Main advantages

Profiled sheets are one of the most durable building materials and are extremely popular. Due to its reliable coating, the material is resistant to various negative weather conditions. A huge assortment of different types of metal profiles allows owners of dachas and private houses to build various homemade products at their discretion. When choosing a profile, weight is of no small importance.

Thus, gates made from corrugated sheets are quite lightweight and easy to use.

In the country

Advantages of the material:

- Resistance to corrosive processes. This is achieved through the use of new modern protective coatings. The service life of a fence made from a profile sheet can be more than 50 years.

- Increased strength of sheet metal. Due to this, the entrance gate can withstand high mechanical loads and strong gusts of wind.

- If the required materials are available, manufacturing a gate structure from corrugated sheets takes 2–3 days.

- The small thickness of the corrugated sheet makes this material quite light, so you can install it yourself.

- Easy to care for. The professional sheet does not require special care.

- Affordable price of material for the manufacture of gate systems. Do-it-yourself wickets and gates made from corrugated sheets will cost much less than forged products.

- Savings on finishing. The corrugated sheet is not exposed to ultraviolet radiation, therefore it does not lose color over time.

- It is possible to construct a fence of any height, since the maximum size of the profile sheet can be up to 12 m.

- You can choose any texture, pattern, color scheme, taking into account the developed project.

After installation

However, judging by the reviews on construction forums, there are certain disadvantages:

- Low quality material cannot guarantee the positive properties listed above, so it should only be purchased in specialized stores.

- Low level of sound insulation.

- If the thickness of the profile sheet is small, it will be easily damaged by a blow from a heavy object.

- Corrosion is inevitable even after minor damage.

Installation of locks

Gates and wickets made of corrugated sheets. We cover the frame.

When working with corrugated sheets, two questions inevitably arise. The first is how to fasten it? And the second - how to cut it? With fasteners, everything is simple: it is most convenient to attach the sheet to the frame with self-tapping screws with a washer and a rubber gasket. Generally speaking, this is a roofing fastener, but here it will not be superfluous, because... the rubber gasket will protect the joint from moisture, and thus protect the metal from corrosion.

Such screws are available for both wood and metal. However, if your frame is welded from metal, then you will still have to drill guide holes for the screws, so stock up on a good drill. Or better yet, two!

With cutting, the situation is much more complicated. Cutting corrugated sheets with a grinder is not the best idea, since the abrasive disc strongly heats the metal, burning zinc and the polymer coating that protects the sheet from corrosion. It is best to use metal cutting shears. They are available both manual and electric.

Another viable option is a jigsaw.

If you still have to use an angle grinder, take the thinnest disc (1mm) and try to cut in one confident motion without interrupting the cut. Otherwise, the grinder will have to be inserted again into the cut that has already been started, and as a rule, this cannot be done accurately. In any case, the edge will not be perfect. Regardless of what you use to cut the corrugated sheets, try to plan everything so that only the factory edges of the sheets are visible in visible places.

As you can see, in order to successfully make gates and wickets from corrugated sheets with your own hands, you will need at least three to four days.

In order for gates and wickets made of corrugated sheets to have a more attractive appearance, simple decorative elements can be welded onto the frame.

Gates made of corrugated sheets acquire a special delicacy and aesthetics even with minimal forging elements in combination with corrugated sheets “like wood”.

Making gates and wickets from corrugated sheets with your own hands is not a super difficult task, however, it is advisable to have some special tools and at least a little knowledge of either welding or carpentry. Anyone can do this if they want!

Main types

Taking into account how the sash will open, fence gates made of corrugated sheets are divided into two types: sliding or swinging. Each corrugated sheet design has advantages and disadvantages.

Swing structures made of corrugated sheets

This type of gate structures made from corrugated sheets is the easiest to install yourself. Swing products have two supporting pillars, where the doors, galvanized with a metal sheet, are attached.

Gate and wicket option

Installed garage door systems can be opened manually or equipped with automation. Moreover, an electric drive can be built in for sashes of any size.

How to make gates from corrugated sheets: video tutorials

If the work is new, then even after the photo report, questions may remain. Video tutorials on the topic can clarify some of them. To begin with, repeat the technology described above: we assemble the frame directly on the installed poles.

The same technology, in photo sequence.

The second video is about how to properly weld a frame when connecting pipes at an angle of 45°. The approach is professional.

Those who have not dealt with welding gates or doors before may have questions about how to weld hinges. It's not as simple as it seems. Let's watch the next video tutorial.

For a more precise explanation of what movements to make when welding gate hinges, where to direct the electrode and other nuances, see the following video.

The best posts

- Beautiful DIY boxes for storing things

- Landscape design of a summer cottage: some features

- Choosing wallpaper for the hall: various combination techniques

- Do-it-yourself bench from a profile pipe

- Cross stitch embroidered paintings: large cross stitch, photo, how quickly, video and gallery, drawing on canvas, flowers and frame

- Bathroom design 3 sq m

- Quilling, decoupage, papier-mâché, decor and other wonders made of paper

- Beautiful Arco lamp in different films

Features of choosing a profiled sheet

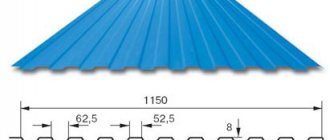

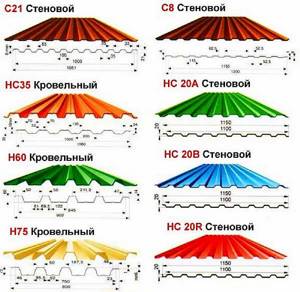

When purchasing a profile sheet, you need to pay attention to the protective coating and designation. Corrugated sheeting differs in corrugation height, shape, and thickness of the product. It is the corrugation that is responsible for the rigidity of the sheet.

Designation of corrugated sheets:

- “N” – carrier. It is used for cladding iron hangars and arranging the roofs of large warehouses. It is not recommended to make conventional gate structures from this material.

- “NS” – universal. It is used for arranging roofs, constructing gate structures, and fences.

- “C” – wall. It has a low corrugation and a small thickness. Used for cladding fences.

Options for corrugated sheets with dimensions

The numerical designation is the height of the corrugation. For assembling gate systems, profile sheet C8 or C10 is recommended.

The profile sheet, in addition to galvanizing, must be coated with a polymer, which improves resistance to mechanical loads.

When choosing a color scheme for the design of the gate system, you can look at different pictures and determine how the corrugated sheet will be combined with the fence, gate, and other buildings.

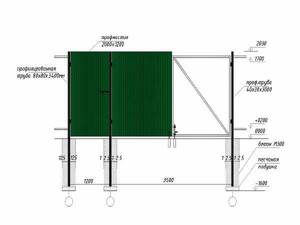

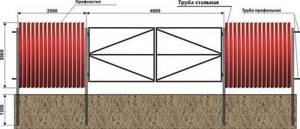

Structural installation diagram

DIY profile gates

The most popular design options for gate systems made from corrugated sheets:

- sliding;

- lifting;

- swing

The choice of a gate system depends on the individual preferences of the home owner. The gate can be built into the leaf, or you can build supports for it separately from the main gate system.

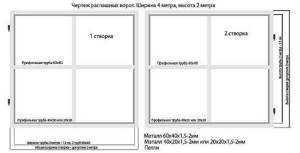

Gate frame dimensions

Manufacturing of swing systems

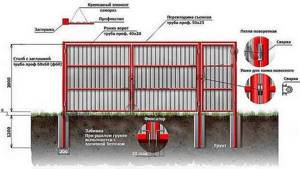

Before you figure out how to weld gates from a profile, you need to prepare drawings, diagrams, and sketches of the design of gates from profiled sheets. The following should be indicated there:

- overall width;

- number of stiffeners;

- place for installation of canopies.

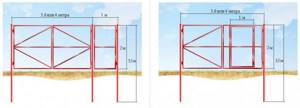

Sash designs

Even such a simple design as a gate leaf or wicket can be made in different ways, and there are many options. First of all, the location of the jumpers differs:

- obliquely;

- horizontally;

- crosswise.

Each method is tested and works, providing a sufficient degree of rigidity. Here you choose what seems more correct or reliable to you.

Gate design made of metal profiles with jibs

There is a difference in the design of the gate itself - with or without a stationary frame (top crossbar). With a frame, the gate is more stable, but then there are height restrictions: tall vehicles - trucks or special equipment - will not be able to enter the yard. With proper reinforcement of the racks (pillars) and properly made doors (with reinforcement in the corners), gates without a frame will also be reliable.

Gate design with top crossbar and crossbars

When installing a gate with a frame, the metal consumption is greater - per the length of the lintel, but the pillars can not be additionally reinforced: the load on them is less.

Cross-shaped lintels on metal profile gates

To make it more convenient to attach the profiled sheet, a thin-walled metal profile 1 cm wide is welded along the outer (sometimes internal, as in the figure above) perimeter of the sashes. This must be taken into account when determining the dimensions of the blanks for the sashes.

To make the structure as rigid as possible, so that it does not “walk” or make noise in the wind, reinforcements are made in the corners. And again there are two ways. The first is to weld the corners cut from sheet metal.

Reinforcement of sashes with metal plates

The second is to install short corner jibs from the same pipe that was used to weld the sash frame.

The second method of strengthening gate leaves

There is also a difference during assembly: at the joints, the pipes are connected at an angle of 45° or simply end-to-end. More professional - at 45°, easier - end-to-end. Some assembly methods do not provide for the possibility of connecting at an angle at all (if both doors are assembled in one piece, and only those hung on poles are sawn into two parts).

Different methods of joining pipes

Another subtlety that depends on the amount of snow in winter. As you can see in the photo, the bottom bar of the sashes is raised to different heights from the ground - somewhere a few centimeters, somewhere 20 cm and higher. Depends on the height of the snow cover in winter: if snow piles up and the gates are as high as the ground, you won’t open them. To prevent any living creatures from climbing into this gap in the summer, after the snow has melted, a plank is screwed onto the screws, and in late autumn it is removed again.

Related article: DIY button crafts - master classes and ideas for creating unusual things (42 photos)

You can install automation on swing gates. Then you can control them from the remote control and there is no need to go out into the snow and rain.