Advantages and disadvantages of frame structures

Prefabricated structures based on a frame have many advantages:

- resistance of the bowl surface to mechanical damage;

- preservation of working qualities under the influence of sunlight and low temperature conditions;

- wide selection of models;

- relative compactness and mobility;

- long service life exceeding ten years;

- intuitive ease of installation even with a surface slope of up to 20º;

- ease of maintenance of the structure;

- Possibility of self-assembly and disassembly.

Finishing with decking boards or wood siding combines well with other buildings and fencing

Models that are not resistant to frost must be dismantled and stored for storage in late autumn, since in conditions of sharply negative temperatures they become deformed and cracked. The most significant disadvantage of a factory-made frame pool is its relatively high cost.

Deepening the tank into the soil: is it necessary?

The question of deepening the tank arises if you dismantle the installed structure in winter. Large and heavy thickets are quite difficult to transport, which is why it is necessary to “put” a fairly rigid base under it. Let's analyze the most popular solutions:

- Reservoir up to 500 liters. The oversized frame pool design is easy to install if necessary and just as easy to dismantle shortly before the first frost approaches. That is why it is installed exclusively in warm seasons. Making depressions in the ground makes little sense: you can place the bowl directly on the ground surface. Important point: it is recommended to create a small PVC flooring; it is able to provide insulation to two tanks: then moisture accumulations will not form underneath and the growing grass will not rot.

- Reservoir up to 5000 liters. Such structures are also dismantled in winter, but they are much heavier; there is a risk of subsidence of soil masses. Therefore, it is recommended to pre-prepare the site by cutting off the soil by five centimeters and sprinkling the resulting surface with sand at the same level as the edge of the ground. The advantage of sand is that it will block plants trying to get to the sun (moisture is absorbed and dried). Don't forget about the PVC mat that needs to be installed under the pool structure.

- Reservoir up to 50,000 liters. Such structures of frame pools are almost never dismantled: this would require serious financial expenses and loss of time. It is assumed that a hole will be dug, the depth of which is about one-third the height of the pool bowl. Example: if the depth of the pool is 1.5 m, then the depth of the installation pit should be 50 cm. Do not take measurements by eye - use a tape measure. But it is impossible to say unequivocally what is better to install a frame pool on. There are many ways to create a solid base under a pond: you can fill the surface with concrete and cover it with gravel, lay a geotextile bedding (the most common answer to the question regarding what can be laid under a frame pool), cover it with regular sand (about five centimeters) or cover it with regular PVC -a rug. Naturally, the first two options are much preferable to the last two.

Types of frame pools

Absolutely all types of frame pools fall into the category of prefabricated structures. The first option is represented by rod models based on vertically or horizontally located galvanized steel slats. Sectional types are characterized by the presence of modules made of metal or high-strength plastic, fastened with bolts and a locking connection.

By type of design

Depending on the typical features, all artificial reservoirs based on a frame structure are divided into rod and sheet models. Both varieties, produced by domestic and foreign manufacturers, are equipped with a convenient and reliable ladder.

Steel slats or plastic tubes form the basis of the rod frame

The frame base is represented by a set of crossbars and special ribs of increased rigidity, used to fix the film elements of the walls of an artificial reservoir. Rod products do not require serious excavation and construction work on the site allocated for installation. The advantages are quick self-assembly and disassembly, as well as fairly high strength. However, rod models are characterized by relatively shallow depth.

A sheet frame is considered stronger than a rod frame

Installation of sheet models is more labor-intensive compared to the installation of rod-type frames, but it is these artificial reservoirs that are more durable and capital. Sheet-type products can be equipped with different fastening methods, including “lock-to-lock”, as well as bolted connections and design models. Frame sheets provide increased rigidity and reliability to the entire wall structure. The main advantages of any leaf pools are also ease of maintenance, including regular cleaning.

According to seasonality

Prefabricated frame hydraulic structures can be frost-resistant, as well as intended exclusively for seasonal use. The average service life of such pools, subject to proper maintenance, is about ten years.

All-season or frost-resistant, mostly stationary pools on a frame do not need to be disassembled before the onset of frost. Thanks to the presence of a metal side, a reinforced frame structure and a reliable enamel or polymer coating, simple preservation allows you to preserve the appearance and technical characteristics of the product even in severe frosts. The complete set of frost-resistant models includes installation instructions, a pumping unit with a filter, a bottom covering and a net, as well as a cover and a small but durable ladder. Modern models are equipped with a water vacuum cleaner for cleaning the bottom and walls.

Models are produced that are not afraid of sub-zero temperatures and can be assembled all year round

Seasonal products must be assembled before the onset of summer and dismantled for storage immediately before the cold weather.

The lightweight rod structure must be disassembled and hidden in the fall until the next swimming season.

Such prefabricated structures are very convenient and very practical, but most often they are designed for simultaneous bathing of a small number of people. The frame base is made of metal, hollow pipes and connecting elements, which are usually complemented by a three-layer polyvinyl chloride bowl. Round, rectangular or square shapes are the most popular, but you can also order the product to be made according to individual sketches.

Baths, saunas and swimming pools

36 votes

+

Vote for!

—

Vote against!

Today, a pool in a country house is far from uncommon, especially since you can buy a pool of any size. A small inflatable tank for a child does not require a special platform with a foundation. A huge stationary pool with equipment requires installation by professionals. And you can install a collapsible pool yourself. But for this you will need a platform for a frame pool so that the entire structure of the tank is stable and reliable. Such a pool will not cost much, but the family will get a lot of pleasure from the water warmed up in the sun.

Table of contents:

- Preliminary stage of preparation for purchasing a swimming pool

- General requirements for preparing a swimming pool site

- Types of pools

- Advantages of frame pools

- Main stages of work

Preliminary stage of preparation for purchasing a swimming pool

Purchasing a container for a swimming pool should not be hasty, even if the family has no financial problems, but there is a great desire to install it on a country plot. Before choosing one or another type of artificial reservoir, it is important:

- get acquainted with the characteristics of each variety;

- read the maintenance instructions for the selected type of pool to get an idea of \u200b\u200bmaintenance;

- evaluate the free space of the site to decide where the pool will be installed;

- calculate the costs of preparing the site for the pool;

- estimate the costs of purchasing and maintaining the tank, including electricity (water supply pump), water consumption and maintaining sanitary and hygienic standards;

- take into account the likelihood of additional costs for a ladder, a children's diving board for the pool, a pedestal for diving, etc.

1. Choosing the right place for a home pool is a very important stage, since this place should not be occupied by other household tasks.

2. It is important to think about where and how the water supply will be organized and how it will be drained after use. If chlorine is used for the pool, will it be harmful to plants growing nearby?

3. Electrical equipment must be easily connected to the network, and no water should splash nearby. After solving these issues, it is worth deciding on the type of pool that suits the conditions of the site. The best option for most country houses is a frame pool.

General requirements for preparing a swimming pool site

It is important to understand that any structure or container must stand on an absolutely flat and horizontal surface in order to avoid distortions - as a prerequisite for destruction. If it is not clear why and how to level the area for the pool, listen to the advice.

1. That part of the site where the frame or prefabricated pool will stand should not have dents, potholes or irregularities around the perimeter or circumference of the bottom.

2. The base of the site for a swimming pool of any type must be leveled horizontally with a building level to eliminate slope.

3. There should be no plant components left in the foundation for the pool - old stumps, snags and other woody debris, as well as stones, brick fragments, construction debris and other foreign objects.

4. Under the pool, the soil must be compacted tightly so that the base can withstand the pressure from a large mass of water in a container filled with water.

5. It is better to compact loose or heterogeneous soil on the pool site and fill it with concrete to prevent distortions in the structure.

6. The pool cannot be placed close to the building, so that in the event of an emergency, water does not penetrate under the foundation or into the basement.

7. You can build a site for a frame pool with your own hands next to a fence or fence provided for by the landscape design, but the best option is that the approaches to it are free from all sides.

8. Large trees standing next to the pool will contribute to its pollution, so you will have to clean and drain it much more often. The worst thing is when there are trees and shrubs growing nearby that bear perishable berries and fruits.

9. Experts do not recommend installing a frame pool:

- in a seismically unfavorable mountain region;

- on a wooden platform;

- in a place cleared of old buildings;

- on an unfinished dacha foundation;

- on creeping and loose soils;

- in an area in close proximity to the railway track or near a bridge where heavy trucks operate;

- on the edge of a cliff or descent to a river.

When installing a frame base, it requires knowledge of how to make a platform for a pool, and a specially prepared horizontal platform. Sometimes it is enough to limit yourself to a small foundation with sand, which is filled with at least 20 - 25 cm. It will also serve as an excellent shock absorber if there is heavy traffic near the site. Such a pool can also be installed near a private beach, especially when the climate does not allow for rapid warming of an open reservoir. In a small container, you can warm up the water additionally or pour ready-made warm water into it. A sandy area is the optimal solution for a small pool with heated water, in which mainly children will swim, for example, in a private kindergarten or family-type orphanage.

Attention: If you decide to please your children or grandchildren with a budget-type mini-pond in an area that is not suitable for this, we advise you to limit yourself to a small inflatable pool for children or a structure with a canvas bottom in a small pit, like a homemade pond.

Types of pools

For personal use, swimming pools and mini-pools of open and closed types are used, that is, inside buildings and in the open air. A mini-pool can be made even in an apartment or the basement of an apartment building, if specialists are involved in its construction and carry out everything according to the rules. For self-installation, it is better to limit yourself to small containers that are easy to install and prepare the site for the pool.

1. An inflatable pool is the simplest in design and transportation. The children's version can even be placed on the loggia in the apartment. At the dacha, any horizontal platform is suitable for its placement, for example, a concreted passage to the house or an asphalt road to the garage. It is better to install a large inflatable pool in a safer place in case of water spillage due to damage to the container film.

2. Seasonal pool of prefabricated type - based on a frame, installed for the summer period. It is distinguished by its reliable design, quick assembly and ease of use, as well as reasonable price. The prefabricated frame type of pool is designed for installation outdoors, but can also be installed in a covered gallery made of translucent roofing materials. A distinctive feature is that they require a horizontal base or foundation filled with a thick layer of sand. Since they do not contain a water purification and filtration system, it is important to ensure that no plant debris accumulates in the pool water.

3. A stationary pool is the most complex design with all the equipment for filling/draining water and a cleaning system. They are also located in a specially designated indoor room or with an open top. An outdoor pool is built without any structures, just in the courtyard of an estate or private household, so as not to deny yourself the pleasure of swimming in the sun.

The water in the open air warms up naturally, although the climate of European countries does not allow the use of a stationary outdoor pool for more than 2–5 months a year. Sometimes, for insulation purposes, covered transparent pavilions are made in the form of a dome over the pool, so that not only “walruses” can swim during the cool period. The warm microclimate in them has to be maintained artificially.

A stationary pool does not have to be made in a separate room; it can also be equipped with:

- in a closed extension;

- in the basement, subject to complete waterproofing;

- in an unused garage, summer kitchen or other building;

- on the first floor of the house;

- convert a spacious bathroom into a mini-pool with a shower;

- placed in the basement level of a private house.

If for some reason the frame pool was not removed at the end of summer, then in a mild climate it can safely overwinter. The main thing is to scoop out the remaining water so that in the cold the ice does not expand and damage the structure. A little water from precipitation will not harm it. But in a harsh climate, with a lot of autumn showers and winter snow, there is a possibility of it filling up. Therefore, it is better not to be lazy, so as not to risk cleaning the pool for the winter. Not all such products are designed for winter load, so it is better to spend money on dismantling and transporting it, if necessary, but not to lose the entire pool. There are also frost-resistant stationary structures, but they are much more expensive.

Advantages of frame pools

A modern frame pool can be made with your own hands from individual panels, provided that the overall structure is reliable, small in volume and fully waterproofed. However, the easiest way is to purchase a ready-made structure based on steel reinforcing elements, somewhat reminiscent of the columns of the load-bearing walls of a building. The inside of the container is covered with a very durable film over the plastic sides of the pool with an additional coating for water disinfection. This design:

- fits perfectly into landscape design;

- is inexpensive;

- assembles quickly;

- meets the basic needs of pool users;

- does not require labor-intensive operation;

- It’s easy to change used water; you can use a hose to drain it into the garden for watering;

- You can use a pump and a handheld vacuum cleaner to clean the bottom.

The domestic market offers different models of portable and stationary pools, including frame-type models. They differ in the type of frame:

- rod;

- leafy.

The rod containers have metal rods and an upper hoop that unites the structure. The bowl of such a pool is made of synthetic building materials, most often polyvinyl chloride. The design of the models has a lot in common, including the addition of a ladder. However, only prefabricated frost-resistant models can stand on a prepared site for a pool without dismantling in winter. It is better to purchase and assemble a lightweight seasonal pool in advance, in the spring or early summer, and then be sure to dismantle it in the fall. In addition to the ladder, the pool is equipped with hoses for drainage, a filtration system and nozzles for water supply.

Stationary frost-resistant structures, in addition, also have:

- reinforced external edging;

- more advanced sand filtration system and skimmer.

Attention: Do not rush to buy a large pool, even if there is enough space on the site to install it. Caring for it can create some inconvenience, and water consumption incurs high costs, subject to a meter. Remember also that the closer the water supply, the easier it is to maintain the pool.

For those who do not know how to prepare a site for a swimming pool, experts recommend starting with choosing a location for a frame structure. An all-season pool, if desired, can be slightly deepened into the pit for greater stability, especially if there is a possibility of hurricane winds during the cold period when the pool is empty.

The collapsible structure can be installed on a shallow, rounded foundation filled with sand for ease of leveling. This may be acceptable for accelerated construction of a site for the initial installation of a tank. To do this, it is enough to dig a shallow round or rectangular pit, depending on the shape of the pool. It should be wider than the perimeter or diameter of the pool bottom. A brick edge is laid out along the edges, and sand is poured in the middle for self-leveling.

But still, for permanent use, it is preferable to make a reliable foundation for a frame pool. A high-quality pool is not so demanding when choosing a location, but the surface of the site must be flat.

Main stages of work

1. Decide on the dimensions of the pool before purchasing it in order to prepare the site in advance. Watch a video on how to prepare a site for a frame pool.

2. Outline the location for the pool structure. An ideal circle can be drawn from a hammered peg and a tape measure attached to it - walk around the circle and leave marks, which are then connected to form a circle. The rectangular base is marked using a square, pegs and rope.

3. In the delineated area, be sure to remove the turf layer of soil, removing all vegetation and uprooting plant roots and weeds. After this, all stones and other solid soil inclusions are removed.

4. The leveling layer is made of sand, which is poured at least 5 - 10 cm deep. You can determine the horizontality by the level of the beacons from the building profile in order to stretch the sand perfectly evenly. If in doubt, this procedure can be repeated after purchasing the pool - before installing it on the site.

5. If you plan to bury an all-season stationary winter frame pool in the ground, then a foundation must be made for the bowl with internal leveling of the surface without slope or unevenness.

6. A special polypropylene bedding provided in the kit is placed on the sand cushion. If it is not there for some reason, then you can use a backing, which is sold in any construction supermarket, and secure it around the edges.

The pool can also be installed on a specially constructed podium, and you can jump into the water from a wooden platform or a children's plastic slide - photo.

The frame pool is assembled according to the instructions that are included with it upon purchase. In most cases, a video instruction is included on how to assemble a pool at home.

Attention: The time required to prepare the site, purchase the container and transport it to the site of installation and assembly with filling depends on the size and design features. Usually this takes no more than a week, so if you intend to please your children or grandchildren at the dacha, start doing this in advance, and not on the day of purchase and arrival at the site!

What materials can be used for construction

Homemade frame pools have both certain advantages and some disadvantages, which are associated with the structural features of such an artificial reservoir. Self-made hydraulic structures, as a rule, do not have a large area, and are also characterized by quite noticeable difficulties in installing any service equipment and the need to constantly monitor the condition of all elements.

The main construction and finishing materials used for the manufacture of a frame pool are as follows:

- For the construction of the frame, wood treated with antifungal compounds, natural or artificial stone, and metal racks are most often used.

All wooden elements must be treated with antiseptic impregnations to protect against rotting

- To equip the bowl, the most durable and reliable, only durable artificial materials are used, which deservedly includes polyvinyl chloride. Usually, when making it yourself, special fabrics are used that are stretched over an already erected frame base.

- High-strength shields based on modern plastics will also be a worthy option for the design of the bowl.

- A variety of modern finishing materials are used for the external cladding of the structure. The exterior finishing of a hydraulic structure is most often done using natural processed wood, including special lining or decking boards. Also for this purpose, you can use natural or composite, waterproof materials, PVC panels and finishing tiles, which are securely fixed to the sheathing.

The terrace board is not afraid of water; it can be used to decorate not only the sides of the pool, but also the adjacent recreation area

Coping decorates the edge, does not slip and prevents water from overflowing over the edge of the pool

For finishing the sides, the optimal solution would be to use functional coping or the so-called edge stone, which has an anti-slip surface and is highly decorative. This material protects the outdoor pool from water overflow and contamination from entering the bowl. Coping can have a gray, pink, white or beige color, due to the color of the marble chips, which are part of the raw material for the manufacture of edge stone.

To filter large volumes of water, you will need to install several filters in different parts of the bowl.

Artificial reservoirs can, if desired, be supplemented with an automatic filtration and disinfection system, devices for heating water, as well as LED lighting.

Don’t rush to get rid of old pallets and tires, because these scrap materials can be a good base for building a pool. Step-by-step instructions in our article: https://aqua-rmnt.com/vodosnab/font_bass/basseyn-na-dache-svoimi-rukami.html.

How to build a swimming pool with your own hands - step-by-step instructions with photos

Self-construction of a swimming pool helps to significantly save money, and also allows you to obtain a hydraulic structure with an individual appearance and optimal shape and size, in accordance with the site allocated for construction.

Preparatory stage

It is with preparatory activities that the construction of a frame pool begins. At this stage, not only must competent design documentation be developed and the amount of materials used be calculated, but also the optimal location must be selected, all construction, finishing and fastening materials must be purchased, and additional equipment for servicing the hydraulic structure must be purchased.

Drawing and dimensions

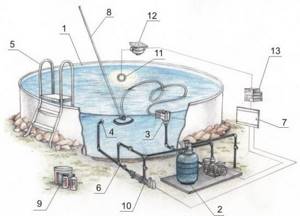

As a basis for design documentation, you can take a diagram of a ready-made frame structure of an artificial reservoir, which includes the following elements:

- 1 - walls;

- 2 - filtering device;

- 3 — skimmer installation;

- 4 — nozzles;

- 5 - staircase design;

- 6 - system of pipes and fittings;

- 7 - electric automatic part;

- 8 - bottom vacuum cleaner;

- 9 — chemicals for water treatment;

- 10 - electric heating element;

- 11 — lighting system;

- 12 — junction box;

- 13 - transformer.

The diagram shows the components of the pool

A list and quantity of required materials may be attached to the drawing.

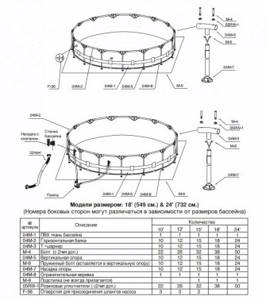

With such a ready-made diagram, you can immediately go to a hardware store; the material consumption is indicated for different bowl sizes

Preparation of materials and tools

Basic tools needed to build a frame pool:

- construction hair dryer;

- Chipboard sheets or fibreboards;

- rolling rollers and eyelets;

- grinder and drill, strong rope,

- sand and gravel, sheet bitumen,

- rule and building level;

- shovel, tape measure;

- cement, sand, crushed stone;

The amount of PVC film depends on the shape and size of the structure being manufactured:

- for a rectangular bowl with a flat bottom, calculating the floor area involves multiplying the length by the width, and to obtain data on the walls, you should multiply the perimeter of the walls with their height. For example: for a hydraulic structure measuring 10 x 5 m with a wall height of one and a half meters, the floor area will be 50 m2, the wall area will be 45 m2, and the total material area will be 95 m2;

- for a round bowl with a flat bottom, calculating the floor area involves multiplying the floor diameter by the floor diameter, and to obtain data on the walls, multiply the perimeter of the walls with their height. For example: for a hydraulic structure with a diameter of 6 m and a wall height of 120 cm, the floor area will be 28.3 m2, the wall area will be 22.6 m2, and the total material area will be 50.9 m2;

- for a rectangular bowl with a pyramidal bottom, calculating the floor area involves multiplying the length by the width with a coefficient of “1.3”, and to obtain data on the walls it is necessary to multiply the perimeter with the height of the vertical wall. For example: for a hydraulic structure 10 x 5 m with a vertical wall height of 120 cm, the floor area will be 65 m2, the wall area will be 36 m2, and the total area of the awning material will be 101 m2.

Choosing a site location

When choosing a site for the construction of a hydraulic structure, you must pay attention to the following recommendations:

- the presence of a fairly flat surface without noticeable bumps and differences in height;

- close location of the electrical power source for trouble-free connection of pumping and filtering equipment;

- availability of an accessible source of water to fill the bowl;

- the presence of a sewerage system for discharging waste water.

In an open sunny place the water will warm up faster