Polycarbonate is the optimal solution for a transparent terrace roof

For some time now, polycarbonate has become especially popular and quickly gained a leading position in the roofing materials market. This is due to the unique properties of the polymer, which make it especially easy to install and give it any shape. Laying plastic flooring takes several hours, and the cost of materials and components will only slightly reduce the family budget.

A polycarbonate roof is installed over those structures where natural light is needed. This includes: terraces, verandas, gazebos, summer recreation areas. In order to carry out the installation of a transparent roof competently and technically correctly, it is necessary to become more familiar with the properties of polycarbonate and the technology of its installation.

The unique physical properties of the high-tech polymer make it the most popular in our country. The material does not lose its properties when used in a huge temperature range - from -40 to +120 degrees Celsius. In addition, products made from it have the following advantages:

- resistance to strong temperature changes, mechanical damage, shock;

- easy installation due to exceptionally low weight and flexibility;

- high rate of light transmission - the ability to use not only for roofing, but also for walls of adjacent buildings;

- despite the small thickness of the sheets, it has high heat and sound insulation properties;

- does not fade under the influence of ultraviolet rays, the property extends even to colored products;

- a variety of geometric roof designs - arched, domed, rectangular, multifaceted;

- possibility to choose sheet thickness – 4-16 mm;

- reliable protection from any precipitation.

Advantages and disadvantages of polycarbonate for roofing

To understand whether choosing the substance in question for the roof of a terrace, veranda or gazebo is the right decision, you should know about the pros and cons of its use.

- Advantages:

- high level of sun resistance;

- a light weight;

- savings on insulation and heating;

- flexibility and strength;

- sound insulation;

- exposure to average precipitation (snow), deciduous masses.

- Flaws:

- poor resistance to abnormal natural phenomena and difficult weather conditions;

- short-term durability due to improper installation and maintenance.

Thus, a polycarbonate roof is a practical, simple and budget solution that will provide you with reliable protection, warmth and comfort, naturally, with proper installation and proper care. And using the variety of polycarbonate offered by today’s market, anyone can bring to life even the most intricate design ideas and make their home a real work of art.

Secrets of working with polycarbonate

When working with different roofing materials, they use their own techniques and tricks. Polycarbonate sheets are no exception. In order to correctly and safely install a roof for a polycarbonate terrace with your own hands, it would be reasonable to follow the following recommendations and tips:

- The protective film is removed only after a full cycle of installation work has been completed.

- If honeycomb-type plastic has accumulated condensation from the inside, the sheets are first blown with compressed air. To prevent such a problem, the material should be stored in a dry place, and before installation, treat the edge with open honeycombs with metallized adhesive tape or sealant.

- To avoid condensation, a polycarbonate roof for a terrace should not be covered with aluminum or polymer films.

- To walk on laid polycarbonate, use special ladders, otherwise the polymer sheet may crack.

- Any roof, even the most flat one, must have a slope of at least 5°.

- If frames are prepared for carbonate sheets, their dimensions must be designed taking into account the thermal expansion of the plastic, the coefficient of which depends on the thickness of the product.

- For sawing/cutting the canvases, use a hand-held portable circular saw or a jigsaw. The holes are drilled using a drill with standard metal drill bits.

- To develop a roof of complex shape, various formation methods are used: thermal, vacuum method, as well as cold and hot bending technology.

Application of polycarbonate

One of the areas of application of this material is the installation of roofs. The material is suitable for installing roof structures of various shapes. It can be a gable, single-pitch polycarbonate roof or a hip roof. Polycarbonate can be used to cover not only the roof of a living space, because... This is also a suitable option for a terrace. It will make it more comfortable and cozy. The terrace area increases the usable area of the house and at the same time allows you to enjoy a good rest in nature. The roof of the terrace should be a continuation of the architectural ensemble of the main building. Mostly she builds without an attic. The main function of a terrace roof is to protect the site from bright sun and precipitation. Polycarbonate will cope with this task successfully.

Roofs made of polycarbonate. Photo:

Installation of rafters for a transparent roof

Even the purchase of the most expensive plastic will not always be able to ensure the reliability of the roof and the performance of all functions assigned to it. The main thing is to correctly design and build a load-bearing rafter system.

For the frame, a wooden beam with a section of 40x60 mm or a standard metal profile is used. To strengthen the base, additional bars are used, placing them in the transverse and longitudinal direction.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

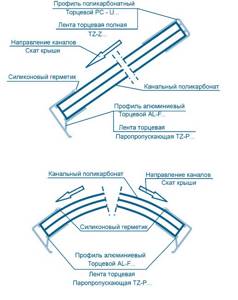

In some cases, it is advisable to purchase a ready-made set of profiles, which is usually always available at a hardware store. For work, you will need various frame elements, including ridge, end profiles, connecting parts for external and internal operations.

The rafters are installed according to pre-prepared drawings. For a veranda or terrace roof, the distance between the longitudinal elements is 70-100 mm. The thinner the plastic, the smaller the distance should be chosen between them. The rafters are fastened in such a way that the joints of the polycarbonate panels are located exactly in the middle of the beams with an overlap of 1-1.5 cm. After the construction of the main frame, connecting and end profiles are installed.

Rules for cutting and drilling

Cutting sheets into fragments must be done as carefully as possible to avoid damage to the top protective layer. This procedure is carried out using a circular saw or jigsaw. It is important to choose the optimal speed. Cutting too slowly will cause chipping. Excessively high speed will lead to overheating and melting of the polymer. Sheets should not vibrate when cutting, this will lead to the appearance of microcracks.

If fastening is carried out using self-tapping screws, you must first prepare holes in the sheets, the diameter of which should be 1-2 mm larger than the size of the fastening elements. To do this, use a drill for non-ferrous metals. Self-tapping screws should not be tightened to the maximum. Sheets will move under temperature changes. A polycarbonate roof for a terrace should be installed taking this condition into account.

Laying polycarbonate sheets

- The plastic is cut into sheets in such an order that the longitudinal stiffeners are located in the direction of the slope. This technique will further facilitate the removal of condensate from inside the extension. Do not forget also that the canvases are placed upward with the side on which the film with ultraviolet protection is applied.

- Along the edge of the plastic sheet, pin holes are drilled, 2-3 mm greater than the thickness of the screws, in increments of 40-50 cm.

- To fasten the polymer, galvanized self-tapping screws with a sealing washer (thermal washer) are used. The fastening screws are screwed in carefully - the washer should fit particularly tightly, without at the same time causing deformation of the material. At the joining site, connecting profiles are installed, for which a self-tapping screw is first attached to the bottom of the element, then a sheet is inserted into it and covered with the upper part of the profile.

- To connect plastic sheets to each other, special detachable or one-piece H-shaped profiles are used, which greatly facilitates the entire installation process.

- Sheets of plastic from the end part are equipped with sealing tape and reinforced with an end profile.

- If the roof is gable, then at the final stage a ridge profile is installed.

- Upon completion of work, all joints are treated with sealant.

Types of polycarbonate

You can make a polycarbonate roof from two of its varieties:

- Monolithic type material is used for arranging roofs of curved and flat shapes. This polycarbonate has significant advantages, the number of which is not inferior to glass. But at the same time, it also has a drawback that prevents its widespread use - it is high cost.

- Structured polycarbonate, also called cellular, is more affordable financially and therefore has gained great popularity. This material is also called light-transmitting plastic. A roof made on its basis will allow you to stay on the terrace in hot weather and not feel discomfort from the sun's rays.

Advantages of polycarbonate material:

- high thermal insulation rates;

- light weight, which simplifies the installation process;

- elasticity, thanks to which you can independently install arched ceilings without the help of specialists;

- resistance to various chemical influences;

- long period of operation - up to 20 years;

- low flammability - the material is able to restrain the spread of fire in the event of fire;

- ability to maintain operational properties at temperatures from -40ºС to +120ºС.

Arched roof for terrace

The roof, made in the form of an arch, additionally acts as an element of the architectural style, favorably emphasizing the respectability of your home. A terrace with a polycarbonate arched roof is not only beautiful and practical, but also economically beneficial, in contrast to the construction of a permanent structure. A roof in the shape of a semicircle can be installed both on the terrace of the house and above the porch, children's playground, or gazebo.

The technology for creating a complex-shaped canopy differs from that described above in terms of designing a supporting frame, but with the right approach it can be easily implemented by a home craftsman.

Choosing polycarbonate for verandas and terraces

When choosing polycarbonate for a roof, it is worth knowing that today it exists in two forms: monolithic and cellular, or cellular. Monolithic is called so because it represents a single solid structure without any inclusions or voids. Based on this, monolith panels have the greatest strength among other polymer building products.

Cellular polycarbonate is a structure of two outer sheets, which form a cellular configuration inside due to a large number of partitions pressed closely against each other. In terms of its general technical parameters and quality, it differs significantly from the first type, however, in construction, as practice shows, it is used more often. The choice must be approached responsibly, knowing all the advantages and disadvantages of each of the varieties, which are discussed further.

Design: selection of roof angle and shape

When designing, you will need to start from where exactly the terrace will be located - near the house as an extension, or as a separate architectural object. If the terrace is attached, then it should be the same angle of inclination as the roof of the house, or flatter.

If it stands alone, then its angle of inclination should be calculated based on the wind and snow loads of your area. After all, it is important that in winter this beautiful coating does not break under the weight of the snow. Therefore, we call the optimal angle of a transparent terrace roof 30°.

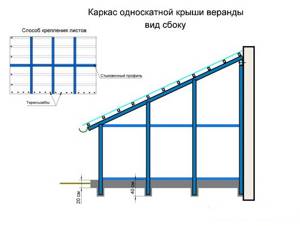

Now let's decide on the shape of the future transparent roof of the terrace. So, the simplest form is a pitched roof, practical, durable and especially convenient for installing transparent materials.

Most often, such a roof is made attached to the house, with the same angle of inclination as that of the roof of the building itself. This way, foliage and snow do not linger on it, and, therefore, light transmittance is not lost. Moreover, it will not be difficult for you to cope with the frame of the terrace under the light-transmitting coating:

Gable roofs of terraces are also in great demand, as they turn the resting place into a particularly cozy place. A roof with two slopes is also more common in our region and reminds us of home. At the same time, being made of transparent material, it does not look massive or heavy.

But the terraces with hipped roofs are especially beautiful. These look like light transparent umbrellas placed around the garden. In terms of durability, these are the strongest roofs, the most stable even under strong wind loads, because the lifting force of the wind no longer acts here.

Another plus: the hipped roof of the terrace looks the same from anywhere in the garden, i.e. the design here is much more advantageous, although the arrangement here is much more complicated than that of a pitched roof. But a hipped or hipped roof is indispensable when implementing an oriental landscape design project.

And, since we are giving courage to our dreams, then the most beautiful design will be the octagonal design. Not to mention the fact that pliable translucent materials make it possible to build terrace roofs of the most unusual and original shapes, such as pentagonal, hexagonal, sliding and even broken asymmetrical.

As a next step, you need to decide on the degree of transparency: will the roof really, like glass, let in all direct sunlight, or is it better to choose a tinted option with light diffusion? The choice of roofing material directly depends on this, because even completely transparent, at first glance, types have completely different throughput.

How to build terraces from polycarbonate sheets

The most popular material for construction - wood in the form of timber or profiled slats, goes very well in simple designs of a terrace attached to a house on the shady side of the building. When choosing the optimal location of the terrace, most suitable for relaxation, take into account the direction of the wind and illumination. All that remains is to hammer in a light foundation, disassemble and move the wooden frame with roof, floor and fence. With metal posts concreted into the ground and a steel frame of the terrace, this number will not work. Therefore, before building a terrace area, be sure to choose which material you like best, and in which place in the household the construction will be most in demand.

Simple terrace design

The easiest way is to build a simple terrace with a roof with your own hands, according to the project shown in the diagram below.

A lightweight wooden structure requires choosing the right way to secure the roof and foundation of the future terrace.

The construction will be carried out in four stages:

- We mark and drill holes in the ground with a diameter of 30 cm to a depth of 40-50 cm. We punch holes in four rows with a step of every 70 cm, insert a piece of asbestos-cement pipe and concrete the space between the soil and the outer wall;

- We install vertical posts made of 70x100 mm timber along the contour, align them vertically and also concrete them. We tie the lower and middle parts of the roof racks with timber;

- We cover the floor with boards, cut the posts to fit the size of the canopy, after which you can install the roof frame and rafters. We sew the upper part of the frame to the wall of the house;

- We lay sheets of cellular polycarbonate with roof fastening on wooden rafters using special compensating screws.

Important! To prevent polycarbonate sheets from rising due to heating in the sun, you will need to make a gap of 4-5 mm between the individual strips, which is covered with a plastic mounting profile.

In addition, the edges of the sheets must be sealed with perforated tape; this method allows you to get rid of condensation and prevent dust and rain moisture from penetrating inside the honeycombs.

If you intend to use the terrace area in the summer heat, the best option would be if you choose the darkest colors for the roof structure, for example, a tobacco or smoky shade. Too bright red, green or blue colors can be annoying.

If it is possible to bend roof arches from a steel profiled pipe using a pipe bender, the terrace building can be equipped with a very nice arched roof, or even a more complex structure that covers the side surface and part of the roof.

To emphasize the reddish color of the antiseptic-treated and varnished frame wood, customers deliberately choose an orange or tea-colored polycarbonate roof. In combination with warm shades of the walls and wooden floors, this technique enhances the atmosphere of warmth and comfort of the terrace.

For a terrace located on the sunny side of the house, you can use a contrasting roof design. To do this, the wood of the frame is tinted with a bright lemon toner and a varnish of the appropriate shade is selected. As a roofing material, the terrace roof is covered with polycarbonate sheets of piercing blue color. Against the background of the blue autumn sky, the effect will be remarkably expressive.

Practical application of polycarbonate in terrace construction

The combination of profiled aluminum and steel profiles with polycarbonate cladding in the terrace design is very effective and harmonious. In addition to the roof, one of the side walls on the terrace can be glazed, thereby eliminating the fresh evening draft.

Of the two materials, cellular and monolithic, the first is used in the glazing of terrace areas much more often. Firstly, cellular material is cheaper and lighter than monolith, and secondly, it has good protection from ultraviolet radiation and partially from the heat rays of the sun. Monolithic polycarbonate as a roofing material can turn the terrace area into a real brazier.

But the monolithic sheet has one invaluable quality - high transparency. If it is necessary to arrange a closed and at the same time well-lit space on the terrace, then the project can only be implemented with the help of a monolith.

In addition, polycarbonate, unlike glass, bends well and can withstand high lateral loads. Even in an arced state, the glazing of the terrace can withstand a significant layer of snow or pressure from rainwater.

In addition to being used as a roofing material, polycarbonate is widely used for the construction of conventional fencing, which is required for terraced areas.

The best design option for a covered terrace would be a combination of forged roof elements and fencing with smoky-colored polycarbonate roofing sheets.