Types and types of sliding gates

Design and design features of mechanisms and installation methods.

By opening method:

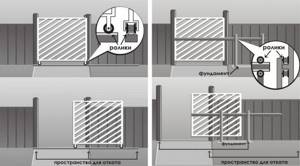

- sliding gates - consist of two leaves that slide in opposite directions. Visually similar to swing gates and combine the advantages of swing and sliding gates;

- sliding gates (self-supporting) - consist of one leaf (rarely two) that slides in one direction.

Installation of sliding and sliding self-supporting gates

The main advantage of sliding gates is that they do not require a lot of free space for operation. Among the advantages are the ability to connect automation, a more modern look, and ease of sliding even in the presence of snow.

By degree of mechanization:

- manual rollback (mechanical opening of the gate). Retracting the sliding gate leaf is absolutely easy. When planning to make a sliding gate with your own hands, many people prefer manually sliding the gate;

- automatic rollback . When designing and installing gates, the need for electrical supply and the installation of additional mechanisms are taken into account. Automation for sliding gates consists of: a remote control, an electric drive, an electric cable, photocells, and a signal lamp.

By type of guides:

- hanging type . In this case, the guide is installed on top, which limits the height of the gate;

- console type . For sliding gates of this type, a guide frame is installed at the bottom of the structure.

The simplest are gates mounted on a rail (Fig. on the left). The option is simple, but not very convenient, because... The bottom guide requires constant care. Otherwise, debris caught in the slide will cause the rollers to jump off and, over time, damage the mechanism. A more modern version of the device is sliding gates with a floating rail (Fig. on the right).

Sliding gates of hanging and cantilever type

It is how to make sliding gates from corrugated sheets on floating rails that will be discussed in the article.

Do-it-yourself sliding gates made of corrugated sheets

Step-by-step instructions for making sliding gates for a summer house or a private home.

Choosing automation for sliding gates

Although the sliding door opens perfectly manually, without creating any difficulties even for women, children and the older generation, it is still much more comfortable when everything happens automatically. To open (close) a light press on the key fob will be enough: you won’t have to get out of the car and waste extra time. Automating sliding gates is much easier and cheaper than swing gates. The main element of the control system is the drive.

Roman KostyuchikLeading Marketing Specialist

In order for the sliding gate automation system to function properly for years, when choosing a drive you need to pay attention to several basic parameters.

- Working life of the motor - the number of operating cycles of the electric drive depends on this indicator.

- Motor power - selected based on the dimensions and weight of the sash; the model range begins with a 500 W motor, designed for a structure weighing up to 500 kg.

- Operating temperature range - the equipment should function without difficulty at -60 ... +30 ˚С.

- Resistance to voltage surges - in the range of 160-270 V.

- Easy to manage - intuitive interface, quick setup.

- Versatility - if necessary, street lighting control and safety elements (photocells, warning lamp) can be integrated into the system.

Even in the standard configuration, automation not only increases the level of comfort, but also ensures the safe operation of sliding gates. At the same time, the cost of a basic automation kit with a drive, installation kit, remote controls and unlocking keys within the overall budget allocated for sliding gates is not so significant as to abandon it in order to save money.

Installation of sliding gates

Main stages of installation:

- installation of support pillars;

- installation of guides;

- fabrication and installation;

- laying and wiring of electrical cables;

- installation and testing of automation and power elements.

Installation of support pillars

To install pillars, three technologies are used depending on the type of soil - concrete, driven or screwed piles.

Concreting is used on soft and loose soils. To do this, dig a hole up to 2 meters deep, install a thick-walled steel pipe into it, level it and fill it with concrete. After the concrete has set in the pit, the pipe is cut to height and also filled with concrete.

On dense soils, steel screw piles are used. They are screwed into a pre-drilled hole of small diameter, after which concrete is poured inside.

On hard and rocky soils, both concrete driven piles and concreting are used, depending on the weight of the gate.

Installation of guides

After installing the support posts, carefully clean the side space near the fence to ensure that the gate can be opened. Then the guides are attached to the supports. They are welded to steel poles and secured to concrete supports using anchor bolts. Before fixing, the guides are cut to the required length, and the installation location is marked to within a fraction of a millimeter. To avoid skewing and jamming of the blade, the guides are set using a laser level.

For rail gates, in addition to the top guide, a bottom rail is installed. To do this, dig a trench across the passage and first lay sand and crushed stone cushions, then pour in a reinforced concrete cushion, on which the rail is installed. Installation of a hanging gate track requires the use of a crane and a construction hoist.

For cantilever gates, it is necessary to secure the upper guide to the supports and install the lower roller supports. In this design, the frame of the canvas is the lower guide, installed upside down. This makes installation easier, but places increased demands on the roller base. For rail and cantilever gates, rolling rollers and upper/lower traps are installed on the “return” post.

Read more about these devices in the article Automation and accessories.

Fabrication and installation of canvas

If the gate is small, our specialists will weld the frame in the workshop. If the size of the gate is so large that it is impossible to transport it to the installation site, the frame will be assembled from prepared and processed parts on site. The highest qualifications of our welders allow them to create ideally shaped frames in any conditions.

If the welder does not have the opportunity to connect to the electrical network, he will use a gasoline generator.

Having created the frame, the master will install rollers and carriages on it. After which he will install it in place and check how the gate opens and closes. Checking at all stages of production is one of the main reasons for the high quality of our products. After making sure that the frame perfectly matches the guides, the craftsman will cover it with materials chosen by the customer.

Making a sliding gate frame

Such gates are fully functional and differ from automatic ones only in the need to open and close them manually. To increase the comfort of using the gate, the technician will install and connect the automation.

Laying and distributing electrical cables

In order to properly install and configure the automation, it is necessary to supply electricity. To do this, the wizard will determine the optimal location for connecting to the electrical network, calculate the path for the cables and lay them.

Depending on many factors, the main one being safety, he will use overhead or underground cable laying. Then the master will carry out wiring to connect all automation devices, install terminals and prepare everything necessary for connection.

Installation and testing of automation and power elements

The technician will install and connect all the automation elements, assembling them into a single system, install the electric motor and gearbox, then check the operation of the power elements by applying supply voltage to them. After which he will connect the automation and fully test the operation of the system in all modes. If everything works properly, he will hand over the work to the customer. If any problems arise, the wizard will fix them and retest the entire system.

Read more about choosing automation and power elements in the articles Manufacturers and Automation and accessories.

It is not for nothing that sliding gates have gained immense popularity, because in terms of reliability, ease of installation and maintenance they are superior to any other type of automatic gate. Now you know what their design is, in what order sliding gates are made and installed. Our company will carry out all work on the manufacture and installation of such gates at the highest level, taking into account any of your wishes.

If you have any questions or would like to order sliding gates in Tambov , please leave a request. Our employee will contact you shortly.

Hanging gates

If we review sliding gates, suspended systems occupy third place in popularity among the three types of similar structures. They are used primarily in enterprises and in protected service areas. The support beam is usually a rail running along the top of the opening. On the beam there are roller mechanisms with a canvas attached to them. The lower part of the sash has no support.

Hanging sliding gates

Advantages of the suspension system:

- Durability. Suspension systems installed more than half a century ago have survived to this day. However, they still work properly to this day.

- Independent of weather conditions, as they do not have a lower point of support.

- Easy to manage.

Disadvantages of hanging sliding gates:

- The height of vehicles that can pass under the support beam is limited. Even though the top beam is placed quite high, there will always be a vehicle that does not fit into this frame.

- The installation of a suspension system requires significant financial investments. The height of the beam forces the manufacture of large-sized sashes.

Advantages and disadvantages of sliding gates

Sliding rail gates

Sliding gates have both advantages and disadvantages. But there are many more advantages.

Advantages:

- unlimited gate size;

- highest reliability;

- noiselessness;

- ease of operation and maintenance.

Flaws:

- the need for sufficient space on the side of the gate;

- the need for regular cleaning of roller bearings.

The main advantage over any other gate is the absence of restrictions on the width of passage for cars.

Frequently, trucks enter and exit the territory through sliding gates in two or three parallel lanes. No other type of gate can provide such a passage width. Another advantage is that opening the gate does not require a large free space in front or behind (depending on the direction of opening of the leaves), because the gate leaf slides to the side, parallel to the fence.

The phenomenal reliability of the gate is due to the absence of heavily loaded load-bearing elements, such as canopies or hinges. The entire load falls on the guides located parallel to the fence and to the side of the driveway. Thanks to the rigid fastening of the guides, the gate can withstand even strong winds.

When the blade is closed, the weight of one side rests on the guides, while the knurling roller and bottom catcher take the weight of the other side. The upper catcher provides fixation in the horizontal plane. Rail-type sliding gates place less load on the roller carriages, due to which this unit lasts much longer, but they are very sensitive to snow. If snow covers the rail, it will be impossible to open or close the gate.

Another positive quality is noiselessness. Due to the absence of heavily loaded moving load-bearing elements, friction losses are reduced. As a result, a motor of the same power as for other types of gates of similar size and weight operates in a lighter mode and produces less noise. Also, a gearbox with a rack and pinion operates in a lighter mode, ensuring the movement of the door leaf.

Opening cantilever sliding gates

The ease of operation and maintenance of sliding gates is directly related to their design and the absence of heavily loaded moving elements. Rollers made from ball bearings significantly reduce frictional resistance compared to hinges and awnings of swing gates, so less power is needed to open them. Thanks to this, the maintenance and operation of such gates is much easier than for any other types.

But sliding gates also have disadvantages, the main one of which is the need for sufficient free space on the side of the driveway to roll the canvas there. The wider the passage that the gate blocks, the more free space is needed. This reduces the scope of application of sliding gates. The second disadvantage is the need to regularly clean the roller supports (carriages and knurling rollers). Otherwise, it will be impossible to open or close the gate.

What is included in the sliding gate kit?

The correct choice of components is the key to the strength, mobility, and durability of the gate. The basic kit most often includes several important parts that you cannot do without during installation:

- Roller bearings are fasteners mounted into the foundation. The main task: to ensure the movement of the valves.

- The guide rail allows the gate to move on roller supports. It is the main one for fastening the gate frame.

- Brackets with rollers to support the gate leaf in a vertical position. They are attached to the top of the opening post.

- The plugs protect the guide from snow, moisture, and dirt, extending its service life.

- The end roller performs fixation in the lower catcher.

- The catcher is the final point of support for the sash in the closed position and allows you to remove the load from the roller supports.