Chainsaw design and general classification of faults

Correctly find the source of the malfunction, as well as perform correct and high-quality repairs of chainsaws; for this you need to have a reliable understanding of its technical specifics. Repairing such equipment is not particularly difficult. Its schematic structure is quite simple. For convenience, the nodes in its composition can be divided into three types:

- The main and very important element, without which further work is impossible, is a two-stroke engine running on gasoline. Acceptable brands of gasoline are indicated in the device passport itself;

- the second equally important component is its working part, which is responsible for sawing the materials themselves. This includes sawing mechanisms;

- The third connecting unit includes a system for supplying and filtering fuel, oil, engine ignition, exhaust gas removal, etc.

Chainsaw engine malfunction

Problems are classified into two nodes:

- Malfunction of the engine itself. It cannot start, it stalls for no reason, it heats up excessively, it smokes a lot, it works unstably with minimum and maximum load. Therefore, repairs need to be carried out on these units.

- Peripheral problems. Here you can identify many symptoms that indicate malfunctions in its operation. For example, if the chainsaw stalls during operation or loses power, there may be a blockage in the gasoline supply system or filter. If it cuts poorly, then the chain may simply be dull. Repairs should begin with a study of the auxiliary components, which will require the least amount of time and equipment.

For convenience, before starting repairs, you should divide the chainsaw into sectors and look for a fault directly where the problem is suspected. The manual also provides a brief description of possible breakdowns and how to eliminate them.

It should also be borne in mind that several factors can serve as sources for the same malfunction. Therefore, it is important to be able to diagnose the cause of the breakdown in order to carry out repairs correctly and efficiently in the future. Before you start disassembling and repairing a chainsaw, you should estimate the possible causes and try to work only with them.

Technological process of repairing a Shtil chainsaw

When disassembling and repairing a chainsaw, a certain sequence must be followed.

First, the cause of the malfunction is determined. Most often what happens:

- open circuit;

- no startup;

- the saw turns itself off;

- oil leaks;

- Full power is not developed.

If there is a malfunction, you must remove the gas tank cap and make sure there is an uninterrupted fuel supply.

If the chain breaks, you just need to replace it with a new one. There shouldn't be any particular problem with this kind of work. Other faults will take several hours to repair.

If the saw does not start, you need to make sure there is fuel. To do this, you need to remove the gas tank cap. If there is enough fuel, the breather, which equalizes the pressure when fuel is consumed, may be clogged. The breather can be cleaned with a needle. The spark plugs are turned out with a special wrench. They need to be cleaned with emery cloth. The combustion chamber must be ventilated. The chainsaw should start.

Automatic shutdown of the chainsaw indicates a malfunction of the starting mechanism. However, this is not always the case. It can work fine. You will have to unscrew all the spark plugs and conduct a thorough inspection of them. If fuel gets on the spark plug, it means the carburetor is clogged. It needs to be removed and cleaned. Soot appearing on the spark plug indicates incorrect carburetor adjustment or bad fuel. The unscrewed spark plug is checked for functionality and the gap is measured. It is best to immediately replace poorly functioning spark plugs with new ones. In addition, the air filter must be clean and not leaking air.

The next step requires disassembling the cylinder-piston group of the chainsaw motor. The design of the Shtil chainsaw engine is similar to that of a scooter engine. It is very easy to understand. You need to unscrew the four bolts securing the cylinder head. The cylinder is then carefully removed from the block. The piston must look perfect. If scoring is detected, it must be replaced. Cylinder repairs are carried out by boring in accordance with the repair size. Sometimes the cylinder changes together with the piston.

The engine of the Shtil chainsaw is similar to the engine of a scooter and can be easily disassembled.

After removing the piston, you must carefully examine the condition of the rings. The rings should fit snugly, but they should fit freely on the piston. Then you need to insert the piston into the cylinder and try to swing it, leaning on the top point. If the piston is loose, we can safely talk about its wear. Due to this malfunction, the chainsaw is not able to work at full strength.

If oil leakage is detected, it is necessary to check the hose connections and its tightness. To replace the hose, you need to disassemble the entire chainsaw.

The main problems with chainsaws are:

- ignition;

- fuel mixture supply;

- piston operation;

- cylinder operation;

- exhaust;

- chain brake;

- supply of lubricating fluid;

- clutch;

- tire.

What is needed to fix the problem?

Repairing a chainsaw does not require a large arsenal of household tools. First of all, this:

- screwdrivers. Cross and flat to remove the casing, chain or other components that are fastened with flat bolts and will definitely be needed to properly repair the chainsaw;

- a set of spanners and wrenches of different sizes. They will be needed when disassembling the engine and other moving parts. Repairing such parts sometimes involves dry cleaning, so they will be needed to scrape off excess dirt;

- key for removing spark plug;

- a diagram of the chainsaw itself in order to know how certain components work and how to properly maintain them.

DIY chainsaw repair, fuel supply system

The most common breakdowns that require repair of their parts include problems with the engine and fuel supply system. It happens that it is impossible to develop the nominally maximum power of a chainsaw, or the chainsaw suddenly stalls after some time, or it is not possible to start it at all.

Fuel supply system

This happens in two cases:

- problems with the fuel mixture ignition;

- problems with the delivery of gasoline from the tank to the engine.

Finding the causes of failure and repairing a chainsaw should always start with the elements that will require the least amount of time and money, namely the spark plug. Its direct purpose is to generate a spark and ignite the gasoline mixture with air. A simple visual inspection of this element can tell you a lot and tell you where to start repairing.

- The absence of a spark in the gap indicates poor contact with the wire or a malfunction of the spark plug itself. It is necessary to check all contacts and the spark plug itself. A new spark plug is installed in the cradle, and if it also does not produce a spark, then the problem lies in the contacts and the wire itself. They need to be changed.

- A dry spark plug is the first sign that fuel is not being supplied to the carburetor at all. The cause of the breakdown is a blockage in the fuel filter element or breather. It is necessary to rinse, if this does not work, then change the filter. Manufacturers recommend changing it at least once every three months.

- Excessive fuel presence on the spark plug head indicates incorrect carburetor adjustment or incorrect starting. The repair involves simply removing the spark plug, which needs to be wiped with a dry cloth. It is also necessary to check the chambers in which the fuel burns directly.

- The candle is covered with soot. This indicates an excessive flow of gasoline mixture into the combustion chambers, poor quality of oil, incorrect carburetor settings, or incorrect proportions of oil and fuel. Repair here is carried out by washing the spark plug, then wipe it dry with a rag. The gaps should also be cleaned with a sharp needle or awl. Problems with the carburetor usually arise when its settings are lost, the membrane wears out (only replacing it will help here), or there is a blockage in its channels (should be disassembled and cleaned).

Replacing the chainsaw filter

Repairing chainsaws with your own hands is always not an easy task, even for an experienced person who knows almost everything about technology. Most of the time is spent diagnosing a malfunction, when you need to find the source of all problems with equipment.

Problems with the fuel supply channel

Lack of normal fuel supply to the combustion zone is possible for a number of reasons, including clogging and carburetor imbalance (or problems with throttle control).

To accurately identify this malfunction, it is necessary to disconnect the supply hose from the fitting and check the fuel pressure. If the stream flowing out of it turns out to be weak, there is a high probability that the filter located in the neck of the filler tank is clogged. If contamination is visible to the eye, it should be removed and cleaned (if the filter element is severely worn, it is recommended to replace it with a new one).

The breather is checked in the same way, and if contamination is detected, it is cleaned with a needle. In case of violations in the carburetor adjustment, it is repeated again until a positive result is obtained. When examining the throttle valve cable and lever, make sure that they are intact and in their proper place.

Troubleshooting muffler problems

It happens that the engine runs calmly and without problems at zero load, but when it increases, it stalls or runs intermittently. This is caused, as one of the reasons, by a blockage in the muffler. The source of the blockage can be combustion products of waste materials, an excess of oil in the combustion mixture, or its poor quality. In such a situation, repairing a chainsaw will not be so time-consuming, since to fix the problem, you only need to clean the muffler. Most often, the spark arrestor becomes clogged with combustion products of gasoline vapors.

Sequencing:

- remove the muffler. It is better to cover the outlet hole with a cloth to prevent dirt from getting there;

- disassemble the muffler itself, if it is collapsible;

- wash it with special detergents. Dry cleaning can be used. This should be done using a respirator or other means of respiratory protection, since the remains of burnt products contain carcinogenic substances that are seriously harmful to our health;

- dry the muffler with a compressor, vacuum cleaner (blowing action) or a regular hairdryer;

- assemble and install in place.

Repair of cylinder-piston group (CPG)

Sometimes it happens that the engine is not able to reach maximum power or start due to insufficient pressure in the cylinders. The source of such problems is sometimes faulty piston rings, problems with the cylinder, bearings, or wear of the piston itself. Therefore, repairing a chainsaw should begin with a visual inspection of the engine cylinders. Inspection is possible through the hole where the spark plug is installed to ignite the mixture. The overview under such conditions will remain minimal, but a first idea of the state of the working group at this stage can be obtained.

Replacing the piston

You can also insert a compression gauge into the spark plug hole. Rotate the starter or crankshaft. The pressure inside must be at least 8 atmospheric units. At lower values, the engine will not work due to insufficient pressure created inside. As the pressure decreases, the engine power itself also decreases.

A more detailed picture of what is happening inside can be seen by disassembling it. To do this, remove the crankcase and visually inspect the piston. If there are chips, dents or scratches, it should definitely be replaced. The piston pins must also be in good condition without damage and not loose. If this happens, then you should definitely change them.

A decrease in pressure inside the engine also involves failure of the piston rings. This can be immediately noticed, since the working ring is not covered with carbon deposits, it is located freely in the groove and does not dangle, and is pressed tightly inside the cylinder.

Replacing chainsaw piston rings

You should also examine the surface of the inside of the cylinder. If it is already worn out, then it should be squandered.

Chainsaw Forward Doesn't Idle

Content

The main malfunctions of chainsaws and their repair in artisanal conditions

A chainsaw is a worthy replacement for hand saws and axes. Now this popular rumor tool is found in almost every household - it is indispensable when arranging a summer cottage, construction and repair work. Severe use and improper care of equipment lead to its premature failure. But the owner of a chainsaw does not necessarily have to immediately go to a workshop - probably because of defects that may happen to it during operation

, really remove it without the help of others.

Chainsaw design and general classification of faults

The main condition for successful repair is correct diagnosis. Because in order to find out why the chainsaw failed and, most importantly, how to make it work again, you first need to know the features of its design.

It should be noted that it is not particularly complex, as it includes:

- engine (two-stroke petrol);

- multifunctional part (saw bar and chain);

- a set of accounting programs that ensure the joint operation of these two components (ignition, filtration, lubrication, etc.), in other words, the entire tool.

In order to simplify the diagnosis of faults, they are usually divided into two main categories:

- motor malfunction;

- malfunctions of other chainsaw components.

For the most part, failures occur in motor systems, but other parts of the tool, due to intensive use or improper care, may always fail. How to find where exactly the breakdown occurred? Ordinary logic will help us solve this issue.

If the problem is in the engine, it will:

- won't start;

- stall;

- work unstably;

- overheat;

- smoke;

- develop insufficient power.

As for all other defects, they manifest themselves with a normally running engine.

Starting the engine: checking the spark plugs

If the chainsaw does not start, the first thing you need to do is check the presence of a fuel mixture

. By the way, it must be prepared in the proportions specified by the engine manufacturer, otherwise the tool simply will not start.

READ Chainsaw Husqvarna 142 Starts and Stalls

After making sure that the fuel mixture is correct and available, you should check the ignition system. To do this, you need to inspect the spark plug.

Her condition can say a lot:

indicates that the fuel mixture does not enter the carburetor, which means the problem is not in the ignition;

- fuel-spattered candle

is the result of an excess of the fuel mixture, which lies either in a violation of the engine starting algorithm or in incorrect carburetor adjustment;

This is a signal about the presence of low-quality oil in the engine lubrication system, incorrect carburetor settings, or an incorrectly prepared fuel mixture.

If the spark plug is splashed with fuel, it must be thoroughly wiped after removal. The fuel supply system should also be cleaned. To do this, it is closed, after which the starter is turned on. A candle covered with soot must be carefully cleaned using an awl and sandpaper.

When checking spark plugs, you should pay attention to the distance between the electrodes (the normal gap is 0.5-0.65 mm), as well as the condition of the gasket and the presence of a spark. A damaged or worn gasket will need to be replaced, and the spark can be checked by putting on the ignition cable, connecting the cylinder and spark plug nut, and turning the starter.

If the discharge does not occur, the spark plug needs to be replaced. If a spark does not appear even with a new spark plug, then the problem is in the connection to the high-voltage wire or in it itself.

DIY chainsaw repair: fuel supply system

If the fuel mixture does not enter the cylinder, but the spark plug works normally, this may mean that:

- The fuel filter is clogged.

To clean this unit, remove the fuel hose and check the flow. If it is weak, the filter must be removed through the filler hole of the fuel tank and cleaned or replaced if completely worn out.

What to do if the chainsaw does not idle?

In this video you will learn one of the breakdowns in which the chainsaw does not work

at low speeds and start.

Adjusting the idle speed of the chainsaw

Article: Buy a chainsaw

: .

As a preventative measure, it is recommended to replace the fuel filter at least once every 3 months.

This is nothing more than a hole in the fuel tank cap, which is cleaned with an awl.

- The fuel mixture is not supplied or is supplied in insufficient quantities.

There may be several reasons for this:

- the air filter is clogged (in this case, it must be removed, washed with water, dried and replaced);

- the carburetor settings have gone wrong (which means this unit needs to be adjusted again);

- the integrity of the carburetor membrane is damaged (must be replaced);

- the carburetor channels are clogged (it must be disassembled and all parts and components cleaned).

READ Which Electric Chainsaw to Choose

Troubleshooting muffler problems

If the chainsaw engine operates normally at low speeds, but starts to stall and smoke at high speeds, the problem may be hidden in the muffler.

To check the quality of its work you should do the following:

- dismantling (with mandatory closing of the outlet);

- disassembly (if the muffler is dismountable);

- cleaning from carbon deposits using special detergents or the dry method;

- drying (using a hair dryer);

- reassembly and installation.

Dry cleaning without respiratory protection is not recommended. Carcinogens present in carbon deposits will be released into the surrounding atmosphere in the form of dust, the inhalation of which is extremely dangerous to health.

To prevent clogging of the muffler during operation of the chainsaw, you should carefully monitor the composition of the fuel mixture and the quality of its components.

Repair of cylinder-piston group (CPG)

If the chainsaw engine does not start or cannot develop normal power, it is likely that there is not enough pressure in the engine cylinder to burn the fuel mixture. The reason for this may be wear of the elements of the cylinder-piston group - piston, rings, bearings, etc. In order to assess the condition of this unit, it should be visually inspected after first removing the muffler.

For a more complete diagnosis, a compression gauge is placed in the spark plug hole of a two-stroke chainsaw engine. It is used to measure compression in the engine. Based on the test results, one can judge the condition of the CPG, but accurate facts can only be obtained by completely disassembling the unit.

If the piston is chipped or scratched, it will obviously have to be replaced. The same applies to deformed or broken piston rings - for normal engine operation they must be fully functional and free of carbon deposits.

Checking the carburetor and signs that it needs adjustment

A correctly functioning carburetor guarantees maximum efficiency of the chainsaw, that is, it is possible to develop full power with the most economical consumption of the fuel mixture. Adjustment of this unit is usually carried out by the manufacturer, but its design provides for the possibility of adjustment during operation.

The fact that such adjustment will have to be made by the owner of the chainsaw is evidenced by:

- Strong vibrations or damage to the protective cap.

- CPG wear.

- Carburetor clogged.

- Inability to start the engine or its spontaneous stopping after starting.

- Increased fuel consumption and exhaust emissions with a simultaneous decrease in engine power.

READ Chinese Chainsaw Carburetor Factory Settings

The chainsaw carburetor is adjusted in strict accordance with the manufacturer’s instructions using three special screws, which are responsible for the maximum (“M”) and minimum (“L”) speeds, as well as engine idle speed (“T”). In order to exclude unwanted interference by an inexperienced user in the operation of the carburetor, some manufacturers install only one idle screw.

Calibration algorithm and safety precautions when troubleshooting a chainsaw carburetor

Carburetor adjustment is performed in two stages:

- Basic (carried out with the engine off).

- Finish (carried out with the engine running, preheated).

For basic adjustment, screw screws H and L until they stop and turn them back 1.5 turns. Final adjustment requires that the engine be warmed up for 5-10 minutes at low speed .

The final calibration is performed by turning out the idle screw until the minimum engine speed is reached (its operation must be stable and the chain must be motionless). If the engine stops idling, the screw must be returned back, and if the saw chain still moves, you should continue turning it counterclockwise.

Calibration check is performed by test:

- Acceleration (when you gently press the accelerator, the engine should quickly gain speed to its maximum).

- Maximum speed (if there are misfires, screw H should be loosened slightly).

- Idling (the chain should not move, and the engine should pick up speed as quickly as possible).

If the owner of the chainsaw is not familiar with the carburetor structure and does not have the necessary tools to calibrate it, you should contact a specialist. A carburetor is a very complex unit, so any incorrect action can lead to irreversible consequences, such as complete engine failure.

Other chainsaw malfunctions

If the diagnostics showed that everything is in order with the engine and its systems, then the cause of the malfunction should be sought in other components of the chainsaw. The most common problems are:

- starter failure;

- improper operation of the lubrication system;

- incorrect operation of the chain brake;

- saw chain wear, etc.

Source

Checking the carburetor and signs that it needs adjustment

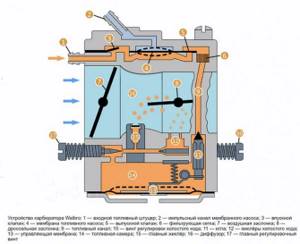

The rated engine power and savings in fuel consumption depend on the good condition of the carburetor. The carburetor of a chainsaw has no functional difference from a car. It mixes gasoline vapors with air entering through the pipe and delivers them further into the combustion chamber.

Carburetor design

It consists of:

- air duct or tube for air supply;

- fuel line or fuel supply tube for mixing it with air;

- air damper.

A sign that the carburetor needs to be adjusted:

- strong vibrations due to unbalanced screws. An engine with a working carburetor runs smoothly and sounds like a four-stroke stroke;

- damage to the protection cap;

- wear of the piston system, which already requires a different mixture in composition;

- involuntary engine shutdown, inability to restart or initially start;

- an unreasonable increase in gasoline consumption, while engine power may remain the same, but most often decrease;

Chainsaw engine repair

The operating principle of a two-stroke chainsaw engine has several distinctive features. The first feature is that the fuel mixture of gasoline and special oil gets under the piston. There it lubricates the crankshaft bearings, is compressed and enters the combustion chamber through special passages, pushing out the gas of the previously burned fuel mixture.

All chainsaw manufacturers Husqvarna, Stihl, Oleo Mac, Makita and others warn consumers in various ways about the need to use special oil to prepare a flammable mixture. In the operating instructions on the first pages, on the body of the chainsaw in the area of the fuel tank cap, the exact proportion of preparation of the combustible mixture is indicated.

Why is it so important to maintain proportions? Lack of oil leads to scuffing on the surface of the cylinder and piston (CPG), and jamming of the crankshaft bearings. Oil filled in excess of the norm is manifested by increased smoke formation, sticking of piston rings and hard carbon deposits. Such carbon deposits contaminate the muffler and the surfaces of the CPG; during operation, it can fall off and damage the chainsaw engine. Manufacturers such as Stihl also warn consumers against operating at high speeds without load or idling for long periods of time - these modes are detrimental to the chainsaw engine. Repair of a chainsaw with damage characteristic of these cases consists of a complete replacement of the engine (motor).

Calibration algorithm and safety precautions when troubleshooting a chainsaw carburetor

Calibration or fine adjustment of the carburetor should be carried out strictly as recommended by the chainsaw manufacturer itself. Often this procedure has already been done during the assembly phase in the assembly shop. However, chainsaw repairs sometimes include carburetor adjustments. This is due to its incorrect operation for technical reasons, settings failure, etc.

Fine adjustment is made using three bolts:

- bolt “L” regulates fuel supply at low speeds;

- bolt “H” regulates the maximum fuel supply to the engine;

- The "T" bolt regulates the fuel supply at idle.

There are two types of carburetor settings:

- main or basic. Performed with the engine turned off;

- exact or final. Performed on a warm engine.

First, the “H” and “L” bolts, which regulate the supply of the fuel mixture at high and low speeds, respectively, are tightened counterclockwise all the way. Next, turn them one and a half turns clockwise. It is advisable, before starting the procedure, to mark the initial position of these bolts with a pencil or felt-tip pen, in order to subsequently return them to the position in which they were before if problems with adjustment arise. The fact is that with an unskilled approach to adjustment, it is possible to completely kill the engine.

Further adjustment takes place with the engine warmed up to the desired temperature. It is left running for 10 minutes. Next, they fine-tune the idle speed adjustment bolt. It is turned until the engine (its speed) reaches the minimum values. The engine must run stably and the chain must remain in place (not rotating).

Then you should check how quickly the momentum picks up. To do this, slowly turn the low speed bolt another eighth of a turn. The maximum possible speed can be set using the tachometer and adjusting the “H” bolt. Next you should check the carburetor operation at idle again.

Problems and DIY repairs

Chainsaw problems can be of two types:

- Malfunctions of the engine, ignition system, fuel supply and exhaust.

- Malfunctions of other components.

The following indicators will indicate that it is necessary to diagnose the engine:

- The tool does not start or starts and stalls.

- It works unstable.

- It works at idle speed, but when under load the speed drops or stalls.

Problems with other nodes:

- Lubrication system problems.

- The chain brake does not work.

- Breakage or wear out of the chain.

- The sprocket is worn out.

Ignition system (does not start, stalls)

It is necessary to check the appearance of the spark plug.

- Take the spark plug key. Remove the insulating cap from the power cable. Use a key to unscrew the spark plug.

Fuel supply system

Fuel does not arrive for three reasons:

- There is a hole in the fuel cap that may be clogged. If this happens, a vacuum is formed, which prevents fuel from leaking out.

- A fuel filter is installed in the tank. It gets dirty over time.

- Fuel is poorly supplied from the carburetor to the cylinder.

Read also: What is a slotted screwdriver?

The first two reasons are identified in the same way. To do this, you need to disconnect the hose through which the fuel passes from the carburetor. And check with what pressure it flows out. If it flows weakly or does not flow at all, then clean the tank cap with a needle and replace the fuel filter. But first you need to drain the flammable mixture and remove the filter from the tank with a wire hook. If fuel flows well from a disconnected hose, it means the air filter is clogged or the carburetor is faulty. The air filter affects the flow of air into the carburetor and the enrichment of the combustible mixture. When it is clogged, the mixture is too rich because there is no air flow. This affects the correct functioning of the engine.

- Carefully remove the air filter to prevent dust from scattering. Cover the hole formed in the combustion chamber with a clean cloth.

- Blow through the filter and clean with a soft brush. If the filter does not clean, wash it. After drying, put it back.

Before adjusting the carburetor, check that the air filter is clean and the chain is tight enough. Read the instructions. The manufacturer describes how to properly adjust the carburetor. If there are no instructions, find the three labeled screws:

- H - maximum speed screw.

- L - minimum speed screw.

- S — screw for fine adjustment of idle speed.

Take a carburetor adjustment screwdriver and get started.

- Basic adjustment. Performed with the engine turned off and cold. Turn screws H and L all the way to the right, i.e. clockwise. Then one and a half turns to the left.

- Idle speed adjustment. Before starting, turn on and warm up the engine. Rotating the screw S to the right increases the speed, and to the left decreases it. You need to lower the speed and control so that the engine runs stably, without pauses. Keep the chain moving. If the engine suddenly stops, increase the speed little by little. And when moving the chain, reduce it.

- Checking the engine for acceleration. Smoothly press the fuel button. A tuned engine should quickly and confidently pick up speed to maximum. If the engine lags and runs unsteadily, turn screw L to the left no more than an eighth of a turn.

- Adjustment of maximum speed. When reaching maximum speed, ignition interruptions occur. Slowly turn screw H to the left until stability is achieved.

- After all adjustments, check the engine at idle speed. It should work stably when the chain is stationary. If you do not achieve the desired result, repeat all adjustments, excluding the basic one.

Disassembling and cleaning the muffler

When the muffler is clogged, the exhaust gases have nowhere to go. The saw will not work or start. The design of the chainsaw allows you to remove the muffler quickly. Depending on the mounting method, you may need a hex key or socket wrench.

- Remove the screws. Lightly rock the muffler and remove it from the studs. Plug the hole in the engine with a clean cloth.

The muffler becomes dirty due to poor quality oil or incorrect fuel mixture composition.

How to remove and clean the muffler on a chainsaw

Cylinder-piston group

Wear and damage to the cylinder-piston group makes it impossible to start the engine.

To detect damage, remove the muffler. The exhaust hole will open to you, into which you will see part of the surface of the cylinder.

Part of the cylinder in the exhaust port

In addition to the piston, which may not have visible damage through this hole, inspect the piston ring. If defects are present, then it is necessary to disassemble the entire piston group in order to fully assess its condition. Malfunctions can only be eliminated by completely replacing the group.

- Take a pressure gauge to measure compression. Screw it into the spark plug hole, gently pressing the sealing rubber.

- Pull the starter while watching the gauge needle.

- The pressure must be at least 8 atmospheres.

If you don’t have such a device, try the traditional method. Unscrew the spark plug.

Checking compression the traditional way

Plug the spark plug hole with your finger and pull the starter. If your finger gets sucked in, it means there is compression.

How to measure compression with a pressure gauge

Chain, tire

Signs of chain wear:

Violation of the integrity of the cutting links.

Gaps, abrasions and cracks in rivets and sides of links.

The cutting link was so worn that sawing became difficult.

The connecting link is damaged.

After replacing 3 chains, change the tire and drive sprocket.

Chainsaw drive sprocket

To replace the sprocket you will need: a spark plug wrench, a piston stopper, and a clutch puller.

- Remove the cover to access the spark plug. Unscrew the spark plug with a wrench.

- Using a clutch remover, turn the clutch clockwise until the piston rises to top dead center. This can be checked through the spark plug hole.

- Screw in the piston stopper instead of the spark plug. If it is not there, then twist a thick bundle of ropes and insert it into the spark plug hole.

- Turn the clutch puller to the right and you will unscrew it.

- Remove sequentially all the parts of the clutch assembly and the plate with the sprocket. Replace it with a new one.

Other chainsaw malfunctions

In addition to the main components, the chainsaw has a number of other less functional, but no less important components. Breakdowns happen here too, but they are much easier to identify and fix.

Chain sharpening

- System malfunction due to fuel vapor ignition. This could include a starter failure. It happens that the cable breaks, the return spring jumps out or completely breaks. The contacts between the high-voltage wire and the spark plugs wear out.

- The operation of the lubrication system itself is disrupted. The cause may be poor quality or unsuitable oil, or the lubricants themselves. You can even simply add lubricant to the necessary components in time.

- It happens that the chain brake starts to work incorrectly. To eliminate this problem, you need to configure it correctly. Clean it, as it sometimes becomes very clogged with sawdust.

- The saw chain becomes dull or wears out. If it is not possible to sharpen the chain yourself, then you should give it to a professional sharpener. It will cost money, but much less than buying a new one.

Causes of spark plug problems

As mentioned earlier, the cause of failure of spark plugs is, first of all, a violation of contacts between the wires or a malfunction of the fuel system itself. To analyze such a malfunction, you should unscrew the spark plug and carefully examine it. Its completely dry condition tells the owner that fuel simply does not enter the cylinders. A wet head indicates that the fuel in the cylinders is not igniting, or there is moisture somewhere in the system. First of all, you need to dry the candle. This is done with the valve open and the tap closed.

Diagnostics of spark plug condition

You may need to replace the gasoline or the spark plug itself. The presence of carbon deposits on the head indicates an imbalance between the gasoline and oil compositions. The fuel filter element may be clogged. The problem can be solved by changing the fuel itself, filters and cleaning the fuel supply system of the chainsaw.

Engine repair, ignition

Breakdowns happen quite often. Disassembly and repair require a lot of time and certain knowledge. Most often, engine repair is required when:

- No start or it just stalls.

- Unsustainable work.

- There is no full power, the engine begins to stall under load.

Most engine problems are related to a malfunction of the ignition system. Therefore, you first need to make sure the spark plug is working. By studying its condition, you can tell how well the fuel system works. To do this, unscrew the spark plug with a special wrench, having previously disconnected the wire.

If the spark plug is completely dry, then the breakdown problem is not related to the ignition system. Perhaps the fuel mixture simply does not get into the cylinder. You can screw the spark plug back in and begin repairing the engine fuel supply system.

When gasoline is detected on the spark plug, it means the spark plugs are being primed. One reason is improper carburetor adjustment or poor starting fundamentals. To repair the spark plug, you need to clean and dry it. To dry the cylinder, you need to close the fuel supply. To ventilate the combustion chamber, the starter is started. After a few minutes, you can screw in the spark plug and start again. If black carbon deposits are found on the spark plug, it means the fuel system has failed.

Failure to receive fuel has a number of reasons:

- The breather hole is clogged, causing a vacuum to form in the tank, preventing fuel from entering the cylinder.

- The fuel filter is clogged.

- The carburetor broke down.

To determine the cause, you just need to remove the fuel hose and make sure that the fuel flow is unimpeded.

If the flow is very weak, it means the breather is clogged, which can be cleaned with a needle.

The fuel filter is removed after the gasoline is drained from the tank through the filler hole. It is hooked with a wire hook together with a hose. The connecting clamps are unscrewed. The filter needs to be cleaned or a new one installed. It is advisable to change it once a quarter.