Stationary and mobile cold smoked smokehouses, features of different modifications

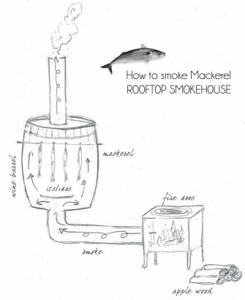

The cold smoked smokehouse given as an example is not difficult to install on your own site.

If the site has suitable terrain, the solution to the problem will be simplified

It can be added that in such a structure it is necessary to make the length of the chimney 3-6 meters. At a shorter distance, cooling in natural conditions is not effective enough. Increasing the distance beyond 7 meters will significantly worsen traction. You will have to raise the level of the smoking compartment, which will be accompanied by additional costs.

Construction of the firebox and chimney of a cold smoked smokehouse from high temperature resistant materials

Multifunctional design

This photo shows an example of convenient equipment for a suburban residential property. This building has:

- fireplace for enjoying an open flame and effectively heating the immediate area;

- it contains special supports for skewers and grates, which transform the decorative block into an excellent barbecue;

- an oven for baking dishes and a cast iron hob, which is heated by burning wood;

- built-in smoking compartment.

The experienced author of the project provided a sink with a water supply, which is turned off in the winter. The wide roof canopy makes it easier to perform work in rainy weather.

Factory prefabricated structure

From this photo you can understand how to make a cold smoked smokehouse from metal. You will need: appropriate skills, a welding machine, pipes and other simple workpieces. Such a project can hardly be called mobile. But disassembly during the winter season or a period of long absence with moving parts to the utility room for storage is quite acceptable.

Smoke generator

To create a truly compact installation you will need a device like this. You can connect different smoking chambers to it.

Functional diagram

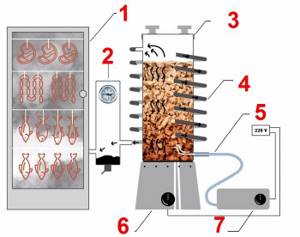

The figure shows the main components of the smoke generator connected to the cold smoker cabinet (1):

- Wood shavings are placed in a steel container. The cover (3) with four bolts ensures the tightness of the structure.

- An electric heater (6) is used for the dosed smoldering process. It is built to the foundation. The smooth power regulator is brought out. With its help, the optimal smoke formation in a cold smoked smokehouse is very precisely established.

- The compressor (7) supplies fresh air through a flexible tube (5). High power is not needed here, so an economical standard aquarium pump will do.

- The smoke is cooled in a coil (4), which wraps around the housing with a small gap. Instead of an air heat exchanger, you can use a more efficient water heat exchanger. In the latter case, the coil (tube) is immersed in a vessel with running cold water.

- To sediment condensate and soot, install a special filter (2). A thermometer is built into its upper part for operational temperature control. A valve is installed at the bottom, which is used to drain the accumulated liquid along with contaminants.

Compact smokehouse with smoke generator assembly

Do not make mistakes when choosing. There are relatively small, cheap products on the market where the shavings are placed at the bottom and the products at the top of the container. Here the smoke is not cooled in accordance with the given standards. This is equipment for hot smoking. The appropriate thermal cooking must be performed according to a special algorithm.

Smokehouse material

The material for sawdust that is used for the procedure is important. Suitable sawdust:

- alders, only peeled from the bark, as it imparts bitterness to the product;

- juniper, it is important not to overdo it with the amount, as the result will be an unpleasant, too strong taste of the product;

- bird cherry and birch;

- oak;

- maple;

- sawdust from fruit trees (apple, pear, cherry, etc.);

To achieve optimal results, the wood used must be dry and not damaged by fungus.

Construction of a mobile smokehouse

To build a camp version of the smokehouse, you will need a sufficient amount of dense polyethylene film, as well as a lot of any available material: fresh tree branches, good boards, twigs. Of course, a mobile smokehouse can only be built with your own hands.

Construction of a smokehouse takes place in four simple steps:

- At the resting place, a suitable area is selected: a gentle slope or the shore of a reservoir. The side to which the surface of the earth is facing should be windward so that the smoke does not fly away where it should not. As in the stationary version, a straight ditch of the same size is dug - 3 m long, 50 cm deep, the width does not matter. The ditch can slope towards the horizon, but the angle should not exceed 60 degrees.

- The ditch is covered with found branches and boards and covered with earth and turf. A fire is built at the lower end of the ditch, and a smoking chamber is installed at the upper end.

- In this case, assembling a solid container for cold smoking is not required; a regular frame made of boards, which should be covered with polyethylene, will do. An exhaust slit is cut at the top.

- The prepared meat and fish are hung in the resulting improvised chamber. For the cooking process to begin, the lighted fire must burn out, leaving only heated smoldering coals. After all the flames have disappeared, the pit is covered with thick fabric, leaving a gap to provide traction. The width of this gap is selected so that the coals smolder well, but do not flare up.

The structure of the smokehouse and the process of making smoked meats

Any smokehouse, regardless of the smoking option, consists of a stove where the fire is lit and maintained; adits or pipes through which smoke from the fire passes; a smoking chamber equipped with grates and hooks; a semi-finished product prepared for smoking will be located here.

There should be no bottom in the chamber where the product is smoked, for obvious reasons. But it is best to cover this part of the smokehouse with a dense but breathable fabric, for example, burlap.

The smoking process is as follows: a container filled with sawdust is placed near a heat source, fire or heated element; this is an important part of the whole process, because maintaining the temperature regime is necessary to maintain sawdust in a state of smoldering.

Smoke from burning wood rises through the manufactured chimney to the semi-finished products, and the smoking process occurs. In this case, you need to place a tray under the products; the fat from the products that has melted due to temperature will drain into it.

The smoke then exits through a special chimney outlet. If provided. Or through the hole in the lid of the smoking chamber. Such a useful device as a smokehouse can be assembled and made with your own hands from materials available in any garage.

How does a cold smoked smokehouse work: principle of operation, design

After studying the basics of the technique, it is not difficult to formulate general requirements for suitable equipment. The main task is to maintain the sawdust smoldering regime for a long time. A good cold smoker is safe and can perform its functions without careful supervision. It will be useful to have a sufficient firebox capacity so that one portion of wood raw material will last for a long time.

Related article: How to make a smoke generator for cold smoking with your own hands. Drawings, videos, detailed step-by-step instructions with photos, an overview of finished models - you will find in our material.

The smoke will need to be cooled to the optimum temperature. And in this case, we should not forget about the duration of work processes. In order not to worsen the economic performance of a cold smoked smokehouse, appropriate “free” technologies are selected. For example, they lengthen the chimney.

Perfect tightness in the smoking chamber is not necessary. But smoke must be contained in this volume, so active ventilation is excluded. A convenient fastening system should be provided inside: guides for gratings, holes for hooks.

For your information! When placing a cold smoked smokehouse on a suburban area, you need to take into account the position relative to the neighbors. Choose a suitable location, taking into account the distance and wind rose, to avoid conflict situations.

This building meets the criteria outlined above

Similar cold-smoked smokehouses were created by mammoth meat lovers with their own hands in the Stone Age. The main advantage of the design is simplicity. It is clear that for reproduction you can use not only a river slope, but also a self-created elevation of the required size.

How to make a smokehouse?

For a smokehouse, a metal barrel, a regular bucket, an unnecessary refrigerator or an old pressure cooker are suitable. Some craftsmen weld the chamber from metal sheets, others assemble it from bricks.

Brick smokehouses are the most common and environmentally friendly, but their assembly is a rather labor-intensive and costly process. Moreover, on the Internet there are many photographs of a smokehouse that combines a Russian oven, barbecue and stove with a hob.

The design of such structures is quite complex, but the result lives up to expectations. This is not only an extremely useful thing in the household. Such a smokehouse will delight the eye with its unusual design, looks very colorful at any dacha and always presents the owners in a favorable light.

How to make a cold smoked smokehouse with your own hands

After studying the general principles and different designs, the intended purpose of the cold smoked smokehouse is clarified. There is no point in thinking about significant investments if you plan to process 5-10 kg of fish caught in the river closest to your dacha in a year. If you plan to completely abandon store-bought smoked meats, you should think about a productive stationary model. For an accurate calculation, it is necessary to select the equipment performance taking into account the characteristics of the feedstock and the processing time.

Below is how to make a smokehouse at home using different projects. When choosing the appropriate option, sensibly assess your own strengths. If creating homemade products is too difficult, skip to the final part of the article. It contains information about manufacturers and thematic equipment.

Inexpensive and effective DIY barrel smokehouse

| Illustration | Sequence of actions, recommendations |

| For the main workpiece, a standard metal barrel with a capacity of 200 liters is suitable. Dents and other external defects do not matter in this case. However, washing must be done to eliminate extraneous odors and potentially dangerous impurities. The lid is cut out. Subsequently, it can be made removable, or act as the author of the project. He used thick fabric to cover the top hole. |

| Using welded joints, several metal crossbars are rigidly fixed at the top. Reinforcement rods, corners, and other suitable products are suitable. Load capacity is calculated as needed. |

| Cut a hole. Weld in a steel adapter with a 2-inch internal thread. The use of other sizes is acceptable, but you will need the appropriate components of a cold smoked smokehouse. |

| A glass is made from a suitable piece of pipe with a similar thread. Weld the bottom. It is tightly packed with sawdust and screwed into the pipe at the bottom of the barrel. |

| To raise the structure above the ground, a simple rectangular stand from metal blanks is welded. Fish, meat, and other products are hung on the hooks of a cold smoked smokehouse. Cover the top hole with fabric. To activate smoldering, use a blowtorch, another source of open flame. After 35-40 minutes it can be removed. Next, the hot walls of the glass will support the process of smoke formation. |

To create such a cold smoked smokehouse with your own hands, you don’t need drawings. Attracts the minimum cost of available materials. But cooling here is carried out due to the large free space in the lower part of the barrel. You won't be able to smoke large pieces of food here. If you accelerate the formation of smoke using a large glass, the temperature will rise above the optimal level. Lack of precise settings, low performance, and unesthetic appearance are the main design disadvantages.

Stationary durable structure: brick smokehouse

| Illustration | Sequence of actions, recommendations |

| This project is designed not only for cold smoking at home. The design of the smokehouse is complemented by a fireplace, a place for storing firewood, and a drying compartment. To repeat the author's ideas, you will need drawings with exact dimensions. They start by preparing the site. The turf is removed, a depression is made, and granular bedding is added. Taking into account the calculated weight, the foundation is poured. To make such a structure stable, reinforcement is recommended. |

| After the screed has hardened, install a layer of waterproofing from roofing felt sheets. They begin to install the masonry. The main parts are made from standard bricks with voids. The firebox and other parts where high temperatures are expected are lined with fireproof fireclay. A chimney made of a metal pipe is installed in the lower part. At this level, another layer of reinforced screed is poured. |

| The most difficult thing to do correctly is a firebox with a chimney. For technological maintenance of the semicircular vault, plywood stencils are used. A complex shape is created in separate rows using pre-prepared layouts. To eliminate errors, you can invite an experienced specialist to perform individual work operations. |

| The roof will prevent the destruction of the structure by atmospheric deposits. Where there will be no high temperature exposure, carpentry can be installed. Cast iron doors of the firebox and ash pan are purchased in accordance with the required dimensions. |

| Such a structure is capable of performing functional and decorative tasks. The appropriate departments provide the necessary conditions for preparing various dishes. |

Do-it-yourself smokehouse from the refrigerator: rational use of old household appliances

| Illustration | Sequence of actions, recommendations |

| You can make a high-quality smoking cabinet for cold smoking with your own hands from an old refrigerator. In this technology, the working volume is not exposed to high temperatures, so there is no need to dismantle rubber seals and plastic parts. The main advantage is the tightness of the container. Standard wire shelves are suitable for storing initial products. |

| The smoke generator is made of a square pipe (100x100x800 mm) with a wall thickness of 4 mm. There are holes in the lower part for the natural flow of fresh air and ignition. Several towers have a mesh installed on which the sawdust poured inside rests. |

| The smokehouse is designed for year-round use. For this reason, the author of the project installed a special heating element at the bottom of the refrigerator. It turns on when necessary in winter. The voltage supply is controlled by a standard thermostat, configured accordingly. |

| A functioning compressor was left in its place. In this design, it is connected by a flexible tube to the fitting of the generator housing. It ensures the movement of smoke into the smokehouse chamber. |

| To fix the external heavy block, metal fasteners are welded to it. Even with this addition, the design of the cold smoked smokehouse turned out to be stable. To install it evenly on a raised surface, you can use the adjustment of the screw supports of the refrigerator. |

DIY electric smokehouse: detailed instructions

All standard designs have one significant drawback - prolonged smoke treatment. It is this that increases the cost of the finished product, which is why manufacturing enterprises often use chemical flavoring additives instead of smoking.

Manufacturers claim that tar and other harmful components are removed from Liquid Smoke. I would like to know what they add there

It is clear that the choice of home smoking is largely due to the desire to personally control technological processes. Therefore, questionable chemicals are not suitable initially. However, electrostatic machining is well worth a closer look. It significantly accelerates the penetration of smoke into the structure of products. This industrial technology can be reproduced at home without great expense.

| Illustration | Sequence of actions, recommendations |

| The body of an electrostatic smokehouse can be made with your own hands from wood plywood or other dielectric. The use of plastic, chipboard, and laminated panels is not recommended. When interacting with an electrostatic field, such materials can release unsafe chemical compounds. |

| The support rod is made of durable stainless steel (diameter 8mm). A grille with pin arresters bent towards the center is installed near the wall. Cell dimensions are 20x20 mm. The distance between the discharge electrodes is 40 mm. |

| Smoke in the right amount is created by a classic generator with a connected aquarium compressor. It enters the work area through a copper tube. For effective cooling, the author used rags, which he decided to moisten with water. |

| To clearly demonstrate the operation of a cold smoked smokehouse, glass of suitable sizes was used instead of a standard lid. After reaching the maximum smoke concentration, turn on the high voltage generator. |

| Within 20-30 seconds the working volume is cleared. Ionized smoke is absorbed by fish (and other foods). High voltage is turned off. Filling the chamber with smoke and high-voltage treatment are repeated. For high-quality smoking, it is enough to spend no more than 12-15 minutes in total. |

In this example, the positive pole of the power source is connected to the grid, and the negative pole to the food products. To complete all processes (hydrolysis and denaturation), the fish is placed in the refrigerator for 2-3 days. Exact time intervals are set taking into account the characteristics of pre-salting, personal taste preferences, and other culinary features.

Buy a home smokehouse

For those who love smoked products, but do not have a summer house or their own plot to build a large smokehouse, the electrical appliance industry has released home smokehouses. Small, portable, they consist of a large saucepan mounted on an electric heating element.

Inside the smokehouse-pan there is a network of sections for wood chips, product, and fat flowing out of the semi-finished product. A thermometer is built into the lid of the device, which greatly facilitates and allows you to regulate the entire smoking process.

How to build a snow igloo with your own hands

What work needs to be done in the fall to prepare fruit trees for winter

Propagation of black currants by cuttings in autumn: instructions and useful tips

The lid handles for such devices are usually made of wood, because such material will not heat up during the process, and this will help avoid injury to people working with such equipment.

Such smokehouses are usually made of stainless steel. It is this property that makes them very resistant to corrosion, and the smooth surface makes the surface easier to clean.

How to quickly buy a cold smoked smokehouse without mistakes: market overview, prices, catalogs

| Image | Brand/Model | price, rub. | Peculiarities |

| Smoke Dymych/ 01B | 3280-3800 | A simple inexpensive set of domestic production with a working volume of 32 liters. Designed for smoke treatment in the temperature range from +19°C to +40°C. |

| Smoke Dymych/ 02B | 4200-5680 | An improved model with a large smoking compartment of 50 liters. Instead of powder coating, this series uses stainless steel, which is more resistant to various external influences. |

| Bradley Smoker/Original Smoker BS611EU/BS611EUB | 53900-56400 | Power 0.5 kW, mechanical control, automatic supply of pressed briquettes to generate smoke. Operation in hot smoking mode is possible at processing temperatures up to +160°C. |

| Bradley Smoker/Digital 4 Rack Smoker BTDS76CE-EU | 63400-67800 | Cold smoked smokehouse with electronic control. Automatic shutdown, temperature adjustment and control. Tray for collecting fat, grate - as standard. |

| Hanhi/Smoke generator | 10900-11820 | Smoke generator with filter, thermometer, coil (6 m) for cooling. Built-in electric heater with adjustable performance. |

Ask questions to obtain the necessary information in the comments to this article. Leave your comments about models from different manufacturers, your own projects, ideas. Productive communication with professionals and like-minded people will help optimize costs.

Interesting fact about smoking

And finally, an interesting fact: it is believed that smoking with pine sawdust is prohibited, because the increased resin content in coniferous wood will give the smoked product a bitter taste. During the time of the Russian Empire, our ancestors in the White Sea region often used fir cones when smoking food.

And in the Volga region, pine sawdust was used for similar purposes. Unfortunately, the recipes for making the products have not survived to this day, but this fact once again proves that it is necessary to experiment in order to get a decent result. Therefore, do not be afraid to try new things, make only the most delicious and high-quality smoked meats.

Tips for use

To ensure high quality smoking, it is recommended to follow several tips for operating the smokehouse.

Cold smoked pork is a delicacy that is not embarrassing to serve to guests.

- The fire in the firebox should burn evenly.

- To obtain a rich and pleasant aroma of finished products, wood chips and shavings of plants such as juniper, birch, alder, and branches of berry bushes are used.

- To prevent the fuel from igniting, it is slightly moistened before placing it in the oven.

- If the above-ground chimney becomes very hot under the sun's rays, damp burlap or other dense fabric is placed over the pipes.

There is nothing complicated in building a cold smoked smokehouse. A wide selection of materials allows you to make a temporary assistant within an hour, and a solid one in a few days.

Smokehouse for meat and fish – what do you need to know when choosing fuel?

The process of preparing food, which involves the use of smoke, has its own subtleties. A very important point is the temperature inside the smokehouse. If it is not controlled, then meat, fish and other dishes can simply go bad.

An equally important factor is the selection of fuel. Wood chips used for cold smoking with your own hands can be made from different types of trees and, accordingly, differ in their characteristics. Depending on what fuel is used for this operation, the taste of the finished products differs.

Despite the fact that wood may be different, the same requirements are put forward to it. The main thing is that the wood chips must be dry. The presence of moisture will not allow it to smolder properly. The wood chips are located at the bottom of the firebox. Experts do not recommend scattering it all over the bottom. The best option is to build a slide.

Each type of wood has its own special aroma

The most common tree species from which wood chips are made for smoking:

- cherry;

- oak;

- maple;

- alder.

In some cases, other tree species can be used for cold smoking fish and meat at home. For example, many people note the exquisite taste of dishes that were cooked with smoke from apple and pear chips.

Note! Experienced chefs recommend smoking food in cold-type devices in the winter. During this period, the ambient temperature prevents the proliferation of pathogenic bacteria inside the products.

It is very important to remember that wood containing resins is absolutely not suitable for smoking. Coniferous trees (spruce, pine, etc.) have this characteristic. If you neglect this rule, then the food cooked in the smokehouse will be very bitter. To improve the taste, you can use one trick - add aromatic herbs used in cooking on top of the smoldering sawdust.

A stationary smokehouse is a very simple device that allows you to cook very tasty dishes

Individual units and modules

How a cold smoked smokehouse will work at home depends on the main components of the design.

It is important to follow the recommendations of professionals when constructing them to ensure that your home smokehouse is functional and effective.

Chimney

The minimum length of the chimney is 1.5-2 meters. The optimal indicator is considered to be 3 m. This length is enough for high-quality cooling. Using longer pipes is not financially feasible as it will require more fuel and smoking time. The length of the chimney also depends on the diameter of the pipes used. The optimal indicator is 20-25 cm. The pipe can be connected to the chamber in various places: below, on the side, on top. This will not affect the quality of cooking.

Firebox

To make a firebox, a hole is dug and filled with concrete 10 cm below the chimney pipe. A clay mortar is laid on the base, on which refractory bricks are placed. It is not recommended to use a cement-sand mixture, since heating will damage the integrity of the firebox. When constructing a firebox, it is important to provide a convenient door for loading fuel and ignition.

Making a simple smoke generator

To produce smoke on your own, you can build a simple smoke generator. For assembly you need:

- Prepare 4 tin cans, a copper tube, clamps and 2 rivets with nuts.

- Make 3 holes in one of the cans: two for the squeegee and copper tube, the third for ignition.

- In the first cut, a groove is cut. A copper tube is inserted into the drive. It is installed inside a tin can.

- The second bracket is attached to the first from the outside.

- A metal plate is installed inside above the drive to prevent sawdust from getting stuck.

- Two tin cans are attached to the base. The joints are wrapped with a fourth container cut into pieces and secured with clamps.

- The compressor is connected.

To put the device into operation, all that remains is to ignite the wood chips and start the blower. You can improve the design by screwing the lid to the bottom and fixing the glass jar. Ash will pour into it.

Compressor

A homemade compressor will help make cold smoking more efficient and also save money.

You can make it from a computer cooler or a vent fan. You can also use ready-made automobile and aquarium compressors by improving their design. Environmentally friendly, safe, tasty delicacies that can be stored in the refrigerator for a long time - all this can be done using cold smoking. A smokehouse assembled with your own hands will not only help you save money, but will also give you confidence in the quality of the prepared dishes. Simple diagrams and drawings of cold smokehouses will help even an inexperienced master cope with the assembly.