For builders and owners of summer cottages, equipment such as a motor drill can be very useful. Labor productivity when using hand tools is extremely low, so you have to think about purchasing more advanced and efficient mechanics for excavation work.

Motor drill - what is it?

Excavation work is extremely hard work and, if the volume is large, it is advisable to mechanize it. When improving an area, drilling wells is often required. If the volume of work is large and, for example, you need to install several tens of meters of fence, it is better to acquire a means of small-scale mechanization. A motorized earth drill is a universal gardening equipment with an auger, which operates primarily on a gasoline engine. It allows you to make holes of the required parameters in soil of any complexity.

What is a motor drill for?

Depending on the engine power, a gas drill for excavation work is used:

- In the agro-sphere

- for arranging a vineyard, preparing holes for planting trees and shrubs. - In geodesy

- for collecting soil for samples. - During construction

- during digging trenches, installing foundations, supports, pillars, fences.

The use of a motor drill is justified when you need to dig many holes in a short time. The tool makes smooth cylindrical holes with a diameter of up to 30 cm and a depth of up to 2 m. For drilling, auger attachments are used, which are purchased separately; their sizes can be selected in different sizes. There are two types of devices - for working in soil and in ice. In the second case, mechanized equipment is widely used by fishermen in the winter season.

Motor drill - device

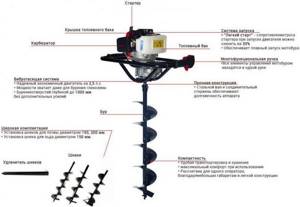

A modern motor drill for excavation work consists of several fundamental elements:

- iron frame;

- internal combustion engine;

- shaft;

- auger;

- control panels.

The engine is mounted on the frame, and a replaceable drilling screw (auger) is rigidly attached to its shaft. The diameter and length of the latter are selected depending on the power of the motor and the type of rock to be worked with. There are special buttons on both sides of the engine that control the device. It has a starter and a motion interrupter. There is an emergency stop button if it is necessary to unexpectedly stop the operation of the equipment. Motor drills are often powered by a gasoline engine.

How does a motor drill work?

A gasoline-powered earth drill operates on the following principle: the engine drives a helical auger, which is rigidly attached to the shaft. The cutters cut into the ground, their shape helps to lift the soil upward, which is why drilling is carried out. Some models are equipped with devices that help in throwing out loosened soil from the drilled well.

Before immersion, the tool is fixed so that the axis of the auger is vertical to the ground plane. The engine starts with a recoil starter. The body of the motor drill is equipped with powerful horseshoe-shaped handles, by which the device is held during operation and at idle speed. The auger can be guided using levers located on the frame.

Tool structure

The basis of any design of this type is an auger drill. The lower part of the functional organ has a starting tip and a special knife, which turns into a spiral screw. The gas drill for excavation work is driven by an engine, which also occupies an important place in the design. As a rule, the power unit is a two-stroke motor, due to which the auger rotates and deepens into the earth cover.

Since during drilling operations the waste soil is extracted to the surface, special devices are also provided in the design for its convenient release. Control is carried out through levers. So, if drilling for piles is carried out, the operator will be able to ensure accurate formation of the well using the mass switch, reverse and accelerator buttons.

Types of motorized drill

Gasoline drills are divided into hand-held and wheeled. The former are considered household appliances, the latter are closer to professional ones. A manual gas auger is preferred by most users as it is much cheaper. The efficiency of its operation suits many; the installation helps to drill holes with a diameter of up to 300 mm. According to the method of transmitting rotation, gas drills are divided into:

- hydraulic;

- mechanical.

The hydraulic structure of the rotation transmission from the engine to the gearbox and auger is considered more reliable and durable. In this case, the load is distributed more evenly, the parts of the device do not wear out so quickly and function longer. If you need to carry out a large amount of work, a hydraulic portable drilling rig is best suited.

Wheel motor drill

Wheeled devices are heavy because they are equipped with a powerful engine, which is difficult to carry manually. A wheeled motor drill can make a hole with a diameter of up to half a meter; the drilling depth reaches two meters. Due to its considerable cost, such equipment is more popular among professional builders. A wheel drill can be:

- Single-frame

, when the engine and gearbox are one unit within an integral structure on one trolley. - Modular

- the motor and gearbox are located on different trolleys.

Hand motor drill

Manual gas drills are characterized by low weight, compact dimensions and low power. They are made for one or two operators. For example, it is advisable to use a manual motor drill for a water well if you need to make a hole with a diameter of no more than 250 mm. One person can handle this task. But it still depends on the density of the soil. If the ground is hard, it is better to purchase weighted equipment for two operators.

Features of ice drills

Ice auger, so beloved by fans of winter fishing, is, in fact, an ordinary motorized auger with an ice auger installed on it. It differs from the “earth” one in the angle of attack of the blades and their shape - it is either spherical or straight, with teeth.

Many amateurs are accustomed to using mechanical ice drills (manual), but if during fishing you have to drill dozens of holes, and the ice thickness is approaching 1 m, then using a hand drill is extremely inconvenient. Fishermen get out of this situation in two ways: buy a powerful screwdriver (usually Metabo) or take a gas drill. Let's compare these options.

Screwdriver

- works quietly,

- has small dimensions and weight.

- In the cold, the battery discharges quickly, so on long trips it is recommended to take a spare one, which will be kept warm.

- Price. The power of a standard Chinese screwdriver for 3-5 thousand rubles will not be enough for drilling thick ice. The price tag for truly suitable models starts from 20,000. Additionally, you will have to pay for a second battery, an ice auger and, if necessary, an adapter. The total amount is about 30,000 rubles.

How to choose a motor drill?

Users who decide to acquire this equipment are faced with questions about how to choose a motor drill and which one is best for excavation work. When purchasing, three criteria are taken into account:

- Power

. It is indicated in horsepower. The higher the power, the faster the installation works. Budget models have a minimum power of 3 hp. - Screw diameter

. When determining the diameter, you need to take into account the dimensions of the holes that need to be drilled. Sometimes augers are not included in the package at all, but they can be purchased additionally. The average diameter of the head, which can cope with a typical volume of work, is 0.8-1.3 m. - Engine capacity

. The parameter affects the rotation speed of the knives in the ground. For sandy soil, a parameter of 33 cm³ with a power of 1.5 hp is suitable. For work on black soil, a volume of at least 40 cm³ per 2.5 hp is required. For compacted soil you will need an engine of 190 cm³ with a power of 5 hp or more.

Rating of motorized drills

When purchasing, you should pay attention to products from trusted manufacturers:

- Hitachi

. Models of semi-professional quality, mid-price category. The drills are multifunctional and equipped with engines with the New Pure Fire system. The operator can adjust the angle of the handle, and the soft start ensures comfortable operation. The devices are suitable for private housing construction and small organizations when periodic drilling operations are required. - Stihl

. The devices are professional, easy to operate and maintain. The engine runs stably, anti-vibration protection and braking mechanism are activated. The Shtil motor drill for excavation work is purchased by organizations that rent such equipment or by companies where the installations are used regularly. - Efco

. The equipment is used for gardening work. The control system is concentrated on one side. The unit is mobile, equipped with automatic shutdown, and additional adapters are present.

Design Features

The motor has an extremely simple design, which includes 4 elements:

- Gasoline engine (two- or four-stroke with power from 2 to 8 hp, started using a recoil starter).

- Gearbox (using a worm or cylindrical gear, transmits force from the motor shaft to the auger, increases torque, and also takes on the risk of breakage if the drill gets stuck).

- Auger (drill in the form of a screw rod).

- Handles (two horseshoe-shaped, symmetrically located).

Motor drills are classified by size:

- Lightweight (weighing up to 30 kg). Designed for making shallow wells in loose soil (sand, sandy loam, peat). Typically, they are equipped with an economical two-stroke motor and an auger of up to 150 mm. Thanks to their compact size and comfortable handles, such devices can be easily operated by one person. Speed adjustment is not provided on most light drills as it is unnecessary.

- Heavy (up to 80 kg). As a rule, these are two-seat motor drills (with symmetrical handles for 2 operators) with a powerful four-stroke engine, an extended auger and a multi-stage gearbox. These devices are suitable for working with alumina, chernozem and other heavy soils.

DIY motor drill

If the equipment for making holes is used infrequently on the farm, you don’t have to spend money on purchasing it. In this case, it is better to make a motor drill with your own hands from a trimmer:

- Take an old trimmer - it's a brushcutter that has a long handle and a small motor. The new device will need a motor from it.

- You also need a gearbox from an old drill and an auger of suitable length.

- Next you need to connect all the elements together. To do this, you can use an old metal back from a chair; the structure is strengthened with aluminum plates.

- After connecting all the elements and securing them securely, you will get a motor drill with low power for household needs.

Motor drill - how to use?

A drilling rig is a complex device; working with it requires compliance with certain rules. The use of a motor drill takes into account the following points:

- Use augers that are suitable in quality and size for the soil where the work is being carried out.

- The handles must be grasped with both hands. Do not place your feet under working cutters.

- If the tool weighs more than 10 kg, it must be operated by two people at the same time.

- The area where drilling is being carried out must be cleared of debris and stones. If foreign objects or tree roots get under the cutters, you need to stop the installation and remove them from the well.

- For proper engine operation, you need to mix fuel in the proportion specified in the instructions.

- Before storing a motor drill, all fuel is drained from it.

- The instrument is placed in a vertical position so that liquid does not leak out of the reservoirs.