In this article we will consider in detail Geofast welded gabions in a combined design option (delivery - June 2021, Krasnoyarsk), as well as options for small landscape forms: zoning of the territory (delivery and installation - April 2021, Serpukhov district of the Moscow region) and small landscape forms (delivery - May 2020, Ryazhsky district of the Ryazan region).

Design features of gabions

A gabion is a kind of box for filling material. Metal wire is usually used to produce such containers. The following can be used as filling material:

- tree;

- stone;

- pebbles;

- crushed stone;

- cobblestones.

Such products are very diverse, both in size and shape, and in style.

Gabions are usually quite large and are made of twisted wire and mesh. To eliminate the risk of deformation of the walls under the weight of the filler, sectional compartments are additionally installed in the structure.

Scope of use of gabions

In the modern world, gabions usually perform a decorative function, being part of landscape design. Interestingly, they were previously used during military operations as a fortification structure.

Gabion allows you to solve two problems at once - strengthening and decorating the walls of the house. As a rule, today gabions are created as:

- bases for furniture sets on the site (in the manufacture of outdoor chairs, benches, armchairs, tables);

- wall supports to strengthen structures;

- bases for partitions, arched and other vertical structures;

- decorative elements in various areas of the site;

- fences for plantings;

- building materials for arranging lawns and stone gardens;

- strengthening structures that fix the soil not far from the banks of reservoirs located near the site;

- building materials for the manufacture of stairs, through which, as a rule, they descend to the water.

Gabions in landscape design allow you to effectively zone the space of a site. They can also be used as fencing around the perimeter of the territory.

The use of gabion structures in garden design

There is a use for each type of container. Most often, gabions in landscape design (photo in Fig. 2) serve as borders and walls. The combination of stone and green plants always looks organic. Any artificial landscape that imitates a mountain slope or rock mass cannot do without the use of stone blocks. But many rocks have cracks into which moisture penetrates and freezes in the winter season. This leads to the rapid destruction of the decorative elements of the rock garden.

Pieces of stone in gabions, even when split, remain in place. They are held in place by a mesh, maintaining the shape of the border for many years. Plant roots penetrating between the stones only strengthen the entire structure.

Unlike the construction of stone walls, which require a lot of time and effort, any structure made from gabions is assembled very simply: a lightweight container is placed in the right place, secured and filled with filler. Rectangular shapes allow you to make the corner of the wall clear or rounded, depending on the needs of the designer.

It is convenient to make bases for garden furniture from box-shaped containers (Fig. 3).

Any other method would require formwork and concrete pouring, masonry work or processing of wooden parts. Assembling furniture from gabion structures is reminiscent of playing with children's blocks: a wire basket is set in place, filled with stone and decorated at the same time. After this, all that remains is to lay the tabletops or seats.

We also recommend reading

- How can a dry stream transform your dacha?

- Landscape design of a small summer cottage

Flat structures (Reno mattresses) are more often used for the construction of fences or light walls dividing the area into zones. The presence of clear corners makes the designs very neat. Stone inserts can be harmoniously combined with wooden elements (Fig. 4).

The flexibility of the wire structure allows the use of flat gabions as fencing for small flowerbeds of original shape, wells or decorative ponds, and other buildings. By combining them with cylindrical and box-shaped containers, it is possible to erect entire complexes of various buildings on a summer cottage (Fig. 5).

Containers of non-standard shape (Fig. 6) provide designers with a lot of opportunities to realize the most daring ideas. But their production is carried out individually in each case. Some construction companies make flowerpots in the form of balls or pyramids to order, but more complex and exclusive designs will have to be created with your own hands.

How to make a building from gabions?

If installation of ready-made forms is required, then you need to prepare:

- mesh, wire or special spirals;

- metal pins (rebar about 1 cm thick);

- braces or wire;

- geotextiles;

- filler of any kind;

- pliers.

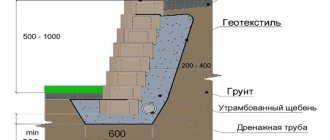

For heavy structures, walls or artificial mountains up to 7-8 m high, it is necessary to build a foundation.

Dig a pit 25-30 cm deep along the contour of the building. Fill the hole with ASG or sand, level the surface and compact it. Simple technology allows you to assemble containers directly at the installation site, fastening the cut mesh with wire or metal spirals. All protruding ends must be bent inside the container to avoid further injury from them.

To ensure the immobility of the baskets during the construction and operation of the building, a number of pins from the reinforcing bar should be driven into the soil. Place the baskets so that the rod fits into the cell on the bottom side and is inside the container. Fill the mesh base with the selected material.

The construction of gabions from box-shaped containers can be multi-tiered. To do this, you need to make several rows of masonry from these elements. After installing the first row of boxes, gabion stone is poured flush with their edges. After this, a mesh cover is applied, securing it around the entire perimeter with wire or a spiral. Place the next row, shifting the containers so that the bottom of the upper tier is above the junction of two adjacent boxes in the lower level.

The container should be attached to the lower elements along the perimeter of the bottom. Fix the gabion installed next to it in the same way, but additionally connect the sides of adjacent containers. Next, the assembled level is backfilled, the lids are fastened and the baskets of the next tier are installed.

When installing flat gabions with your own hands, it is recommended to attach the mesh base to supports made of wood or metal. Fill it to a height of 30-35 cm. Then several braces should be made inside, which will not allow the wall to deform under the pressure of bulk material (Fig. 7). It is advisable to install the braces in increments of 4-5 cells, then the wire mesh will maintain a flat surface for a long time. For fences and fences, covers are usually not placed on flat gabions, but they are filled so that the stones are approximately 2-5 cm above the edge of the mesh.

The same applies when installing cylindrical forms. To ensure stability of the structure in this case, a pin made of a rod or pipe should be installed along the axis of the cylinder. Its height should be slightly less than the height of the column. When filling the product with filler, the support will be hidden.

Ready-made containers of non-standard shapes are sold already assembled. If they had to be disassembled during transportation, then the assembly of the flower bed from gabions is carried out according to the principle described for box-shaped containers. The parts just need to be connected with spirals or wire. After filling, the container looks like a flowerpot with a recess in the middle. It is filled with soil where plants are planted.

How to make a green sculpture?

You can make non-standard containers with your own hands. To do this, you will need a rod or welding wire about 1 cm thick and a mesh with a fine mesh. You need to bend the contour base of the sculpture from wire using your sketch. After this, all that remains is to attach the mesh to the base and fill the structure with soil.

To make such a sculpture green, grass seeds are added to the soil before filling to create lawns. If the lawn mixture also includes flower seeds, then the sculpture will turn out to be blooming. After backfilling, you should water the sculpture daily with water from a hose with a sprayer, being careful not to leave dry areas. Then the grass will grow evenly and simultaneously over the entire surface.

The main condition for the successful construction of any gabion structures is the correct selection of the mesh. It must be strong enough to support the weight of the filler. Therefore, the larger the structure, the larger the wire cross-section. The mesh cell size should be approximately 2 times smaller than the filler fraction. This will allow the material not secured with binders to be securely held within the structure.

Proper execution of installation work will ensure the reliability and stability of the structure made from mesh containers for a long time. Self-assembled gabion structures can serve until the need arises to remove them and create a new landscape on the site.

Classification of gabions

Based on the design, it is customary to distinguish several types of gabions:

- box-shaped;

- flat;

- cylindrical.

Stacks for box-shaped gabions have hexagonal or rectangular cells. This is the largest version of such products. The width of a box-shaped gabion can be about 2 m, length - 6 m, and height - about 1 m. Due to the possibility of their manufacture in almost any size, the internal design, as a rule, involves the use of partitions.

Box gabions can be produced not only by the mesh method, but also by welding. Such products were called “Jumbo”. They are used to protect soil from erosion, construct retaining walls, control soil conditions and for decorative purposes.

Cylindrical gabions are usually called bag gabions. Can be used for the construction of underwater foundations. They feature a high level of flexibility.

Flat gabions have a small height - 17-30 cm. They are called “Reno mattress” and are laid on winding surfaces, since they are able to adapt to them.

Gabions - instructions

A separate basket, bench, low retaining wall or fence can be made without specialist advice. A basket filled with aggregate is heavy, so it is recommended to place it on a hardened base - on a compacted 20-50 cm layer of crushed stone or on a solid support. Thanks to this, it does not deform due to uneven deposition of the substrate. If the height of the basket is twice its width, we must place a stabilizing post in it, which will protect the structure from falling.

One pole is enough to support a gabion with a maximum length of 1.5 m. If the structure is longer, it must have more poles. The column is built into the foundation of the foundation, built to the depth of ground frost. There are also posts with a special base for attaching to baseboards.

Step-by-step instructions on how to make gabions

Such products are available for sale in ready-made form. But, if desired, if you have free time, materials and tools, such structures can be built independently.

Photos of gabions on the site and drawings will help you with this. Based on them, you can design and manufacture your own gabions. The first stage of construction is the creation of a project, which involves the following actions:

- Measurements on site.

- Marking the area for the structure.

- Preparation of a paper plan for the location of products.

- Create a drawing for each gabion.

- Selection of materials.

Total information

First of all, it is worth understanding what gabions are and how they are created. This is the name of a semblance of containers made of metal wire. Depending on the desired effect, they are filled with large or smaller stones. Previously, they were used as defensive structures on battlefields. Nowadays they are often used to strengthen coastlines or serve as retaining structures. But most often, gabions are used precisely as objects that decorate the landscape of a suburban area. Especially among others, those products that have a laconic form stand out, as they stand out against the general background and favorably emphasize the style of the local area.

Gabions can be made in various shapes. Recently, spherical models have become the most popular in the areas. As a rule, gabions are not made independently, but are bought ready-made, but if you wish and have everything you need, you can try to make them yourself.

Material for frame assembly

Steel mesh is the best option for the construction of gabions. It allows you to construct structures with complex configurations. Such gabions can have bends, which allows them to be made into arcs and turns. An ideal solution for decorating flower beds or fountains.

It is advisable to choose a mesh with a special coating or apply it yourself to protect against corrosion and other external factors.

For example, the service life of galvanized mesh is about 100 years. Choose a fairly strong mesh; its thickness should not be less than 2.7 mm.

FAQ

- Is it possible to fill a gabion with any stone?

Answer: The grade of stone is determined by construction requirements and standards. Strength is not lower than 800 M, the size of the stone is larger than the size of the cells, the stone must be frost-resistant. If the structures serve as a decorative element and do not have large loads, then there are more options.

- Is it possible to simply place a gabion on the ground?

Answer: No. Like any structure, a gabion needs a foundation. This is either a compacted pillow of sand and crushed stone, or a Reno mattress.

- What height should you choose for your terrain?

Answer: The gabion is buried 8-10 cm into the ground. This must be taken into account. In general, it is better to call a surveyor who will “shoot” the terrain and we will select the required dimensions for you. Heights may be variable.

- Can I just put up a wall that is 40cm wide and 2m high? Will this protect my slope?

Answer: The principle of installation of gabions is pyramidal. Conventionally, the height of the shoulder should be equal to the height of the wall. If the height of the wall is 2 m, then the lower gabion should be 2 m wide and 1 m high. And on top of it there will be a 1*1 m gabion. Or you need to provide piles, mortgages or other supports. A narrow wall will not stand on its own.

- What is cheaper - concrete or gabion?

Answer: Prices are comparable. If you compare high-quality concrete, the correct layout of the reinforcement, its thickness, etc. If you are satisfied with any concrete, thin reinforcement, then the concrete will be cheaper. At the same time, the risks that concrete will crack in the spring increase.

Filling options

The filler can be almost any material, which opens up wide possibilities for the implementation of design ideas. Therefore, you should proceed from your tastes, financial capabilities and location of the structure (underwater or on land).

Usually natural or artificial stones of various shapes, types and sizes are used. But, as a rule, fairly large stones are used. The color also depends on your tastes.

Non-traditional materials can also be used as filler, for example:

- broken tiles;

- pieces of PPR pipes;

- tin and aluminum cans;

- glass bottles;

- tree bark;

- brick, including broken brick;

- tree;

- pieces of tires from vehicles;

- big shots, etc.