Do-it-yourself straw, hay, grass chopper

In this article we will look at how to make a chopper for straw, hay and grass with your own hands, the so-called straw cutter.

Consumables, spare parts, belts, waste knives, they can be found in any garage. By making this device yourself, you will save money and be assured that you have a reliable device that will always get the job done. It is difficult for a summer resident to do without such a chopper. In a simple way, he will chop up grass, tops, straw, hay, which can be collected on the site, and then put it in a compost pit. Thus, the compost quickly rots and turns into fertilizers that will be useful for the beds. It will grow a good harvest of vegetables and will please the gardener.

It will be necessary to prepare a plastic barrel in which the chopped straw or grass will be collected.

Popular models for combines

We recommend reading our other articles

- How to get rid of moles

- Autoclave Bulat

- Zucchini Iskander F1

- Cochin chicken breed

There are many different types of hay choppers on the market today. Each type has its own characteristics and operating features, so you need to familiarize yourself with them before purchasing.

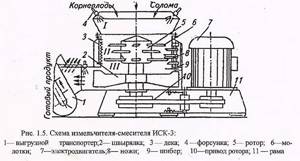

- "Niva" - This is a chopper that is installed on a combine that collects straw and hay. With its help, the straw that comes out of the combine's threshing apparatus does not enter the field, but into this mechanism, is crushed to the required size and only then poured onto the ground. The main variety of this design is “Pier 2”. This is a prefabricated model that is hung on the back of the combine. The hopper of the chopper is a closed type, and the knife rotor is installed in it. The mechanism is easy to maintain.

Photo of a mounted straw chopper (ISN) for Don and Vector

- “Don-1500” is a line of well-known straw choppers for combines, among which the “Piers-6” model especially stands out. The unit is easy to use, can be easily mounted on a combine, and evenly scatters hay after chopping, following the progress of the combine. It operates in two modes - chopping and spreading straw or collecting crushed scrap into a dense windrow.

- "Yenisei IRS-1200" chops and scatters straw across the field while it is being harvested by a combine. The body is made of steel, the knife mechanism is double-row, anti-cut. It chops not only straw and hay, but also various types of grass. To spread hay evenly across the field, an ejection wing is used, which can be adjusted to adjust the angle and width of the spread. This device is capable of chopping and scattering raw materials or laying unchopped straw in a dense windrow.

Step-by-step production of a straw chopper with your own hands

The chopper is manufactured using the following materials:

• electric motor; • circular saw blade; • metal sheet 2–3 mm thick; • corner; • bolts, nuts, washers.

List of required tools:

• welding inverter; • Bulgarian; • drill; • set of wrenches.

As a result, we have such a practical straw cutter that will help you chop straw, grass for a compost pit, and perform the work necessary on the site.

How a straw and hay chopper works is shown in the video:

Tools and procedure for assembling a homemade chopper

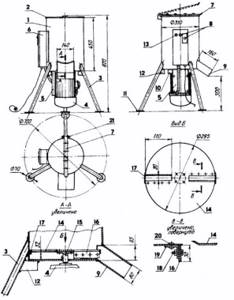

Before constructing a straw cutter, you must carefully read the design drawings. With the help of a correctly drawn up diagram, you can figure out the dimensions of the parts and the location of their installation.

All metal components of the device must be made of sheet steel with a diameter of no more than 3 mm. To make the bracket, thicker metal should be used. Other parts of straw cutters for private farmsteads should be used:

- The electric motor can be taken from any household appliance;

- 200-liter iron barrel, which will act as a loading hopper;

- Several metal sheets welded into one area, at least 3 mm thick;

- 3 metal pipes, 2.5 cm in diameter - they will serve as support for the structure;

- Food processor knives that will need sharpening;

- Shaft - taken from any unnecessary equipment. The main thing is that it is smooth and properly balanced. Otherwise, the structure will vibrate and shake violently.

As an unloading device, you can use a plastic pipe that will be attached to the side of the barrel for loading. In this case, one hole is made in both the barrel and the pipe. The pipe must be installed so that its hole coincides with the hole in the barrel.

To make a hay grinder into flour, you will need certain tools:

- Sander;

- Drill;

- Welding apparatus;

- Standard set for metalwork.

Having prepared everything you need, you can make a straw cutter without any problems. Unlike a simple manual design, it will require a minimum of effort from you, and will process raw materials much faster and more efficiently.

Pages

Questions can only be asked after registration. Please login or register.

Good afternoon, I’m also puzzled whether to buy a grass shredder for private household plots inexpensively or make it effectively. Here's one that's inexpensive to buy, and I liked this one. It’s convenient to load, well, 12000 rpm should turn everything into dust. Who can comment on this product? Thanks to all!

Tolya, are you planning on chopping grass or hay? If it’s grass, then I can take a photo of my grass cutter, it looks like it’s a factory one, I bought it at the market. It’s perfect for green grass, alfalfa, and corn stalks. Dry hay breaks down rather poorly. I have already figured out how to make a hay chopper, but I haven’t gotten around to it yet. If you have anything, write me a personal message.

Ilyich crusher diagram in the studio

Tolya, are you planning on chopping grass or hay?

I wanted everything to beat, but that doesn’t happen! You need to beat dry alfalfa, and preferably smaller ones. Yes, even 220 watts. I have ideas, but I don’t want to get into trouble. You can kill a large fraction with anything, but you need a state, if not flour, then as close as possible.

The years take their toll, the bastards take what belongs to others!

I'll post a picture of the grass cutter. Works great for grass. I haven’t made any drawings for the dry hay chopper yet, but a plan has matured in my head. In my case, I want to minimize turning work, because a turner charges 100 UAH/hour and works in no particular hurry. There is practically no alternative. So, I want to do it according to the IS-500 principle, i.e. a hopper, a disk with knives, a calibration grid in a circle to regulate the fraction, a drive from below. The main problem for me was the disk on which the knives are attached. The idea came to use a disk with a BDT or something similar. There, both the thickness of the metal and the grade of steel are quite decent. I haven't decided on the drive yet. Either from the PTO of the T-25 tractor, or a 220W/3kW electric motor. If there is an electric motor, then you need to find a smaller disk, because you can’t turn much at 3 kW, and there are no motors for sale larger than 3 kilowatts from 220 W. The factory IS-500, produced in Kharkov, is driven by a nine-kilowatt 380W motor. If I do it from the PTO, then the disk can be used to the maximum. The T-25 has 18 kW of power, I think it’s enough, but to increase the speed, use a used one. road bridge. The T-25 has a PTO speed of 540 rpm. The gear ratio of the VAZ, Moskvich gearbox is approximately 1*4. That is, on the working disk we have a little more than 2000 revolutions. On factory shredders the speed is 1800-2000. If you use an electric motor with the required speed, you can connect the working disk directly to the motor shaft. By the way, this is exactly how it was done at the factory. Well, if the engine speed is higher or lower, then through the pulleys. It would also be good to balance the disc with the blades, but you can try to do this at a tire shop. Here are my thoughts on the chopper.

Introduction about shredders

When I was in the tenth grade, and it was 2000, the school, together with the state farm, in the village of Miltyushi, Cherepanovsky district, Novosibirsk region, sent us in the spring to burn straw. We walked through huge fields and set fire to straw; students from grades 8 to 11 took part in this activity, which is more than 200 people. In addition, the state farm also burned straw on its own.

When the straw burning period was underway, all the surrounding villages were in smoke. At the same time, the state farm itself was barely making ends meet, wages were meager, and the equipment was outdated. It turns out that if they knew about crushing and granulating straw, the state farm’s income would increase significantly.

It turns out that abroad they have long ago resolved the issue of recycling agricultural waste, such as seed husks, sunflower stems, hay, grass, peat, reeds and even branches. This entire line has the required humidity and is simply granulated into pellets. Next, the pellets are used both as bedding for animals and to generate heat in special automatic boilers. Oh, and by the way, in China for a long time they have been making not only pellets, but even chipboards from all this waste, for example, I have an article about making wood boards from reeds.

The hay chopper can also be used for other agricultural waste. It processes bales, rolls and simply bulk material into a fine crushed fraction. At the beginning of the article you can see a picture with a fraction from weed waste. There are vertical and horizontal shredders.

Structure

You can either buy such a waste crusher or make it yourself. In order to do this, you need to understand its structure.

The chopper consists of:

- Containers for loading bales, rolls or bulk raw materials;

- Knives and counter knives;

- Unloading device;

- The shaft on which the knives are located;

- The electric motor is 380 Volt, the power for a 200 liter barrel is 1500 rpm and 2.2 - 5.5 kW. If crushing in rolls is planned, then a more powerful engine will be needed, 11 - 18 kW and also 1500 rpm;

- A mesh for pellets is suitable for us with a mesh size of 7-8 mm;

- A pulley system that transmits rotation from the electric motor to the blade shaft. Sometimes pulleys are not used and the motor is mounted at the bottom of the shredder.

Materials and manufacturing process

The manufacture of a house shredder begins with a drawing on paper. This allows you to have a visual representation of the design and identify shortcomings or refine important nuances at the design stage. Remaking the finished product will be more expensive, and unnecessary time will be spent.

Assembly materials:

- Electric motor.

- The container for the bunker is ready-made from some device or welded to specified dimensions from steel sheets.

- A lid for the hopper that will be securely installed on it.

- A steel plate at least a centimeter thick for a platform for an electric motor.

- Sheets of metal for the manufacture of supports and other elements with a thickness of at least 3 mm.

- Drive shaft.

- Side pipe as a dump.

We recommend: Wood chipper: DIY chipper

The electric motor is the main part of the device , which determines its characteristics. The motor is selected depending on the volume of the straw chopper hopper. The greater the mass of raw materials per load, the more powerful the engine required. Typically, an electric motor with a power of 2.2 to 6 kW is installed on a hay and straw chopper for private farmsteads. The speed of rotation should not exceed 2 thousand/min for safety reasons. Optimal - 1.5 thousand/min.

An electric motor with a rotation speed higher than optimal can also be adapted for installation in a structure, but it is not directly connected to the shaft. To do this, use a reduction gear , often a belt drive. You can use a gear drive. The reduction gear allows you to increase the output of the motor and chop root crops and even small branches.

The motor is connected to a shaft on which a disk with knives will be installed. A tube can act as a shaft, but only straight, without distortions. This is necessary for proper balance, otherwise vibration will occur, which is unacceptable.

The knives are installed on the shaft so that there is a minimum distance between them and the counter blades. This will ensure high-quality grinding of raw materials.

How to make your own chopper

Let's create step-by-step instructions for making our crusher; I don't think we'll need any drawings, since everything is quite simple:

- We are looking for a container that will hold our bales or rolls; if we are crushing small volumes, then a 200 liter barrel of regular oil will do. If you plan to crush straw in bales or even rolls, then you will have to make the body yourself.

- Next, the engine - pulley system, it is advisable to make the pulleys 1:1. We are making a platform for the engine, if you have metalworking skills and can use welding, then everything will be simple.

- Next, we make the body; it can be welded from existing old metal. We attach the engine to the body.

- We insert axle boxes with bearings and a shaft with a knife into the housing. Since the speed is quite high, the shaft with knives must be balanced and aligned. The shaft can be turned in any place where there is a lathe.

- We attach knives to the motor shaft, and make counter knives under them. The smaller the gap between the knife and the counter knife, the smaller the fraction will be.

- We make an unloading hole in the container to allow the material to exit. It must be installed in such a way that the material flies out of the grinding chamber by centrifugal motion. In order for the material to escape faster, you can make blades under the counter knife that will spin with the engine. These blades will force air into the discharge opening.

The chopper is ready! Next, we install a granulator and make pellets from our straw or hay.

Design features

Hay choppers come in different varieties. The standard design consists of the following elements :

- Electric drive. The speed of processing depends on the power of the part.

- A reservoir into which raw materials (straw or hay) are supplied. Its dimensions may vary.

- Shaft with cutting parts. These elements must be made of strong steel.

- Compartment for recycled material. For convenience, it is installed at a slight angle.

- Supports. Often made from thick pipes. The height depends on the size of the engine.

Various additional elements can be built into the shredder. But to perform basic tasks, the basic configuration is quite enough.

Straw chopper design

A homely owner who has a plot of land and, in addition, has various living creatures, knows perfectly well why such a machine is needed. We will only add one more area of application to the list: you can chop hay and straw to make fuel briquettes at home. If someone is planning such a thing, then you can’t do it without a straw cutter; try cutting or chopping this amount of straw by hand.

Home craftsmen have adapted to making various handicraft straw choppers from old pumps and vacuum cleaners. The principle of their operation is the same as that of knives mounted on a rod rotated by an electric drill. The hopper is an ordinary old bucket, into which grass or straw is placed, after which rotating knives are lowered into it and thus chopping occurs. Descriptions of such devices are easy to find on the Internet.

Only these mechanized cutting tools are too inefficient and impractical, and are only suitable for preparing food for a dozen rabbits. For the production of briquettes or other purposes when you need to process a lot of raw materials, you will need a reliable homemade straw chopper with sufficient power and performance. This is exactly what we will make.

The heart of any straw cutter is the working unit, which is a metal hopper with sharp knives rotating inside. The latter are rigidly fixed to a steel disk, which is mounted on the axis of the electric motor. The hopper is cylindrical in shape and, for safety reasons, is made high so that you cannot accidentally touch the knives with your hands when loading straw. At the bottom of the bunker there is a pipe for discharging chopped straw; for convenience it is made inclined.

Description of typical design

A typical design involves the elements from which the device is made. Their minimum set can be supplemented with auxiliary ones. The goal is to improve the comfort of working with the device.

Standard chopper set:

- The bunker is a container of sufficient volume. Usually they take an old barrel or a large can into which the processed vegetation is placed.

- The electric motor is installed at the bottom of the bunker. The main thing is that its power is sufficient to work non-stop and for heavy loads.

- An axis on which 3 to 6 knives are attached. It is attached directly to the axis of the electric motor.

The basis of the apparatus is a hopper with sharp knives, which are rigidly fixed to a steel disk. The disk is mounted on an axis, which is the shaft of the electric motor or is connected to it through a gearbox.

A bunker is a container for storing material - hay or straw, which requires chopping. The cutting process takes place in it. For safety reasons, the bunker is made as high as possible so that when loading raw materials your hands do not touch the knives. The shape of the container is usually cylindrical, but you can find the shape of an inverted cone. Place the container on a stand, usually in the form of a tripod. The height of the stand is such that an electric motor can be installed below. The latter is fixed to the bottom.

We recommend: The content of precious metals in microcircuits or how to mine gold

Sometimes the bunker is made small in height, but with a lid for safety reasons. The lid must have a hole for loading raw materials.

Production on a flow principle is created by installing a waste dump . Through the device, the crushed material is thrown out of the hopper. This allows raw materials to be added continuously. That is, there is no need to stop the engine to remove the chaff and add raw materials. This results in significant time savings. It will be made from the bottom of the bunker. The shape is not important, the main thing is that there is a slope for dumping the material.

A disk with knives placed on it is an extremely difficult part to manufacture. The design can be arbitrary. The goal during assembly is to achieve maximum balance so that the device does not shake from vibrations during operation.

Scheme of work

- The electric motor is turned on.

- Load material into the hopper.

- The processed material flies out of the nozzle and falls into a pre-prepared container.

The container is usually a plastic barrel. It is advisable to cover it with a lid and make a hole on the side so that the chaff does not fly away in all directions. The operator just has to supply the raw material and empty the container with the chaff in time. Ideally, several of them are used, changing as they are filled.

Tools and materials

The tool kit you will need is a regular locksmith kit, which is available to every thrifty owner. In addition, you need a welding machine, an angle grinder and a drill. As for materials, we will present a list provided for by this design, and you can use metal available on the farm. So, to make a household shredder, you will need:

- single or three-phase electric motor at 1500 rpm;

- sheet metal 2 mm thick - for the cover and lintel;

- the same, 3 mm thick - for the hopper, pipe, gussets and thrust bearings;

- metal 5 mm thick for the bracket;

- steel plate 10 mm thick;

- pipe Ø25 mm or similar angles - on supports;

- metal strip 25 x 3 mm - for reinforcement.

Knives are made from high-quality carbon steel, for example, St45, or cut from an old circular saw, or from hacksaw blades of metal-cutting machines. A piece of Ø300 mm pipe or an old barrel can save you from unnecessary work on making the machine body. To make connections you need electrodes and bolts with nuts.

Advice. If you have an electric motor on your farm with a speed of over 2000, then it is extremely undesirable to directly install knives on its shaft. It’s better to spend more time, but make a more powerful machine with a belt drive; it will be possible not only to chop straw, but even to crush branches and root crops. The diagram below shows the structure of a straw chopper with a decrease in speed and an increase in power:

Manufacturing recommendations

The metal must be marked and the blanks cut out in accordance with the drawing. Cut pipes and angles to the required length and clean them. The bottom is welded to the bunker, and to it is a bracket for attaching the electric motor. The steel plate is attached vertically to the bracket; first you need to make holes in it that coincide with the mating part of the engine. To strengthen it, gussets are welded to the side of the slab.

The supports are attached to the body at an angle, and gussets are also welded to them, playing the role of stiffeners. When the straw chopper, made by yourself, is already standing on supports, a chaff ejection pipe is attached to it. Then the electric motor is bolted to the plate, and knives are mounted on its axis and securely fixed. Lastly, the cover is attached and the electrical part is installed.

It is not at all necessary to repeat the design presented in the article. The main thing is to correctly manufacture the working unit with knives, and you can adapt an electric drive to it in any convenient way. Just remember that the speed of the cutting shaft shaft should be within 2000 rpm. And then, if the span of the knives is no larger than those shown in the drawing. Otherwise, the machine will become a source of increased danger.

Hay chopper device

The simplest hay and straw chopper is made from a regular vacuum cleaner. An ordinary plastic or aluminum bucket serves as a working chamber into which raw materials are placed, and then a knife mounted on a rotating shaft is lowered. You can make such a device in a few minutes, but it has one significant drawback: low productivity and impracticality. If the number of poultry or livestock is large, you will need a more reliable hay crusher.

The working unit is the most important part of the straw chopper. It consists of a steel hopper with knives inside. The knives are attached to the engine axis with a special axis. Usually the bunker is made in the shape of a cylinder, and for greater safety the walls are left high. You can do it with short walls, but then equip the device with a lid.

Main components of the straw chopper:

- Working chamber with lid,

- Support,

- Motor,

- gain strip,

- Knives or cutting disc,

- Receiver of raw materials.

Materials

The hay cutting machine is assembled at home with your own hands from materials available to everyone. And its production does not require special technical skills. To make a hay chopper with your own hands, you need to have a mechanic's kit, a welding machine, a drill and a grinding machine. The materials needed are:

- Motor (an electric motor from a washing machine is suitable),

- Sheet of metal, with a thickness of about two millimeters,

- A sheet of metal, about three millimeters thick,

- Steel sheet, ten millimeters thick,

- Pipe cut (do not use a diameter larger than 25 mm),

- A strip of metal, 3 mm wide, 25 mm long.

Manufacturing

Instead of knives, you can take a disk from a circular saw or a powerful food processor. A barrel or a piece of pipe with a diameter of at least thirty centimeters is well suited for the role of the device’s body.

Before making a straw chopper with your own hands, it is advisable to find clear and detailed drawings of the device on the Internet. They will help prevent errors in the location of parts and fastening. Manufacturing begins by marking and cutting out a blank from a section of pipe. An additional bottom is attached to the resulting container by welding, and a holder for the motor is already attached to it. Several holes are pre-drilled into the steel sheet to simplify the process of attaching the motor. A do-it-yourself straw cutter made from a pipe will be stronger if metal corner gussets are welded to the sides. A container for the already crushed product is attached to the bottom. Only after this the engine is installed. It is attached to a steel sheet, and cutting knives or discs are mounted on the axis and securely fixed

The last point: an electrical cable and a power switch are installed, as well as a cover and an indicator light. The device is ready for use.