Benefits of a brick barbecue

Often, barbecues and barbecues in private homes are built using improvised materials: barrels, cylinders, welded elements. Recently, brick has become often used for such purposes, because it has a number of undeniable advantages over its competitors.

The way heat is distributed in brick products is very different. In open barbecues, the heat from the fire is directed upward, while the meat is processed on only one side. Therefore, during cooking, it is necessary to frequently turn the food to the other side to ensure even browning. Brick structures work on a completely different principle. The heat is reflected from the inner coating and distributed over the entire surface of the meat, ensuring uniform roasting. Thanks to this, the taste of the dish changes significantly for the better, the meat becomes softer and juicier.

Cooking with a brick barbecue Source fruugo.qa

The main advantages of a brick barbecue include:

- Uniform processing of food.

- You can build complex structures with additional functionality in the form of a smokehouse, grill, or cooking.

- With the help of decorative cladding, a barbecue can become a real decoration for any summer cottage.

Preparatory process

To build a barbecue, you will need to learn the basic rules and recommendations. These include:

- The grill must be installed with a height of about 70-80 cm. You also need to take into account the height of the owner.

- The stove should be installed 10 cm below the grill.

- Many people advise making a separate place for firewood and tools.

It is also necessary to pre-plan the construction so that using the barbecue is comfortable. You will need to draw up drawings, perform calculations and prepare a list of all necessary materials.

Drawing of a barbecue oven Source novamett.ru

The construction of a brick barbecue is carried out using the following materials:

- Facing brick.

- Clay composition.

- Steel sheet 5 mm thick.

- Metal rod with a diameter of 30 mm.

- Firebox doors and grate.

- Cement based mortar.

- Reinforcement bars.

- Boards for installation of formwork.

- Sand and crushed stone of medium or fine fraction.

The barbecue is built on a slab base, the frame is constructed using fireclay bricks. Then it will need to be treated with stone. You can use granite, sandstone or rubble type. The stove can be well decorated by changing the shape of the stone.

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

Fire brick

Fireproof (fireclay) brick

used in places where high temperatures are present, these can be: fireplaces, stoves, chimneys and other types of heating structures.

A simple red or ceramic brick will not last long in such conditions; it cannot withstand high temperatures and can begin to melt at temperatures above 1200 degrees Celsius. Due to the regular cycle of heating and cooling, this brick crumbles, which subsequently leads to its complete destruction. In such conditions, where there are high temperatures and regular cycle changes, fire bricks

will be the best choice.

It is made from fireclay refractory clay

, which is the main component in its production.

In appearance, fire brick

almost no different from simple red brick, but it can easily withstand temperatures above 1350 degrees.

The ability to withstand high temperatures is explained by the fact that refractory brick consists of 70% fired fireclay clay and 30% graphite or coke powder (these components are binders, they are added so that the brick does not crack during firing.) The weight of refractory fireclay brick is 3 .4 kg. scope of application - furnaces, chimneys, simple home stoves, fireplaces and even combustion chambers for oil and gases in the production of glass, porcelain and steel. Refractory brick

can withstand high temperatures for a long time and has a high heat capacity, thanks to which it is able to transfer heat to the room for a long time after the end of the fire.

Refractory bricks are divided into subtypes: basic, carbon, quartz and alumina. Two of these subtypes - carbon and basic - are used in steel production.

- The main one

is that a lime-magnesia base is used for its production; this type of refractory brick is used for the production of Bessemer steel. - Carbon

is the main material for constructing blast furnaces. - Quartz

- This brick is primarily composed of quartz and sandstone and does not involve contact with anything other than metal and fire. In particular, quartz brick has poor contact with various alkalis. - Alumina

- the temperature range of application of this type of brick is 1000 - 1300 degrees Celsius. It tolerates repeated sudden changes in temperature well. Convenient for use in household stoves; most household fireboxes are made from this brick.

Barbecue construction technology

As with any other building, creating a stove will require a high-quality foundation. The frame should look harmonious with the overall interior of a private house. Since the structure will be used throughout the year, it is recommended to give preference to the garden type of hearth.

The design of the barbecue must comply with basic safety rules; the roof must be equipped with a pipe. The construction of such a product is characterized by a rather complex technology. Externally, it looks like an ordinary stove, which is used to decorate a summer cottage.

Barbecue in the gazebo Source pikabu.ru

A barbecue can be arranged in a gazebo or a special pavilion, and it is not difficult to beautifully style them as a summer house or a fairy-tale hut. It is better to entrust all construction work to professionals, especially if there is no experience and skills. The main element of such products is a quadrangular frame in which coals are placed, after which it is covered with a grate. Experts recommend making the most functional stoves; for this purpose, firewood sheds are often installed below, shelves for dishes are attached on top, and a smokehouse can be installed even higher.

Multi-storey structures are difficult to implement, but at the same time they have advanced functionality. You will first need to select a fireplace design, draw up drawings and a construction plan.

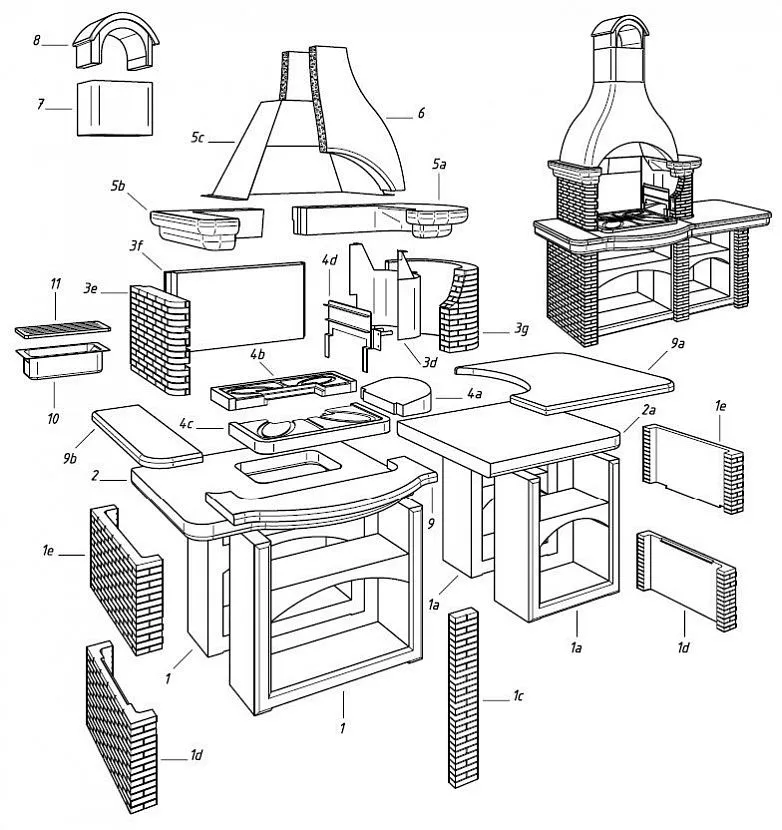

We are building a barbecue complex with a hob

Any home craftsman who knows how to work with brick can make an outdoor barbecue oven in his dacha. The purpose of this article is to help the homeowner correctly build a garden stove with his own hands, using a ready-made project with instructions. For convenience, we provide some drawings and examples of masonry.

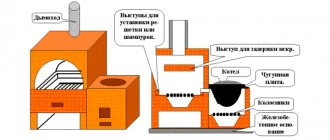

To build an outdoor stove on a summer cottage, we propose to implement the project shown in the photo. Let us list the technical features of the structure:

- 2 workplaces capable of functioning simultaneously - barbecue and hob;

- overall dimensions in plan – 1660 x 1020 mm, height – 3220 mm (including the chimney with the cap);

- the collection of flue gases from both fireboxes is organized into one pipe;

- the design is simplified as much as possible - instead of the arched arch of the firebox used in the Russian stove, there is a direct ceiling on a metal frame;

- under the kebab grill there is a niche for storing and drying firewood;

- the chimney is equipped with a closed brick cap, which prevents precipitation from entering the flue.

At first glance, the design of a universal barbecue stove seems complicated, but in reality it is quite simple to implement. It is better to place the structure under a canopy or inside a gazebo so that the masonry is not washed by rain and lasts longer.

Before starting construction, a platform measuring 176 x 112 cm must be provided on the veranda (a margin of 50 mm on each side of the stove body). Make sure that the chimney pipe does not coincide with the load-bearing roof beams, otherwise the roof will have to be redone. Reference. There is a simpler solution - build a barbecue outside in the form of a corner fireplace in which you can fry kebabs

Varieties of barbecue

When studying ready-made projects of brick buildings, do not forget that they can be supplemented with various elements, guided by personal tastes and preferences. Many additionally install a barbecue and cooking stove.

There are the following types of barbecue:

- Barbecue with fireplace or grill.

- Multifunctional buildings.

- Barbecue with fireplace.

- Design with barbecue and cauldron.

Additional components can vary quite a bit. An oven, cauldron, spit and other options are often used. Complex structures can be divided into types of manual masonry and composite.

Barbecue with fireplace Source nl.decoratex.biz

A rather original solution is to install a barbecue complex with a smokehouse. Such structures can be erected in the form of a three-tier structure. Food can be placed in a special chamber or hung. Hot smoking is done using wood, and cold smoking is done using a brazier with coals and a baking sheet with wood chips.

The disadvantages of such smoking structures include strong absorption of odors. Therefore, if meat is processed after fish, it may acquire an unpleasant odor or even taste. Using iron for arrangement will help get rid of this disadvantage.

A few words about barbecue oven models

The oven presented above is far from the only barbecue option on the site; you can use these instructions as a basis and develop your own model.

Here are some of the most popular designs:

| Image | General characteristics |

| Fireplace. Convenient small design designed exclusively for barbecuing. A small countertop around the perimeter of the base of the fireplace will be a good help. | |

| Complex: cauldron, grill and smokehouse. The central element of this complex is a smokehouse for hot smoking. The cauldron is built into the countertop, and the fireplace under the barbecue simultaneously acts as a barbecue. | |

| Stove with fireplace and sink. There is no barbecue here; instead, stands for skewers are made in the fireplace. A countertop with a sink and convenient cabinets for dishes turns the barbecue into a full-fledged kitchen. But the stove is not installed very conveniently; it is located too far from the work table and the owners will have to make too many unnecessary movements. | |

| Metal stove. A compact mobile barbecue oven made of metal is very convenient, the quality of cooking in such ovens is quite high, and the main advantage is that the structure can be easily removed if necessary. In addition, in terms of cost, such barbecues are several times cheaper than brick ones. | |

| Light brick oven. The easiest brick oven to make. Under such a structure there is no need to pour a powerful foundation slab. You can build this stove with your own hands right on the asphalt in your yard in one weekend. | |

| Corner stove. Perhaps the most convenient design, it follows the principle of the golden triangle, when the distance between key sectors does not exceed 2.5 m. The stove on the frying surface of the oven is also convenient because it has round removable rings, after removing which you can insert a cauldron into it. |

Video description

You can learn more about the construction of a barbecue from this video:

Firing and drying

Immediately after the construction of the barbecue, firing must take place. To do this, firewood and coal are laid and set on fire. This will help ensure internal firing of the surface of the structure. It is recommended to raise the temperature to the maximum possible.

After firing, you will need to ensure drying. In summer it will take at least 5 days, and in autumn or spring – 20 days. In this case, it is better to cover the structure with film to ensure protection from precipitation.

Barbecue oven with decorative cladding Source uslugio.com

After which the structure is decorated. The remaining mortar is removed from the bricks. If desired, you can perform decorative cladding using various materials. The barbecue will then be completely ready for use.

Types of bricks

Ceramic brick

made from baked clay, it has high strength, thermal conductivity, frost resistance and water resistance. Thanks to these properties, ceramic brick holds a high position among the variety of masonry materials. Ceramic bricks can be used for laying channels and chimneys in barbecues. And Vitebsk ceramic brick can also be used to build a barbecue firebox (barbecue).

Hollow brick

, also slotted and facing, is a brick with through holes, which can be round, oval, rectangular or square. Oval and round voids significantly reduce the formation of cracks during brick production. Also, voids make up a significant part of the volume and therefore less raw materials are required to produce such bricks than to produce solid bricks. Well, closed volumes of dry air increase the heat-insulating properties of the material, but only in this case, the masonry mortar must be thick enough so as not to fill the holes. This brick is not suitable for laying barbecues in places where there is contact with fire.

Solid brick

used for laying stoves, barbecues, fireplaces and chimneys. It can be embossed, in which case its use will be necessary in places requiring plastering (walls, partitions), because such a brick provides good adhesion to the plaster mortar. Solid bricks can be produced with technological voids in order to relieve internal stress during firing, which significantly reduces the number of cracks. Well, since solid bricks are generally produced without voids and with low porosity, its water absorption will be low to 8%, and its calorific value will be high. In cases where such bricks are used, additional insulation may be required. If we talk about the construction of a barbecue, then it is solid brick that needs to be used so that the structure is durable and not subject to destruction.

Clinker brick

has unique physicochemical properties. This brick has very low water absorption, which provides it with a high level of operational and decorative properties. The material can be used in aggressive environments, both for finishing and cladding. It has a rough texture that ranges in color from light yellow to dark brown. There are about a hundred shades developed by adding various additives to the raw materials. The main raw material for the production of clinker bricks is a special type of clay (lean clay), and mineral additives from igneous rocks are used as a charge. Solid clinker brick, well suited for laying barbecues in places such as ducts and chimneys.

Pressed (silicate) brick

is one of the most budget options for choosing bricks. Pressed brick has good compatibility with any type of masonry mortar; pressed brick also has high sound insulation. But qualities such as high moisture absorption and low thermal conductivity and fire resistance do not allow this brick to be used for laying stoves and barbecues.

af3f48d82b0f56ee074a49cca009da9b.jpe

01cfd8924e127f00a69e2d2e764eadbd.pic e3cc4f6b648109c2203905171e6434cb.jpe