An integral component of a suburban area is its enclosing structure. A fence made from high-quality, beautiful materials should fit into the overall picture of the local area and be in harmony with the style of the house.

Fence with concrete pillars

Timber fence

The fence should perform not only an aesthetic function, but also a main one – protective. The site should not be exposed to noise from the street, dust or prying eyes. The strength and reliability of the fence structure directly depends on the material from which the supports or pillars are made, and the method of their immersion in the ground.

Like fencing materials, there are different types of fence posts.

Rubble stone fence

Driving posts

Drive-in fence posts are the simplest and most economical method of driving fence posts into the ground. It is recommended for temporary fencing, for example during construction. The reason for this is the unreliable fixation of the pillar in the ground. If the driven pipe is not concreted, it will quickly collapse due to moisture penetration. Even if it was previously painted. The issue of arranging reliable supports for the fence cannot be solved by driving in posts.

Fence with decor

Fence with wooden posts

Wooden pillars

This once traditional material for the construction of fences and their constituent structures is increasingly being replaced by modern materials. However, constructing a wooden fence is an inexpensive and accessible method of fencing.

Wooden fence posts have a short service life, which can be extended after treatment with special compounds that protect the wood from rotting and pests. The need for annual treatment of wooden supports makes the operation of such a fence troublesome.

Wooden fence with brick pillars

If, after all, the choice fell on wooden fence posts, then it is important to know some of the nuances of their use:

- Coniferous wood is the least susceptible to rotting;

- Oak posts will be the most durable;

- It is not recommended to use timber due to the fact that it does not have a protective layer against rotting;

- To protect the wooden post from direct contact with the ground, a steel pipe is installed on its lower part or fired and a resin layer is applied. You can also use antiseptics or paint the surface of the pillar;

- When choosing wooden fence posts, you need to pay attention to ensure that there are no defects on their surface: chips, cracks and other damage;

- Preference should be given to solid wood supports.

The positive qualities of wooden supports include low cost, ease of installation, the possibility of self-production, environmental friendliness and the noble, natural appearance of the selected surface.

A wooden post can have different shapes, it can be painted or decorated with different options. The disadvantages are sensitivity to precipitation and short service life.

Fence with oak posts

Stone pillars

Stone has long been used in the construction of fences as often as wood. But it differed from the latter in strength and long service life. Manufacturers offer a variety of decorative stone materials:

- Cobblestone. It is also called boulder stone. This is the most economical option and has very high strength. It has a rounded shape, which makes the surface of the fence textured. To obtain a smooth texture, the boulder can be divided into two parts.

- Pebbles. Due to its small size, it is used in combination with larger products. To make the fence durable, it is recommended to choose brick as the material for the corners and base.

- Dolomite. It has a flat shape and different dimensions.

- Shell rock and marbled limestone. Despite its softness, this rock is strong enough for the construction of fence posts. Limestone absorbs moisture quickly, but also evaporates quickly due to its porosity. Treatment with water repellents improves the characteristics of this material.

- Sandstone. A common material that is moisture and frost resistant. When processing, you can achieve a smooth polished surface.

By installing stone fence posts, you can be sure that they will last a long time and blend harmoniously into the surrounding landscape.

Fence with granite pillars

Fence with stone pillars

Brick pillars

Brick fence posts always look solid and neat; they can be used with various types of materials, including forged sections, polycarbonate, wooden boards, silicate or ceramic bricks. But when assembling such pillars, the use of reinforcing reinforcement is required, usually metal rods or a special mounting mesh. The distance between individual supports can be different, it depends on the height of the fence, the material of the sections, wind and snow loads, but it is not recommended to make it more than 3 meters.

During assembly, brick pillars in the upper part are necessarily protected with special steel or plastic caps that protect the structure from bad weather and destruction. Also during installation, concrete pads are installed or a common strip foundation is used for the fence. There can be several options for masonry, it all depends on the appearance of the supports and the requirements for their design:

- decorative supports with a mini-flower bed instead of a protective cap: decorative corner and semicircular bricks with a textured surface are used for assembly;

- cylindrical support pillars made of Finnish semicircular bricks of one or more colors;

- hexagonal and octagonal pillars made of standard ceramic bricks;

- octagonal one- and two-color columns made of marble wall bricks;

- classic supports made of bonded bricks.

For masonry, a central metal post or a grid of reinforcing bars is used. The masonry is carried out with a side of one, two, two and a half bricks, which depends on the expected loads on the supports and the fence as a whole.

Sand-lime brick

Pillars made of sand-lime brick look beautiful and modern; using this type of brick you can get a very interesting effect, especially when combining it with spans made of metal profiles, polycarbonate or forged sections.

The advantages of sand-lime brick include:

- strength;

- durability;

- frost resistance;

- sound insulation;

- environmental friendliness.

Hyperpressed brick

Hyper-pressed, high-strength brick is created using high-pressure pressing technology. This type of material is available in a wide range of colors and a variety of textures: aged, torn, with an imitation of a chipped surface. In terms of strength, hyperpressed brick is not inferior to natural stone, but its cost is more favorable, and processing is easier and faster.

Hyper-pressed decorative bricks have many advantages:

- variety of color and texture;

- aesthetics and excellent compatibility with various materials;

- mechanical strength;

- resistance to temperature changes and humidity;

- abrasion resistance;

- durability.

Clinker brick

Clinker as a material for fence supports has many advantages:

- Durable and durable. This material will last a long time, it is resistant to negative external factors, withstands frost and high humidity, and is suitable for use in coastal areas with high salinity.

- A wide selection of textures and colors for constructing pillars, you can use classic clinker, imitation wild stone, unusual options with bright colors and even brick with a relief pattern

- Ease of installation. Laying clinker pillars does not require expensive tools - you only need masonry skills, but they are quite easy to acquire by making a couple of trial rows (not to be confused with building a brick house, in this case quite a lot of experience and qualifications are required).

- Easy care and practicality. Such poles do not need to be painted or additionally protected; they have an attractive appearance and are easy to clean from dirt and dust.

Metal poles

Most often, such posts are used for fences made of corrugated sheets. This is a durable and cost-effective option, since it does not require a foundation and is suitable for fencing large areas.

In order for a fence made of corrugated sheets to last for a long time, metal posts are firmly fixed in the soil using concreting, their surface is primed and enamel coated. On top of it, if it is hollow inside, a special plug is installed, the material of which can be durable plastic.

Corrugated fence posts can be made of galvanized steel. These can be round posts or supports with a square cross-section. Galvanized fence posts can withstand significant loads. They are practical, non-corrosive and affordable.

Metal decorative fence posts have forged elements on their surface.

Fence with stone pillars

Fence with brick pillars

Types of fence posts

The variety of materials makes it possible to build a fence on the site with your own hands that will be in perfect harmony with the entire territory and architecture of the buildings on the site. The choice of material for the fence depends on the financial capabilities of the owners and their tastes. Now manufacturers offer ready-made options for fence supports, made in compliance with all technologies.

Wooden

Wood is considered a traditional material among the population. Wooden supports today are quite expensive, although solid hardwood logs, even with the necessary processing, will last no more than three years. Wood is unstable to changes in temperature and humidity, and is susceptible to rot and mold. The most resistant to these factors are larch, oak, pine and some other species. Birch, maple, fir, and beech are considered unsuitable for making poles. To increase their service life, special antiseptic treatment is required. Therefore, wood is more often used to build low fences for front gardens and temporary barriers.

The solution to the question of how to install the posts evenly lies in the method of drilling holes. When deepening, the drill should be kept in a strictly vertical position. Each column is checked for verticality with a level.

Installing wooden fence posts in metal cylinder sleeves will increase their service life, and these devices are quite easy to make with your own hands. The sleeve should have a smaller diameter than the girth of the post, fit tightly and prevent moisture from entering the tree. Often the choice of such material is determined by the existing style of the site. The filling of fencing sections is often also made of wood.

Concrete

Fence posts made of concrete are distinguished by their low price and high technological qualities. The material is resistant to mechanical stress, does not rot and does not require constant maintenance. Concrete is reliable and has high strength characteristics, thanks to which it serves its owners for many years without losing its original appearance. The building materials market offers many ready-made forms made of plastic, metal and other materials into which concrete can be poured and finished products obtained. You can create a mold yourself by making a matrix, with the help of which several products are made at once. For this you need:

- boards 3×25×250 cm (9 pieces);

- boards 3×25×100 cm (2 pieces);

- screws, screwdriver, sheets of tin, metal plates (8 pieces), fittings, concrete mixture, oil.

Boards (6 pieces) 250 cm long and boards 100 cm long are covered with tin on one side, and the remaining three (dividing) are covered on both sides. Formwork is assembled from them using screws. Before laying the concrete mixture, the formwork is lubricated with waste oil. The reinforcement is being prepared and laid. Concrete is poured into the resulting structure, which should be carefully leveled. The workpiece is covered with burlap and must be wetted for a week. After the concrete is ready, the formwork can be easily disassembled. The forms are ready.

There is a simpler technology for making concrete supports - using plastic pipes. For this, a well with a depth of at least 1.2 m is prepared. A pipe with dimensions corresponding to the required dimensions of the column is selected. It should be buried, installed strictly vertically. Wire formwork is placed inside the pipe and concrete is poured. After a week, the pipe can be carefully removed, the support is ready. Concrete posts are usually used for fences with heavy, bulky filling.

Asbestos pipes

If the fence builder does not aim to create a structure of increased strength and durability, the use of asbestos-cement pipes is appropriate. They are suitable for light fences: made of wood, profiled sheet or mesh. If installed correctly, such supports can be used for a long time, since the material is not subject to corrosion and rotting. Installation considerations:

- correctly calculated depth of holes for supports;

- high-quality concrete filling;

- connecting pipes using special couplings.

Cuttings of asbestos pipes are attached to each other using couplings (polyethylene or asbestos). When connecting the coupling to the workpiece, a gap remains, allowing the pipe to deviate at an acceptable angle. By connecting pipe cuttings with couplings, you can get a finished support. The disadvantages of asbestos-cement racks include:

- fragility. The material splits when hit or dropped;

- pipes that are not filled with concrete may collapse if water gets inside. Water frozen inside the pipe will simply tear the workpiece;

- ugly view.

Before installing asbestos poles, pipes (thickness - 9 mm, length - 3950 mm, diameter - 118 mm) are cut into blanks, focusing on the height of the future fence. An ordinary drill is used to prepare the holes. By choosing their depth, the type of soil and the length of the spans are determined. For a pole made of asbestos pipes, a depth of 0.8 m will be sufficient.

Brick pillars

Laying brick pillars is quite accessible even to a person far from construction. Prefabricated combined fences made of brick posts and corrugated sheet or wood filling will cost the owners much less than a fence made of solid brickwork.

When choosing the type of foundation for a brick, the material from which the fence itself will be built is taken into account. If it is supposed to be light, you can use a pile foundation for each support, taking into account the type of soil and the proximity of groundwater. If the fence is being built on heaving soils, holes should be drilled 20 cm below their freezing level. On light and well-drained soils, a depth of 0.8 m will be sufficient.

Crushed stone is poured into the prepared hole, a pipe is placed around which the pillar will be laid. For difficult soils, several reinforcing bars are inserted into the hole and concrete is poured. Bricks are placed around the pipe, installed strictly vertically. Each row is clearly checked with a level and rods.

Metal fence posts

Metal pillars are a structural element that bears the weight of the entire load on the structure. The iron supports hold the logs attached to them, onto which the fence filling is attached. Pipe posts can be used in the construction of fences made of wood, corrugated sheets, mesh, and picket fences. Metal supports have a number of undeniable advantages over other types of poles:

- high strength indicators;

- resistance to loads;

- ease of use;

- simple installation;

- long service life;

- affordable price.

To install metal supports, two types of pipes are used: profile and round. A round blank is cheaper than a profile blank, but is not very convenient for installation. Such products are used for simple and inexpensive fencing. The profile blank is stronger and easier to work with during installation. The optimal dimensions to ensure structural strength are: diameter - 6 mm, wall thickness - from 2 mm. Installation, strengthening of metal fence posts and installation of horizontal logs to them are simple and will not take much time.

Concrete pillars

Concrete fence posts will last no less than metal posts. The significant weight of the structure will guarantee stability on any ground.

Wrought iron fence

Positive properties include:

- The material is not afraid of moisture, rust and temperature changes;

- This fence post support is highly reliable and has a long service life;

- Its surface can be subjected to additional finishing: cladding, painting, plastering;

- Possibility of constructing a monolithic structure or using stacked pillars of various shapes and sizes;

- You can install electrical wiring into the “body” of the pole, which will allow you to install lighting sources on the top of the support;

- Easy to install and maintain.

Cons:

- Concrete fence posts require preliminary preparation of the foundation in terms of reinforcement;

- Concrete fence posts have significant weight. To deliver products to the construction site, you will have to use special equipment, and this entails considerable costs.

Concrete fence posts can have different shapes: round, semicircular, square, rectangular, trapezoidal.

Fence with metal posts

How do you know which fence posts are needed?

The dimensions of metal posts directly depend on the height of the planned fence. Based on the height of the fence, the strength of the support post is calculated. When installing metal posts, the composition of the soil is also taken into account.

If the soil contains a large amount of peat, it is very difficult to install the columns so that over time they do not bend and stand straight. The optimal solution to this problem is to twist the pile into a 1.5 m recess.

In the case of large footage, this option turns out to be a little expensive. To install metal poles on a large area, there is a budget method and no less reliable!

The work begins with the need to drill a hole in the ground to a depth of 1.2 with a diameter of 200 mm. After all the holes have been prepared, metal poles 4 meters long are inserted into them and then driven in with a sledgehammer.

The pillar is compacted with crushed granite stone, fraction 5.20. From this installation it is clear that our four-meter pillar is deepened into the hole by 1.90, tightly driven into the clay, and its upper part is tightly compacted. The crushed stone used in the upper part absorbs pressure from the ground.

The moisture that freezes in the soil begins to expand and press in all directions with terrible force. This type of installation of a metal pole can last a long time when the soil freezes and thaws.

Reinforced concrete pillars

Concrete pillars reinforced with metal reinforcement are included in the category of reinforced concrete products.

Fence with wooden posts

Positive characteristics include:

- Simplicity of designs;

- Affordable price;

- Technological production;

- Long service life;

- Bio- and chemical resistance;

- Resistance to dynamic and static loads.

Reinforced concrete fence posts, despite their significant weight, have little strength - the impact of the payload on it is less than the impact of its own weight.

Fence with plastic posts

Decorative concrete pillars

Decorative special concrete pillars have a very attractive appearance. These are unusual and very attractive supports that imitate brickwork, wood surface or have a beautiful texture. Concrete pillars have many advantages, these are not only aesthetic properties, but also strength and resistance to external negative factors. Concrete pillars can be used with fences of any shooting range; various options are used for installation:

- monolithic reinforced concrete pillars of various sections;

- cast posts with grooves for Euro fences;

- supports made up of individual elements;

- figured concrete supports with mortgages for fencing sections, decorative elements, for example, miniature flower beds.

Among the advantages of such concrete pillars, it is necessary to highlight:

- quick installation;

- long service life;

- high aesthetics, the ability to paint the finished post or use a colored mixture for filling;

- easy care;

- affordable price;

- possibility of laying wiring for the lighting system, controlling gate automation, installing mortgages for sections.

Brick pillars

A fence with brick pillars will look neat and solid. Installation of the support will be long and labor-intensive - each row will need to be reinforced with reinforcing tape. The distance between fence posts should be no more than three meters to provide the necessary rigidity and aesthetic appearance.

Brick fence posts from above must be protected from destruction by special caps that have a slope to allow precipitation to drain.

Fence with stone pillars

To concrete the supports, a monolithic strip reinforced concrete foundation is installed, the width of which is equal to the width of the pillar. Installation of such poles will require significant financial investments. But the result will be a reliable, durable fence that will not require special care and will last for many years.

An easier and faster option would be to build pillars from foam blocks.

Screw posts

Screw fence supports are the fastest way to install a strong fence, regardless of the quality of the soil.

A steel pipe with a cutting blade at the end can be easily screwed into any soil and makes the support reliable and stable. Thanks to this device, no foundation is required.

Corrugated fence with brick pillars

Corrugated fence with steel posts

Positive traits:

- Screw fence posts are treated with an anti-corrosion compound, which ensures their durability;

- There is no need for preliminary preparation of the area for installation;

- Possibility to install on a surface that has a slope;

- Easy installation;

- Suitable for organizing temporary fencing - can be dismantled and moved for reuse;

- They do not contain harmful substances on their surface, therefore they are safe for the soil in which they are installed.

By installing screw fence posts, you can be sure of their reliability and durability.

Fence with pipe posts

Photos of posts for fences and gates

Advantages of steel supports

- Strength. Profile pipes made using seamless rolling technology have a large margin of safety, are distinguished by structural rigidity and resistance to combined loads. A fence on such supports will not “lead” and will not break even under strong gusts of wind.

- Reliability. Competent calculations and correct installation ensure the stability of gates and fences in areas with differences in height.

- A wide range of. A large selection of standard sizes and section shapes allows you to select support pillars of any configuration.

- Weather resistance. Metal coated with anti-corrosion compounds does not oxidize or rust when exposed to temperature changes, moisture or aggressive environments.

- Versatility. Iron posts are suitable for installation on any type of soil. They are used for prefabricated and sectional fences made of corrugated sheets, metal picket fences, wood, 2D and 3D mesh, and chain-link mesh.

- Durability. The service life of steel poles, subject to high-quality anti-corrosion treatment, is 80 years.

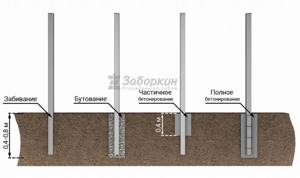

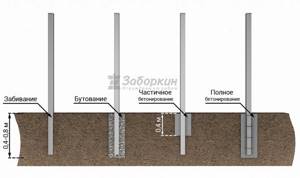

Pole installation methods

The supports must remain stable when the soil freezes and thaws, and can withstand the weight of the frame and sections, wind and snow loads. Installation of pillars is carried out in 4 ways - driving, backfilling, partial or full concreting. When choosing installation technology, climatic conditions and soil characteristics on the site are taken into account.

- Clogging. According to the markings, deep holes are drilled, the diameter of which is less than the diameter of the support. Supports are inserted into the holes and hammered to the required depth with a sledgehammer. In this way, you can install mesh fence posts on stable, dense soil, without stones and construction debris.

- Butting. Pillars are placed in the prepared wells. Then the wells are filled with a sand-gravel mixture with layer-by-layer compaction. This method is used to install supports in areas with soil prone to frost heaving.

- Partial concreting. This method is used when constructing a fence on stable soil and light loads on the supports. For example, when installing fences made of metal picket fences, euro-blinds or mesh. The column is installed in the prepared well, the lower part is backfilled, and the upper part, to a depth of 40 cm, is filled with concrete.

- Full concreting. First, wells are drilled, a sand cushion 10 cm thick is poured into them. The support is immersed in a hole, which is then completely filled with concrete. This method is more suitable for installing supports on sites with sandy soil and high groundwater levels.

Plastic poles

Plastic is also widely used for fencing in suburban areas. In a hardware store, you can choose a ready-made set containing plastic forms, posts, brackets, crossbars, pipes and boards.

Plastic poles can be made in various colors. A plastic pole can last for many years and will never rust.

Fence with reinforced concrete pillars

Installation of plastic fences is very simple and takes little time: the posts are fixed to a concrete foundation using anchor bolts. Then the installation of horizontal crossbars and plastic panels occurs.

With all the variety of building materials that can be used for the manufacture of suburban fence posts, it is important to choose high-quality and durable ones.

Stages of installation of metal poles

Installation of metal poles without concreting is carried out as follows:

- The future fence is marked.

- Holes are dug that exceed the depth of the part of the pillar being buried.

- Sand and gravel are poured into the bottom of the pit.

- The post is lined up along the fence line in a strict vertical line.

- Next, the pit is filled with sand and crushed stone using a layer-by-layer tamper.

Our advantages

Affordable prices

We have low prices for materials and installation - 15% -20% lower than the average for Moscow and the Moscow region.

2 year warranty

We provide a guarantee on structures and all types of installation. We offer unlimited post-warranty service - we will come and repair your fence after a flood or hurricane.

Free measurement

Our specialist will visit your site at a pre-agreed time, take free measurements, and calculate the required amount of materials and components.

All payment methods

We accept payment in any way convenient for the customer - cash. by transfer to a bank account using the details, by card via an online cash register.

Own production

Thanks to our own production, materials and components are always in stock and with a quality guarantee.

Bonuses

We often hold promotions and sales - follow the news on the website! When ordering a fence longer than 50 m, we offer a 10% discount on your next order.

We work all year round

We build fences regardless of the weather and time of year. We work 7 days a week, without weekends and holidays.

Everything is in stock

We have transport, all necessary equipment and tools. We install fences in 1 day.

The Zaborkin company offers high-quality and inexpensive products at an affordable price thanks to its own production. We provide prompt installation and a wide range of designs for standard or individual projects. To order and delivery, please contact our managers using the feedback form on the website.

Still have questions? Free consultation with a specialist.

For lightweight country fences made of chain-link mesh, pipes of 40x20 mm with a wall thickness of 1.5 mm are used. For fences made of corrugated sheets or metal pickets, take a corrugated pipe 60x40 mm or 60x60 mm, metal thickness 2 mm. For the entrance group, gates and wickets, pipes with a wall thickness of 3 mm and sizes 80x60 or 80x80 mm are used.

The material for the production of pipe metal is alloy steel of structural grades. Due to the stiffening ribs and the absence of connecting seams, a cast fence post is able to withstand severe bending loads while maintaining its integrity and original shape.

Structural steel can be welded without restrictions, which allows you to use both welding and bolting to attach beams and joists to racks. To protect against moisture, soil and electrochemical corrosion, the surface of finished steel supports is galvanized, painted with primer-enamel, sprayed with polymer compounds, and treated with epoxy resin.