Advantages and disadvantages of installation

Swing gates consist of two or one wings mounted on posts. They can open both outside and inside the yard, and be either automatic or mechanical.

This type of fencing has a simple and convenient design.

As a rule, such structures are made 5-6 meters high to ensure the safety of the private sector from criminals. The design often includes a gate that will allow you to enter the yard without opening the entire door.

For additional convenience, an additional passage is made

Installing swing gates has both pros and cons. Let's take a closer look at them.

Advantages:

- Relatively low cost in comparison with other types of structures;

- Simple installation, which with proper skill can be done independently, long service life;

- The ability to implement your own designs and developments into the design;

- If the opening in the fence is not limited by anything, you can install the gate to the size of any vehicle.

Swing gates have a number of advantages

Flaws:

- During installation, it will be necessary to carefully strengthen the pillars by burying them deeply and concreted;

- Such a device is difficult to use in conditions of frequent strong winds, since it will not be easy to open and hold them;

- Installing automation can significantly increase the final cost.

The fence also has its disadvantages, which must be taken into account without fail.

Types of metal garage doors

- Swing gates.

This most popular design opens as the front door to a house. The number of doors in it varies from one to two; they can be metal or wood. In order to insulate the gate, any insulating thermal material is laid inside.

The hanging part is secured to the side posts or into the opening using hinges. You can open the gate either inward (which is not always convenient and is rare) or outward.

There are several main advantages of swing gates:

- ease of assembly and operation;

- low price;

- the ability to adjust and fit into the opening of any configuration;

- excellent resistance to burglary.

The disadvantages include the large area required to open the gate, especially in winter, when clearing the area to open the garage is required.

- Up and over gates.

The design of this product consists of guides along which rollers move, attached to a solid sheet of metal. The latter is necessarily reinforced with overlays, after which it is covered with plastic or metal, onto which polymer has previously been applied.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

The gate opens upward and is placed under the garage ceiling, which significantly saves space. The width of such a product cannot exceed 3 m. Therefore, this design is not suitable for garages with two or more cars.

The main advantages of this design:

- ease of opening;

- space saving;

- good thermal insulation;

- low cost;

- resistance to burglary.

The disadvantages are:

- complete replacement of the canvas even if a small area is damaged;

- The height of the garage must be sufficient for the door to open upward, that is, it is difficult to use them in low rooms.

- Lift-guillotine gates.

Just like up-and-over gates, these gates are a solid sheet that slides upward. Opening occurs silently and easily due to a torsion spring - a shock absorber that balances the entire structure.

The advantages of the gate can be considered high thermal insulation values (due to the tightness of the connection to the wall) and their tightness. The downside is that you need space to move the gate up, above the entrance, which not every building has.

- Sectional doors.

Several panels assembled together create a canvas that rises and folds into the space under the ceiling. The most common material for sections is sandwich panels with gaskets for a tighter fit to each other.

The advantages are: the current appearance of the product, a significant period of its use and space saving. The disadvantages include the high cost of the gate, maximum width not exceeding 3 m, and low resistance to burglary.

- Rolling gates.

The fabric of the product is composed of 10-centimeter panels, the material for which is aluminum or steel. The drum winds the web due to the flexible connection of its parts. The structure can be placed outside or inside the garage. The inside of each panel contains polyurethane. Rolling gates have gained popularity due to their relatively low cost. They began to be used in garages, restaurants, various stores, etc.

Their advantages include:

- ease of installation;

- small sizes;

- low cost of the product.

The disadvantages of roller gates are:

- low heat-saving qualities;

- resistant to burglary.

- Sliding gates.

Such gates are also called sliding gates. Rollers are fixed to the product canvas, which are installed on the upper and lower rails; the gate moves along them. At the same time, 5 to 6 m of space is required along the fence to move simple sliding structures.

Currently, the latest versions of the product have already been developed - telescopic. What gives them modernity is the ability to save space for opening, since the gates are retracted inside themselves.

The main advantages are:

- long service life and high reliability;

- aesthetics;

- ease of practical use.

The disadvantages include:

- high cost;

- the need for large free space for opening.

Swing metal gates with a wicket. Photos and descriptions of construction types

Metal structures have a number of different configurations, based on which you can choose the best option.

Frame with mesh

This option is perfect for those buildings where sun is needed for plants. This type can be made with any decorative elements, and, in addition, has a low cost.

Mesh gates

Gates made of corrugated sheets with forging elements. Photo and description

Gates made of corrugated sheets with forged elements have recently become increasingly popular. The photo shows that the structure is strong and durable. In addition, this material has a wide range of color and design solutions, and gates from corrugated sheets can be made with your own hands.

Corrugated sheeting is a durable and strong material

Forged mesh gates. Photo and characteristics

This design has a stylish appearance, and, despite its fragile appearance, it has a very strong frame. In addition, it has a relatively low cost.

Wrought iron gates - a stylish and durable solution

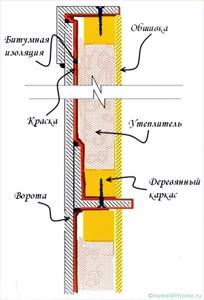

With additional insulation

This solution is most often used in harsh climates, for garages or sheds. A variety of materials, including wooden boards, can act as insulation.

Gates with insulation are a reliable option in severe frost conditions

Helpful information! When choosing, pay attention to the material from which the fence itself is made, since the design should combine favorably with it.

What to pay attention to

When choosing metal gates, you should first decide on their type, depending on your conditions and financial capabilities. Fence manufacturers will be happy to help you with this; they can show you numerous photos of metal gates and give you the necessary recommendations.

If you are limited in funds, then you need to take into account a few tips that can reduce your financial costs:

- Pay attention to the draft of your order. If you don’t have extra money, then it’s better to choose standard options, which will always be cheaper than individual ones.

- The design of the gate significantly affects its final cost. If you need to save money, it is better to choose simple gate designs that are not burdened with decorative elements and represent the correct geometric shapes. If the appearance of metal gates plays a decisive role for you, then it is better not to skimp.

- You need to inquire about the quality of the material. Raw materials for future gates must comply with GOST. Most often, such material is used by large manufacturers who, through wholesale purchases of raw materials, obtain lower material costs.

- All elements of metal gates must be wear-resistant, corrosion-resistant and take into account the likelihood of mechanical damage. Therefore, it is better not to skimp on the quality of raw materials.

- The manufacturing process of metal gates is very important for their further operation. It is necessary to avoid unscrupulous entities who try to organize the production of gates using the simplest tools, due to which the quality will suffer greatly. And even the low price of such gates will not be able to compensate for the inevitable errors in the design.

- Therefore, it is preferable to deal with large manufacturers who have sufficient material and technical resources and are able to set up the production process of metal fencing with maximum precision.

- Painting finished metal gates is necessary not only for the aesthetic appearance of the product. The coating prevents corrosion and protects against precipitation. Therefore, it is important that the entire surface is painted evenly and in sufficient quantity. The maximum effect can be achieved with the help of special equipment, which is available from reliable manufacturers, and the use of a conventional roller or paint brush is highly undesirable.

To ensure that the gates you install in your dacha or garage serve for a long time, you should approach the process of selecting and installing them very carefully. It is best to turn to reliable specialists and ask for reviews from other clients. High-quality and correctly installed metal gates will not create problems for the owners and will reliably protect their property.

Construction of swing products, recommendations for choosing material

Any swing metal gate with a wicket, the photo of which is presented above, consists of the same set of elements:

- The frame on which decorative elements are installed.

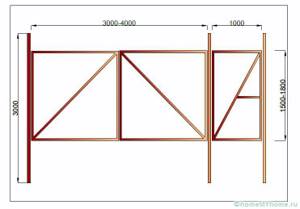

The frame is the basis of any structure

- Sheathing that is attached to the frame.

Sheathing fills the space of the structure frame

- Loops on which the frame is hung.

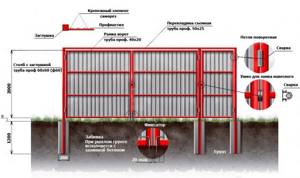

- The pillars that support the entire installation.

- A locking mechanism that allows you to close and open the gate.

To perform the installation you will need a whole arsenal of materials and various tools: sand, cement, crushed stone, brick, paint, nails. If you decide to make swing gates with your own hands (drawings, photos and videos are presented below), then you will need, in addition to the above, additional devices: an angle grinder, welding, various brushes.

It is easy to build such a building with your own hands. Drawings, diagrams, sketches and designs are freely available on the Internet

Installation

When installing the gate, you may need the following tools:

- Welding machine;

- Drill/hammer;

- Angle grinder;

- Level;

- Plumb;

- Fasteners;

- Concrete mortar;

- Small metalworking tools.

You can install swing gates yourself

Metal gates require periodic painting

Gate installation includes several stages:

- Site preparation. You should measure the length of the gate and the length of the opening again to finally ensure their compatibility;

Installation diagram for swing gates with a wicket made of corrugated sheets

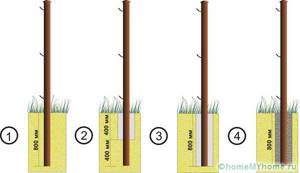

- Installation of pillars. Their number depends on the type of gate. For a design with two sashes you need 2 pillars. If a gate is installed nearby, there should be three posts. Installation begins from the outermost pillar. It is aligned horizontally and vertically. Then it is filled with concrete;

Installation of pillars

Advice! Pour some solution into the hole before you insert the post so that it does not come into direct contact with the ground.

- Installation of sashes. Often the hinges are welded before installation. However, in some cases they have to be leveled after the pillars have been poured. Before hanging the doors, the hinges should be lubricated with grease or oil;

Installation of gate leaves

- Primer and painting. The final stage is to clean the gate and give it the desired color.

Selecting materials

It is necessary to approach the choice of materials for swing metal gates with a wicket with all responsibility. Photos, descriptions and other characteristics must be carefully studied.

Choice of skin:

For this design, durable, strong material must be used. If this is a tree, then it must be additionally protected from rotting and treated against the appearance of various wood parasites. If you plan to use corrugated sheeting, choose class C, N or NS.

Corrugated sheeting must be class C, N or NS

Choice of material for the frame:

- Welded frame – has the greatest durability and strength. Not suitable for automatic gates due to its impressive weight.

- The aluminum frame is an excellent reliable option for automation, as it is light in weight.

- The bolted frame is the easiest to manufacture, but also the least durable.

Helpful information! To create a frame, use metal, as it can withstand adverse influences more easily than wood.

Metal is the best option for a gate frame

Selection of material for pillars:

- Brick is a strong and durable option that can withstand the weight of large structures.

Brick is highly durable

- Concrete is the most reliable material, which, among other things, lends itself well to processing and cosmetic repairs.

Concrete is the best option

Installation: step by step instructions

With the right approach, it is easy to install any structure, such as mesh or wrought iron gates. Photos and detailed descriptions will help you get the job done easily and simply.

- The first step is to draw up a detailed drawing with all the necessary calculations for do-it-yourself swing gates. Drawings, diagrams, sketches and designs are easy to find on the Internet.

Example drawing

- The support is being installed. To do this, a support is immersed in the hole, and the remaining space is filled with construction waste and filled with mortar.

Options for concreting metal supports

- The frame is installed along with the installed sheathing.

Swing metal gates are ready

Drawing conclusions

So, in this article we were able to disassemble the design of swing gates, their types, materials for manufacturing and step-by-step installation. Be sure that by carefully preparing and studying the proposed materials, you will be able to bring even the most complex idea into reality.

A thorough approach is the key to success

It is important to remember that you can only get a durable and reliable design by approaching the work responsibly.