SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Swimming pools are artificial reservoirs of water that lack a natural purification system. Stagnation of liquid leads to the accumulation of various harmful impurities, such as bacteria, dust, hair, etc. To remove these contaminants, a special filtration device is used - a pool skimmer. To select suitable equipment, it is necessary to consider the types of such cleaning devices and their features.

Artificial reservoirs and pools require systematic cleaning

How skimmer pools differ from overflow pools

Many people do not have a sufficient understanding of what pool options exist today. Reservoirs of this type are divided into two types according to their design:

- overflow;

- skimmer

Skimmer pools are equipped with an overflow system and filtration units

Infinity pools have a spectacular appearance. In such artificial reservoirs, the top water line is located at the same level as the sides. Arranging such a reservoir is quite a difficult task from an engineering point of view. This is reflected in the final cost of the pool. The skimmer variety of pools has a more attractive price, which is reflected in its popularity.

Overflow type tanks function as follows: water overflowing over the side subsequently falls into a special chute. After this, it flows into the tank, where it is cleaned of impurities formed during the operation of the pool. At the end of filtration, it returns through the bottom nozzles into the reservoir bowl.

What is a skimmer? Pools equipped with such filtration units have smaller dimensions and a simplified design. The skimmer includes an emergency overflow system. Due to this, the water level in the tank is regulated. As a rule, the top water line is located 15-25 cm below the sides.

Note! One skimmer-type filtration system is capable of filtering 25-35 m² of area occupied by water. Thus, the number of installations is selected depending on the dimensions of the artificial reservoir.

Water in overflow pools is poured over the sides and moved into special gutters

In this case, filtration is carried out using a mesh basket, which is an integral part of the system. Let's take a closer look at the filtration process itself. First, the upper layer of liquid enters the treatment equipment. Next, the water is filtered and disinfected. After this, the liquid that has undergone the cleaning procedure is returned to the reservoir.

The main advantage of pools equipped with skimmers is that all the necessary elements of the filtration system in this case are located in the bowl. In turn, when arranging an overflow pool, it is necessary to build an additional room in which the treatment plant will be located. The installation of an overflow pool affects the final cost of construction. It is also worth noting that such artificial reservoirs require more careful maintenance.

Maintenance of a pool that has a skimmer filtration system does not require significant expenses and frequent calls to qualified technicians. It must be remembered that such tanks require periodic backwashing of the cleaning elements. It is also the user's responsibility to maintain the main line, which may become clogged over time.

How to remove oil products from the water surface using skimmers?

For oil collection, there are several different methods that use different types of such devices:

- adhesion method.

- threshold method;

- a method involving the use of cyclone skimmers;

- vacuum method.

Let's look at these methods in more detail.

Adhesive cleaning

Oil and its refined products adhere well to so-called oleophilic surfaces. The application of this technique involves the use of oleophilic skimmers, which are equipped with rotating disks, brush equipment or belts in constant rotation (belt devices).

Read also:

Design features and types of vane pumps

Oil and petroleum products stick to them, and then they are removed mechanically. Devices of this type, along with petroleum products, also take small volumes of water; the type of petroleum product is not important for them; they can be used in shallow water, in backwaters and standing reservoirs with dense underwater vegetation.

Threshold technique

The use of this method of oil collection involves the use of so-called threshold devices, the operating principle of which is as follows: a thin surface layer of water with oil contaminants flows through the threshold; after its passage, water and oil products are separated; the latter end up in a special container, from where they are subsequently removed. Threshold skimmers are characterized by ease of maintenance and a high degree of reliability, as well as a long period of trouble-free operation.

Skimmers-cyclones

In such devices, a whirlpool is artificially created, which in the central part is accompanied by a decrease in level. This is where oil pollution is pumped out. Cyclone-type devices are used to collect oil from the water surface during the liquidation of the consequences of accidents that occur, for example, at places where oil main pipelines cross navigable rivers. The assembly of cyclone skimmers at manufacturing plants is carried out very scrupulously and carefully, since rapid oil collection using the cyclone effect requires high quality equipment used.

Vacuum technique

This method is based on the method of suction of the contaminated upper layer of the water surface with subsequent separation of oil contaminants from it. The principle of operation of such a vacuum device is as follows: using a vacuum pump, a vacuum is created in the settling tank, the action of which leads to the fact that the oil film along with water is sucked into the oil skimmer; after this, the water-oil mixture settles, and then the water is returned to the reservoir, and the settled oil products are poured into special containers.

Skimmer with brush conveyors

Variations of this type of device are hand-held brush skimmers designed to remove heavy and viscous oil contaminants from hard surfaces, as well as for cleaning the shoreline and eliminating contaminants in hard-to-reach places.

Read also:

Main types of pumps for petroleum products

Pool skimmer: what is it and what functions does it perform?

Filters of this type are widely used in the domestic market. As mentioned above, their main function is to maintain proper purity of water in an artificial reservoir. Let's take a closer look at what other functions this equipment performs.

A skimmer is a filtration device for purifying pool water.

Using a filter of this type allows you to subsequently connect a hydrovacuum cleaner, which is used to remove contaminants from the bottom of the pool. Also, with the help of a skimmer, the water level in the pool is controlled, which is a very important function.

Photos of such systems allow you to visually evaluate their advantages and answer the question of what a skimmer is. This device is indispensable for a swimming pool. It is used to add chemicals that are used to purify water in the tank.

With the help of such filtration installations, up to 75% of the area of an artificial reservoir can be treated. The treatment that water undergoes includes heating. After this, it is returned to the pool bowl. It is important to remember that during the operation of an artificial reservoir it is necessary to control the liquid level. It should not be lower than the center line of the device's intake window.

A pool skimmer is not only an effective device that allows you to clean water from contaminants, but also a device that eliminates possible stagnation of water in the tank. The required number of filters is calculated taking into account the number of nozzles. These elements are mounted opposite the skimmers. Maintaining the required balance makes it possible to ensure proper circulation of water in an artificial reservoir.

Skimmers also control the water level, preventing overflow.

Maintenance Tips

In order to ensure the constant purity of the water in the pool, it is not enough to know what a skimmer is, what types there are and how they are installed. It also requires an idea of how to properly maintain it. The main operating procedures are as follows:

- Regular cleaning of the coarse filtration mesh/basket in accordance with the instructions from the model manufacturer.

- Periodic removal of plaque on the internal and external sides of the housing.

- The frequency of preventive measures is determined by the intensity of operation of the tank and the presence of external polluting factors - at least once every 2-3 weeks.

The maximum degree of water purity is observed in pools equipped not only with a skimmer, but also with a filtering bottom drain. Since the intake comes from the surface and from the lower part of the water column, where heavier particles of debris settle.

Pool skimmer: design features

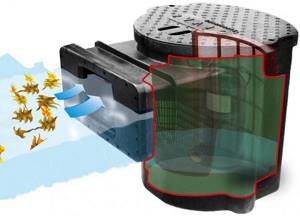

The skimmer is the main element of the pool filtration system. Outwardly, it resembles an empty tank, for the manufacture of which plastic is most often used. You can also find filters made of stainless steel on sale.

There is a threaded connection in close proximity to the bottom of the product. It performs a transitional function and connects the filter to the water intake main. The corresponding video materials on this topic allow you to answer the question of what a pool skimmer is. On the side of such a filter there is a hole that performs a very important function, namely: it collects liquid for further filtration.

Filters of this type perform not only a cleaning function. Skimmer systems heat water in an artificial reservoir. Maintaining a comfortable temperature for a person is a very important criterion for swimming pools. Thus, these devices are irreplaceable elements included in the design of artificial tanks.

Such filters are most often distinguished by compact dimensions. It is quite difficult to make a skimmer with your own hands. The design assembled at home is most often characterized by low efficiency. These devices are often included with hand-held vacuum cleaners. A cleaning device of this type consists of the following parts:

Skimmers suck in contaminated water and then filter it.

- intake nozzles;

- coarse filter;

- pumping equipment;

- control unit;

- bottom drain for the pool.

Skimmers are classified according to different criteria. One of the most important indicators is the power of the device. When choosing a filtration device, you should also pay attention to its dimensions and the size of the pool itself.

How to install

Before you begin installing the equipment yourself, you need to carefully study the drawing; it usually comes with the purchased device. This material will tell you about underwater lights for the pool.

After reading it, you should not have any questions about assembling the element.

In the video - mounted skimmers for intex pools:

There are also several rules that must be followed when installing the device:

- If you have an outdoor pool, then you need to install the skimmer on the windward side, so all the debris will independently fall into the cleaning system, thanks to the current that the wind will create. If you have an indoor pool, then you need to place skimmers evenly over the entire area.

- The skimmer is capable of cleaning up to 25 sq.m. water surface. Based on this, you must independently calculate the number of skimmers needed for your pool.

The mounted skimmer is very easy to install. It is mounted at the desired level on fastenings; the fastenings can be adjusted and changed relative to the water level. Each model includes fasteners for an inflatable and frame pool; they are quite easy to distinguish. A mesh bucket must be inserted into the skimmer tank (this bucket will need to be pulled out during periods of use and cleaned and rinsed with water). You need to install a float on the top of the bucket, thanks to the movements of this float, debris is sucked into the skimmer. Also included with the device are adapters with which the device can be connected to the pump. If you are setting up a swimming pool, then you may need lamps to illuminate the pool. This link will tell you about a sliding pavilion for a polycarbonate pool.

Skimmer: what is it, types of filtration devices

Depending on the design and location, there are several types of filtration devices for artificial reservoirs. Each type has its own advantages and disadvantages. Let's take a closer look at what options for this equipment can be found on the modern market:

- mounted;

- built-in;

- floating.

Skimmers come in three types: mounted, floating and built-in.

Mounted skimmers for artificial reservoirs are most often made of polymer materials. Such devices are mounted on the side of the bowl. A distinctive feature of such devices is their simple design, which does not in any way reduce the overall efficiency.

Mounted models may have a return pipe. Its presence allows the device to function in two modes. The first of them is aimed at the outflow of water, and the second supplies it after the cleaning is completed. Experts advise using filtration devices of this type in cases where there is no desire to compromise the integrity of the waterproofing of the pool bowl.

Such filtration devices are popular among owners of Bestway inflatable pools. Skimmers for pools of this type are reasonably priced.

Built-in and floating skimmers: distinctive features of the equipment

Built-in filter models for artificial reservoirs are mounted directly into the wall of the bowl. Thus, to install them, in any case, it is necessary to violate the integrity of the structure at the stage of its laying. Such models include drainage holes equipped with a floating flap. This element performs a delimiting function, preventing clean water, which is usually found in the lower layers, from entering the filter.

Floating devices have a simple design and are easy to install even for a beginner

In order to answer the question of what this type of skimmer looks like, it is recommended to study the corresponding pictures. Before installing such equipment, experts recommend taking into account the prevailing wind direction in a particular area. This is a very important point, which allows you to improve the functional performance of the device and minimize the possibility of stagnation zones.

The latest type of filtration device for pools is floating devices. The main advantage of such filters is that they have a very simple installation technology. This allows you to install the equipment yourself and save money. Such models are quite often used for frame tanks.

Floating pool skimmers include a special mount in their design. It allows you to change the height of the filtration equipment relative to the top water line. Inside the container of the floating device there is a filtration element in the shape of a bucket. When purchasing such a skimmer, it is recommended to remember that this element is subject to periodic cleaning.

It is also worth mentioning that floating models include special floats. With the help of this part, debris is drawn into the filtration device. It should be noted that when purchasing a floating skimmer, the standard kit includes several transition elements. They are necessary for connecting corrugated hoses.

Built-in skimmers are installed directly into the pool bowl

Thus, the type of device is determined by its design features and installation location. When choosing one of the types of filtration equipment, it is recommended to focus on some nuances.

Pond skimmers: types and purchasing tips

Treatment plants used in ponds are differentiated into types depending on their design. Configuration features affect the location of the device. The following types of filtration devices can be purchased for a pond:

- bottom;

- floating;

- coastal.

Bottom type cleaning equipment is very popular. Pond skimmers differ in design from pool skimmers. Why is such a filter needed? The main function of this device is to remove various debris that accumulates in the reservoir.

Skimmers for ponds come in the following types: coastal, floating, bottom

From the name it becomes clear that this variety is usually placed at the bottom of the pond. The filtration equipment platform is usually located under the bottom. It is dug in or covered with pebbles. Bottom devices have a pipe, the length of which is 30-80 cm.

Bottom filters are also equipped with a basket. Its function is to collect large debris. The filter of the device, unlike the platform, is located on the surface of the pond. Most of these models are height adjustable. The buyer can choose a device for both large and small bodies of water.

Related article:

Water heater for a pool: how to heat water in a pool at the cottage

How to heat water in a swimming pool at the dacha. Popular types of heaters, flow systems, solar heating. Unit selection criteria.

Floating models are equipped with a special element - a float. This is necessary to ensure that the filter does not drown in water. Effectively keeping the hull, cleaning device and basket afloat is the main task of this element. Many experts agree that the most effective device is one that includes a water aeration mode in its functionality. Making a floating skimmer for a pond with your own hands is not difficult, since its design is not complicated.

Note! When choosing filtration equipment for a pool, many people focus solely on the type of device and its price. Skimmers for pools are also classified according to other indicators, which it is highly advisable to take into account before making a purchase, namely: dimensions, power and material used for manufacturing.

Bottom-type devices can be selected for both a small reservoir and a large pond

Coastal devices are located almost entirely under water. Only a small part of the body is above the surface. These models are traditionally installed in close proximity to the shore. The main advantage of such devices is their power. Devices of this type are suitable for cleaning large areas of water.

Equipment characteristics

A skimmer is a tank made of plastic or any other metal material. A pipeline is connected to this tank through which water is drawn. There is a window on the side of the skimmer that has a floating flap.

The operating principle of such a device is quite primitive and consists of the following processes:

- Through the side window of the skimmer, clogged water enters the tank.

- The provided valve separates the clean layers of water from the clogged upper layers, thus, purification occurs only of the water that has become clogged.

- Large pieces of debris entering the tank are retained using the installed filter.

- At the last stage, the purified water is sent for heating , after which it is returned back to the pool.

To increase the efficiency of the skimmer, you can connect a water vacuum cleaner to the connector provided by the design.

Skimmers for pools are produced not only on the surface; there are also simpler designs, such as mounted and deep-mounted devices. Mounted skimmers are installed when the pool structure is integral and does not require the installation of any additional devices.

Submersible devices are used not only as water purifiers. The functionality of this device allows you to drain water through it , which is necessary when the design of swimming pools or water tanks does not provide other drainage mechanisms.

Intex pool skimmers: American quality at an affordable price

The devices manufactured by this American company are distinguished by high quality components. This is reflected in their service life. It is noteworthy that the cost of these devices is not very high, so anyone can buy such a device if they wish.

The appearance of the filters from this manufacturer resembles a funnel. Similar devices are used to collect debris in the pool. The device operates autonomously, which is very convenient. Skimmers for Intex pools are installed on special pumps that are used for filtration work. It is important to remember that such a pump must have good performance - at least 3028 l/h.

Models of this brand have another positive quality - ease of fixation on the sides of an artificial reservoir. Most of these devices have a lightweight body made from plastic. The advantage of using polymer material is its resistance to aggressive chemicals. A skimmer pool is an excellent solution that will save owners from the need for labor-intensive cleaning work.

Filters from the American brand Intex are characterized by good quality and durability

The cost of devices manufactured by this American company averages 850-900 rubles. The cheapest models can be purchased for 750 rubles. It is also worth noting that this company produces other products for swimming pools. An example is circulation pumps.

Oil skimmers. Oil skimmers

Description

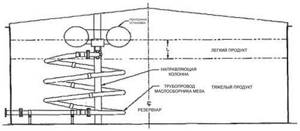

The proposed skimmer system is a proven solution for skimming light product from the surface of heavier product. The skimmer floats on top of the product to collect the lighter portion of both unmixed liquids. The liquid is then drained through a flexible pipe and exits the reservoir through the housing connection. The skimmer system rises and falls with the product level.

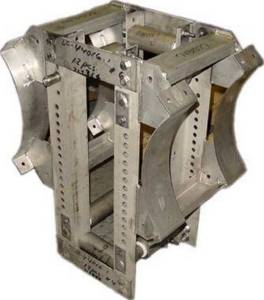

The float, together with the pontoons, rollers and intake fitting, is constantly immersed in the interface between the light and heavy liquids in the tank or in the light product. The "float assembly" consists of a main square frame that supports two sets of idler rollers, two pontoons and an intake fitting. A drain line connects the intake fitting to the body fitting (or floor reel), allowing the top (light) product to be removed from the tank. A standard skimmer system uses drain piping, available in 2, 3 or 4 inch diameters.

A 6" x 6" square vertical tubular guide (not included) extends from the tank floor to the roof to hold the float in position and orientation as it moves up and down. Angle stops (not supplied) must be welded to the square track, both top and bottom, to limit travel and prevent the float from colliding with the tank roof or floor.

- Teflon ball bearings located on stainless steel axles will not require regular maintenance

. - All skimmer floats can be dismantled and fit into a 508mm hatch.

- The intake fitting is equipped with a flow stabilizer

, which ensures optimal flow when the liquid begins to move into the skimmer pipeline.

Material version: steel 316 (316 SS, Russian equivalent 03Х17Н14м³ and 10Х17Н13М2Т).

Skimmer Tubing: DN 2″ (50.8 mm), 5 turns, complete with 150# R/F flange at each end

The kit also includes: floating system complete with double stainless steel pontoons, stainless steel system components including support bracket, siphon intake tube and SS rollers with Teflon bearings. 316 stainless steel steel components.

Note: Distinctive features of our skimmer system:

1. The skimmer moves up and down on a 6 inch square guide. 2. The pipeline is equipped with 2 inch 150# R/F flanges. 3. The piping length for this application is 94 feet. It is wound into a roll and moves along a trajectory up and down

Manual. Installation

The skimmer allows you to remove liquid product from a storage tank by skimming it from the top instead of removing it from the bottom of the tank. This top removal system evacuates product into the housing fitting in a manner similar to the bottom removal system. This system is used when two immiscible liquids (eg acid water and hydrocarbons) are separated in a tank and light product needs to be removed.

There are two main types of skimmers:

Type 1) Floating roof or pontoon tank is equipped with a bleeder fitting which is attached to the bottom of the floating roof/pontoon. A drain line connects the roof/pontoon-mounted drain fitting to the body fitting, allowing the top (light) product to be removed from the tank. The drainage line can be of any model and its dimensions can vary from 2 to 8 inches.

The Type 1 skimmer consists of an L-welded pipe, where the vertical component is the intake device and the horizontal component is the connection to the drainage pipeline. The intake device is equipped with a flow stabilizer, which helps ensure optimal fluid flow as it enters the skimmer pipes. There are two mounting brackets facing vertically toward the roof, which have drilled holes at 1-inch intervals for height adjustment. This skimmer is rigidly fixed to the roof/pontoon, so the distance between the intake device and the roof remains unchanged.

Type 2) Tank with a fixed conical or domed roof with a pontoon installation that floats on the product level. This "floating unit" consists of a main rectangular frame that supports two sets of guide rollers, two pontoons and an intake fitting. A drain line connects the floating bleeder to the body fitting (or pipe assembly), allowing the top (light) product to be removed from the tank. A standard skimmer uses a 2-, 3-, or 4-inch drain line.

The floating installation has a series of holes that allow the intake device to be installed above or below the center of the floating pontoons. These mounting holes allow for 10" height adjustments, in 1" increments, relative to the floating pontoons. We supply a floating installation with an intake device at the level of the center of the pontoons. If the operator wants to ensure that light product is completely removed, it is recommended that the intake device be lowered 2 to 3 inches. If some of the light product needs to remain in the tank after the collection stops, the intake device must be installed above the center. Once installed, the vertical position of the skimmer system intake device relative to the vertical position of the interface between heavy and light liquids will not be noticeable.

As the height of the light product (L) increases, the pontoons will sink more and more into the liquid; thus, the intake device will go deeper into the light product. The process of hydrocarbon intake continues until the L value is equal to 0, at this moment the pontoons are lowered into the heavy product and the intake increases relative to the upper part of the product.

When immersed in the product, the weight of the drainage pipeline is significantly reduced. However, as the product level in the tank increases, the pontoon system must support the increasing mass of the drainage piping. Thus, collection will be slower at high product levels compared to low levels.

The intake device itself is equipped with a flow stabilizer, which helps ensure optimal fluid flow as it enters the skimmer pipes.

The top (light) product may be gravity fed through a drain line, with a shut-off valve at the body fitting, or with a pump that can be used to remove the liquid from the top.

The standard skimmer consists of components made of stainless steel, which can withstand operation in extremely aggressive environments. Metal components, including beams, pontoons, brackets, braces, etc., are made of 304 stainless steel, and fasteners are made of 18/8 stainless steel. Skimmers are also made of carbon steel.

A vertical 6" x 6" square tubular guide that runs from the bottom to the roof of the tank holds the position and orientation of the pontoon rig as it floats up and down. The tank designer must provide details of how a given column is secured to the bottom and roof. In addition, angle stops must be welded to the square column, on the roof and on the bottom, to limit the movement of the pontoon installation and prevent it from hitting the roof or bottom.

The pontoon unit, together with the pontoons, rollers and intake device, will be constantly submerged at the level of the interface between light and heavy liquids in the tank or light product. Teflon ball bearings, which are mounted on stainless steel guides, do not require regular maintenance. All of the skimmer's floating components can be disassembled to fit through the 24-inch diameter access hole. The minimum hole diameter may be smaller depending on the type of drainage pipe used and the size.

An important factor is the position of the intake device on the installation. The pontoon unit is located at the surface of the product, so its height, together with the height of the product, changes as the product oscillates in the tank. Not only the height of the product changes, but also the weight of the drainage pipeline. The Reynolds number of a liquid also affects product flow

INSTALLATION INSTRUCTIONS

For skimmer system with pontoon (type 2)

- Make sure the 6" x 6" guide column is installed and oriented correctly in the correct location according to the drawing (tank diagram).

- Make sure the bottom stops are welded or secured to the guide column.

- The installation of upper limiters on the guide column is not necessary; the need for it depends on the distance between the roof and the product when the tank is maximally filled.

- If necessary, disassemble the pontoons and pontoon unit to place them in the tank. The pontoon unit is supplied assembled with loose fasteners, which makes it easier to disassemble. Before disassembling, note the location of components and fasteners.

- Assemble the pontoon support piece, leaving the pontoons, two rollers/pins (on one side) and two coupling nuts (on one side). This will leave the pontoon support member with clearance for the guide column (C-shaped when viewed from above).

- Move the support piece around the guide column until it is above the bottom stop. Check the drawing for the correct direction of the skimmer, as some applications may require special options.

- Assemble the two remaining rollers/pins, the two coupling nuts and the pontoons. Pontoons must be mounted in such a way that the inspection holes point upward. Install the remaining parts of the installation (outer pipe, downpipe, pipe installation pipe, bracket, etc.) as required, depending on the type of drainage pipe used. The support element is specially marked to accommodate the intake pipe with the intake device in the center of the pontoons. The height of the receiving device can be adjusted.

- Check the distance between the bottom flange and the skimmer flange, as well as the location of the elements.

- Install a drain line between the skimmer flange and the bottom flange. Drainage pipelines usually have many turns and are twisted in a spiral around a guide column. Connect all support brackets using the color codes as a guide. The upper spiral support bracket must connect to the outer pipe on the pontoon rig. Make sure all staples pull straight and do not get tangled when lifting the skimmer. Note: Use gaskets on all flange connections.

- 10. Make sure all fasteners are securely tightened. Make sure the bottom stop is holding the pontoons and there are no piping spiral(s) on the support member.

Caution: Stainless steel fasteners must be installed correctly to avoid seizing. Seizing is a solid-state weld that, in this case, can occur between a bolt and nut during tightening. Sticking of the bolt and nut can cause the parts they hold together to become loose. Seizing also makes it difficult to remove and reuse fasteners. Seizing can be avoided by applying anti-seize lubricant to the bolt threads and by not using excessive force when tightening fasteners.

Bastway: skimmers that are easy to use

This company is one of the most popular filtration equipment for artificial water tanks on the market. The visitor can purchase various models of this device. This company specializes in the production of two types of cleaning devices:

- cartridge;

- sandy

Skimmers for Bestway pools are distinguished by their design simplicity and ease of use. There are several models of this equipment, which are the most popular among buyers. The Flowclear device (number 58404/58199) deserves special attention, which can be purchased in a specialized store or placed an order via the Internet. This cleaning product is characterized by high quality workmanship and good performance.

Bestway produces sand and cartridge skimmers

It is also worth mentioning models numbered 58148 and 58381. Some Bestway pool skimmers are equipped with special devices - ozonizers. These are the models recommended by experts for purchase.

Cartridge-type devices of this brand perform cleaning using a special membrane made of propylene material. It is important to remember that over time, debris accumulates on it, which must be cleaned. It is advisable that preventive cleaning of the membrane be performed at least once every 10 days. The device models of this company are excellent for small artificial reservoirs.

How to make a skimmer for a pond with your own hands

Considering that high-quality models are not affordable for everyone, some craftsmen make such devices on their own. This will require certain knowledge, tools and parts. Below is one of the ways to make a skimmer at home, after familiarizing yourself with which, you can show your imagination and make the device at your own discretion.

So, you will need:

- construction plastic container with a volume of 60 liters (bought in a specialized store);

- a mesh lid from a laundry basket to the size of the drawer so that it fits tightly into it;

- dense foam;

- PVC film with a minimum thickness of 1 mm;

- mosquito net;

- plastic pipe bent at an angle of 90°;

- sewer plug with a diameter of 40 mm;

- 10 screws;

- aluminum tube from a vacuum cleaner;

- glue for PVC pipes;

- To connect, you need a pump or pump and a hose.

Did you know? It is believed that the first simple water filters were invented 4000 years ago. For this, sand or crushed pumice was used.

After preparing all the necessary materials, you can begin assembling the device:

- First, make a hole in the side of the container, at a height of 10 cm from the bottom, with a diameter such that the plug fits in.

- Insert it, put the corner pipe on the back side.

- Then cut a float hole on the side and top, 12 cm high and 25–30 cm wide (without cutting the top side, which is needed for structural rigidity).

- Make a float from PVC film across the width of the rectangular window with wings in the upper part along the height of the hole. Its length should be such that the rectangular part can be folded in half.

- Attach it to the cutout using a pipe from a vacuum cleaner. To do this, a part of it is cut off according to the height of the window, cut in half and leveled. The film is folded in half to form a pocket at the bottom of the float and glued to the bottom of the float hole.

- You need to insert a piece of foam plastic of a suitable size into the resulting envelope, and glue the plastic that remains after cutting out the window onto its lower part.

- Secure the lid of the laundry basket with screws at an angle to the float hole so that the float rests evenly on it under the pressure of water; a mosquito net is placed on top.

The coastal skimmer is ready - all that remains is to install it near the reservoir, press it with heavy stones and connect the hose leading to the pump.

Video: DIY pond skimmer

Rules for installing different types of skimmers

Before installing filtration equipment yourself, it is recommended that you familiarize yourself with the basic rules that allow you to carry out the installation as competently as possible. First of all, you need to decide on the type of device. The appropriate type of equipment is selected depending on the material of manufacture and the design of the artificial reservoir itself.

Installing skimmers for frame pools differs from installing devices in concrete tanks. For the simplest inflatable pools, mounted models of filtration devices are best suited. It is recommended to place them on the windward side, as this will create the most suitable conditions for water filtration.

Mounted and floating skimmers can be easily and quickly installed by yourself

It should also be remembered that for pools located indoors, it is recommended to use a larger number of skimmers. This is explained quite simply. In enclosed spaces there is no natural air flow, so the efficiency of the equipment will be lower. In this case, all filtration devices should be located at the same distance from each other.

If you do not want to carry out complex installation work, you can use mounted skimmer models in the pool. This will save time and labor costs. The most complex installation algorithm is for built-in models of filtration equipment. They are mounted into the sides, which is quite difficult to do independently, without the involvement of specialists.

Installing a skimmer in a concrete pool: features of operation

Installation of filtration devices in artificial reservoirs made of concrete has its own characteristics that require consideration. Before starting work, it is recommended to calculate the number of filtration products taking into account the area of the pool. One device can effectively clean 25 m².

It is also worth remembering that when installing one skimmer, 2 nozzles are used, the function of which is to return water. Manufacturers of filtration equipment most often include installation instructions with the devices. Therefore, all work must be carried out in accordance with this document.

One filtration skimmer can clean up to 25 square meters. m area

When installing a skimmer in a concrete pool, it is recommended to familiarize yourself with training videos on this topic. Let us consider step by step the process of installing a filtration device in a concrete structure. First of all, you need to determine the point at which the installation will be carried out. As a rule, skimmers are mounted at the end wall of the tank. As for the inlet pipe, it is located on the opposite wall.

Note! Before you start pouring the side, you need to insulate the flange. This manipulation will protect the part from concrete.

The filtration device is installed using special fasteners. When connecting a pipeline, you must remember that the threaded connection needs high-quality insulation.

How to install a skimmer in a concrete pool? Installation of the filtration device in the formwork is carried out using plates that are located on the flange. It is important to remember that the flange must be located at the point corresponding to the center of the formwork. Its height is selected so that the surface of the water does not rise above or below the middle of the hole.

Before installation, please read the instructions in detail.

During installation, the flange must be located at the same level with the plane of the wall of the artificial reservoir. Upon completion of fixation, a film coating is applied. It must be cut along the internal contours of the front frame of the filtration device. Of course, it is easier to install a mounted pool skimmer, but built-in models are more reliable.

At the next stage of installing the built-in device, the front frame is installed. Next, the sealing material is fixed. In order to eliminate the possibility of the device subsiding during operation, it is necessary to fill the free space located in the back of the skimmer with sand. Installation of the device can be done by another method - using crossbars.

What types of skimmers are there?

These devices are divided into two categories: built-in and wall-mounted. They differ in design and installation method, but the operating principle remains the same.

Built-in water intake

Built-in models should be included in the drawings before tank construction begins. They are used in permanent pools made of concrete, brick or blocks. It is not always possible to install such a skimmer in a frame structure or an inflatable one.

Mounted model

But there is a way out - mounted models of water intakes. They are made of lightweight material and have a special device for attaching to the wall of the pool. Installation of mounted models takes literally 10-20 minutes.

How to make a skimmer

To assemble the skimmer, prepare the following materials and accessories:

- plastic or steel container or any other similar container;

- coarse filter;

- cleaning mesh;

- flexible hose;

- containers for chemicals.

For a large pool, not a single skimmer may be needed.

The skimmer is designed according to the following scheme:

- Make a special funnel at the bottom of the working container - through it, water will flow from the pool bowl into the skimmer.

- Attach a cleaning mesh to the funnel - its mesh openings should be of such a size as to ensure the retention of large contaminants.

- Place several small containers in the middle of the skimmer for subsequent filling of chemical compounds - the reagents will provide additional purification of the incoming water.

- Install a coarse filter into the skimmer - making it yourself is not very easy, so it is recommended to use a ready-made device.

- Drill an outlet hole in the container and insert a hose into it - with its help, the skimmer is connected to the circulation pump, which is responsible for circulating water in the bowl.

Now all that remains is to install a homemade skimmer on the pool bowl. It is recommended to fasten the device only with stainless steel hardware. In the future, do not forget to regularly clean the skimmer from the contaminants that accumulate in it - this will systematically restore the original performance of the equipment and extend its service life.

As you can see, in order to properly maintain a pool, you really can’t do without a skimmer. But now you are familiar with the basic subtleties of its design, so you can easily make the device yourself. The main thing is to adhere to the basic assembly rules and do not forget about the drawings.

Advantages of skimmer pools

Swimming pools with a cleaning system of this type have a number of advantages that make them very popular among owners of country houses and dachas.

The main advantages include the following features:

- the level of construction costs is approximately 2 times less compared to overflow;

- the layout principle allows you to select the most convenient options for placing equipment;

- ease of maintenance;

- high reliability and long service life when using stainless steel skimmers;

- possibility of using the system for tanks of different designs.

The disadvantages include the limited characteristics of cleaning equipment, which is not able to cope with large volumes of liquid. Therefore, it is used only for small pools.

Where to hang it

The structure is installed on the top of the wall. The intake window should be located in a place corresponding to the expected water level. Usually the mirror is installed 10-15 cm below the level of the sides. The indicator varies depending on the size of the device. The lid is installed above the water - this will make the skimmer easier to maintain and clean.

It happens that during bathing, splashing water floods the lid. To solve the problem, you need to reduce the water level in the font. For this purpose, an extension crown is installed.

A short overview of skimmers - which equipment to choose?

The cost of filtration units depends on the material they are made of, the manufacturer, equipment configuration and its technical characteristics. Stainless steel skimmers are always more expensive than plastic models. The most popular manufacturers of built-in pool cleaners are the following companies:

- Kripsol is a well-known Spanish brand that produces mid-priced equipment. This company makes devices for filtering water in swimming pools from high-quality ABS plastic.

- PROCOPI is a French manufacturer working for the average consumer. The company produces technical devices from plastic with ultra-durable properties.

- PAHLEN - expensive skimmers from a Swedish brand. All devices are made from alloyed special steel, which gives them unique durability. PAHLEN filter units are equipped with a full set of fasteners, sealing gaskets and additional elements.

Spanish cleaning device "Kripsol"

High-quality mounted cleaners are offered by the German brands MTH and MTS, as well as the American company Intex. In addition, there are a lot of inexpensive skimmers made in China and Turkey on the market. It is not recommended to purchase the latter. They are usually made of cheap plastic, which quickly loses both its beautiful appearance and performance characteristics.

How to connect a skimmer to a pool

The attachment is easy to install. Skimmers that go on sale have a hook-shaped mount. When the body is assembled, the structure is hung on the side and the immersion depth is adjusted. The outlet pipe coming from the bottom of the body is connected to the filtration system serving the font.

It is more difficult to install a structure in a stationary pool. Windows for built-in skimmers are often provided during design. If they are missing, they have to be drilled. This is a difficult process that requires special skills. You should not tackle it yourself, otherwise the waterproofing will most likely be damaged and cracks will appear on the concrete surface. Built-in models are supplied with fasteners. In order for the device to work correctly, it is advisable to use branded components and not replace them with others. The joints must be properly sealed.

The baskets available in the buildings become clogged over time. Therefore, they must be removed and washed periodically. If it is necessary to adjust the water level, the device is immersed or raised by means of a regulating mechanism. If you purchased a model with an ozonizer, the membrane must be washed every 10 days.

Even a beginner can assemble a product from bottles or sewer components. It is suitable for servicing a small private pool (inflatable or frame), including as a temporary replacement for an industrial device. If the pool is large and is used regularly, it is better to purchase a commercial device.