Setting up an individual water intake point is not difficult if you use special drilling rigs. In the article we will tell you about the method of drilling water wells with an auger - we will give a description of the technology and photos. The presence of their own source on the site increases the level of comfort in general - the owners themselves can control the quality and purity of the resource, minimize their costs for utilities, and also arrange a separate life even far from civilization and laid main pipelines.

There are several reasons why this method is increasingly being used for private purposes: high speed of penetration through the ground, the ability to drill to a sufficient depth, and low cost of work.

Auger drilling of wells: what is it and where is it used?

A rotary drilling rig resembles a fisherman’s drill for ice fishing. The device is used in the same way - it is equipped with blades arranged in a spiral. It is installed perpendicular to the surface or at the angle that is necessary, this happens rarely, much more often it is in an even vertical direction. Then two forces are applied - rotation and pressure. The result is a smooth cutting of the tool into the rocks.

Technologically, the apparatus consists of a head (it is the one that cuts into the ground and is a bladed bit or drill) and augers. Their task is to pull out cuttings from the drilled hole, that is, already destroyed layers. The type and materials used to make the tool can be different, depending on the characteristics of the soil. Sometimes these parts are one-piece, monolithic, in which case the equipment is called an auger. The flanges (protruding parts) are designed to move the slurry upward.

The size of the tool is selected based on the fact that the space between two adjacent turns should be occupied by waste rock no more than 20-40% of the total volume. If a larger quantity is filled, it will not be possible to organize sufficiently good cooling of the cutting edges, because they heat up under the influence of friction.

There is a dependency for the flange:

| Drill diameter, mm | Rotation, rpm |

| Up to 100 | 200-500 |

| 150-200 | 100-200 |

In this case, the head is somewhat larger.

This method is widespread. It is mainly used:

- during research - various types of engineering surveys, hydrogeological studies of the area;

- as exploration work to discover minerals and study their properties;

- during construction when installing piles (if you need to install a fence or build a pile-screw foundation);

- for trenchless installation of utility networks;

- to create some type of maps.

But most often drilling with augers is used to obtain wells. In this way, you can extract water from sufficiently deep depths and quickly and efficiently organize a source of hydraulic extraction on your own site. An important point - when organizing the process, be sure to pay attention to the filtration system. Filters are installed for coarse purification, and then for fine purification. The first layer (mechanical mesh) removes large debris and rock debris, then sand, clay, and other suspended matter are removed. Already when entering the house there are cartridges for the most thorough water treatment. You can order installation of the system at – we offer high-quality products and favorable conditions.

Regardless of the purpose for which the well is made, it usually does not exceed 50 meters, however, some soils that are most suitable for destruction allow you to drill up to 100-120 m.

In this case, the diameter directly depends on the depth. With average values, you can take a tool with a cross section from 60 to 600 mm.

Manufacturing of drilling tools

You can make a well with your own hands without special equipment. Making a hand auger does not require complex tools or experience. The garden version of the brace does not need a collapsible rod: you can make a shallow hole for seedlings or under a pole with a monolithic device. When drilling a well under water, the tool is equipped with sectional rods. The latter are needed to build up the drill as it goes deeper into the ground.

The sections are made from seamless water and gas pipes. This material transfers torque well from the handle to the working element. The length of the section is 1.2-1.4 m. The main element of the composite rod is the lock, a part that connects all parts into a single drill rod. Its design should ensure ease of assembly during drilling operations. Lock options:

- Threaded couplings. At the ends of each section, screw threads are made or metal nipples are welded. In the latter case, the alignment of the parts is controlled, otherwise the drill will move to the side. The sections are screwed together and then fixed to prevent unwinding during operation.

- Screw. A nut is welded to one edge of the section, and a bolt to the other. This drill design is suitable for summer cottages when the depth of the well does not exceed 10 m. During extended excavation, the rod will bend and deform.

- Welded couplings. They are made from larger diameter pipes. The couplings are welded at one end of the section, and the other is left free. All elements are assembled sequentially, fixing each joint with a bolt or pin.

For your information!

To equip a summer cottage with a water well, the drill is extended using welded couplings. Such a connection is easy to assemble, because each ascent is accompanied by separation into its component parts, and the subsequent descent is accompanied by new articulation and extension.

In addition to the rod, a working element and a handle are made. The cutting part of the drill is made of a metal pipe and a steel sheet 5 mm thick. Manufacturing sequence:

- A thick drill or metal spike made from a car spring is welded to a pipe with a diameter of 40-50 mm. In the latter case, the shank is shaped like a spear. The peak will set the direction and loosen the soil directly under the drill.

- Screw elements are cut out of sheet metal. To do this, two concentric circles are marked on the surface - the inner one according to the diameter of the pipe, and the outer one according to the size of the well.

- The discs are cut radially on one side. Give the workpieces a screw shape, twisting them at an angle of 30°.

- They are put on the pipe and connected in series. A blade is welded to the bottom to loosen the soil. The knife is made of alloy steel, which will work for a long time without sharpening.

- A coupling is welded to the top of the drill to connect it to the rod.

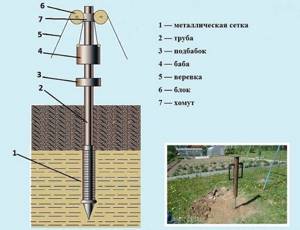

Abyssinian well

The maximum depth is 15 meters, but this is usually enough to mine deep-flowing waters. Such sources are quite suitable for drinking, watering the garden and other household needs on your own plot, dacha, or country cottage. The pumps do not capture perched water (an aquifer that is unsuitable for drinking, as various impurities accumulate in it). There is another name for such a well - needle.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

However, the liquid that accumulates is formed in the upper layers - not below the clay deposit; it comes due to precipitation, as well as with the help of nearby reservoirs. Thus, the level constantly fluctuates and depends on humidity and the amount of rain. In dry summers, the resource may not be enough to supply the house.

Below is the structure of the well:

Advantages:

- Sufficient volume of liquid to supply a large home with all the necessary plumbing and appliances.

- Long-term use - at least 30 years without re-drilling.

- The dimensions (diameter) are small, so you can make such a well anywhere on the site, as well as even in the basement of your own house.

- Verkhovodka does not pollute the extracted water resource.

- No papers or permits are required to carry out work and obtain results.

Flaws:

- It is impossible to make such a depression in hard ground, or where there are a lot of stones or clay. Or rather, it is possible, but it will not be economically profitable.

- Due to the small diameter of the hole, it is rarely possible to equip the system with a submersible pump.

- Vacuum pumping equipment, as a rule, cannot lift liquid from more than 20 meters, so this option is not very suitable in areas where the groundwater lies too deep.

- There is a need for a mechanical filter, because without it a layer of silt may form on the aquifer.

- Sometimes pipes get clogged, you can get stones and clay clots out of them.

Despite the disadvantages, they can be eliminated, so the method of extracting drinking liquid is very profitable.

Sandy spring

If you imagine the soil in cross-section, the layers will be visible. Those located between hard layers consist mainly of sand and fine gravel. They are water-bearing. The good thing is that the resource is immediately purified as it passes through the sorbent. The depths are as follows:

- From 40 to 90 m – on sandstone.

- Up to 40 meters - on fine sand.

A pipe is placed inside the well. In its lower part the walls have perforations so that moisture oozes between the holes. Similarly, a material (mesh) with small cells is spread at the bottom. It looks like this:

Pros:

- High speed of generation of drinking liquid - up to 1-2 cubic meters per hour.

- Documentary permission is also not required, as when creating an Abyssinian well.

- Quite high stability.

- The speed of drilling and arrangement of the source will take about two days in total.

- Long period of operation - up to 30 years.

Minuses:

- If there is a centrifugal pump, it will quickly clog.

- With a slight depth (up to 40 m), the water level will depend on the amount of rain.

- When environmental conditions change, the chemical composition of moisture may change. You need to do analysis regularly.

- Possible siltation and requires regular cleaning.

If you need to use water as a drinking water resource, you should definitely install filtering equipment.

Well and its types

Wells, the depth of which does not exceed 20 meters, are more like wells. They, as a rule, have all the disadvantages characteristic of such man-made water sources:

- firstly, contamination of the aquifer by surface runoff;

- secondly, a short service life, usually not exceeding 4 years;

- thirdly, low productivity, and with the prospect of complete drying out in the hot summer season.

If you can clean a well with your own hands, then this will not work with such a well. It's better to dig a well right away. Because the costs of constructing a well will not correspond to the quality of the water, into which various types of pollutants will enter along with surface runoff. This is for example:

- sewage water;

- small debris;

- chemicals from agricultural fields and vegetable gardens, etc.

If the aquifer lies close to the surface, then all runoff easily flows into it. And then, as a rule, they are carried by groundwater over many tens of kilometers. If the soil layer is shallow, the water absorbed into the soil does not have time to be thoroughly purified, resulting in polluting the aquifer.

Well on sand

Such a well is considered shallow. It is drilled to a depth of 20 to 40 meters. Moreover, the aquifer in this case should lie in a sandy horizon. A water well has the shape of a pipe, at one end of which a pipe-shaped perforated filter is installed. Typically having a brass winding or stainless steel mesh. The filter should be located in coarse sand.

A well of this type has a productivity of 0.5-1 cubic meter of water per hour. For a house in which a family of 3-4 people lives permanently, this is probably not enough. Such a water source can last up to 10 years if used constantly. However, with periodic use, the well will become covered with silt. And within two years it will become unusable.

As a rule, washing the filter with water supplied to the well under high pressure will help get rid of siltation. If this does not help, you will need to drill a new water well.

Artesian depth

Despite the fact that hydraulic production technology is the most complex and expensive, such wells are used very often. The equipment helps to obtain the purest water, immediately intended for drinking, at a depth of up to 200 meters. Such a liquid of crystal purity with an ideal mineral composition (by the way, stable) is found in inter-rock spaces - between rocky and hard rocks. In addition, the volumes of the extracted resource are so large that it is easy to supply not only one site, but also the neighboring one.

AMETHYST - 02 M Residential building for up to 10 people or up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

Advantages:

- The highest quality drinking liquid is tasty, clean, with an optimal level of minerals.

- High productivity - up to three cubic meters per hour.

- Uninterrupted and constant level of moisture, which does not depend on the environment or climate.

- Such a well will operate without re-drilling for about half a century.

Flaws:

- Heavy equipment.

- The need to draw up a project and obtain a permit, notify the water cadastral authority.

- Large financial expenses.

- Long construction period.

Pump types. Installation

There are many types of pumps; let’s look at the most commonly used pumps in water wells:

- There are two varieties - manual and electric. By the way, it would be nice to have both types (for backup in case of a power outage)

- An electric pump is installed at the very beginning of the well

- If the pump is installed on the surface, then pumping groundwater is possible from a depth of only up to 9 m

Surface pump piping diagram

- If the water lies at a depth of 10 - 12 meters, make a pit and immerse the pump in the pit.

- This approach will make it possible to collect water from a depth of 11–12 meters.

- To pump water from deeper layers, you need a submersible pump.

Such a pump is immersed in a well, it squeezes water out under pressure

Before putting the well into operation, take water samples for analysis.

When you turn on the electric pump, water must be poured into the housing, only after that the electric motor is turned on and the valve is opened to supply water to the water supply system.

Specifics of the method

Here are some specific facts about the hydro mining site:

- Cylindrical shape.

- Small diameter and fairly long length.

- Names of parts: the mouth is the beginning, the bottom is the bottom.

Before starting excavation work, calculations and selection are made - mode (rotation speed) and type of equipment. This is determined by the following required and initial parameters:

- What is it intended for?

- What diameter should it be?

- Required depth.

- Duration of operation.

- Conditions (soil type, climatic conditions, site features).

All this does not include economic benefits.

In general, the drilling process can be divided into three successive stages, namely:

- Destruction of natural formations.

- Production of material is its extraction to the surface.

- Cleaning the well and equipping it with pumping equipment, installing a filter.

How effective the method is depends on the physical characteristics of the soil - its porosity, density, hygroscopicity. There is a pattern: the denser the rocks and the larger the mineral elements, the more difficult and longer the work. But the technology is not suitable for mining at all.

Types of drilling

You can drill a water well with your own hands in several ways: auger, rotary, core, shock-rope. The applicability of each type depends on the technical equipment, the depth at which the aquifer is located, and the characteristics of the soil. They differ from each other in the method of rock destruction and the method of removing soil from the canal.

Auger

This type of drilling is the simplest and most accessible. Screw equipment is light in weight and dimensions. You can make a drilling rig yourself. The working body is a screw auger that destroys the soil, holds it on its surface and removes it out. When forming a pit, drilling fluid is not used to lubricate the tool or soften the earth. The auger cannot be used to drill into rocky or rocky formations, as well as quicksand.

Advantages and disadvantages of the method

First let's evaluate the advantages:

- The raising of waste soil occurs continuously.

- There is no need to take out and re-submerge the drilling rig.

- The column plunges at high speed, giving excellent results.

- The ability to use technology on a different scale - from a hand drill to industrial deployment of a site.

- There is no flushing liquid or gas flow as with other methods. This makes the whole process cheaper and easier.

- It is possible to create not only vertical holes, such as for a source of hydraulic extraction or for piles for construction, but also horizontal ones. They are needed for laying utility systems without digging trenches.

- Casing pipes can be installed immediately. In general, the method from start to finish has a very high speed of operation.

- You can dig in any weather, including severe frosts.

- Many areas of use.

There are also disadvantages:

- The need for a powerful installation that ensures the immersion and rotation of a heavy tool at high speeds.

- With classic equipment and conditions, you can drill to a depth of up to 50 meters - the average value.

- Inability to pass through rocky areas. Even if one large boulder is found in the sandy soil along the way, you will have to either pull it out or drill it at a distance.

- If the soils are sticky, viscous (swampy areas, clay), then there will be sticking on the augers and regular cleaning will be required.

- If the rock is abrasive, then the cutters will quickly be used up, and frequent re-equipment of the tool will be necessary.

Step-by-step drilling technology

The auger method is the simplest method of drilling a water well. They can make a hole up to 40 m deep. However, some soils cannot be drilled. If there are rocks or rocky soil in the area, the tool will not be able to overcome them. The greatest efficiency of the drill is achieved on loose and clayey soils. You can learn about the nature of the soil from your closest neighbors who have installed a water source on their site.

Required Tools

Before starting work, prepare the necessary equipment and devices. First of all, they make a drill, a rod, a support tower. The latter is assembled from round or square pipes. The drilling tripod must be stable and rigid to support the weight of all system components. The number of sections of the rod, as well as the casing, depends on the depth of the aquifers; they can be prepared with a reserve or added during operation. In addition, a hand winch and a mechanized wrench will make drilling easier.

Making a screw from scrap materials

The main component of drilling equipment is the auger ripper. It is designed for excavating soil from a borehole channel. In general, an auger drill consists of a central pipe with a diameter of 10 cm, a guide tip and helical blades. The central rod is made of alloy steel, its edges are flattened or sharpened. The auger itself is assembled from individual bent elements. All parts are connected by welding.

For your information!

If there are hard soils or small stones on the site, the auger ripper is equipped with a blade made of durable steel.

Carrying out drilling operations

The construction of a well at a summer cottage begins with the erection of a drilling tripod. Directly under its center, dig a hole slightly larger in diameter than the drill. To prevent the walls from crumbling, they are reinforced with wooden or plywood panels, then the main work begins. Drilling sequence:

- The tool is lowered into the hole and gradually begins to go deeper into the ground.

- As soil accumulates, the drill is removed and cleaned.

- After passing the first meter, the walls of the pit are strengthened with casing pipe.

- When the drill reaches solid ground, lengthen the handles of the rotator to facilitate rotation of the tool.

- They continue to go deeper into the ground, periodically removing and cleaning the equipment and extending the rod. At the same time, the casing pipe is driven in.

- They drill a hole until the extracted soil becomes wet. Then the channel is deepened a little more. When forming a column, do not lower the pipes to the bottom. They should not reach the lowest point by about half a meter.

- The space between the casing pipe and the channel walls is filled with concrete, forming the neck of the source.

- A submersible pump is lowered to the bottom and a cap is installed to close the top of the well.

- Coarse and fine filters are screwed onto the pipeline.

To create wells of various types and purposes in loose sandy soils, auger drilling is most often practiced. The popularity of the method is due to its effectiveness, simplicity, high speed and the absence of complex equipment.

Vertical tunneling technology

The working part (head) plunges into the ground, destroying rocks. The already loosened soil begins to rise upward along the rotor trajectory. It is pushed along the blades of the column without hindrance, because the sliding along the spiral is quite good, while high friction is formed with the walls. With this procedure, the bulk of the soil leaves the mouth to the outside, but a certain proportion falls back into the face. As a result, very good cleaning and final rinsing is required.

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Floor-standing dispenser AquaPro 6207CH (cooling/heating/room temp.)

Horizontal direction

In cases where it is not possible to dig a trench, for example, under a highway or railway, trenchless installation of communications is carried out. This is possible using auger drilling. First, two pits are dug at the same level - the initial and final ones, and the soil will be drilled between them. Then the equipment is installed in the first trench, the column will be directed towards the second, respectively.

In general, the procedure has only a few differences. For example, this is the presence of monitors and motion sensors. Everything is done so that the operator can find out the exact location of the drill head, as well as adjust its direction. After the auger has completely traveled the specified distance and is in the receiving pit, the tool is removed there and a water pipe (or a fragment of another communication) is fixed. When reverse is turned on, the equipment “pulls” it through the hole.

The method not only allows you to cope with obstacles when laying engineering systems, but is also recognized as faster and more economical. The length of the resulting horizontal well can reach 80 meters.

Features of drilling in different rocks

- Clay interspersed with limestone and loam may be accompanied by sticking to the spiral.

- For loose and medium-density sand, an axial load is not needed; the pressure from the drill string’s own weight is sufficient.

- If hard sandy loam, mudstone or siltstone is being processed, apply up to 5 kN per axle only at the initial stage, at startup.

- When there is an admixture of gravel, crushed stone, quartz or the sands are highly saturated with moisture, about 5 kN is suitable.

- Rocks are not processed using this method.

Tool

All equipment varies according to:

- the number of turns and the size of the interturn space;

- geometric features of cutting edges;

- the presence of additional attachments;

- diameter

The type of drill head depends on the type of soil you will have to work with. Sometimes there is a supply of additional cutters, and in other cases a standard set is enough. To go deeper into the earth's crust, rods are built up.

In addition, the angle of rotation of the blades is distinguished. Some are turned to the bottom only by 40-60 degrees (loose sands and soft loams require this), others - by 90 when drilling, for example, clay.