Projects made from virgin natural materials

The designs of many log gazebos surprise with their uniqueness. If for rounded material there are traditional ways to build a log house, then for buildings made from unprocessed trees there are no architectural rules at all. In the latter, relying solely on the original imagination of the master.

Practice has shown that logs of the largest cross-section are used as the main supports of the frame, and all other heterogeneous elements are used as additional ties, decorations and to create a unique shape for the gazebo itself.

Structures made from untreated wood will require several large trunks and large branches. It’s not easy to find such material – you can’t buy it in a store. It will be useful to find one of the mature trees on the site. Cutting it down should not harm the appearance of the yard.

If this is not found, there is a way out to contact local lumberjacks or woodworking companies; they will certainly give away uneven sections of trunks for next to nothing.

The shape of a structure made from original logs may follow the configurations of conventional gazebos, but often has its own unique design. For example, such a masterpiece as a “mushroom” made of a log in the center and a round roof can hardly be included in the usual architectural projects.

It is difficult to give advice on assembling such ambiguous structures: this is a matter of individual construction technique. Several general laws in the construction of gazebos include achieving the following necessary qualities:

- strength of the building;

- its ability to withstand external climatic loads;

- the quality of fastening elements to each other to ensure safety during operation (heavy logs of non-standard parameters are the most dangerous if the mechanical balance of the structure is incorrectly calculated);

- safety precautions when installing heat sources (stoves, barbecues, etc.) inside the gazebo.

Rounded logs are the basis of reliable construction

Thanks to processed materials, a gazebo made of logs is built in the correct geometric shape using traditional construction technologies. Coniferous trees (spruce, pine) are optimally suited and are used most often. The diameter of the log is chosen to be the same for the main frame of the gazebo - from 200 to 280 mm. It is convenient that the material is sold ready-made with standard sections - you just need to calculate its quantity for individual projects.

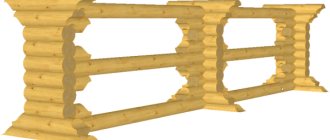

Gazebos made of rounded logs have the usual geometric configurations: hexagon, rectangle, combination, etc. The buildings differ from their counterparts made of timber, metal and other materials in the technology of the frame - it requires the obligatory bracing of the corners with horizontal logs - log house. Only the angle of connection of these elements depends on the number of conditional walls.

Thematic material

:

- Wooden gazebos for summer cottages

- Gazebo made of profiled timber

A special feature is that log gazebos may not have vertical posts - their function is performed by crossing logs that are rigidly connected to each other. The critical parts of wooden elements are the places of the so-called cutting - the connection of parallel and transverse ties.

A difficult stage in the construction of a gazebo is cutting out the connecting cups and feet in all the logs that make up the log house. It is recommended to entrust this matter to a professional or purchase already prepared elements.

How to build a brick grill fireplace in a gazebo?

First, waterproofing sheets are laid on the foundation where the brick barbecue fireplace will be located and a solution is prepared in which clay and sand have a predominant content.

Photo 11. Laying waterproofing on the foundation site where the barbecue will be located

Photo 12. First of all, draw out the corners of the grill

Photo 13. Bricklaying under the water level

Photo 14. Red facing brick on the outside, heat-resistant fireclay inside

To ensure that the masonry is level, you should use a water level and a counterweight. First of all, the outer corners of the stove base are exposed using red facing bricks.

Fireclay heat-resistant bricks are used to lay out the inner layer of the barbecue. This guarantees it a long service life.

Photo 15. Construction of a brick grill for a gazebo made of logs

Choosing a foundation

The base for a gazebo made of rounded logs must be strong, since the building is heavy and has a high load-bearing load.

Monolithic

Suitable for gazebos with a stone stove, large cross-section of logs, as well as closed and combined structures.

A pit is dug under it, with a depth slightly above the freezing level of the soil. The lining is sand and crushed stone; a reinforcement frame is installed in the formwork and filled with concrete mortar.

Tape

Suitable for lighter buildings, as well as gazebos of combined geometric shapes (several “rooms”). A trench is dug along the perimeter of the future walls.

Columnar

Designed for light summer options. Typically, supports are installed under the concentration points of the gazebo (corners, doors). The columnar base is formed from a cushion (backfill made of non-heaving materials) and a square-shaped brick structure. Screw piles or concrete blocks are also used.

Loghouse assembly technology

“The logs seem to hang on each other,” an ignorant person will say. An amazing example is how in Ancient Rus' they managed to implement wooden projects without a single nail. The frame of the gazebo is really a single-layer row of logs stacked on top of each other in height.

The secret of keeping them in constant balance lies in their connection. In each log of the gazebo, laid on top of the previous one, a recess is formed at the junction of the round surfaces - a longitudinal bowl. Such that when the trunks are placed, they fit tightly together along the entire length. The thickness of the excavation is approximately a fifth of the diameter of the trees.

Since arbors made of rounded logs do not require completely closed walls, part of the space between the roof and the lower ties remains unfilled or is retained under a double-glazed window. A frame element is needed that will serve as an intermediate support.

It can be a small log house formed by crossing short logs in the corners of the gazebo - a kind of rack. Such columns are erected at the site of each support. The intermediate post of the gazebo can be a log of the same cross-section, installed vertically at the intersection of the lower ties.

A decorative log house is formed in a similar way - a certain shape can be “cut” from any part of the wall, leaving only the corner joints untouched. A traditional architectural solution is the formation of spacious windows in the upper part of the gazebo. Small patterned cutouts are often made in the lower screed.

Connection "in the paw"

The transverse connection of the ties is carried out using two methods: “into the paw” and “into the bowl”. The first log house is characterized by savings in material, but is characterized as more complex and labor-intensive. It involves processing the ends of the logs for joining. Cutting down trees prevents elements from moving in the longitudinal and transverse directions - it firmly holds them together.

The processed ends are 1.5-2 diameters long and have an irregular quadrangular shape. The edge turned inside the wall should be 5-7 cm larger than the external one in height, and the internal thickness of the joint should be the same amount less than the end one. The cutting parameters must be kept identical for all crossed trunks.

Assembly options: 1) “in the paw”, 2) “in the bowl”.

“Bowl” connection

The cup connection is simpler; the process of assembling a gazebo is reminiscent of building a children's pyramid. At a distance of 1.5 log diameters from the end, a round recess is made in the trunk for a transverse log with a thickness up to the core. The elements are laid alternately from each of the two walls. As a result, some of the wood protrudes from the edges, and the outer corners become cross-shaped.

How to make floors in a log gazebo?

Attention!

Since wooden floor elements may be exposed to moisture accumulated on the ground, they are treated with a protective compound before installation.

First, fasteners are prepared from metal studs and profiles for the installation of the logs, into which the logs from edged boards 40 by 120 mm are then tightly laid (Photo 41, 42).

Photo 40. Metal fasteners for wooden logs of the gazebo floor

Photo 41. Installed wooden logs under the flooring of the gazebo

Floor boards are laid on the finished logs, for which edged pine boards are also used (Photo 43).

Photo 42. Flooring in the gazebo

Since the gazebo is semi-closed, under certain weather conditions moisture can get inside it, therefore, when laying floors, gaps are left between the boards for water drainage, their size is up to 5 mm.

Roof construction

The roof of the building should not be heavy; it is characterized by lightness and rigidity. Strength is assessed taking into account external loads - wind and precipitation. The gazebo rafter system does not differ in construction approach from conventional roofs - the elements are the same:

- Mauerlat - the last row of log framing is used.

- Rafters are smaller section logs or beams.

- Ridge purlin is a vein at the intersection of rafters. It is recommended to use timber.

- The pediment of the gazebo, if there is one, is made from a pyramidal row of logs of the same section as the log house. The connection is made with the outer rafters.

- The sheathing for the roofing of the gazebo is attached across the rafters. Usually these are thin slats or boards of small cross-section.

The roofing covering is selected taking into account the design. Bright colored shades and variegation are not suitable for chopped arbors. Stylistically, moderate tones matching the color of wood or paintwork are more combined. Projects where a log frame and a wooden roof (with waterproofing) are combined are considered pristine and unified in execution.

Protecting a material means extending its life

It is necessary to treat the surface of the wood after it has dried. This is a long natural process that can take more than a year. Antiseptic is the main protection of the gazebo from harmful insects and fungi of all types. After a while, a fire-resistant mixture is applied as a second layer for fire safety. And only the last, after thorough drying, are used coloring agents: primer, varnish, enamel and others. It is strongly recommended to put the gazebo into permanent operation after ensuring all levels of protection.

We make the steps of the gazebo

Photo 43. Blind area for installing staircase steps in a log gazebo

The steps of the gazebo are also made of logs. To do this, one post is split lengthwise in the middle into two parts, the cut points are sanded with emery cloth.

Massive staircase railings and balusters made of cedar or pine logs.

Photo 44. Log staircase to the gazebo

At the end of the work, all wooden surfaces of the structure are coated in three or four layers of protective primer based on alkyd resins.

After the primer has dried, we paint the resulting gazebo in the color of dark walnut with a moisture-resistant glaze that can easily withstand temperature changes, while the structure of the wood remains visually visible, which does not impair the aesthetic beauty of natural wood.

To protect the floor surface from abrasion, we cover it with two layers of clear varnish.