Land owners are increasingly using pergolas on their property. The structure consists of several arches that are connected to each other by means of transverse beams. A pergola can be easily built with your own hands; all you need is the necessary materials and tools.

What is a DIY pergola used for?

The structure performs the following functions:

- support for climbing plants;

- dividing the territory into zones;

- great place to relax;

- decoration of the local area;

- camouflage of utility rooms;

- protection from the scorching sun;

A pergola is usually located behind the house or above garden paths. The structure is permanent, does not move from place to place and is not dismantled in the winter. For these reasons, it is very important to decide on the choice of model.

Functions and structure

Translated from Latin, pergola is a canopy, an extension. Thus, this design has the appearance of an arched structure on supports with a lattice roof. It can stand alone or be attached to residential buildings, for example, to cover the terrace of a house, serve as a kind of corridor between buildings, and can also form a garden path from the house to the gazebo or pool.

Today, pergolas are used for the following purposes:

- support for climbing and weaving plants;

- protection from the sun, partly from wind and light rainfall;

- creating a place for comfortable rest and privacy;

- zoning of the territory;

- increasing the decorative quality of the territory;

- connection of two functional areas of the site;

- hiding unattractive areas of the garden and outbuildings.

Pergola in site design.

Pergolas can be made from a variety of materials: metal and wood, stone, brick and concrete. Also, the design can be of different types:

- Screen (trellis). It has the appearance of a mesh partition, which is ideal for zoning the garden and covering unattractive areas of the yard.

- Tent. Such structures can stand alone or be attached to a building. They have the appearance of a round or square arbor. Also used to create a shadow over a car or over a children's play area. The roof is usually openwork, so there is light partial shade below.

- Tunnel (corridors). Usually used above garden paths, connecting two buildings or two sections of territory. They can be created from broken or winding lines with a common guide.

- Canopy. They are attached to the facade or installed above windows for shading.

Considering the variety of building materials, the possibilities of their combination, as well as the versatility of shapes, decorative canopies for plants can have completely different looks, from the most laconic to the elaborate and luxurious, for example, with a base made of natural stone and wooden carved arches.

Pergola with arched top.

Pergola as a decoration

An openwork pergola will successfully decorate the territory of any garden. Romantic designs entwined with green plants were used in Russian gardens, in Europe, and in the countries of the East. Modern landscape designers are increasingly using original landscaping in the form of pergolas in garden compositions. Beautiful garden pergolas not only decorate the garden, but also provide shade on hot days.

Interesting! The first pergolas appeared in the Mediterranean.

They were used to support grapevines.

What types of pergolas are there?

In order for a beautiful architectural structure to fit into the arrangement of the site, you need to carefully choose the shape and style of the building. First you need to determine for what purpose the building is needed. Depending on the area of the site and the presence of the main buildings, pergolas are constructed in various shapes:

- Rounded. With original lines of design details, you can create an oriental style.

- Fan-shaped. The shape of the building is rectangular, the roof is made of wood, there are columns. Well suited for classic and country styles.

- Openwork. The design has a lattice braided with greenery. Creates a feeling of romance. Suitable for small areas.

- Made of stone or brick. Will serve as an excellent decoration for a large estate.

Pergolas for the garden

Species diversity of pergolas for summer cottages

A pergola is a canopy whose support is represented by repeating arched sections connected by cross beams. A garden pergola can be a free-standing structure or part of a building. This design has several purposes, including:

How to choose New Year's gifts for school Features of boiler rooms and descriptions of varieties How to build a gazebo out of wood with your own hands? Quarantine at home! How not to get sick?

- zoning of the area;

- decoration of the site;

- vertical gardening;

- decorative design of the landscape;

- camouflage of buildings;

- design of gates, fences with gates.

The versatility of the design has made it extremely popular in modern landscape design.

A pergola is a canopy whose support is represented by repeating arched sections connected by cross beams

By type and style of construction

In terms of configuration features, all pergolas are presented in the following options:

- awning-type models are used as effective protection from ultraviolet radiation and a canopy over children's playgrounds or parking lots;

- models in the form of a visor are especially in demand for creating an area for shading windows from direct sunlight;

- models represented by carports have become widespread due to practicality and functionality;

- models in the form of a gazebo can serve as a good shelter from direct sunlight, but cannot provide complete protection from precipitation;

- models in the form of a screen conveniently divide the area into separate zones and allow you to delimit spaces with different design styles;

- tunnel pergolas are a classic landscape option, and are used to create a beautiful passage between all structures;

- models in the form of a bench make it easy to create a romantic corner in the local area.

Models in the form of a gazebo can serve as a good shelter from direct sunlight, but cannot provide complete protection from precipitation

By material

Depending on the materials used, the designs can be:

- wooden;

- forged;

- metal;

- plastic;

- stone;

- brick.

Of particular interest are combined structures made from several types of building and finishing materials.

Of particular interest are combined structures made from several types of building and finishing materials.

By purpose

Wall-mounted or stationary pergolas, reminiscent of gazebos in appearance, are designed to decorate recreation areas and are located directly next to the household. Free-standing structures are independent elements of landscape design and are widely used in decorating a garden plot:

- garden pergolas can be round, square or broken-shaped;

- pergolas in the interior of a private house can also be presented in different configurations. Most often, openwork type structures are used in home design.

The second option is very original and is a part of the household or a kind of veranda, on which a pergola is used instead of a roof, the walls have the form of columns and latticework. When choosing a type, you need to correctly determine the size. Too large and cumbersome structures in small areas look ridiculous. The wrong choice of height creates insufficient shade, and small structures rarely support the weight of large climbing plants.

What can you use to build a pergola with your own hands?

At the beginning of the pergola construction process, you need to choose a base. The main condition is its perfectly flat surface. This could be a platform covered with concrete, crushed stone, grass for lawns or paving slabs. If necessary, the top layer of soil is removed.

The structures can be metal, plastic, stone, and brick is used for supports. The most popular and simple material is wood. Wood can be used both cheap and expensive varieties: oak, pine, larch. The supports and crossbars are usually decorated with ornate carvings. Birch logs are excellent for pergolas. The wood must be dry and treated with an antiseptic.

Interesting! During the Renaissance, designs were reborn as European demand for ancient architectural elements emerged.

You especially need to guess the size of the pergola. A small narrow structure looks boring, a large one will most likely not be overgrown with plants to the top. The optimal height of the building is approximately 2.3-2.5 m, width - 1-1.5 m. The length of the structure varies.

How to make a pergola with your own hands: step-by-step instructions

Constructing an elegant building yourself is not particularly difficult; it may only take 2-3 days. But the pergola will only become beautiful after about a year, when plants fill the ceiling and walls of the building.

How to make a wooden pergola with your own hands: step-by-step instructions

It is better to choose a rectangular structure for your own construction.

What you will need

The following parts are needed for work:

- pillars for support and wooden blocks (12x12 cm) for supporting structures;

- boards (10x5 cm) for beams that will lie across;

- slats (5x5 cm);

- gratings with trellises made of wooden slats or metal mesh;

- nails;

- self-tapping screws;

- brackets for fastening;

- concrete solution;

- container for mixing the solution;

- screwdriver;

- hammer;

- a garden drill or at least a shovel;

- mixer for construction;

- level;

- axe;

- chisels.

Preparation

For installation, a place with fertile soil suitable for planting is selected. You need to think about which object the structure will be adjacent to: a building, a fountain, a sculpture. Then make a plan and draw a diagram.

Methods

According to the number of pillars, you need to dig holes 80 cm deep. The minimum width of the building is 1 m 50 cm. Next, you should prepare molds for the formwork, pour cement into them and insert metal tips into them. After 2 days the cement will harden.

Pergolas for cafes

The beams are attached to the ends using screws. The beams are secured with self-tapping screws in such a way that sharp corners are formed at the point of their connection to hold plants on them.

The supporting beams are placed in a horizontal position using screws, metal plates or grooves. The sheathing is made with slats that are connected crosswise; you can create a different pattern.

Nuances

The building should look light, weightless, openwork, despite the material from which the pergola is made. The structure must be strong and not bend or break under the weight of plants or snow. The direction of the winds should be taken into account.

Interesting! Berso was the name given to the intertwined willow or hazel rods at the top, creating a series of arches.

In winter, autumn or spring there will be no plants on the building, so you need to make sure that the pergola elements have a pleasant appearance. Wooden buildings must be periodically coated with antiseptic agents to prevent the wood from rotting.

Ready-made parts for the structure can be purchased in specialized stores and assembled yourself. You can also order elements from specialists.

Let's start construction

When building a wooden pergola, the problem arises of isolating the wood from the ground - for greater durability. You can also treat the wood with an antiseptic to increase its service life. Today they use the following solution. These are metal cups or U-shaped structures; metal reinforcement is welded to them. This reinforcement is placed in the foundation, and wood posts are installed in glasses. At home, to implement this idea, you can use pipe scraps and a square profile of a sufficiently large cross-section. You can also use multiple corners. That is, it is necessary to cut the corner into two pieces of 50–60 cm each. Next, according to the size of the beam, the posts drive these corners into the ground so that the post is held tightly between these corners. After this, the corners are secured by welding with metal reinforcement near the ground surface.

34765d1a880357cccf31c995942079fe.jpe

f00125222f6a5411d508b601dfec0a95.jpe

f2270e98d7b651908afe9f0e97bfae96.jpe

7a0ed0a8bcd184e4c9281c18ad761b05.jpe

When using a bench with a curved design, the back row of bench supports was initially used as supports for the pergola itself. For the supports of a circular structure, a beam of small thickness (50 × 50 mm) is usually used, since this shape resists strong winds well. It is attached to the legs of the bench, which are shaped like the letter L, using self-tapping screws. It is also necessary to place a stone under the support to insulate it from the ground. After the lawn grows, the gap between the pergola and the ground will not be noticeable, and there will be a feeling that it is dug into the ground. This gap increases the wear resistance of the wood. After the support is completely installed, the top must be cut at an angle of 30–40 degrees, and the entire support must be soaked with an antiseptic solution.

Next, all other supports are installed using the same method. The thickness of the beam will differ only at the central support - it is equal to 100 × 100 mm. A special device is made in this support for fastening all horizontal rafters. We are not talking about ideal horizontal rafters here. They are attached at a slight angle relative to the main support. This place will be the highest. Accordingly, the main support should be higher than the others.

Main components of pergolas

Despite the simplicity of the design, you need to correctly assess the load of plants and snow. Therefore, connections and fasteners are created strong, with the addition of corners. It is necessary to make stops and jibs to impart rigidity. When creating supports from stone or brick, there must be metal pipes inside.

Dimensions

The dimensions are taken in direct proportion to the territory. If the area is small, the space between the posts is 1.5 m. For larger areas, the distance is correspondingly greater.

How to connect the parts at the top

Particular attention should be paid to the connection nodes. The simplest way is to connect the post and the main beam using a beautiful buttress. A beam is placed on top of the support and strengthened with nails. To enhance the eversion, a decorative buttress is stuffed. A spacer or jib will give the building more rigidity.

Pergola for your garden. Styles and types of pergolas

Beam edge decoration

To diversify the appearance, you can decorate the edges of the main and auxiliary beams. To ensure that the cuts are the same, you need to make a template. Then you need to apply the template to the workpiece and trace it with a thin pencil, then cut it out.

Cheaper design

The beams and main beams used are not of small cross-section, so they are expensive. It will be cheaper if you nail boards to the racks at the top on both sides. They are connected with nails or bolts. Instead of the main beams, it is quite possible to use double boards.

(4 ways)

Method one (put on top and nail)

This is the easiest way - take our horizontal beam and simply place it on TOP OF our support posts. And secure it with a long screw.

One important detail

– in order for such a fastening to be resistant to gusts of wind and other loads, we will screw one screw vertically (through the beam - in the center of the support column) and insert two more screws at an angle (on the left and right) - like here in the photo.

Method two - metal plate

We also place the beam on top of the support post - and attach two L-shaped (or one T-shaped) metal bracket and drill it with screws.

On the other wall of the beam, we do the same.

Method three - groove in the support column.

You can make a groove in the support column itself (choose the width of our horizontal beam). And insert a beam into this groove

. The method is good, reliable - in ancient times this is how they did it, without nails. In our time, it is still recommended to secure such a “groove” connection - so that it is stronger.

You can do the same work on the ground

(below) – so as not to climb so high... it’s scary..

...and then install the pillars - immediately with horizontal beams inserted into them...

This is only suitable if your pillars will not be cemented into the foundation... and then you can assemble the frames on the ground (2 pillars + a horizontal beam and again 2 pillars + a horizontal beam) - and then install these two “portals” in the planned location... and finish the roof. Decide what is more convenient for you...

Method four (without beams) – EDGING BOARD.

Why do we need beams (boards are cheaper). And the horizontal beam can be replaced with two edged boards placed on the support post on one side and the other (Fig. 1)

The top of the post can be left sticking out - we can then attach transverse beams-boards to it (Fig. 2). Or we may not leave...

This method is good because -

that there is no need to lift heavy beams to a height (the board is much lighter). I found a video on YouTube where a young married couple assembled such a pergola together) the wife held one end of the board - the husband drilled the other... It was nice and friendly - they did everything in one evening.

Do-it-yourself wooden pergola: step-by-step assembly instructions

First you need to decide how the supports will be attached. If larch is used for pillars, they are buried in the ground. If another tree is used, its contact with the ground is undesirable.

You can also build a pile of concrete with a pin or several placed in it, it all depends on the dimensions and weight of the building. The stand is attached with a small gap, up to 1 cm.

For a covered or concreted platform, metal bearings are taken in the shape of the letter “P”. The post is secured with long bolts through the plates. Errors will be covered in green.

Metal pergola

Pergolas are made of metal in all shapes and sizes, but most often they are small structures. For installation, 2 types of connection of parts are used:

- Welded.

- Bolted on.

You can find frames twisted with knitting wire, but we will not consider this method in this article.

Let’s make a reservation right away that bolting a pergola from metal reinforcement simply won’t work. This method is suitable for connecting a frame made of corners or profile pipes. Over time, such a connection may weaken due to corrosion and the structure will be shaky, and if plants grow on one side, it may become skewed.

Let's focus on welding connections, especially since this is not a problem now. By purchasing or renting an inverter welding machine, you don’t have to worry about the fact that the network won’t withstand it and the wiring will burn out.

At welded joints, the metal rusts intensely. If you cook with CO, then there will be no such problem.

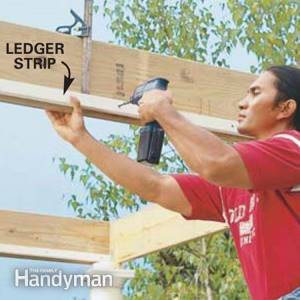

Features of pergolas attached to the house

Pergolas attached to the building are a kind of terraces. Some of the supports are adjacent to the holders on the wall of the building, the other part rests on beams placed on the pillars. You can install steel stops of the desired configuration on the wall.

All steps are the same, but have some special features:

- Marking the mounting locations of poles and their installation.

- The distance from the house is equal to the depth of the pergola.

- Another marking is placed on the wall of the building, where the other edges of the auxiliary beams will be mounted. This is where the plates or supports are attached.

- 2 boards or a support beam in the upper part are attached to the posts.

- Auxiliary beams adjacent to the support on the wall are laid on the boards.

Top assembly

Capitals are placed on top of the columns, after which the outer beams (50x250), marked in the diagram with the letter “E”, are installed, which are secured with steel corners.

Two beams F1 and a middle one F2 (50x250 mm) are attached to them using corners and self-tapping screws. After installing these three beams, 25x50 mm guides are screwed to them over their entire length. Self-tapping screws should grab the guides every 20 cm.

Cross bars (50x200) are installed on guides and attached to the main beams on each side with three self-tapping screws.

Manufacturing of sidewalls

The sides are cut according to a template from a board of the same size as the crossbars (50x200). Then the planks are screwed onto them from above, and the entire structure is attached to the beams and cross members using self-tapping screws.

After placing the sidewalls, the upper strips are installed. Their number can be arbitrary depending on how shady you want to make the area under the pergola.

Finally, you should make ventilation holes in the column caps and install a PVC pipe with an angle fitting in them on the sealant.

Before painting the pergola, do not forget to putty and sand the heads of the screws.

Based on materials from The Family Handyman magazine.

You may also be interested in: - 8 mistakes when building frame houses (photos)

How to build a metal pergola with your own hands

A do-it-yourself pergola for climbing plants can be built from metal. The material is stronger, more reliable and durable compared to wood. An arched building made of metal is easier than one made of wood. Externally, the original pergola looks like an openwork forged product.

Pergolas for gazebos

The material is selected depending on the ability to handle metal. The choice should fall on solid and durable metal, since it will have to withstand a lot of weight. The structure is fixed in the ground and concreted. An important condition for installing an arch is to strengthen it and increase its durability. The stronger the fastenings, the longer it will last.

Material used

You can make a canopy on your site from all available materials, but you should pay attention to those that have proven themselves most successfully in this area.

Brick

It is suitable for the construction of an arch only if all structures on the site are made with its help and only for the purpose of supporting the general background of the architecture. But in general, this material looks bulky and heavy. The entwining plants on it will be inorganic and weakly expressive.

Metal arches

They look delicate and interesting. The disadvantages of this type will be the high cost of construction and installation - it is impossible to install such an arch without special equipment - as well as the natural corrosion of the metal over time. Additional funds will be needed to maintain the arch in proper form.

Tree

The best choice when looking for building materials for a pergola. It is impossible to imagine a more harmonious and natural support for climbing plants. Natural material looks luxurious in its natural form without additional processing or painting.

Ease of use and ease of construction are ensured by the low weight of the material itself, of course, if it is well dried. In addition, the tree is affordable to anyone who decides to decorate their site with such a building. Creating a canopy made of wood is as easy as shelling pears – just follow the instructions and advice of professionals.