A bathhouse, in the construction of which profiled timber is used, is quickly erected, is considered environmentally friendly and can serve you for decades. Profiled timber began to be used as a construction material several decades ago. The Finns were the first to use this technology. Now similar buildings are being built all over the world. Saunas made of profiled timber delight their owners with strength and durability.

Pros and cons of the design

When building a bathhouse, you can use building material with natural humidity or chamber drying. It is more profitable to purchase one that has been chamber dried, although its cost will be more expensive. The main danger of using wet material is that when it dries naturally, it tends to crack. This problem can be eliminated by caulking the walls, but this work is difficult to carry out on profiled lumber. If you nevertheless decide to purchase timber with natural humidity, buy one that was prepared in winter. Its humidity is as close as possible to kiln-dried lumber.

There are two types of profiled timber: solid and glued. Glued is absolutely not suitable for such warm rooms as a bathhouse. When heated, it will release glue vapors, and this can affect the health of visitors.

Larch, aspen, oak are the best wood for building a bathhouse. It is acceptable to use coniferous trees, but in this case you will need to cover the walls of the steam room with linden clapboard. If this is not done, then at high temperatures in the room, resin will begin to release from the wood, and droplets will remain on the walls.

The shape of the lumber can be as follows.

- Two straight sides.

- One straight side, one rounded.

- Two rounded sides that imitate real log masonry.

The advantages of profiled timber include:

- a seam that has no gaps;

- a form that is very easy to work with;

- good thermal insulation and tightness;

- environmental friendliness;

- ease of assembly of the structure;

- slight shrinkage.

The lumber has a locking connection. It is desirable that there be from 2 to 5 locks, then the seam will be gapless, and frost and wind will not penetrate into the bathhouse.

Construction from timber: benefits and advantages

Domestic manufacturers took the technology for processing logs of different tree species by giving the elements a planed rectangular shape for ease of installation of the log house from Finnish woodworking enterprises. The use of timber in low-rise construction is characterized by the following advantages:

- simple and quick assembly. The block after drying has a small mass. To build a bathhouse with your own hands from wooden elements, 2-3 people who have no experience in construction can handle it;

- tight fit of the crowns due to the correct geometric shape and inter-crown insulation;

- environmental friendliness. A machine-processed block retains the qualities of natural wood even after drying. When heated in a sauna room, the material releases only beneficial volatile esters, which have a beneficial effect on the body;

- no need for alignment. Walls made of wooden blocks, inside and out, provide a flat surface, on top of which you can begin interior cladding immediately after shrinkage.

You can start building a bathhouse from timber with your own hands with detailed diagrams, videos and photographs immediately after purchasing the required amount of materials. Carry out construction in stages in compliance with building codes and safety regulations. With a competent approach to construction, you will get a reliable, inexpensive structure for relaxation and washing procedures.

How to choose a material and not make a mistake

Profiled timber is made from a solid log or a pre-processed carriage. Using a special machine, the log is processed from all sides to the desired section. This lumber is easy to install and has high structural strength.

Profiled timber is distinguished by such features.

- Neat appearance.

- 100% environmentally friendly material.

- Inexpensive price, and as a result - low costs for building a bathhouse from profiled timber.

- Durability, since a structure made from this lumber will last more than 20 years.

- Good thermal insulation.

- Lightweight and easy to assemble.

- Does not require external or internal finishing.

- This is not a heavy material, so you can install a light foundation under it.

What to look for when purchasing profiled material. First of all, the price - it should be at market level. If you are offered material for a temptingly low amount, we do not recommend buying it. A low price may hide poor quality and future problems when assembling a bathhouse.

Ask the seller for the production date of the material. Wood harvested in winter is usually of higher quality than wood harvested in summer. In addition, lumber harvested in summer is susceptible to rotting. Suitable and inexpensive wood species are conifers. The recommended diameter of the workpiece is 22–26 cm. The material must be well dried and treated with insect, rot and fire repellents. The surface is free of protrusions and knots. The importance should be natural.

A bathhouse made of dry profiled timber will be cold; in addition, dry wood will absorb environmental moisture and this will lead to curvature of the structure. The gaps and puzzles must match perfectly, then the wall will be smooth.

The disadvantage of profiled timber is that its shrinkage will continue for about 6 months, and it may be exposed to snow, rain and ice.

Choosing material for the steam room

The steam room is the main attribute of the Russian bath, Finnish sauna and Turkish hammam; in fact, for the sake of the opportunity to steam, construction is started. You can just wash yourself in a residential building. Proper arrangement of the steam room is the main feature of building a bathhouse from profiled timber.

The steam room is a special room; the temperature in it can reach 150 degrees with 100 percent humidity. The material used to equip the steam room has special requirements:

- There should be no metal or plastic products in the steam room;

- The wood must only be solid; laminated wood evaporates formaldehyde;

- The use of ceramic tiles is not allowed - only wooden floors;

- It is advisable to use special types of wood that are resistant to temperature changes.

To decorate the walls of steam rooms, lumber from linden, aspen or birch is used. The wood of these species is denser, does not contain natural resins, heats up quickly, retains heat well, and is resistant to moisture and high temperatures.

Experts do not have a clear answer to the question of what material to cover the walls of the steam room with. Walls are most often sheathed:

- Lining 20x100;

- Edged board 30x100;

- Imitation of timber 50x150.

Lumber made from linden or aspen is less susceptible to the negative effects of temperature changes, retains its shape well, shrinks less, and provides additional thermal insulation. The disadvantage is the high cost of the material. The board quickly loses its shape, cracks form in the sheathing, this structure must be changed every 2-3 years.

Heaters and electric heaters are insulated from wooden surfaces with a layer of clay or plaster and covered with a sheet of aluminum. Polished metal reflects thermal radiation well.

Typical designs of baths made of profiled timber

If you are building with your own hands, then it will be easier and more correct to choose a standard and ready-made bathhouse project. This way you can avoid errors in calculations and get an excellent structure in which all your wishes will be taken into account.

Options for baths assembled from profiled timber

| Projects | Advantages |

| Bathhouse with attic. | This is a fairly popular type. The structure is distinguished by the presence of a veranda and a small room under the roof. You can equip a bedroom there and there will be no excessive load on the foundation. |

| Bathhouse with terrace. | Good when you plan to spend a lot of time outdoors. |

| A bathhouse with a veranda along the entire length of one of the walls of the house. | A convenient option for those who have a large family or many guests staying overnight. On the spacious veranda you can equip a bedroom and a small kitchen. |

| Bathhouse with a porch. | A fairly simple classic project. It is advisable to make the porch wide, and immediately behind it to equip a hallway in which you can leave your outerwear. |

| Bathhouse with attic and veranda. | This is an excellent project where the veranda will be covered with an attic, which has a significant area. At the same time, the veranda will be warmer, and more sleeping places can be placed in the attic or a recreation area can be equipped there. |

You can choose a project, and then the area of the bathhouse will depend only on your wishes. But profiled timber has a standard length of 2, 4, 6 meters. And if the length is non-standard, you will have to think through the joints and angles.

The optimal dimensions of the bathhouse are 2x3 meters or 4x4 meters.

What is profiled timber?

Profiled timber is a modern, in-demand building material. It is usually made from coniferous wood: pine, spruce, cedar or larch. Depending on the purpose, such timber is cut in different sizes and different configurations. On the front side it can be straight, or maybe rounded (inner and outer sides of the building). A tenon is made on the upper side of the beam, and a groove is made on the lower side. Due to this, such a system for fastening building materials is called “tenon and groove”.

Types of prof. timber

Profiled timber

Types of prof. timber

Profiled timber is obtained from wood by planing or milling. First, the log is spread onto a carriage, and then onto timber of the required shapes and sizes. Then choose a tenon and groove. They come in different forms. If you look at the beam from the end, it will have a peculiar profile. That is why it is called profiled. The entire manufacturing process is quite complex, which is why the cost of profiled timber is much higher than usual. In our area it costs 10-12 thousand per cubic meter. I named the minimum price, since it consists of many factors: type of wood, size of timber, configuration, etc.

So why has construction from profiled timber been gaining momentum so quickly lately? Why do many construction companies' projects for bathhouses made of profiled timber go so well? Let's look in a little more detail. And who is interested in the question of how and where to order the construction of a turnkey bathhouse or house - I’ll tell you about this at the end of the article. Look, analyze, calculate, order...

What foundation is needed

There are two options for foundations for buildings made of profiled lumber. The first is suitable for light buildings. It's called tape.

Stage-by-stage implementation of such a foundation.

- We create formwork around the perimeter of the pit and fill it with concrete. It is desirable that the formwork be deepened to the depth of soil freezing.

- The height of the foundation above ground level must be at least 50 centimeters. This will help protect the bottom of the beams from moisture.

- The inside of the foundation must be filled with sand and crushed stone.

- Leave the structure to harden for a couple of weeks, and only after that can you begin to lay the first rows of the log house.

The second foundation option is columnar. To build it, you need to perform the following steps step by step.

- We place brick columns along the perimeter, corners and future load-bearing walls inside the bathhouse. The recommended distance between posts is about two meters.

- Place a concrete pad under each of the pillars, thanks to which you can avoid subsidence of the foundation and deformation of the entire building.

- Strengthen the foundation with reinforcement.

Finally, it is necessary to waterproof the foundation surface. Bitumen and roofing felt are suitable for these purposes.

How to build a sauna from timber yourself

The building material from which you will build the log house has a regular geometric shape and in cross-section is a square or rectangle. Assembling a box from a wooden block does not require the involvement of a team of builders or the need to have special skills. To build your own sauna from timber, follow the step-by-step algorithm.

Design

Draw the future structure using professional programs or manually. Use a scale of 1:100 or 1:50. Draw on the drawing a view from the facade of the bathhouse, the end and a top view in section with a breakdown of the rooms. In the figure display:

- dimensions of walls, base, roof;

- location and dimensions of entrances, windows, heating stove, shelves, partitions, porch or veranda;

- prepare a three-dimensional image and an object in different planes.

For independent construction, you can take ready-made design solutions from the Internet. Sketches and drawing documents can be found on the relevant thematic forums or you can order an individual project from a specialist. Don't forget to make a plan of the area with the future building on it. Please note that the distance to the site boundary must be at least 3 m; a distance of 10-12 m must be maintained from residential buildings for fire safety purposes.

Site preparation

Mark the perimeter of the future building on the ground using pegs and rope. Remove the growth, cut down the trees, uproot the stumps. Choose a location for the construction site taking into account the drainage of wastewater from the bathhouse. The building should not be located next to a well with drinking water.

Important!

Study the standards from GOST 27751-88 for the construction of buildings made of timber. The document will help to avoid mistakes in construction or selection of materials.

On waterlogged soils and soils with high water levels, it is necessary to carry out strengthening work. Backfill with quarry sand or strengthen the ground with gravel, crushed stone, or asphalt chips. Start preparing the site after the snow melts and the water level in the soil drops.

Foundation organization

To build a bathhouse from timber, you do not need to pour a powerful foundation. The wooden box will be securely held by a concrete shallow tape, a pile-screw field or foam blocks. Features of construction:

- for the strip type, dig a trench 30-40 cm wide, 30-50 cm deep, install formwork with an outlet of 20-30 cm to the surface and fill the space on top of the gravel-sand cushion with concrete mortar using M200 cement, water and sand. For strengthening, you can use reinforcement, broken bricks, gravel, crushed stone, and stones.

- screw piles do not require digging. You can screw in steel blade supports at any time of the year. The pile rack is screwed in together using the lever principle. Using a level, determine the level position for the frame and saw off the excess metal rods. Secure the heads at the ends. If necessary, pour concrete solution into the cavity of the screw product and treat with anti-corrosion compounds. You can make a pile field on any type of soil, except rocky rocks;

- blocks for a log frame are installed in the corners. Deepen each element by first digging a hole 20-30 cm deep, corresponding to the size of the foam block. Fill the bottom with sand and gravel. Place a support in the recess and compact it with soil.

On top of the foundation, before the stage of wall construction, lay a grillage made of 200 x 200 timber. Choose wooden material from larch or aspen. Treat the row with antiseptics and impregnations to prevent rotting. When laying on screw steel posts, tie the tier with metal pins.

Construction of a log house

To build a bathhouse on a private plot or in a country house, use timber from one batch. This will ensure the same percentage of moisture in the material, which will allow the box to experience uniform shrinkage in the future. Choose a wooden block without dark spots, cracks, or deformation. To build a log house for a private bath, you can use elements with the following cross-section:

- 150 x 150 mm;

- 150 x 200 mm;

- 200 x 200 mm.

Use jute fiber, tape, forest construction moss or “cuckoo flax” as an interventional filler.

Lay the first row of beams on the grillage. Assemble the corners one to one, changing sides each time, or make a cut for a claw or dovetail assembly. To secure each crown, attach it to the previous one using wooden dowels. Fill the space between the tiers with moss or jute. The construction of the log house can be completed by 2 people. Raise the walls to the height required by the project.

Roof installation

The roof for the bathhouse is mounted on a system of rafters. The frame can be in the form of a single, gable or sloping roof. For its construction, a wooden block with a cross-section of 15 x 10 cm and logs from unedged boards 10 cm thick are used.

Attention!

The time it takes to build a bathhouse yourself depends on the type of foundation chosen. The structure on a concrete foundation is erected in 2-3 months. Construction on blocks or pile-screw field - in 1 month.

Build the rafter system in the following sequence:

- on the ground, assemble corners of wooden material, which are secured near the center with a cross member for strength;

- lift the assembled elements and install them on the log house so that the edges of the roof extend beyond the walls by 30-40 cm;

- secure the frame with corners;

- make a sheathing of unplaned boards 20 cm wide transverse to the rafters. Place the elements in increments of 20 to 50 cm. Fasten the lumber with self-tapping screws;

- cover the roof plane with roofing material - slate, ondulin, sheet iron, profiled sheet, metal or flexible tiles. For fastening, use hardware with rubber washers to prevent moisture from getting under the roof.

After installing the roof, the structure needs to stand for 1 year for shrinkage. During drying of lumber, the timber may crack. Only after this period, proceed with insulation work, finishing, installation of window frames, doors, installation of shelves, heating stove.

How to assemble a wall from profiled timber

There are a number of rules for their installation. If you stick to them, the walls will be perfectly smooth. First, use a level to check how smooth the surface of the timber is. For the first rows, you need to choose the thickest beams, since they will take on the entire weight of the structure being built. The optimal thickness of the first beams is 20x20 cm, and the subsequent ones - 15x15.

Before laying the bottom row, lay thin slats on the foundation plinth. Their thickness should be about 15 mm, and the approximate distance between them should be 25–30 cm. This is necessary to protect the first rows from rotting and dampness. Do not lay the frame of a bathhouse made of profiled timber too tightly: it will still shrink within 6–9 months. The bottom beam does not need to be secured in any way, since the pressure from the upper rows will give it the necessary strength.

Designing a future building

Bathhouse projects made from profiled timber do not require special knowledge in the construction industry; you just need to understand a few features:

- The stove should be positioned so that the heat from it is used as efficiently as possible. For example, so that it heats the sink, steam room and goes into the rest room, if one is provided.

- One small window should be placed in the steam room, which will allow you to artificially regulate the humidity in the room, and also, in case of smoke, quickly get rid of the smoke.

- A monolithic slab foundation is not suitable for a bathhouse for one simple reason - it requires a place where water will drain without harming the strength of the structure.

- When designing, do not forget that a timber bathhouse is not used every day; it does not require enhanced thermal insulation and additional costs for load-bearing walls. For external walls, a beam with a cross-section of 150x150 mm is sufficient to make the structure reliable and durable.

- Baths should be built from profiled timber with minimal use of metal fasteners. This is due to the fact that with high humidity, hardware is subject to corrosion and rust appears, which harms the wood.

- Designs for bathhouses made of profiled timber also include finishing from the inside - it is better to sheathe the walls with clapboard, under which a foiled thermal insulation material is secured, which retains heat in the room.

Features related to construction

This is what a film with foil looks like, which allows you to retain steam and heat in the room

- Do not forget about good ventilation so that there is always access to fresh air in the premises, as well as to create ventilation. If you treat this moment with negligence, then fungus may soon appear due to abundant dampness.

Wall assembly methods

There are several basic ways to install walls and secure them together. The first is the connection of profiled timber with wooden dowels or metal crown pins. To do this, you need to drill holes at a distance of 1.5 meters, and it should go through 2 logs for greater rigidity.

The second method is to use nails without heads. Such sunken nails will sink into the wood and will naturally be protected from rust and further rotting of the wood. The third is the use of square bars 18x18 mm and up to 25 cm long. Such bars are inserted into pre-drilled holes, staggered and piercing right through the bars.

The fourth method is fastening using a “force” spring unit. This unit looks like a screw equipped with a compression spring inside. Thanks to the use of this system, the beams will be pressed against each other without leaving gaps. This is the best of the above methods, as thanks to it you can easily avoid wall deformation and gaps.

How to make corner joints

The corners in the bath structure are assembled with or without residue. By leaving the remainder of the profiled timber, you can achieve an aesthetic appearance and additional insulation of the corner. But be prepared for increased material consumption. You can cut the bowls to connect to the rest yourself or order a set of timber with ready-made bowls made by production specialists.

In the option where the connection is without residue, the material consumption will be small and it will be easier to complete. The appearance of the bathhouse will slightly lose, and there will also be problems with insulating the corner after the building shrinks.

Finishing and thermal insulation of timber bath walls

After the roofing system is installed and windows and doors are installed, you can begin installing the subfloor and decorating the walls. If the bathhouse was built from planed or profiled timber, you can do without finishing at all, since this material is distinguished by its rather high aesthetics and presentability, which is preserved for many years and decades.

But to protect against natural phenomena unfavorable to wood, the façade can be treated with special primers and varnished. This treatment should not be used indoors, and especially in a steam room.

But in order to protect the timber from destruction, ceramic tiles can be used in the washing compartment to cover the surfaces, but it is recommended to decorate the steam room with clapboard, preferably made from hardwood: linden, cherry, oak.

Do-it-yourself sauna made of rounded logs. - there is more useful information here.

Despite the fact that the timber has a fairly low thermal conductivity coefficient, the small thickness of the walls of the bathhouse is the reason that they need to be insulated. In some cases, this is only relevant for the steam room.

Before insulating a timber bathhouse from the inside , you should decide what material to choose for this.

You will be interested in this article - Bath stones: which ones are better to choose?

The best option is insulation based on mineral wool, but it should be borne in mind that it must be provided with reliable waterproofing, since when wet it loses its properties and, accordingly, efficiency decreases.

In cases where sufficiently wide gaps have formed between the crowns of the log house, and additional caulking of the walls does not produce results, it is recommended to insulate the walls of the bathhouse in the remaining rooms.

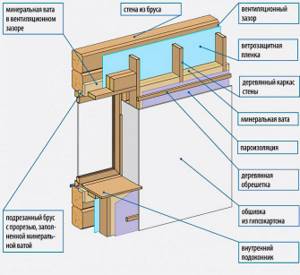

As a rule, to do this, the sheathing is first installed, a vapor barrier and windproof membrane is laid, and insulation boards are installed, although rolled types can also be used, but the former have a higher density and retain their shape better on vertical surfaces.

When finishing the bathhouse premises, one should not forget about the ceiling, given that it is, along with windows and doors, a vulnerable structural element of the bathhouse in terms of heat loss.

Roof: which option to choose

The timing of installation of a finished roof depends on what building material was used in its manufacture. If you used chamber-drying material, you can immediately cover the bathhouse with a finished version of the roof. If the timber was of natural moisture for shrinkage, then you need to cover the bathhouse made of profiled timber with a rough roof and leave it to shrink for 9–12 months.

Choose the simplest possible roof structure for your bathhouse. There should not be any heavy or complex elements, bends or skates on it. The ideal option would be a pitched or gable roof. To attach it, you must use a Mauerlat; instead, you can use the top beam in the wall.

The rafter system also needs to be assembled from timber on the ground and lifted in small parts and mounted on the roof. Be sure to use battens under the roof. Here, follow the rule: the heavier the roof, the smaller the pitch of the sheathing. Choose a lightweight roof for your roof; ondulin or metal tiles are ideal. These materials are easy to attach and lightweight.

Installation of the structure

Having purchased high-quality material and familiarized yourself with the regulatory documents, you can proceed directly to the practical stage. In this case, the best solution would be to immediately purchase a ready-made bathhouse set made from profiled timber. In this case, the manufacturing company supplies you not only with a construction set of wall, roofing, and other elements, but also provides assembly instructions and a warranty for its products. Otherwise, the project, the choice of material, its adjustment, and the risks fall entirely on your shoulders.

Assembly stages

The technology under consideration for constructing a bathhouse from timber with your own hands consists of standard two main and a number of intermediate stages, which are carried out for all log-type buildings.

Erection of a box under the roof

You have to do:

- tying the bathhouse on the site with the removal of the axes for laying the foundation. For a simple one-story structure on dense soil, installing columns from solid blocks at all angles and intersections of the walls is sufficient. Free air flow under the building on columnar supports is a good way to ventilate and dry the underground space;

- installation of a crown (trimming, bench) along the outer perimeter, as well as under the walls of all rooms. Thus, a bathhouse made of profiled timber from the starting tier of a set of walls is connected into a single structure;

- laying all the next crowns with gasket laying, cutting corners and installing dowels;

- assembly of rafters with lathing and a layer of waterproofing. You can lay roofing material during the shrinkage period;

- installation of floor joists, floor beams;

- You can also fold the stove if it is a permanent brick structure.

After going under the roof, the bathhouse construction technology involves letting it stand until the end of the main shrinkage. The optimal solution would be to build a log house in late autumn so that the residual moisture from it is thoroughly frozen out by the winter cold. Then, in the spring, feel free to start finishing and arranging the building.

Important! Profiled timber with a moisture content of less than 12% practically does not shrink. If you manage to purchase one, which won’t be cheap, then proceed to the next big stage immediately after building the box. At the same time, be sure to carefully seat the beams during assembly to ensure good compaction of the inter-crown spacer tape.

Finishing and arrangement

The stage at which a bathhouse made of profiled timber can be completely brought with your own hands to the logical completion of construction, even if the box was installed by contractors. You should:

- assemble a permanent roofing pie. If the attic is not in use, then roll waterproofing, sheathing and roofing (slate, metal tiles) are sufficient. If you are planning, for example, an attic, then you will also have to lay insulation and vapor barrier, stuff the counter-batten and the bottom sheathing;

- cut window and door openings. This stage can also be carried out at the stage of laying the box;

- insulate floors and ceilings, lay facing flooring on them;

- install windows and doors;

- line the steam room with clapboard with lining layers. In other rooms, the technology for constructing a bathhouse from profiled timber allows for the presence or absence of internal lining at your discretion.

During the process of assembling the log house, do not forget to start and install communications: water, sewerage, electricity, ventilation.

Some additional tips for assembling a sauna from profiled timber with your own hands

Despite the fact that using profiled beams, you greatly facilitate the task of constructing a bathhouse, a high-quality result can only be obtained by observing technological requirements, showing maximum care, and also taking into account the characteristics of the material.

- The moister the lumber is at the time of purchase, the greater the likelihood of twisting and cracking. If there is significant damage to the surface of the walls, the assembly of the bathhouse may also require decorative finishing. Therefore, it is better to purchase wood blanks of standard humidity. In addition, some manufacturers make additional compensation longitudinal cuts on their products. They allow you to relieve buckling stress and also direct the development of cracks inside the material mass. Thus, the cleanliness of its surface is maintained.

- Choosing an antiseptic for a bath is a rather important moment, which causes a lot of controversy. If you do not want to use even the declared environmentally friendly modern compositions, then you can use one of the old-fashioned methods of bioprotection, for example, impregnating wood with a solution of copper sulfate.

- The construction of a bathhouse from profiled timber involves laying an inter-crown seal; it eliminates blowing between the beams. Tow or even moss is suitable as an economical option for cushioning material, however, today, jute tape is the best choice. It rolls out perfectly and quickly between the crowns, filling all the gaps without interfering with the mating of their locks.

As mentioned above, for self-assembly it is better to choose a ready-made factory bathhouse kit made from profiled timber. The slightly higher cost of purchases will be justified by the speed and quality of installation of the building. After all, even corner cuttings in production are made on machine tools according to standard templates, which guarantees the accuracy of all connections. This means that your bath will last for decades and will always be warm.

Interior decoration

The wooden texture itself is an excellent finish, so the walls of the bathhouse from the inside only need to be treated a little. You will only have to sand the walls using nozzles from larger to smaller, cover them with an antiseptic solution and a transparent natural water-based paint composition.

If your bathhouse is built of coniferous timber, then cover the walls of the steam room with foil insulation, and on top of it with clapboard made of linden or aspen. Be sure to leave a small gap between the finish and the wall; there will be an air gap there that will prevent condensation from accumulating.

A bathhouse, in the construction of which profiled timber was used, is a variant of a rational approach to business. You can significantly save time when constructing a structure, since the beams are easily and quickly laid. There will also be no need to spend money on the exterior and interior decoration of the building.

Bathhouse construction process

Like any construction project, a sauna made of profiled timber begins with a foundation. Since this material is not entirely heavy, you can choose a screw foundation for the bathhouse. Of course, if you have a bathhouse with an attic and a large terrace, then a “ribbon” is already needed here. Consider this moment seriously. The success of the entire construction depends on how you make the foundation.

After building the foundation, be sure to waterproof it. This will significantly extend the service life of wooden walls. Be sure to saturate the entire beam with fire protection, especially the lower crown. Due to its tongue-and-groove design, building a bathhouse from profiled timber is similar to assembling a construction set. The main thing is to lay out the first crown evenly: exactly along the horizon and maintaining the same diagonals of the perimeter.

Bath walls made of timber

Construction of a bathhouse from profiled timber

Then we lay inter-crown jute insulation on the first row of timber. We drill holes for wooden dowels (usually 20 mm). Place the next row on top with a tenon in the groove. And so, slowly, maintaining the vertical, leaving openings for windows and doors (although they can be cut out later), we build all the walls. This assembly of the “constructor” is very convenient in that there is no need for additional caulking of the walls; they will never be blown through thanks to a kind of lock.

Due to the planed or milled sides, the need for external and internal finishing is eliminated. You can, of course, line the inside with clapboard, but this is at the discretion of the developer. The outside walls can be treated with stain by choosing the desired color. Then with weatherproof varnish, it will look gorgeous.

During construction, the following important point must be taken into account - the shrinkage of the profiled timber. It depends on many reasons. Among them, one can highlight the type of wood, the size and shape of the timber, its length, the time of harvesting the timber, the quality of the wood itself, etc. Remember that the shrinkage of the timber occurs more and faster on the south side, since there is more sun there. If your timber is not dry enough, then on the sunny side it can cause a long wall to “drift” a lot. To avoid such problems, install a load-bearing partition into it. It will restrain the wall from moving.

Bathhouse made of profiled timber.

Small sauna made of profiled timber

Bathhouse made of profiled timber.

A bathhouse built in the summer will complete its shrinkage only after a year, that is, next summer. The winter structure will complete its shrinkage by autumn. These are all approximate dates and they may vary, but be guided by approximately this time period. Using raw and low-quality material, shrinkage of the log house can take two to three years. This also happens when they try to complete construction work on time, thereby violating the entire construction technology.

Now about the dimensions of the profiled timber. If you are not going to add additional insulation to your bathhouse, then what thickness should you choose for the walls? Residents of the western and southern regions of our country can use timber with a thickness of 100-150 mm, in Siberia 150-180 is reasonable, but in the northern regions 180-220 mm will be appropriate. But, as practice shows, it is better to choose timber of greater thickness than thinner. As they say - the supply is not enough.