Why do you need to build a well?

Taking into account the property of a liquid to change its state of aggregation at subzero temperatures, installing a water well is a mandatory measure to ensure uninterrupted water supply to a private home. Special equipment protects moisture extracted from the depths of the earth from freezing. Devices are used to protect the source from the negative influences of the external environment. Special devices purify the liquid, making it suitable for drinking.

To create conditions that facilitate the installation and subsequent maintenance of the necessary equipment, after drilling the mine, a number of measures are taken to improve the autonomous source. At the initial stage, pipes are laid and power is connected.

What will be needed to install a water well?

Before starting work, the homeowner must understand that successful installation of a deep water well is impossible without the presence of special components . The equipment that must be used includes the following structural elements:

- hermetic container - caisson;

- submersible pumping equipment;

- cover for the water tank - head;

- automation unit and hydraulic accumulator.

To protect yourself from interruptions in the water supply of a country house, it is advisable to purchase only high-quality components and elements that correspond to their operation.

Well protection from atmospheric influences

A local source of water located on a summer cottage must be protected from the negative influences of an aggressive environment. To protect the well, it is surrounded by a special structure located on the surface or underground.

Overhead pavilion house

Suitable option for industrial-scale wells. It is not practical to build such structures in suburban areas. The pavilion occupies space on private property, violating the aesthetic integrity of the composition. The disadvantage of a separate house is the difficult process of effectively carrying out measures to insulate the building.

For large areas of household plots, the option of constructing an above-ground pavilion is acceptable. The house is located above the water intake system. It is recommended to cover a small recess in the building, similar to a separate entrance to a cellar, with soil. This event helps reduce heat losses.

Placing the source inside the building

The location of a water intake well in the basement of a private house or in an insulated outbuilding is a technically sound decision. The building reliably protects the autonomous source from the aggressive influence of natural factors, while simultaneously preventing the penetration of thieves and vandals. In a warm room, installation and maintenance of equipment is simplified.

Water intake equipment is distinguished by the absence of vibrations and reduced noise effects that accompany the operation of the mechanisms. The clicks of the triggered relay do not cause any inconvenience to the residents of the home when the doors of the technical room are closed.

The disadvantage of the option of internal location of a local source in a private house is the need for initial drilling of a well prior to the construction of the building. Most owners of personal plots prefer the reverse procedure.

Underground well caisson

A special well, built to protect an individual water source on a private plot, is in high demand. An alternative name is caisson. The popularity of the underground device is due to its hidden design. There is a small hatch on the surface that does not clutter up the territory of the country property.

When installing finished factory-made products, it is necessary to lower the tank to the required depth into the water intake shaft. Special technological holes are designed for connection to communications. Using sealed cuffs, water pipes and electrical cables are secured in factory caissons.

Steel or plastic is used to make underground wells. The high cost of factory products is compensated by quick and simplified installation. There is no need to carry out waterproofing measures for industrially produced caissons.

How to ensure uninterrupted operation of a well

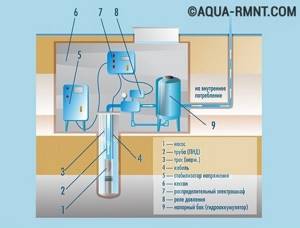

How to properly equip a well can be clearly seen in the video. This article discusses the general rules for constructing a well for its normal, permanent operation. This can be provided by a caisson for a well, which is an insulated waterproof container with the necessary equipment installed inside. Usually it is installed:

- Pump.

- Shut-off valves.

- Measuring instruments.

- Filters.

- All kinds of automatic devices.

Caissons are made from different materials.

Plastic caissons

Their advantages over other types of such devices are:

- Excellent thermal insulation. In this case, without additional insulation, the temperature inside the caisson is maintained at 5C.

- Long service life.

- Good waterproofing characteristics, allowing you to eliminate additional costs for insulation work.

- Reasonable price compared to other options.

- Light weight, which allows the system to be installed by the site owner himself, without the additional use of lifting equipment.

The main disadvantage of the design is its low rigidity. This can lead to structural deformation and equipment failure.

Tip: You can increase the rigidity of the structure by filling the perimeter of the container with cement mortar, with a layer thickness of 80 to 100 millimeters.

Plastic caissons

Steel caissons

The most common arrangement of a water well with this design. This is due to the fact that:

- The material can be used to make a caisson of the desired shape without much effort.

- To do this, it is enough to weld the parts together.

- The finished structure should be treated with a special anti-corrosion coating inside and out.

- To make a reliable container, a metal sheet 4 mm thick is taken.

- If you have sufficient funds, you can purchase a ready-made structure.

The disadvantage of steel structures is their reduced corrosion resistance.

Steel caissons

Reinforced concrete caissons

Not long ago these were the most common settings. These are quite strong and durable devices. But existing shortcomings do not allow them to be widely used in the presence of other types of caissons. These include:

- Very high cost.

- Installation can only be carried out using special equipment due to the heavy weight of the equipment.

- The same reason is the subsidence of the concrete caisson during long-term operation. Deformation of the pipelines inside it occurs.

- Concrete has low thermal insulation properties, which can cause water to freeze in the pump during severe frosts, and insufficient waterproofing due to the hygroscopicity of the material.

Construction of a reinforced concrete caisson

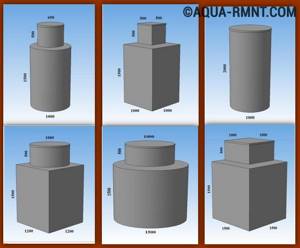

Dimensions of the well protection structure

An important point in independently arranging an autonomous source at the dacha is the correct choice of caisson dimensions. Special attention is paid to the dimensions of the device located above the well. The parameters are determined based on the installation location of the equipment. For equipment placed in the house, an acceptable cross-sectional value is considered to be a diameter of 80 cm, which does not limit the movement of the master when installing the pumping unit.

In areas with harsh winter conditions, a mandatory requirement is to position the bottom of the caisson 15 cm below the soil freezing depth. Professionals recommend placing the bottom third of the guard in a frost-free area.

When calculating the minimum dimensions of an underground well, 50 cm is added to the dimensions of the equipment in front and side. For comfortable maintenance of mechanisms, free space is required.

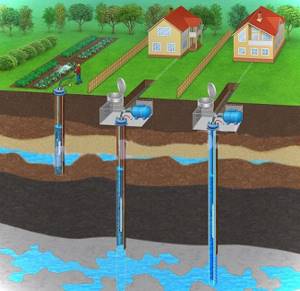

How to choose and install a pump for a well

After installing the well equipment at your dacha, you need to select a submersible pump model. To begin with, its performance and maximum pressure are calculated. In this case, the following criteria are taken into account:

- Well depth.

- What is the length of the water pipe?

- How many floors are there in the house?

- Number of water points.

During installation, the pump is lowered into the well to a level below the static water level. The following are lowered simultaneously with the pump:

- A plastic pipe will carry water to the top.

- Stainless steel cable to secure the lowering of the pump.

- Cable for controlling the operation of the electric motor pump.

- The cable is fixed to the well head.

Tip: Pipe and cable can be brought into the house if automation systems and water-lifting equipment are located directly in the room.

Ensuring the tightness of the casing pipe

A prerequisite for the improvement of an individual well is to protect the source from dust, condensate accumulating inside the caisson, groundwater, melt and rainwater. Harmful microorganisms can cause harm to the health of consumers. Cleanup activities lead to financial losses.

As a protective device, a cap is used, made in the form of a steel cover with special holes for connecting to communications. The design provides a reliable hook for hanging the pump.

The product package includes a rubber crimp collar designed to seal the casing. Seals are used to enter the water pipe and electrical power.

Why do you need to dig a well?

Such a pit is necessary in order to provide the possibility of convenient repairs. The slope directed away from the well ensures the removal of dirty and melt water. A moisture-proof junction box is installed inside the pit, through which the cable is routed to the pump.

If the casing pipe is made of plastic, it is necessary to purchase a steel cap 60 cm high. To protect the well, it is necessary to cover it with a concrete cover.

If you use a metal hatch, condensation will form. It pollutes the water in the well.

Using a Downhole Adapter

An above-ground pavilion house or an underground caisson well effectively protects an autonomous source. The construction of such structures requires considerable financial investments. For owners of small summer cottages with a limited budget, an alternative option for constructing a well, which involves the use of a well adapter, is a profitable solution.

The design of the device is represented by 2 parts of a collapsible fitting. Using the outer part, located on the outside of the casing, a connection is made to the water pipe supplying water to the living space. The internal part is designed to connect the pump.

The adapter halves are connected through a double seal on the casing. The radial configuration of the fragments follows the diameter of the trunk.

The protective device must be located deeper than the freezing line of the soil. A cover with a cable passed through to power the pumping equipment is mounted on the part of the casing that rises above the ground.

To prevent the volume of water intended for drinking from freezing when the temperature drops to -20°C, it is recommended to insulate the well with straw, sawdust, spruce branches or another method.

Types and features of installation of caissons

The uninterrupted operation of the well is ensured by a caisson, an insulated waterproof container with the necessary equipment inside.

Usually a pump, shut-off valves, measuring instruments, automation, filters, etc. are mounted in it. Structures are made from different materials. The most common:

- Plastic. They are distinguished by excellent thermal insulation, which makes it possible to maintain the temperature inside the caisson at a level of 5C even without additional insulation. Durability, excellent waterproofing characteristics, which makes it possible to avoid additional costs for insulation work, and at an affordable price, especially in comparison with other options. In addition, installing the system is quite simple due to its light weight. The main disadvantage is low rigidity, which can cause deformation of the structure and damage to equipment. However, it is easy to deal with by filling the container around the perimeter with cement mortar with a layer of 80-100 mm.

Plastic caissons have excellent thermal insulation, which allows them to be installed without additional insulation

- Steel. Most often, a water well is constructed with just such a design. The material allows you to make a caisson of any desired shape, without requiring much effort. It will be enough just to weld the parts together and treat the structure inside and out with a special anti-corrosion coating. For a high-quality container, 4 mm thick metal will be sufficient. You can also find ready-made structures for sale, but purchasing them will cost much more than making them yourself.

There are various forms of steel caissons - for different needs

- Reinforced concrete. Very strong and durable installations, previously extremely common. Due to their shortcomings, they are used much less frequently today. Their cost is very high, and installation requires special equipment, due to the large weight of the equipment. For the same reason, over time, the concrete caisson sags, deforming the pipelines inside it.

Concrete has insufficient thermal insulation, which can cause the water in the pump to freeze in severe frosts, and poor waterproofing, since concrete is hygroscopic

Here is an approximate diagram of installing equipment in a caisson and connecting communications:

Diagram of equipment installation in a caisson

If you are planning to construct a well with your own hands, it is worth getting acquainted with the stages of installing a caisson. They are almost the same for any type of structure, with minor nuances depending on the material of the equipment. Consider the stages of installing a steel container:

- Preparing the pit. We dig a hole, the diameter of which is 20-30 cm greater than the diameter of the caisson. The depth must be calculated so that the neck of the structure rises approximately 15 cm above ground level. This will prevent flooding of the container during floods and heavy rainfall.

- Installation of casing sleeve. We make a hole in the bottom of the container. It can be traditionally positioned in the center or shifted as needed to install equipment. A sleeve 10-15 cm long must be welded to the hole. Its diameter must be greater than the diameter of the casing pipe. Be sure to check that the sleeve fits easily onto the pipe.

- Installation of nipples for water pipes. We weld them into the wall of the container.

- Installation of the caisson. We cut the casing at ground level. We place the container on the bars above the pit so that the sleeve on the bottom of the container “fits” onto the pipe. We check that the axes of the caisson and the casing pipe coincide exactly, then carefully remove the beams and carefully lower the structure down the casing pipe. We install the container in the hole strictly vertically and secure it with bars. We weld the pipe to the bottom, sealing the caisson. We insert water pipes into the structure through nipples.

Backfilling of the structure.

The caisson is “put on” the casing pipe and carefully lowered into the pit

It should be noted that, in principle, it is possible to construct a well without a caisson, but only if there is a heated building nearby where the equipment is located.

The convenience of such a system is undeniable - all nodes are easily accessible. However, the disadvantages are also significant: it takes up quite a lot of space in the room and most often makes a lot of noise.

You will find more detailed instructions for installing a caisson for a well in our following material:.

Tips for constructing a well

When creating a local source yourself, you need to carefully study the recommendations of specialists.

Professionals offer beginners some useful tips:

- When groundwater occurs below the soil freezing level, it is better to place protective structures on the surface. An adapter may be used.

- For permanent residence, placing equipment in a dry and warm main building is suitable. Maintenance activities for mechanisms are simplified and the service life of equipment is extended.

- An underground caisson is a suitable option for houses with seasonal residence. A buried well does not freeze, maintaining a positive temperature.

- For unstable soils, it is recommended to use a protective casing to protect the water supply from mechanical damage. The cable must be placed in a HDPE pipe.

- The equipment connection diagram must include a check valve installed after the pump. The system must have a coarse filter located in front of the storage tank.

During operation, it is necessary to control the pressure level in the pneumatic part of the hydraulic accumulator. When the standard indicator decreases, pumping is required.

Types of caissons for wells

For uninterrupted operation of the well, a caisson is designed - a high-quality insulated, waterproof tank in which all the associated equipment that ensures the operation of the pump is located. Typically, an automation unit, water pressure control devices, a filter, etc. are placed inside the container. To manufacture such a device, a variety of materials are used, the most common of which include the following:

- Plastic - a caisson made from which has high thermal insulation characteristics and does not require additional insulation. Such a device is durable, does not allow water to pass through, which eliminates the need for additional waterproofing and is relatively inexpensive. Plus, thanks to the low weight of the product, it is easy to install it yourself.

- Steel is the most common material used to make caissons. The flexibility of the material for processing allows you to give the finished product any shape without much effort. To assemble a steel caisson yourself, you just need to cut the sheet metal into blanks and connect the individual elements using electric welding. A high-quality container can be assembled from 4 mm metal, which must be opened with a corrosion-preventing agent. Naturally, you can purchase a finished product, but its cost will be much higher than that of a homemade analogue.

- Reinforced concrete, which will make a durable and strong caisson , which not so long ago was very popular when building with your own hands. However, due to the large number of disadvantages of this design, it is increasingly being replaced with steel or plastic analogues. The cost of a concrete structure is quite high and, on top of that, it can sag under its own weight, deforming some elements of the well equipment.

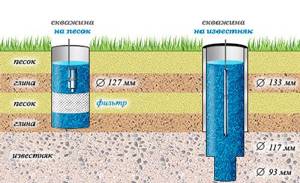

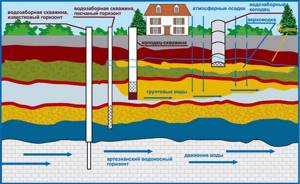

What wells exist

Water suitable for domestic use can be obtained from 2 levels:

- The first level does not lie relatively deep; it is conventionally called sandy, since the water is in the sandy layer.

- The second level is deeper and is located in a layer of limestone; such wells are usually called artesian wells; we will consider them in more detail later.

The depth of the wells, as can be seen in the photo, varies significantly.

Extracting water from a sand layer

- This type of well is used for purely personal use, since the thickness of the aquifer is on average 0.5 m³ per hour. This is quite enough to provide household needs in the house and water the garden plot. But it will not be enough to meet the needs of the dacha cooperative.

- The depth of the sandy aquifer ranges on average from 10 m to 50 m. A distinctive feature here is that all work can be done with your own hands, within a few days. Of course the work is hard, but simple and completely doable.

- The advantages of such designs.

- The price for equipment and work will not be high compared to the artesian version.

- In terms of time, the work is completed quickly; it can be completely completed in a maximum of a week.

- Minuses.

- There is no guarantee that if your neighbors have water, it will be at the same depth on your property.

- There is a high probability of contamination of the aquifer.

- The maximum service life is up to 15 years, which is why it is not recommended to install such wells directly under the house.

- Instability and floating nature of groundwater.

- Quite often, such water is only suitable for technical needs and requires the installation of an additional expensive filtration system.

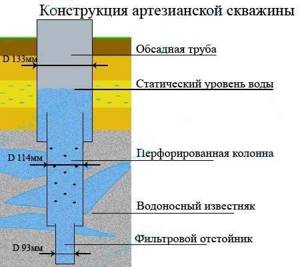

Design diagram.

Advice: according to building codes, it is strongly not recommended to drill wells closer than 20 m from any potential source of pollution, local garbage dumps, compost pits, toilets, etc.

Artesian wells

- This type of well is the most preferred, since the water from them has high quality characteristics. But you won’t be able to drill it yourself, since the depth of such aquifers ranges from 50 m to 200 m. Plus, limestone is a fairly strong rock and it’s practically impossible to drill it with your own hands, without using special equipment, at such a depth.

Artesian well design.

- What are the benefits of artesian wells?

- As a rule, in local geological exploration it is possible to relatively accurately determine the depth of water.

- Fairly high water yield, with an average capacity of 10 m³ per hour, which can satisfy the needs of an average dacha cooperative or a large private estate with a swimming pool, several bathrooms and automatic watering of a personal plot.

- If you arrange the structure correctly, it will serve you for a long time, up to 50 years. Thanks to this, they can be drilled under the house.

- Stable level of the aquifer.

- And most importantly, the quality of such water is very high. As a rule, additional filters are not required, because thanks to the limestone shell and great depth, the likelihood of contamination penetration is almost zero.

- The only downside is the high cost of construction. But after investing once, you will forget about the problem of clean, drinking water for decades.

Types of wells.

Ways to locate a well on a site

In total, there are two types of source locations on the site - in the basement of the house and outside the building.

The first option is carried out even before the construction of the cottage. Here they operate rather on the principle of “where I found it, I drilled there.” Then they start planning the building, based on what they have. The advantages of such drilling are as follows:

- the presence of a well in an almost heated basement, which means preventing the system from freezing in winter;

- minimum distances for transporting water, which requires less powerful pumping equipment.

There are more disadvantages here:

- constant moisture in the basement;

- noise of operating pumping equipment;

- difficulties with bringing in special equipment in case of need for repairs or flushing of the source.

Thus, “internal” drilling of a well is not the best option. In addition, it strongly diverges from sanitary requirements.

As for the location of the hydraulic structure outside the building, there are more advantages:

- Convenience of access for special equipment when maintenance is required;

- less noise from a running pump;

- the ability to freely water the garden without having to pull a long hose from the basement;

- arrangement of a caisson or head in interesting landscape design options.

The downside is the need to install a protective platform and insulate the upper part of the casing to avoid freezing of the system in winter.

To choose a good place for drilling, it is important to consider the following parameters:

- Depth of the aquifer. Moreover, if several neighboring structures have already been built on it, it is important to remove the new one as much as possible so that they are not all fed from one section of the horizon. Otherwise, the productivity of all wells will drop.

- Presence of plantings in the proposed location of the source. Here it is better to choose less green (cultivated) areas.

- Relief of the site. The well is not made in its lower part on the slopes, since during the rainy season a large amount of precipitation will flow here and the caisson will be flooded.

It is important to consider that the source must have free access for special equipment. Otherwise, in the event of an emergency, the machine will damage the landscape design of the area.

What criteria influence the choice of location for a well?

When determining the source location area, the following points must be taken into account:

- Possibility of free access to the well at any time of the year. If, in order to drill a mine, a master drives equipment through a neighboring, not yet developed area, this phenomenon is temporary. Someday they will buy it and definitely inhabit it. It is unlikely that future neighbors will allow you to drive equipment through their yard.

- The need to conserve the source over time. It will be impossible to do this with a well located in the house (basement). The minimally prohibited option for locating a hydraulic structure in a building is to erect a greenhouse over it. In a pinch, it can be quickly disassembled. In addition, the sources that were decided to be located inside the house are not repairable. This means they are disposable structures.

Momentary short-sightedness when choosing a place for drilling often results in big problems during the operation of a ready-made autonomous source.