Decorative concrete: characteristics, advantages and disadvantages

Decorative concretes are monolithic materials compacted with special stamps. During the production process, it is subjected to special chemical treatments, which allows for installation in a special way. This technology is very popular in most developed countries, including Japan, America, Germany and England.

The main, most important advantages:

- decorative concrete is many times superior to paving or road facing tiles in terms of resistance to loads;

- the presence of the richest and widest range of colors and shades;

- increased resistance to compounds such as petroleum products, organic solvents, acids and alkalis;

- ability to easily withstand compressive and bending loads;

- possibility of operation in severe frosts and heat;

- resistance to negative ultraviolet effects.

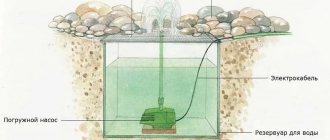

As a rule, decorative concrete is used in suburban construction. The material is widely used as finishing the facades of cottages and other country properties, and is also popular in the design of garden paths and paths, in the arrangement of fountains, waterfalls and areas around a pool or artificial reservoir. Decorative concrete can be represented by panels, borders, gutters and elements of small architectural forms.

Operation must be accompanied by annual treatments of the coating surface with special water repellents capable of maintaining optimal moisture resistance parameters and full integrity.

Undoubtedly, finishing the garden area with decorative cement mixtures becomes every year the most economical option compared to the use of expensive natural stone or noble wood.

Advantages and disadvantages of formulations

In addition to the advantages of the previously listed types of decorative concrete, there are several more noticeable advantages of this coating.

Decorative concrete for walls has the following positive characteristics:

- working with the material is quite easy, especially if you have instructions and advice from designers at hand - an ideal option for those who decide to do the repairs themselves;

- despite the minimalism and ease of application of such plaster, the end result looks aesthetically pleasing and original;

- Concrete-like plaster can be used to finish concrete, wood, and plasterboard walls;

- such walls go well with any other material in the interior - glass, metal, wood, textiles, leather;

- large scope for creativity - a variety of colors, textures, reliefs and compatibility allows you to create the perfect interior;

- a wall with decorative plaster can be painted and varnished;

- in a room whose walls are finished with concrete plaster, it becomes much warmer and quieter due to the characteristics of the material;

- Decorative concrete can be used to decorate any room from the inside, and any part of the building from the outside.

Take note: painting the walls to look like concrete will allow you to complement the interior design with bright colors, original drawings, motivating inscriptions, etc.

The disadvantages of this material include:

- high cost;

- the need to use protective equipment when working with it.

Naturally, a significant disadvantage may be the fact that you simply do not like the look of partitions with decorative concrete as a finishing touch. That is why we recommend that you familiarize yourself in advance with photographs of interiors where this material is used.

Types of decorative concrete

There are several types of such material:

- stamped solutions;

- stencil mixtures;

- sprayed mixtures.

The first option involves applying a colored fixative, hydrophobic additives and a mixture that prevents sticking to a wet surface. The surface is carefully smoothed, and then a “template” is used in the form of textured rubber matrices. After hardening, the matrix is removed, the surfaces are washed to remove any remaining composition and components used. At the last stage, protective impregnation is applied.

The stencil method is characterized by the application of paper templates that imitate finishing materials. In order to imitate stone or brick, the “spraying” technology is used using acid dyes, applied to the mixture in several thin layers, which allows you to obtain an attractive color shade with various effects. The use of sprays, masking tapes or stencils is allowed.

The difference between art concrete and conventional material

Architectural concrete began to be sold on the market as a building material in the 60s of the last century. Its important difference from the standard solution is that it is used not only in gray, but also in colored form, and in the widest range of colors.

Other distinctive characteristics of art concrete are:

- fine-grained texture of the mixture, thanks to which the finished coating is sanded to perfect evenness and smoothness;

- low absorbency, which makes it possible to use outdoors and maintain integrity even under the influence of precipitation;

- no cracking due to regular temperature changes;

- extensive application possibilities and high aesthetics;

- the ability to add unusual ingredients to the composition (for example, shells).

What is the difference between decorative concrete and classic concrete?

From the point of view of manufacturing technology, decorative concrete belongs to the category of composite materials, the composition of which is represented by:

- fine aggregate;

- coarse aggregate;

- water;

- cement;

- dyes;

- additives.

It is the composition that distinguishes decorative concrete from the classical material. Pigments for cements can be presented:

- titanium dioxide to obtain white color;

- manganese oxide to obtain a lilac color;

- chromium oxide to produce a green color;

- ocher to obtain yellow color;

- iron oxide to produce red color;

- iron oxide and kaolin to obtain a pink color;

- manganese peroxide to obtain a black color.

This colored material holds almost any shape, so its scope of application is almost limitless:

- colored decorative concretes are used in the production of high-quality and beautiful paving slabs;

- artistic concretes are widely used in the decoration of buildings, as well as in the manufacture of various sculptures and figures;

- Concrete imitating stone is used in the arrangement of the basement, in the design of facades and blind areas.

It is the purpose that determines the composition, appearance and other main characteristics of the finishing material.

Artistic concrete

Artistic concrete is very popular due to its simultaneous architectural and aesthetic functions.

The composition of a color mixture with a decorative function can pursue several goals at the same time: constructively - geometric, artistic-sculptural, and stamped-artistic. The plasticity of the mass allows you to imitate various natural surfaces (use of stamps and seals).

Pressed concrete is produced according to the press principle , which can also be modified by adding plasticizers and mineral additives.

After hardening, any decorative cement needs a protective fixing layer that will protect the product in the future from abrasion, mechanical damage, ultraviolet rays, natural precipitation, etc.

By changing the composition of the decorative concrete mixture or technology, you get:

- stamped;

- color;

- artistic relief (garden figures, architectural elements for decoration, etc.).

Manufacturers of building materials have gone further and created new products that can be safely used for decorative purposes. Such a product is composite slabs , which successfully imitate decorative concrete in appearance. A distinctive feature of such materials is their low weight, a wide selection of colors and textures, but a lower degree of strength and short service life.

0

( 18 ratings, average: 4.28 out of 5)

Back

Furniture made from pallets or pallets: features

MORE

Options for using landscape decor in garden decor

Decorative concrete, in the broad sense of the term, is a material intended for laying and undergoing a three-stage chemical treatment followed by finishing.

Landscape material is most often represented by printed concrete, dozens of different colors and shades of which allow you to combine external aesthetics with excellent performance. It is used in gardening landscapes, when decorating sidewalks and shopping areas, as the main materials for decorating the interiors of restaurants and cafes:

- creation of garden sculptures, benches, small architectural forms;

- creation of small landscape compositions;

- creation of gazebos;

- creating gates and fences;

- creation of barbecues and fireplaces;

- creation of recreation areas and playgrounds.

Fences and barriers made of such concrete are much more cost effective and can be erected faster, and in terms of their basic characteristics they are not inferior to products made of stone or traditional brick. Concrete decorative columns look impressive on large areas with a lawn.

Flowerpots and flower stands made from colored concrete mixtures are used not only for their intended purpose, but also as a very attractive, decorative landscape element. These forms can successfully complement an alley, park or recreation area. A garden bench and fountain are in great demand among country property owners . In addition to durability, this design will be a wonderful modern decoration element.

Production and Application

To obtain the desired, decorative effect, stamping is used by pressing stamps into a still damp surface. Stamps are made of rubber, polyurethane or silicone. Fine lines, giving expressiveness and clarity to the design, are created by saws with diamond blades. Thanks to this technology, you can achieve any pattern: paving stones, savage stone, marble.

Imprinting a design into concrete using a polyurethane stamp

Stamping technology can be used on both horizontal and vertical surfaces. In the manufacture of massive structures, reinforcement is used; the resulting voids in the concrete mixture provide stability and are less sensitive to strong temperature fluctuations.

READ ALSO: Brass pipe plugs

Decorative concrete can be used not only to create a floor or sidewalk path, but also to create decorative elements, for example: waterfalls, streams, figurines, decorative columns, benches, railings, flowerpots and even fences. The range of applications for this type of concrete is huge.

How to install the coating yourself

The step-by-step creation of a coating is not too complicated, but requires strict adherence to a certain technology.

Materials and tools must be provided:

- roller;

- flat brush;

- protective impregnation;

- a brush with stiff bristles;

- texture matrix;

- disconnector;

- colored fixative;

- rollerball;

- concrete mixture;

- corner and aluminum trowels;

- vibration rack;

- crushed stone;

- plastic film

- reinforcing fiber.

Preparatory activities:

- check the quality of cement, the grade of which should not be less than M300;

- at positive temperatures add a plasticizer;

- marking with wooden pegs with stretched twine;

- remove the top layer of soil to a depth of 15-20 cm;

- install formwork along the entire length of the structure;

- fill in a crushed stone-sand cushion 10-15 cm high;

- compact the crushed stone-sand cushion;

- lay polyethylene film with an overlap of 10 cm at the joints;

- reinforcement with metal mesh or reinforcing fabric.

Self-installation technology at positive temperatures in dry weather:

- production of concrete mortar based on one part of PC M400, three parts of granite crushed stone of fraction 5/20, three parts of sifted sand, 0.5% aqueous solution of C3 plasticizer with the addition of polypropylene fiber at the rate of 600 g per cubic meter of mixture;

- uniform pouring of the resulting solution into the formwork and compaction using a vibrating lath;

- rolling the roller over a concrete surface and then smoothing the surface with an aluminum trowel;

- processing the perimeter using a corner trowel;

- applying colored sealers by hand scattering and smoothing using an aluminum and then a steel trowel, followed by coating with a thin layer of disconnector;

- applying texture with matrices over the entire area.

After the surface has dried well, remove any remaining compounds from the surface with a brush. At the final stage, treatment is carried out with acrylic impregnation applied to the roller.

Characteristics and composition of the material

Any art concrete has high strength. On average, it is 39 MPa 3 days after setting and 59 MPa after 28 days. The whiteness of the finished composition varies between 68-85%, the minimum frost resistance is 100 cycles of freezing and thawing. Art concrete sets quickly and gains strength after 15 hours.

The basic composition of the material is not fundamentally different from classical solutions. Art concrete includes a binder component - Portland cement of white, light gray color M400 or M500 strictly without foreign inclusions and lumps. M600 and M700 cements are used much less frequently for the production of mixtures. The composition also includes quartz sand, which can be partially (up to 5-10%) replaced with granite, marble chips or glass powder.

In addition, art concrete may include other ingredients:

- fine-grained crushed stone, pebbles, shells of a certain shade (to add decorativeness);

- plasticizers, curing regulators, additives to enhance frost resistance, water repellents;

- fiberglass or other reinforcing fibers.

Pigments can be added to the mixture so that it immediately acquires the desired color. Also, purified water in a certain amount is used to prepare the material. In addition to the main binder (cement), art concrete may also include other components with similar properties:

- Acrylic (acrylic resin). The finished material dries quickly, has high elasticity, is easier to tint, and is suitable for rooms with unstable humidity and temperature. The service life of art concrete increases to 10-15 years.

- Minerals - clay, lime, gypsum. They make the composition more decorative, increase abrasion resistance, and provide fire safety.

- Silicates. Provide the highest resistance to damage and chemicals, and repel water. They are used if art concrete is intended for outdoor use.

- Silicone. Gives plasticity, strength, resistance to moisture and ultraviolet radiation.

Decorative plaster for concrete - do it yourself

You can create art concrete for various works with your own hands. To do this, you need to take 1 part white Portland cement, 3 parts fine quartz sand and about 2 parts water. To obtain the desired shade, 2-5% of dry pigment is introduced. Plasticizers and modifiers are also added (usually at home this is PVA, which is poured in when diluting the solution).

The dry ingredients are sifted through a fine-mesh sieve, then combined and mixed until smooth. Make a depression in the center of the mass, add water and stir until a homogeneous solution is obtained.

Pros and cons of art concrete

The material has many positive characteristics. Its advantages include the following:

- strength, good load tolerance;

- abrasion resistance, suitable for pouring floors;

- resistance to temperature changes, water, chemicals;

- long service life;

- environmental friendliness, breathability and fire safety;

- versatility, ability to be used for interior and exterior decoration, pouring, sculpting;

- high decorativeness, use of different shades, textures, suitability for many interior styles;

- rapid hardening, early start of operation;

- easy to care for, no damage from washing with SMS;

- UV tolerance;

- leveling differences and defects in foundations;

- additional noise and heat insulation of premises;

- affordability.

The disadvantages include the presence of chemical components in some types of art concrete, due to which its environmental friendliness is reduced. When planning complex finishing, there is a risk of not being able to complete the job if you do not have sufficient experience. In some cases, you will have to abandon decorating walls with art concrete, because it creates quite a large additional load.