Buying a good-quality garage structure in our time is not a cheap pleasure. It is cheaper to make a garage door yourself, but certain knowledge and skills are required. It is also advisable to have welding skills. Therefore, how to make a garage door with your own hands is a question that needs to be thoroughly understood. But then it will be possible to begin to complete the task.

On a plot in the village

Types of garage doors

First you need to determine which model will be used for the garage. Nowadays there are many types of them, and it is not easy for the owner to make a choice.

Sectional doors

They are a set of panels (sliding sections) connected to each other by hinges. They are attached and moved upward along special guides. When opened, they rise one after another and go into a niche under the ceiling. Sectional garage doors are very convenient.

Sectional folding gates are used in private homes, farms, and parking lots.

Near a private house

Most users choose them for their compact size.

Advantages: convenience, burglary protection, universal use. Disadvantages: high cost, folding structures are subject to damage.

Swing gates

The swing model is a classic garage structure consisting of two doors suspended on hinges from support posts. The most common model. There are 2 types: simple and automatic gates. The main advantages are simplicity of design and reliability.

Disadvantage: difficulties associated with opening in winter: snow removal is required. Systematic lubrication of the hinges is also required. It is not difficult for the owner to make just such a garage door with his own hands.

The photo shows a swing version of the design.

On a suburban area

Sliding gates

New modern model. They look aesthetically pleasing and are easy to use. Operating principle: guides are attached at the bottom and top of the opening, along which 2 sashes move in and out. There are 2 types of opening: automatic and manual. Advantages: compact, do not take up much space, long service life, reliability.

Disadvantage: systematic maintenance of the roller system is required: it is necessary to prevent the ingress of snow, water, and foreign objects.

Rollback option

Up and over gates

These are the most practical and convenient vertical structures. When opened, the sheet of metal rises up and lies horizontally in the form of a visor. The design of such a mechanism is simple. The canvas is attached to the frame and moves around an axis, changing its horizontal position to a vertical one. Folding gates are easy to use.

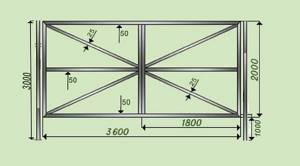

Lifting structure drawing

Advantages: resistance to corrosion and burglary, do not require additional space.

The process of making swing garage doors with your own hands

Support frame

When planning a garage at the initial stage of construction, you can set certain dimensions for the garage door and its opening and manufacture the gate at the same time. Also, there are cases when there is already a gate, but there is no opening. In this case, the structure must be completed completely, and the gate must be fixed in the right place, then the process of erecting the walls of the garage begins. As for the width of the gate, it can be different, depending on your requirements.

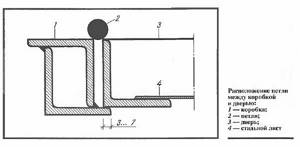

Important! The garage door frame is made of iron angles and has external and internal parts. The corners are connected by welding in such a way that they fit freely into the opening and can fit tightly into the opening and cover it. After installing the outer and inner parts of the frame, they must be connected with a metal plate.

Work on the construction of the frame must be done on a horizontal surface, so you will get a flat structure. To get started, you need to take a square, a tape measure, a metal welding machine and a grinder with a metal disc. The corner needs to be cut into 8 pieces, 4 of which should correspond to the width of the garage opening, and the rest to the height. Place the corners on a flat surface and weld them together.

As a result, you will have a rectangular frame. To give strength, make joints at a certain angle. To ensure straight corners, use a square. The frame needs to be measured diagonally, this way you will be sure that everything will turn out even. The hollow metal garage door frame design has two parts that you need to weld. Don't touch the inside yet, work on the outside.

To do this, lay it out on a flat surface, making sure the corners are even. The seams formed after welding must be cleaned. To do this, you will need a hammer to knock down the slag, and the joints must be carefully sealed to ensure the strength of the structure. Seams must be processed on both sides of the frame.

Note.

Experts advise assembling the garage door frame using the tack method. This will allow you to easily level the structure if unevenness is suddenly discovered. Only after you are sure that everything is fine can you completely seal the seams.

Frame for garage door leaves

After the frame is made, you can start working with the sashes. For excellent functioning of the structure, it is necessary to create sashes 0.8 - 1 cm smaller than the internal size of the external supporting frame. This will allow you to open and close the gate without any problems.

To work, you will need a metal profile, which also needs to be cut into 8 parts if we are talking about double-leaf garage doors. Make 4 vertical parts 1 – 1.5 cm smaller than the frame. The pieces are placed inside the frame, which you have already placed on a horizontal surface. Two profiles must be installed along the edge on both sides, and 2 in the center. The distance between the central parts is 1 - 1.5 cm.

Then comes a series of horizontal elements that need to be laid so that the edges meet the vertical parts. Following the perimeter, you should get a space between the elements of the frame and sashes, into which you will subsequently need to install a metal corner.

During the manufacturing process of garage doors, care must be taken to strengthen the doors. This must be done to ensure that the structure is as strong as possible. To do this, you need to install a crossbar made of metal profile pipe, which can be mounted in any position, vertically or horizontally.

When the preparatory work is completed, you can begin welding work. Here it is also important to work using the tack method, this will avoid deformation. See if the doors are even, and only then connect the elements completely.

Note. Do not forget about grinding the seams after welding the metal.

After the folds are done, you can exhale, the most difficult part of the work is done. Now you can move on to lining the garage door.

Covering garage door leaves and attaching hinges

For cladding work, a steel sheet with a thickness of 2–4 mm or corrugated sheets will do. The first material is most suitable for garage doors, since steel is particularly durable.

Take a steel sheet and cut two pieces of the same size from it. It is important not to miss the fact that the sheets should be 3 - 4 cm larger than the gate leaves. This way you can bridge the gap that forms between the sash and the frame.

Calculate the width in such a way that you can cover the gaps where the hinges are installed. In the center, the sheet should be placed on the adjacent sash within 1 cm, thus, it will be possible to block the place where the lock is attached.

Fasten steel sheets using the tack method around the perimeter. After checking the evenness of the metal garage door structure, you can fasten the elements completely. The welding of the sheets is carried out entirely from the inside, and the sheets are attached to the metal profile. There is no need to create a continuous seam; dotted welding 1x5 is sufficient (1 cm of seam every 5 cm).

At the final stage of installing the garage door, you need to attach 4 hinges to the door leaf. The lower part is welded to the frame, and the upper part to the sashes. To ensure reliable fastening, the hinges are reinforced with a metal plate. To increase the welding area, take a metal rod.

Once the work is done, you can move on to the exterior of the garage door. Sand all uneven surfaces and treat with anti-rust agents. You can also paint the doors any color you like.

Next, you can install the gate in place. If you already have a garage box built, then the structure must be inserted into the opening, pressing tightly. To secure it in the desired position, use bars that will serve occasionally. The inner frame can also already be installed and secured with the outer part, using metal plates that are placed at the level of the hinges. If there is no opening yet, then the frame with the gate structure should be installed in the intended location of the opening.

Choice

The variety of garage designs makes it difficult to choose. The owner of the car is primarily concerned with the safety of his vehicle. Only then does he take into account other characteristics, such as ease of use, price, and design dimensions.

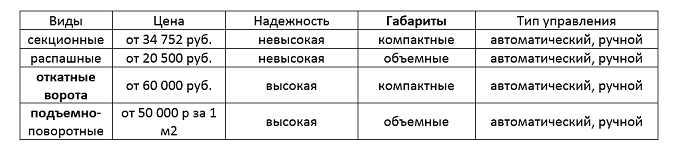

Comparison table of the main characteristics of garage doors.

Comparison of characteristics

Based on the indicators in the table, we can say that the choice is only up to the buyer. It all depends on cost and reliability. For example, swing and sectional models are good to install in a home garage, but they are not suitable for garage cooperatives, as they have a low degree of reliability.

Up-and-over garage doors are suitable for any building, but their main drawback is their high cost. Due to their low price, swing gates are suitable for a private garage. If necessary, they can be insulated, automated and reinforced with an additional sheet of metal. In addition, it is easy to weld garage doors at home.

During installation

How to insulate gates

Insulated garage doors keep heat inside the room, preventing cold air from penetrating inside. This helps create a comfortable microclimate and reduce energy consumption and heating costs.

Garage structures can be insulated in different ways. If previously foam plastic was used for this, now builders give preference to EPP - extruded polystyrene foam sheets. They are distributed inside the frame, sewn up with plywood or wooden paneling. As for cotton wool materials, it is not recommended to use them, because they quickly lose their original properties.

DIY installation

Swinging garage doors are the most common type of building structure. They are easy to install and easy to maintain. If necessary, they can be upgraded. It will also be easy for an experienced craftsman to make a wooden garage door with his own hands. Sliding or up-and-over gates are much more difficult to manufacture and install. However, to install these gates with your own hands, drawings, photos and videos with diagrams on our website will help.

Frame

To make the frame, the exact length and width of the garage opening is required. First, determine the size of the future gate. They also make drawings of the future design. To make the basis of a garage structure, you need a welding machine.

Frame structure diagram

The frame is made of a metal corner, which is welded around the entire perimeter of the doorway. This is how the slope is finished inside and outside. The inner and outer corners are welded together with metal strips in several places. You should get a frame frame.

Installation of canvases

Then sheets are cut from a metal sheet to a height exceeding the opening by thirty to forty millimeters. One canvas is made a couple of centimeters narrower than the frame, the other is wider by the same distance.

If a doorway is to be constructed, a hinged gate is inserted into one of the leaves (the first one that swings open).

The sheets are welded to the frame so that at the top and bottom of the sheet they protrude up to two centimeters beyond the frame. In length, one of them does not reach the side of the frame a little, the second protrudes up to four centimeters so that the sashes fit snugly against each other.

First, it is necessary to install the sheets, perform tack welding on all sides, then the final welding is performed. To prevent the structure from moving, welding is performed alternately from opposite sides.

Painting and fittings

Upon completion of work, the product must be treated with any degreaser - solvent or white spirit, and prepared for painting. All damage is covered with automotive putty. Allow the product to dry.

Then the place where the product is filled must be sanded to level the overall surface. Next, use an anti-corrosion primer for metal. After it dries, the structure is painted with special hammer paint. It is weather-resistant and will protect the metal from the effects of precipitation.

Hinges before installation

This paint is also resistant to mechanical damage. It is advisable to apply the product several times. After each layer has dried, it must be treated with the finest sandpaper. This will make the paint last longer and give it a glossy finish.

The deadbolt acts as additional garage security when using automated and mechanical locks. It is good to install iron sliding bolts, which increase the degree of security. It is almost impossible to open such protection from the outside.

Sectional drawing

What to pay attention to

When choosing or manufacturing swing garage structures, you should pay attention to the following nuances:

- Determine which direction the doors will open and make room for them. Take into account the presence and proximity of other buildings. The doors must open freely. The most common method is to open outwards.

- It is better to choose steel with a thickness of 5 mm, in which case the property will be under the reliable protection of durable metal.

- You should not make the structure from aluminum: it will require repairs in a few years.

- To increase the wear resistance of the product, it is necessary to paint it with good machine paint.

- You can make a structure from corrugated sheets with your own hands. Such sashes are easy to install and will last a long time even with a small sheet thickness. Products made from corrugated sheets have a good appearance and are suitable for any structure.

- Initially, one of the doors must be equipped with a gate. It can also be mounted separately. This option is more practical. This position is convenient if you have heavy, massive gates that are inconvenient to open.

- You should not choose wooden products: they will not become a reliable structure. But they can be a good budget option for a while.

- Self-made metal gates can later be equipped with automation. Currently, several drive options can be found on the market.

Sectional loop

Arranging a garage structure is a responsible undertaking. It is necessary to take into account wear resistance, reliability, ease of installation, and the availability of free space for the structure. You can create durable and reliable products with your own hands using only high-quality materials. Based on the photo, you can choose the design of the model being manufactured.

How to make a mounting frame, frame and sheathing

The supporting frame is made using a steel angle. Its “composition” includes two elements – an external and an internal frame.

First of all, determine what width and height the opening has (the measurements must be accurate). Afterwards, the corner, which has a square cross-section, the sides of which are 160 - 200 millimeters, is measured, and then the required blanks for the outer frame are cut. These blanks must be placed on a surface (flat!), setting the horizontal position using a level (it is adjusted using pads), and also leveling the corners. Next, measure the diagonals and adjust the right angles. As a result, you will have blanks laid out on a flat surface in the shape of the future frame.

Next, the frame is welded. The gate must fit very tightly to the frame, therefore it is necessary that the outer side of the frame be smooth and even, which can be achieved by grinding the seams remaining after welding with a grinder. Next, vertical levers are welded into the corners (the role of the levers can be played by cutting corners). This is done so that the frame does not deform over time, so that the corner does not move.

The frame is made for 2 swinging doors. Later you will need to attach a metal sheet to them. When making a frame, you can use a profile measuring 60 by 20 millimeters.

So, lay the garage pipe frame so that its face is facing up. The surface on which it is placed must be flat. Then insert the guides into this frame, aligning the placement of all sides. In order for each sash to move freely, a twenty-millimeter gap is made between the frame and the frame using liners (more is possible, less is not allowed). Next, the right angles of the frame are checked, and after that the profiles are welded.

As for the cladding, this stage of work is extremely responsible and important. The functionality, as well as the design of the future gate, is determined precisely by how well the cladding was made. It requires knowledge about the “correct” way of welding garage doors.

— First of all, cut the galvanized iron sheet, based on the size of the sashes. Do not forget that the sash, which is on the left, will “cover” the right one by one to two centimeters.

— To secure the canvas to the frame, it is welded at the bottom (not in one place, but in several).

— Cut off the sash trim, which is located on the right. Its width will be one or two centimeters smaller than the left one (in other words, the canvas will not reach the edge of the profile by one to two centimeters).

— Next comes the turn of welding. Weld the canvas at the corners of the box, as well as in the middle - this way it will not move. When the work is completed, these points need to be cut off, otherwise it is possible that one corner of the sheet will bend outward. This defect can be corrected using a sledgehammer.