Pumps are indispensable for providing a home with clean water, draining wastewater, pumping coolant in a heating system, supplying water to a swimming pool, draining basements, etc. — as you can see, the range of their use in everyday life is very wide.

- What is a pump

- Pump types

- Submersible, surface and circulation pumps

- Electric pumps and liquid fuel pumps

- Clean water pumps

- Surface pumps

- Submersible pumps

- Circulation pumps

- Drainage pumps

- Fecal pumps

- Fountain pumps

- Main technical characteristics of pumps

The variety of tasks performed leads to differences in the design features of the pumps. In other words, each pump has a rather narrow specialization. Therefore, it can be difficult for a non-specialist to select the equipment necessary to solve a specific problem.

There are many types of household pumps

This publication provides basic information that will help in choosing the right pump, provides an overview of the main characteristics of this equipment, and discusses various nuances that must be taken into account so that the pumps work well and for a long time, and their owner does not overpay at the acquisition stage. First you need to understand what a pump is.

What is a pump

A pump is a mechanical device for supplying/pumping some fluid substance, for example, liquid or gas, from a lower to a higher point or from a low to a high pressure zone, i.e. where this substance cannot come by gravity.

Most often, pumps are hydraulic machines for ensuring the movement of liquids under pressure. By converting the mechanical energy of the drive motor into the mechanical energy of fluid movement, the pumps are able to:

- raise the liquid to a certain height,

- move it to the required distance in the horizontal direction,

- will force liquid to circulate in any closed system.

Pump types

There are many types of pumps, which differ in their technical characteristics and intended purpose. The main technical characteristics of the pumps include:

- efficiency,

- pump power (net pump power),

- productivity or volume of liquid pumped per unit of time,

- maximum pressure of outgoing liquid,

- created pump pressure.

According to their intended purpose, household pumps are divided into:

- clean water pumps,

- pumps for dirty water, including sewage.

Clean water pumps are mainly used to operate the water supply system as well as for the swimming pool. Clean water means water that has a solid content of less than 150 g/m3. m.

| Other TopClimat.ru publications on the topic | |

| What is a pumping station | |

| A well pump is a faithful assistant to every summer resident | |

Dirty water pumps have a wider range of applications. These include drainage pumps, fecal and sewer pumps, fountain and watering pumps. They, in turn, are divided into units that work with medium-contaminated liquids (the content of solid impurities in water is less than 200 g/cubic m) and units that work with highly polluted liquids (the content of solid impurities in water is more than 200 g /cubic m).

Units of the first type should not be used for pumping heavily contaminated liquids - violation of operating conditions will inevitably lead to rapid wear of the mechanical parts of the pump and its failure. On the other hand, there is no point in overpaying for an expensive pump designed for heavy pollution if you are using it for cleaner water.

But it is very difficult to independently assess the degree of purity of water. Most often this is done visually - by the amount of sediment and floating solids. How reliable this method is is for you to judge.

Recommendations for selection

To purchase submersible or surface pumps, you first need to correctly select them according to their performance characteristics. The amount of liquid pumped per unit of time depends on the performance. Typically, measurements are taken in cubic meters per hour or liters per minute. The performance should be sufficient to ensure that all water intake points are supplied with water, but in such a way that there is no risk of water hammer or shutdown of the device as a whole.

Types of pumps can be selected according to:

- Operating principle;

- Brand name;

- Station configurations.

. As for the pressure characteristics, they must be able to ensure the rise of liquid to a specific level, as well as transport it through horizontal pipes. If such a criterion as the permissible concentration and linear size of impurity elements is needed, then they are determined based on the quality of the water.

If you need to use a device for particularly difficult conditions, for example, for pumping water containing large and fibrous inclusions, then you should give preference to fecal models with an additional module in the form of a chopper.

There is such a criterion as the ability to pump liquids with high temperatures. As a rule, these are circulation pumps installed in the heating or drainage system, where boiling water can be drained, for example, where dishwashers and laundry equipment are connected. In terms of overall dimensions, the choice is made solely based on where exactly the installation will be carried out.

Submersible, surface and circulation pumps

In addition to the above classification, household pumps can be divided according to their installation location into:

- submersible pumps,

- surface pumps,

- circulation pumps.

Submersible pumps or submersible pumps, as the name suggests, are placed directly in the liquid they are working with. The housing of such a pump must be completely or partially immersed in water. If the pump is completely “recessed”, it is secured under water using a safety rope at a certain depth (usually 0.5–1 meter from the bottom surface).

Igor Aksenov, Head of Purchasing Department NeoClima

“Vortex-type submersible borehole pumps are among the most reliable. In these pumps, the parts in contact with water are made of brass. This gives them high corrosion resistance and ensures structural strength.”

Surface pumps are installed at some distance from the source of liquid, most often in a utility room, and communicate with it through a pipeline or hose.

Submersible and surface pumps are classified as external pumping equipment.

Circulation pumps are internal devices, installed as part of a water supply or heating system and promote the circulation of liquid in them. There are also pumps for increasing the pressure in the system, which are also internal.

Electric pumps and liquid fuel pumps

It is important to choose a pump not only according to its intended purpose or technical characteristics, but also according to the type of power supply. There are conditions when electricity, for some reason, is expensive or not available at all, and the pump needs to be connected. In this case, you can use a pump running on liquid fuel.

Exist:

Petrol motor pump Patriot Garden BMWP-10PC

- electric pumps,

- gasoline pumps,

- diesel pumps.

As a rule, the most economical option is to install a diesel pump. But this option is not without its drawbacks: you will have to take care of timely filling of fuel, in addition, the diesel pump is very noisy during operation. Gasoline is quieter than diesel, but the cost of gasoline is higher. The electric pump is the most versatile, and therefore the most widely used.

Pump classification

The pump can be river, for wells, etc. It is worth noting that you must initially select a standard pump based on the purpose for which it is purchased.

Highlight settings:

- Downhole, mounted directly in the well space;

- Drainage, which can work with clean liquid and for transporting dirty liquid;

- Wells, the installation of which is carried out in a mine well.

If the category of surface pumps is considered, then they can be fountain pumps, sewer pumps, which can be external or internal, and pumping stations in the form of large-sized stations. Today, a huge number of pumps for pumping and taking water are produced, there are about 3000 models, each of which can amaze with its performance properties, technical characteristics, cost and service life.

In order for the pump to serve for a long time, it is worth replacing worn parts regularly.

Not many people know that when choosing pumping equipment, you need to pay attention to the type of power supply, since some operate exclusively on electricity, while others need other types of recharge.

As a rule, these are units in which an internal combustion engine is installed, and according to the type of energy consumption, the installations can be of three types:

- Electric ones, the operation of which requires a connection to alternating current, and therefore they are dependent on the electrical network, but this has its own advantage, since there is no need to replenish fuel reserves. The choice of such devices should be made when there is an electrical network in the area of application, with a specific voltage in the network and taking into account the number of phases the equipment is designed for.

- Liquid fuel gasoline. In general, liquid fuel pumps are motor pumps that operate on a propulsion system. Gasoline means the use of a gasoline-oil mixture, for the preparation of which you must follow the proportions specified by the manufacturer. Such devices are considered quieter in operation and less expensive compared to diesel ones.

- Diesel engines run on diesel fuel, they are quite economical and noisy.

In general, the principle of operation and scope of application may differ, but the difference is not significant, but you need to choose them as carefully as possible, since the price of installation and its installation is far from small, and replacement will cost a large sum and require a lot of time.

Water pumps

Clean water can be collected from a well, a well, a reservoir, or an open reservoir. However, in the latter case, you will need to spend extra money on a water purification station. You can pump clean water using both submersible and surface pumps. Both types do a good job, but each has its own characteristics that you should know.

Surface pumps

They have the simplest device and low cost. Generally, surface pumps come in two main types: centrifugal and vortex. Centrifugal pumps are the most common. They are easy to repair, simple to operate and maintain. Vortex-type pumps are more expensive and provide greater pressure than centrifugal pumps, but their performance and efficiency are lower. Therefore, if you require high water flow, it is better to choose a centrifugal pump. And if the pressure is critical, then it is better to use a vortex pump.

Surface pump with internal ejector Unipump JET 80 L for depths up to 8 meters

There is one more detail that must be taken into account when choosing any pump - this is the so-called self-priming. Self-priming is the ability of the pump to start working immediately, without first pouring liquid into it. So, unlike vortex pumps, centrifugal pumps do not have self-priming, i.e. Before starting work, they need to be filled with water. Filling the pump is usually done using a hand pump. A self-priming pump is, of course, more convenient to use.

Surface pumps are cooled using air, i.e. do not require additional cooling, like some types of submersible. They can be placed either near the source of moisture from a well or borehole, or at some distance from it. In general, they have many advantages, but there are also a number of significant disadvantages.

Pumps for home

✮Large selection of pumping equipment on the portal TopClimat.ru

Firstly, surface pumps need to be protected from the cold in winter, so most often their use is seasonal. Secondly, they are capable of lifting water from a depth of no more than 8-9 meters. If your well or borehole is deeper, then you will have to either abandon the surface pump in favor of a submersible one, or buy a special device for the submersible pump called an ejector.

Surface vortex pump Unipump QB 70

An ejector is a relatively simple device that allows you to increase the depth of water intake by a surface pump to 20 and even 40 meters. You need to know that the liquid in the ejector comes not from a well or well, but from a pump, which complicates the overall design of the pump. Some pumps have a built-in ejector, which is however less efficient than an external one.

There are special portable models of surface pumps for pumping water out of the pool.

Submersible pumps

Unlike surface pumps, submersible pumps can be used all year round. They are able to “get” water even from a depth of 70-80 meters. These pumps usually operate silently, because... immersed in water. All submersible pumps can be classified into two broad categories: borehole pumps and well pumps.

Already by the name it is clear that well pumps are designed to extract water from wells and therefore have a small diameter: usually 3 or 4 inches. Well pumps are more versatile; their diameter can be quite large.

In addition, submersible pumps come in four main types:

- centrifugal,

- screw,

- vortex,

- vibration.

Submersible centrifugal well pump Unipump ECO 8

If the first three types are fundamentally similar to each other, then vibrating submersible pumps have a number of serious differences. Firstly, pumps of this type have lower productivity and efficiency, produce more noise during operation, and most importantly, they can “get” water from a depth of no more than 40 m. And most importantly, vibration pumps are a temporary solution for the home. The fact is that the vibration that this pump creates during operation negatively affects the condition of the well into which it is placed. Therefore, the well will inevitably deteriorate over time, and the quality of the water supplied by the pump will accordingly become worse and worse. What is the appeal of vibration pumps? It's simple - they are the cheapest.

By the way, many owners of vibration pumps do not notice their shortcomings and claim that they can “pump up” a well, clean it and successfully cope with the main task - providing water to their home.

Centrifugal, screw and vortex submersible pumps can operate for a long time and with high quality. To increase their service life, it is better to choose models that have a special cooling circuit. True, the presence of such an option will immediately lead to a significant increase in the price of this equipment.

Submersible vibration pump Aosta AB VMP U4 10 SLIM

A special float switch, which is equipped with some pump models, also extends the service life. If the liquid level is below the critical level, i.e. When the water in the well runs out, the switch trips and the pump automatically stops working. Thus, the device does not operate “dry”, and the “dry” mode is very dangerous for the pump. Typically, float switches have submersible pumps for wells, not boreholes. Although other types of pumps, such as drainage ones, are also equipped with float switches.

NeoClima drainage pump DP 550 DN series with float switch

In principle, for the average user there is not much difference between a centrifugal, screw or vortex submersible pump. A little hint. For high-flow wells (1500 l/h or more), centrifugal wells are better suited, and for low-flow wells (less than 1000 l/h) - vortex or screw wells. Screw pumps are capable of pumping liquids containing solid particles (except abrasive) without compromising their performance.

There are also semi-submersible pumps for clean water, but they are less common.

Circulation pumps

Circulation pumps are “responsible” for ensuring that the water in the pipes of the water supply, sewerage or heating system moves and does not stand still, i.e. circulated. In other words, they provide fluid flow.

Circulation pumps are used to pump both clean and dirty water. Of course, the models used to ensure the circulation of wastewater are somewhat different from those installed in the drinking water supply system, but in general their design is similar. Therefore, we will not separately consider circulation pumps for dirty and clean water and will talk about the features of this type of pump in this section.

Dry rotor circulation pump Wilo Stratos GIGA

Circulation pumps are usually of the rotary type. This type is characterized by high efficiency, low operating noise and low vibration. There are two main types of rotary pumps, which differ in the way the rotor is cooled. This:

- wet rotor pumps,

- dry rotor pumps.

The latter have a more complex design, because The rotor of such a pump, unlike equipment with a wet rotor, is not located in the pumped liquid itself, which naturally cools the rotor. For glanded rotor pumps, cooling occurs due to the environment, mainly due to air.

Pumps for home

✮Large selection of pumping equipment on the portal TopClimat.ru

It is important to know that wet rotor pumps are smaller than dry rotor pumps and are easier to install. If the dimensions of the pump are critical for you, this factor may be decisive in your choice. They are cheaper and less noisy, but have significantly lower efficiency and performance. In addition, dry rotor pumps can be used even in environments with aggressive liquids.

Electrical varieties for home plumbing

Electric pumps have become most widespread due to their reliability, efficiency, low noise level, high performance and ease of use. It is possible to ensure automatic operation of the electric pump by adding control and protection devices to its control circuit.

Water pumps come in a wide variety of designs, but several basic types are used for domestic use. Let's take a look at them in more detail.

Centrifugal

centrifugal type water pump . The role of the working body is performed by a wheel with blades placed in the housing. The housing has two pipes: for water suction, located opposite the center of rotation of the wheel, and for supply, located on the periphery in the center plane.

The operating principle is based on the use of centrifugal force. Water is supplied to the center of the wheel. Rotating, the blades capture water and throw it towards the walls of the housing. Thus, a vacuum arises in the center, under the influence of which a new portion of water is sucked in, and excess pressure is created at the edges, displacing water into the outlet pipe.

Centrifugal water pumps can be submersible or surface-mounted.

The main advantage of a centrifugal water pump is its simplicity and reliability of design, so with proper operation it will last for many years. It can be used to pump water with a small amount of impurities, so it is ideal for wells.

The main disadvantage is the shallow suction depth . A surface water pump of this type can lift liquid from a depth of no more than eight meters. Hydraulic units of this type are not capable of dry suction, that is, they must be filled with water before use.

To increase the suction depth, injection devices are used that make it possible to lift water from a depth of up to fifty meters. The difference between these pumps and centrifugal pumps is that two tubes are lowered into the well, connected below to the injector. One tube (small diameter) supplies part of the water from above to the injector, due to which a vacuum is created in the second tube (larger diameter), which ensures an increase in the suction depth.

The injector can also be built into the pump housing. With this design, the device becomes very noisy, and it is not recommended to install it in residential areas.

Vortex

Vortex electric pumps can work not only with an aqueous medium, but also with a mixture of water and gas. Such abilities are ensured by the design of the housing and the use of a special impeller - impeller. It is the impeller that captures air and pushes it inside the snail-shaped body. There is a small amount of water inside the housing; air is mixed with the liquid and discharged through the outlet pipe. As a result, a vacuum is created in the housing, and water is drawn in through the inlet pipe.

By creating a flow inside the pump, the impeller acts like an injector, thereby creating a high level of suction force, which allows water to be pumped to a height of up to 20 meters, while its pressure and productivity are several times higher than those of centrifugal pumps of similar power.

Such features of vortex units are also due to very small (tenths of a millimeter) gaps between the rotating parts and the housing, so the pumped liquid must be free of mechanical impurities .

Rotary

The operation of a rotary water pump is carried out due to periodic changes in the volume of the working cavity. Hand pumps are most often built according to this principle. Such a pump consists of a cylinder moving inside its piston and two valves at the inlet and outlet; when the piston moves downward, the water in the cylinder is compressed, due to this compression the water is forced upward, and when it moves back, a vacuum is created, and the next portion enters the cylinder cavity water.

From this family, it is worth paying attention to vibrating submersible electric pumps - these are low-power water pumps, and at the same time they provide a flow of up to seventy meters. Thanks to their cylindrical body and compact size, they are convenient to use in wells.

The design and principle of operation of a vibration pump are similar to a manual one. The difference between them is that the piston of the electric pump is driven by an electromagnet, and the piston moves only a few millimeters, but due to the high vibration frequency, a of about one or two cubic meters per hour is ensured

Dirty water pumps

Pumps for dirty water solve more problems than their counterparts designed for clean water. They pump wastewater, pump water out of a basement or pit, supply moisture for irrigation, and even make fountains work. The design of pumps for dirty water allows them, without much damage to their design, to cope with water that contains a large amount of various impurities: sand, grass, clay, silt, feces and other small debris. In this article we will look at the three main types of dirty water pumps:

- drainage,

- fecal,

- fountain.

Drainage pumps

These pumps are indispensable when you need to get rid of a large amount of dirty water that has accumulated in one place. Such water is not only contaminated, but also a chemically aggressive liquid. Like clean water pumps, sump pumps are available in submersible, semi-submersible, and surface pump types. And by type - centrifugal or screw. And also most often they are equipped with float switches.

Submersible drainage pump Wilo Drain TS40

In addition to the float switch, the drainage pump always has a special inlet filter that prevents large debris from entering the device. The pump data sheet indicates the maximum amount of solid particles that it can handle. It is better that larger particles are not found in the working fluid.

But when choosing a drainage pump, you should pay attention not only to the “caliber” of pollution particles, but also to the location of the suction valve. Depending on this location there are:

- pumps with a suction valve in the bottom of the housing,

- pumps with a suction valve on top.

Pumps with an overhead valve have a long service life because... The risk of large debris getting inside the device is reduced. But the option is noticeably higher. To protect pumps with a suction valve in the bottom of the housing from becoming clogged with debris, they are installed on special stands.

Fecal pumps

Sewage or sewage pumps are mainly needed to ensure the operation of an autonomous sewage system at home. Structurally, they are very similar to drainage ones and differ from them in the presence of special knives that crush organic residues and even plastic before entering the working chamber of the pump. They are also made from materials with increased resistance to temperature and aggressive environments.

There are models of fecal pumps that are cooled by the pumped liquid itself and have a special cooling circuit. Of course, the latter are more reliable, but also have a higher price.

Submersible drainage/sewage pump Gilex Drainage 255/11 FN

Unlike pumps for clean water, semi-submersible pumps are somewhat popular among sewage pumps. In them, only the pumping chamber itself is immersed in liquid, and the upper part, where the engine is located, is located on a special float that can withstand exposure to an aggressive environment for a long time. Such pumps are inexpensive, they are easy to install, but they only work with liquids where the particle size of the contaminants does not exceed 1.5 cm, because they are not equipped with knives.

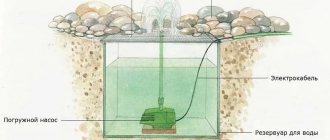

Fountain pumps

Fountain pumps allow you to equip a real fountain on your site. As a rule, a set of telescopic nozzles is sold along with a fountain pump, with which you can create a fountain jet of different heights and geometric shapes. There are surface and submersible fountain pumps.

Fountain pump DAB NINPHAEA 1

By the way, the fountain on the site not only pleases the eye, but also helps saturate the water with oxygen, which prevents it from blooming, silting and simplifies the care of the reservoir.

Features of pumping stations

The pumping station is so called because it is complex equipment that must be selected as clearly and accurately as possible in order to optimize the operation of the water supply system.

As a rule, hydraulic or centrifugal installations have additional elements in the form:

- Pressure gauges by which pressure is controlled;

- Hydraulic accumulators to stabilize pressure and water supply in order to reduce the frequency of switching on the device and its wear;

- Pressure switch - a parameter is set on it at which the equipment turns on and off to prevent overheating of the propulsion system.

. In addition, depending on where exactly the device will be located, since they are divided into surface and submersible models, there is also an additional division into well, borehole, drainage and motor pump.

Main technical characteristics of pumps

Performance - determines how much liquid the pump is capable of pumping per unit of time. Measured in cubic meters/liters per second/hour.

Pressure is a value characterizing the ability of the pump to supply water to the point of water collection, i.e. to where it will be used. Measured in meters.

Power . It exists in two forms: consumed or pump motor power and useful power. Power consumption is of little concern to the consumer. Much more important for it is the useful power of the pump, which characterizes its ability to pump a certain amount of liquid. Measured in watts or kilowatts.

Efficiency shows how consumed and useful power are related to each other and thus characterizes the efficiency of the pump. The more advanced the pump design, the less power loss and, accordingly, the higher the efficiency.

Igor Aksenov, Head of Purchasing Department NeoClima

“The float switch of the sump pumps is designed to not cling to the environment, so these pumps can operate successfully and reliably even in swamps.”

There are also a number of consumer qualities that are of secondary importance, but are important from the point of view of ease of use and the comfort of others. And also those that are inherent only to certain types of equipment. These include:

- noise level of a running pump,

- corrosion resistance of parts in contact with water,

- pump tightness,

- device diameter,

- the material from which the body is made,

- whether or not the pump is self-priming.

To estimate the required pump performance, you can roughly estimate the water supply in the house. Let's say, to take a bath you need a capacity of 300 l/h; for a washbasin, 60 l/h is sufficient; for the kitchen you will need about 500 l/h; for a toilet, on average, about 80 l/h. And for a bath you need about 1000 l/h of moisture.

To estimate the required pressure, you need to determine how far the pump must deliver water from the water intake point to the house. To the resulting figure it is worth adding 20%, which is needed to take into account the friction of the liquid passing through the hose or pipeline.

It is better to leave the calculation of pump power to specialists. And with efficiency everything is clear - the more, the better.