for installing an arched canopy from a profile

It has an attractive and neater appearance, which does not in any way affect its quality characteristics, giving any home or area individuality.

The main disadvantage of such canopies will be their higher cost. This is explained by the fact that it is almost impossible to make a canopy from an arched profile with your own hands. This will require special tools, as well as knowledge and skills in working with metal.

Types of awnings

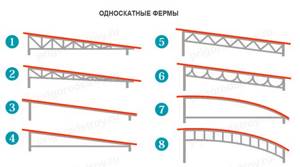

Single-pitch

Mortgages are concreted to a depth of 1.5 m; Polycarbonate thickness: 8 mm; Withstand loads up to 180 kg/m2; Service life up to 50 years.

Pole dimensions : 80×80 mm (standard), 100×100 mm (for canopy width more than 5 m), 120×120 mm (for canopy width more than 8 m)

Basic colors of corrugated sheets for canopies?

Options for lean-to canopy trusses?

Canopy price (per set)

Canopy price with turnkey installation

More options for lean-to sheds

Gable

Mortgages are concreted to a depth of 1.5 m; Polycarbonate thickness: 8 mm; Withstand loads up to 180 kg/m2; Service life up to 50 years.

Pole dimensions : 80×80 mm (standard), 100×100 mm (for canopy width more than 5 m), 120×120 mm (for canopy width more than 8 m)

Basic colors of corrugated sheets for canopies?

Options for gable canopy trusses?

Canopy price (per set)

Canopy price with turnkey installation

More options for double awnings

Arched

Mortgages are concreted to a depth of 1.5 m; Polycarbonate thickness: 8 mm; Withstand loads up to 180 kg/m2; Service life up to 50 years.

Pole dimensions : 80×80 mm (standard), 100×100 mm (for canopy width more than 5 m), 120×120 mm (for canopy width more than 8 m)

Basic colors of corrugated sheets for canopies?

Options for arched trusses for a canopy?

Canopy price (per set)

Canopy price with turnkey installation

More options for arched canopies

Console

Mortgages are concreted to a depth of 1.5 m; Polycarbonate thickness: 8 mm; Withstand loads up to 180 kg/m2; Service life up to 50 years.

Pole dimensions : 80×80 mm (standard), 100×100 mm (for canopy width more than 5 m), 120×120 mm (for canopy width more than 8 m)

Basic colors of corrugated sheets for canopies?

Options for canopy canopy trusses?

Canopy price (per set)

Canopy price with turnkey installation

More options for cantilever awnings

If you want to install a translucent canopy on your property, see our options for polycarbonate canopies

Didn't find your option? Send us a sketch and we’ll do it quickly and inexpensively!

How to build a canopy with your own hands

If there is a need to build a canopy, then the easiest, fastest and cheapest way to build a lean-to canopy with your own hands. Let's consider a simplified version of building a small lean-to canopy.

Measurements and calculation of the required material

You need to arm yourself with a tape measure and take measurements of the length, width and height of the future canopy. In accordance with these indicators, the amount of building material and components is calculated. A profile pipe with a cross-section of 60x40 mm is ideal for the supports and frame. This will be quite enough to support a small canopy.

Detailed drawing with dimensions of a lean-to canopy

Preparing the area and installing supports

The soil must be leveled and cleared of unnecessary sticks, branches and reinforcement. According to the marked indicators for the racks (installed every 1 m), recesses are made, the bottom of which is well compacted, covered with crushed stone and sand, thus forming a drainage system. After this, the supports are installed in the recesses, leveled and concreted.

The height of the racks is fully adjustable independently, depending on what angle of inclination is ultimately required.

It is important to wrap those parts of the profile pipe that will be directly immersed in the ground with roofing material in order to prevent oxidation and rusting of the entire structure.

Beams and purlins

When the supports are ready, longitudinal beams and purlins are welded to them, which will serve as a place for attaching the metal profile. If you don’t have a welding machine, you can use a screwdriver and metal screws, but it’s difficult to call such a design completely reliable, although it’s quite possible to use it for home purposes.

Profile flooring

Take a sheet of metal profile and lay it on the lowest level, securing it to the beam with self-tapping screws intended for roofing installations (has a rubber washer). Next, lay the sheet in exactly the same way, making sure that it overlaps slightly with the previous one.

Tips and tricks for building a shed

Like any other work, the construction of a canopy has its own characteristics, without observing which you can get a flimsy structure and it will not be able to fully perform its functions.

- At the planning stage, it is necessary to take measurements as accurately as possible, and also determine the level of soil freezing, on which the depth of the foundation of the supports depends.

- The ideal option for a canopy roof would be a wave-shaped profile, which will ensure unimpeded rolling of moisture from the roof surface.

- Since we are dealing with metal structures, it is recommended to secure them using a welding machine, which will increase the quality of the canopy and its holding capacity several times.

An example of attaching corrugated sheets to a canopy frame using a welding machine - If the choice of fasteners fell on self-tapping screws, make sure that they are designed for roofing and have special rubber washers.

- There is no need to tighten the screws too much, since rubber tends to quickly deform, which will be the main prerequisite for a leak.

- All installation work must begin from the lower layers, gradually moving to the top.

- Profile sheets are cut with metal scissors. It is better to avoid exposing it to an angle grinder, as it can damage the upper protective layers of the sheet.

- Before painting, metal canopies must be treated with an anti-corrosion compound, not forgetting the supports.

- A canopy made from a profile pipe will last at least 50 years, provided that the recommendations above are fully followed.

As you can see, building a canopy is not that difficult. The main thing is desire, thanks to which you can acquire excellent protection from precipitation and excessive sun.

Metal canopies with polycarbonate coating

The smaller the future building, the easier it is to calculate it. The exception is shelters with an area of 15 m2 or more - here it is better to entrust the project of a canopy made of metal structures to professionals.

Advantages of metal canopies

It is no coincidence that metal is so popular as a material for the manufacture of polycarbonate canopy frames. Its most important advantage is durability. With proper installation and maintenance during operation, such a building can last for several decades. All care involves treatment with anti-corrosion compounds or paints containing them. If rust stains occur, it is enough to spot clean the affected areas and treat them with special preparations.

Canopies made of metal profiles: photo of a structure attached to the house

It should also be noted that there is a wide selection of metal profiles: different wall thicknesses, geometry and cross-sectional diameters. Pipes also vary in metal thickness and diameter. Thanks to this, you can always choose the item that corresponds to the purpose and dimensions of the future building. For example, for a small steel canopy over the porch you will need a profile, rectangular in cross-section, with a diameter of 15 mm and a wall thickness of 1 mm; the supports of the car parking shelter are erected from pipes or profiles with a diameter of 40 - 50 mm, with a wall thickness of 2 mm, etc.

Do-it-yourself polycarbonate canopies from a profile pipe: photo of a cascading roof over the porch

Types of materials

Canopies are made from stainless steel, as mentioned above, from a metal profile, a metal pipe and from forged metal. The first option is the most common, since it is presented in a wide range in stores. In addition, square and rectangular profiles can be equally conveniently mounted either with self-tapping screws or by welding. For small parts or small canopies, corners of different sizes work well.

How to make a metal canopy with your own hands: the video describes how to assemble a canopy from a steel pipe.

Less commonly, metal canopies made of pipes. In principle, the range of them in stores is also wide, both in diameter and in wall thickness. But in installation they are a little more complicated, it is more difficult to create right angles with them. Although there are also advantages - it’s not difficult to buy old heating pipes from which you can assemble a budget building. For example, you can make a canopy from a profile pipe with your own hands for firewood or a country shower. Forged metal is mentioned above.

Different types of profile pipes

What type of canopies are made of metal?

Such shelters can be used for different purposes. For example, very often do-it-yourself carports are made from metal. This can be either a small roof over a single parking lot or a swimming pool, or a huge shelter with an area of more than 30 m2. All differences will be in the design and technical characteristics of the material used.

It is very good to make metal canopies over a porch or balcony from a thin profile or forging. In the first case, we get a durable, visually lightweight frame that is easy to assemble with your own hands. Forging is either just a beautiful, openwork canopy, or an entire work of art, made according to an individual project. True, a forged frame will cost much more than a profile one.

Wrought iron pool cover

How to calculate a metal canopy

In principle, it is not difficult to calculate a small frame for a canopy made of a profile pipe over a porch or balcony:

- We draw a sketch with approximate dimensions and marks regarding the type of profile used.

- We accurately measure the installation location and, based on the obtained figures, create a drawing of a canopy from a profile pipe.

- We decide what cross-section the metal profiles or pipes of the trusses and lathing will be.

- We enter new data into the drawing and use it to calculate the amount of required materials. At this stage it will become clear how much and what kind of hardware will be required.

We do not take into account the parameters of roofing materials, since the roof area will be small. When calculating a truss made from a profile pipe for a canopy, do not forget to include the required number of diagonal grids. If it is a forged metal structure, then we only make a sketch of it with the desired dimensions. The master will do the rest for you.

Drawing of a forged visor

Large buildings like carports or adjoining galleries require more careful attention. In addition to performing the above steps, here you need to correctly determine the shape of the roof frame from the profile. The most common option is an arched design. It will resist snow and wind loads well, and installation will not cause any special problems.

We design a canopy from a metal profile: drawings can be made in special programs and then printed

1