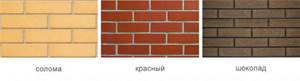

A fence made of corrugated sheets with brick pillars is highly durable and reliably protects the area from the penetration of uninvited guests and animals, and brick pillars give such a fence a very rich and aesthetic appearance. When building fences for a summer residence, corrugated sheeting with a colored polymer coating (polyester) is usually used. It provides excellent corrosion resistance of the installed fence, attractive appearance and color schemes in accordance with the overall design concept of the house and site. The primer and polymer coating are applied to the corrugated fence by the manufacturer. The brick pillars themselves can be laid out of facing bricks of various colors and textures, clinker and ordinary building bricks. Next, such a pillar can be covered with decorative plaster or covered with decorative stone.

Materials and components for the construction of corrugated fences with brick pillars

- Types of bricks

- Profile types

- Color palette

- Pillar decor

- Caps

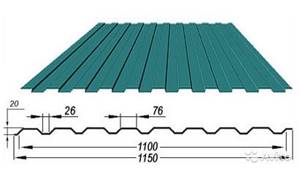

Profiled sheet S-8

Profiled sheet S-8

The most common type of corrugated fence.

It has an optimal combination of price and quality. Due to the symmetry of the waves, an imitation of a picket fence is created. To ensure normal fence rigidity, it is recommended to use a thickness of 0.4-0.5 mm. Profiled sheet C-20

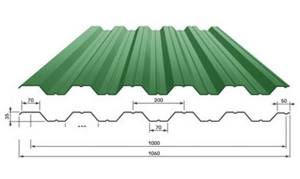

Profiled sheet S-20

A beautiful type of corrugated board for a fence.

Has significantly greater section rigidity. It can be used in a thickness of 0.35-0.5 mm, especially when adding additional logs. Profiled sheet NS-35

Profiled sheet HC-8

The most rigid corrugated sheeting for a fence.

When using such a profile, you can increase the spans between pillars and reduce the number of logs. Such a profiled sheet can be installed horizontally without crossbars at all. Such corrugated sheeting can be used in a thickness of 0.32-0.35 mm, especially when using additional logs. Facing brick

Clinker brick

How to make a combined fence from brick and corrugated board: the main stages of construction

If you decide to build a fence from corrugated board and brick with your own hands, you need to familiarize yourself with the details of each stage of work in advance.

Fence project

Before you start drawing a sketch, you need to mark the area where construction is planned. This is done using pegs. Mark the places where the supports will be placed and measure the distance between them. The gate is not taken into account when calculating profile sheets.

If a sectional option is chosen, the width of the span between the supports should be equal to the width of the profiled sheet. This will avoid wasting material when cutting sheets.

After this, you can start drawing the project. In the sketch, it is necessary to note surface unevenness, obstacles in the form of pipelines, gas pipelines, and electrical communications.

Calculations and selection of materials

It is necessary to calculate not only the volume of materials spent, but also which tools are available and which ones will have to be purchased.

Pay attention to the type of coverage

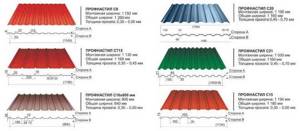

Fences in which brick supports are connected by corrugated sheeting have an endless number of design solutions. However, it is necessary to pay attention to the technical markings of the sheets. The number indicates the width of the wave on the canvas (in mm).

The most common markings:

- S-8. A budget option. Such sheets will be subject to deformation due to gusts of wind. The material is easy to damage. Therefore, this variety is suitable for wall cladding, and not for fencing.

- S-10. This material produces lightweight and reliable structures that are resistant to mechanical stress and retain their original appearance. More expensive than S-8.

- S-14. Has increased anti-vandal characteristics. Used in areas with harsh climates. It is in demand among buyers due to its trapezoidal shape. It is preferred for decorating entrance gates with metal sheets.

- S-15. This marking value begins with the types of coatings that can be used for roofing, facades, and fences.

- S-18, S-20, S-21. The most durable varieties. They are recommended to be used if the fence is higher than 2.5 m.

The choice is determined by the size of the fence, climatic conditions and soil. In many cases, grades C-8 and C-10 are suitable.

The quality of the sheets’ protective coating is no less important. It is not recommended to compensate for the low quality of a metal profile with expensive paint. For each type it is better to choose the appropriate color option:

- zinc is an inexpensive but reliable coating that is used in most cases for non-residential buildings;

- aluzinc - has a more attractive appearance, but is not used when processing profiled sheets for residential buildings;

- polyester - protects the material from rust and corrosion, easy to clean;

- pural or plastisol - used for fences whose service life should exceed 10 years, the most expensive type of coating.

Preparing tools

Most of the devices are in every workshop, these are:

- rope;

- hammer;

- shovel;

- roulette;

- level;

- plumb line;

- screwdriver

Specific to these types of work are a welding machine and a concrete mixer. The latter can be replaced with a drill with a mixer attachment.

When designing, you need to consider whether it is worth purchasing expensive tools and whether they will be needed for further work. You can also rent them at a rental service.

Soil preparation

The top layer of soil must be removed. Subsequently, it can be used for fertilizer. Then you need to dig a trench for the foundation of at least 30 cm. In this case, the dimensions of the future fence are taken into account.

This procedure can be performed independently or by hiring workers. No special equipment required.

Installation of formwork

The structure is made from recycled wood. It should include reinforcement for strength, which is made from rods with a cross-section of 1 cm. It is recommended to start assembling the formwork from the top board.

The distance from the bottom of the trench to the reinforcement should be 10 cm, and to the top - 5 cm.

Metal pipes secured with reinforcement are also installed in place of future brick pillars.

At all stages, a level is used for leveling.

Pouring the foundation

You can mix concrete by hand, although its quality will be lower than that prepared in a concrete mixer.

To enhance the frost resistance of the mixture, soap is added to it in a proportion of 10 ml per bucket of concrete.

After the solution is poured, the foundation is covered for 1-1.5 weeks with plastic film so that when it dries, cracks do not form or uncured cement is not washed away by rain.

Construction of pillars and installation of covers

The height of brick pillars depends on the design. The permissible clutch size per day is no more than half a meter. To fasten the bricks, use a solution of cement and sand (1:3) with the addition of soap and reinforcing mesh. The corners for fastening the corrugated sheets and the plate are placed at an equal distance.

To give the structure a complete look, the pillars are covered with covers. They can be made of galvanized iron, attached with dowels. Concrete supports are completed with concrete covers, which are placed on cement mortar.

Frame construction

The construction of the frame can begin only after the foundation has dried. To do this, rectangular frames are made from metal pipes. Before installation, they are coated with alkyd enamel and installed on the fence.

Before starting the final stage of installation, fastening the corrugated sheets, it is recommended to cover the foundation with cardboard to avoid damage to the panels.

Cost of a corrugated fence with brick pillars

Covering: PRINTEK Color: Log Light wood Number of joists: 2 Self-tapping screws in color: YES Brick column: 380x380x2000 Foundation: 380x400 mm Fence - 1580 RUR/linear meter Foundation - 3980 RUB/linear meter Pillar - 12734 RUR/piece

Covering: POLYESTER Color: RAL 7024 Number of joists: 2 Self-tapping screws in color: YES Foundation: 380x400 mm Brick column: 380x380x2000 Facing: CLINKER TILES Fence - 1010 RUR/linear meter Foundation - 3980 RUB/linear meter. m Pillar - 21,460 RUR/piece

Height 2.0 m Profiled sheet C8

Coating: POLYESTER Color: RAL 3005 Number of joists: 2 Self-tapping screws in color: YES Foundation: 380x400 mm Brick base: 3 rows Brick column: 380x380x2000 Fence - 960 RUR/linear meter Foundation - 3980 RUB/linear meter Plinth - 3528 RUR/pcs Pillar — 12734 RUR/pcs

|

Fences made of metal picket fences with polymer coating Printech

The package includes: Strong metal picket fence with Printech coating on one side Bog oak and Pine, posts 60x60x2 mm, joists 40x20x1.8 mm, frame color - Soil GF-021. Brick pillars and strip foundations are paid separately.

| Fence height | Picket fence profile | Distance 5 cm between picket fences | Distance 3 cm between picket fences | Checkerboard (double-sided fence with a distance between picket fences of 8-9 cm) |

| 1,5 | M | 1450 rub./m | 1540 rub./m | 2000 rub./m |

| 1,8 | M | 1580 rub./m | 1690 RUR/m | 2200 rub./m |

| 2,0 | M | 1570 rub./m | 1680 rub./m | 2170 RUR/m |

| 2,2 | M | 1720 RUR/m | 1850 rub./m | 2400 rub./m |

| 2,5 | M | 1650 rub./m | 1750 rub./m | 2250 rub./m |

The procedure for installing a fence made of corrugated board on brick pillars

- 01 Marking the site When marking the site, we use a level, tape measure, pegs and string. At this stage of fence construction, pegs are placed at the border of the site, under the entrance group, as well as marking the levels of the foundation and brick pillars when there is a difference in the relief of the site.

- 02 Arranging the foundation

At this stage, we dig a trench for the future strip foundation and separately make a foundation for each brick pillar. Then we install formwork made of laminated plywood, add a sand cushion, lay a frame of reinforcement and fill everything with concrete grade M200-M300, followed by vibratory compaction. - 03 Laying brick pillars

At this stage, brick pillars are laid. The brick is laid around a metal pillar 1.5 bricks wide. Thus, the column turns out to be 380x380 mm in size. When laying into a pillar, metal embedded elements from the corner are laid in advance. The internal cavity is filled with cement mortar. After masonry, the masonry joints are jointed to seal and give the joints a beautiful appearance. - 04 Installation of decorative elements

The tops of the brick pillars are capped with decorative caps made of sheet metal in the same color as the corrugated sheet, or cast from concrete or alabaster. A metal casting of the same color as the corrugated sheeting is installed on the surface of the foundation. - 05 Installation of metal frame and corrugated sheets

At this stage, horizontal crossbars are welded to the brick pillars, to the pre-installed mortgages. The welds are cleaned and treated with a primer or paint, which provides anti-corrosion protection for the fence. Sheets of corrugated sheets are attached to the logs, overlapping one wave, using metal screws in every second wave. - 06 Installation of gates and wickets

After installing the corrugated sheeting, we proceed to installing the gates and wickets. To do this, racks with hinges and also wicket recesses are welded to the protruding embedded elements of the brick pillars. The frames of gates and gates must fit into the opening very accurately, with a gap of no more than 10 mm. Gates and wickets are equipped with all necessary locking hardware.

Examples of beautiful fence designs

Options for design solutions may be different. The main thing is to lay a strong, solid strip foundation, on which a brick fence with corrugated sheeting will last for many years without deformation.

The service life of a combined fence is determined by the quality of the foundation

4 main types of structures:

- The inside of the columns is filled with reinforcement and filled with concrete mixture. They are laid out in 1.5-2 bricks on the front and back and 1 on the sides. For a longer service life and aesthetic appearance, decorative metal, concrete caps or lighting elements are installed on the surface of the poles.

- The lower part of the fence is made of brickwork or monolithic concrete; this option looks much more beautiful than installing a profiled panel along the entire height of the fence.

- Installing a corrugated sheet when it completely covers the supports does not look very good; it is much more aesthetically pleasing when mounted on poles. A prerequisite is that its length should not exceed 3 meters.

- You can install a metal profile in two ways, in a vertical and horizontal position. You should choose a metal thickness of 0.5 mm.

It is best to use profiled panels with double-sided polymer coating. It provides good anti-corrosion protection and is resistant to mechanical damage. Uncoated sheets are only suitable for temporary fencing.

Why our company

- High quality Thanks to our own production, the use of high-quality materials and professional equipment, we always achieve high quality.

- 2-year warranty Thanks to our own production, the use of high-quality materials and professional equipment, we always achieve high quality.

- Competitive prices Since we work closely with domestic suppliers who provide us with discounts, we are able to maintain affordable prices for wood-look corrugated board fences.

- Stable budget After we draw up a budget plan and agree on it with you, the final amount will be approved. This means that there will no longer be any additional costs included in the estimate.

- Delivery of materialsOur teams are fully staffed. We cover all costs for delivery of materials to your site. All you have to do is call and order fence installation.

- Convenient payment options Our company provides various payment options. You can pay us directly at the site or through any Bank of Moscow office using a bank card.

- Manager visit We can organize a team visit to your site at a time convenient for you. At the site you will be able to sign an agreement, after which our specialists will begin fulfilling the order.

- We do it thoughtfully and responsibly. Fast, but neat, smooth, beautiful.

Details

Drawing up a foundation project

When constructing a fence made of profiled flooring and with brick pillars, the base is an extremely important component. The foundation will provide reliability, stability and prevent premature structural deformation. The difference in the price of certain foundations can be noticeable, and therefore, before starting work, you should perform a full calculation of all types of foundations and select the most suitable one, taking into account the properties of the soil and terrain. Brick fences with profiled decking are a very heavy structure, and therefore, in order to avoid the need for complex repairs in the future, when choosing a base, it is worth taking into account even the depth of freezing of the ground. For fences with brick pillars made of profiled sheets, a combined, columnar and strip type of foundation is usually used.

How to build a fence from brick and corrugated board

Installing a high-strength fence made of profiled decking is not the easiest thing, and therefore, if you do not have experience, then it is better to trust the construction process to professionals. This makes it possible to create a durable, beautiful fencing of a private area and avoid additional expenses for repairs already in the first few years of the operational process. The construction of a fence involves the formation of brick pillars and reliable fixation of a profiled sheet. In this case, the following operating technology is performed:

- Territorial marking consists of installing boundary pegs at the same distance along the general perimeter of a plot of land. Between them it is worth stretching a rope or a strong cord, which will mark the boundaries of the fence.

To calculate the number of supports, it is worth dividing the length of the fence by the width of the span and adding support posts, which are important for the design of gates and wickets. The size of the support pillars is chosen taking into account their deepening into the ground by 1/3 of the total length. To install support pillars, you need to form holes lower than the freezing point of the ground. This makes it possible to prevent deformation of the base and structural elements of the fence as a result of snow melting in the spring. on rocky soil, the freezing depth can be ignored, and a sand cushion with a height of 0.1 meter is created at the bottom of the pits.

- Between the support pillars it is worth digging a trench for the strip base, and the usual width of the base is approximately 0.3 meters, and the height above ground level will be 0.15 meters. Depending on local geodesy and soil characteristics, such indicators can be adjusted to varying degrees.

- At the bottom it is worth forming a dense sandy cushion from a mixture of gravel and sand, and the thickness should be approximately 0.1 meter, and it should also be thoroughly compacted.

- The formwork should be assembled from edged boards or OSB boards. The frame for the formwork should be made of transverse beams.

- The reinforcing frame should be assembled from metal rods with a cross-section of 1 cm. Vertical posts are mounted at a distance of 0.4 meters from each other, and then fastened with transverse rods using soft wire.

- The installation of support pillars is carried out taking into account the vertical level, and the filling is carried out with concrete mortar using Portland cement, the grade of which is at least M400.

- To make a concrete solution you need cement, crushed stone and sand in a ratio of 1:5:3. If the length of the fence is short, then you can make a high-quality solution with a uniform consistency, which ensures the necessary structural strength, using a concrete mixer. If the fence must be long, then it is more convenient to order ready-made concrete from the factory.

- After pouring the base, it is covered with film and constantly moistened with water. In this form, the base for a fence made of profiled sheets stands until it dries completely, and then you can begin finishing the base with stone or brick.

- To create brick pillars, moisture-repellent bricks of the highest quality are used. A protective cap made of metal or cement should be installed on top of each support column.

Now about the gates and their creation.

By ordering a fence made of corrugated board with brick pillars you will receive

When ordering the construction and installation of a fence made of corrugated sheets with brick pillars in our company, you will receive a guarantee certificate that will confirm not only the quality of the work performed, but also our legal responsibility. Consequently, we will provide you with post-warranty service for the installed fencing for two years.

Order the construction of a fence from corrugated sheets with a 2-year guarantee

Advantages

Exterior view of a fence made of corrugated sheets on brick pillars

A fencing structure with brick pillars and corrugated sheet filling has a number of undeniable advantages:

- such a combination of materials allows not only to reduce construction costs, but also to significantly improve the aesthetic characteristics of the fencing structure itself, which harmoniously fits into the surrounding landscape and looks good against the background of any building;

- profiled steel sheets are reliable, durable, and able to withstand wind and mechanical loads;

- due to the presence of a protective polymer layer, corrugated sheeting is highly resistant to ultraviolet radiation and corrosion;

- a wide variety of color schemes, which makes it possible to select the material to match the appearance of the building, in particular the roof, and other elements present in the garden area;

- light weight of the structure, due to which there is no need to build a powerful foundation;

- the ability to quickly replace damaged profiled sheets;

- durability - the operational period can vary from 25 to 50 years, depending on the correct installation and climatic conditions.

The advantage also lies in the simple installation and the ability to do the work yourself. Thanks to the brick pillars, the structure acquires originality and solidity.

Sectional or combined

The desire to save money or appearance - it is difficult to say which of these factors makes such masonry so popular.

The stone goes well with other materials; it can enhance them. For example, a fence made of corrugated sheets with brick pillars looks much more interesting than a simple fence made of corrugated sheets.

From brick and forging

The most elegant and beautiful brick fence is a combination of fine artistic forging and solid stone. The classic open type - with brick pillars and a small base, no more than half a meter high.

Instagram @markthebricklayer

Instagram @thisfrenchhouse

Instagram @aleksey_russvar

Instagram @zaborsst

Instagram @slavkirp.official

There is also a more closed model of a fence made of brick and forging, where the ratio of materials is approximately the same. The pillars and lower part are made of stone, and the upper part involves artistic decoration; it is this that gives the whole structure lightness.

Instagram @enarchitects

Instagram @gmdiamonds

The third option is to use forged elements only in the upper part of the wall. At the same time, the fence itself is made using the technique of solid masonry, that is, without gaps. Forging in this case has only decorative and protective functions.

Instagram @alexeyguselnickov

Instagram @alexeyguselnickov

Instagram @kovkamodern_istra

Instagram @elitniezabory

If you like this type of fencing, be careful when choosing the manufacturer who will forge the composites and the installer. This is a fairly heavy structure and if installed incorrectly, it can be damaged, or even worse, it can quickly fail.

Fence made of brick and corrugated board

This option is chosen most often. The advantages are obvious: such a structure will cost less than a solid brick one, but will last at least 50 years, or even 70 years. Do you want a solid wall? Choose solid profiled sheets. And the structure we are looking at is made from Euro picket fence; it looks like corrugated sheeting, cut into separate parts.

Instagram @stroimvmeste_stupino

Instagram @metalroof.by

Instagram @kzm2006.ru

Instagram @zaborprofil.ru

Instagram @stroitelstvo_domov_krd

One of the main advantages is the simplicity of construction. The combined model can be built independently with a minimum set of tools. The design features allow you to use sheets of any size; the main thing is to choose the material and correctly calculate its quantity.

Any type of profiled metal sheets is suitable for constructing a fence: polyvinyl chloride, pural, polyester and plastisol. Even a dark metal profile will retain its appearance for a long time, since it is resistant to sunlight and temperature changes.

Instagram @brickus_ltd

Instagram @brickus_ltd

Instagram @topbuild_zabor

Instagram @tetto_ru

Instagram @skm.kg

Instagram @stroidvorangarsk

Combined with wood

A wooden fence with brick pillars is suitable for those who value the warmth of wood, but want a more durable material. After all, the most vulnerable point of a wooden fence is the support - it rots first. Brick pillars will solve this problem.

In addition to the classic vertical arrangement, there is also a more modern one - horizontal placement of boards, as well as original diagonal options with wood carvings or figured fastening. They come in both solid and with openings.

Instagram @skk_rodnoidom

Instagram @alexander_builder

Instagram @topbuild_zabor

Instagram @markiza_kapriza

Instagram @justwood_krd

Instagram @brigadirby

During installation, do not forget about waterproofing. And already during operation, be sure to monitor the condition of the structure, since wood is the most fragile and capricious material from this point of view. If you notice that the varnish is coming off the board, be sure to renew it in a timely manner.