Projects of structures made of various materials

The extension can have many options for shapes, designs and technical capabilities. Not only the construction material may also differ. Each frame extension to a wooden house requires compliance with certain rules and has its own characteristics. A certain type of project may have its pros and cons. That's why it's important to weigh everything carefully and decide which type of project is best suited.

In construction, material plays a key role. The functionality and cost of the building depend on what raw materials are chosen for construction. For example, a timber frame building can be lived in both summer and winter. If the wall material consists largely of glass, then this type is repurposed only for the warm season. So, there are several types of materials:

- foam blocks,

- beam,

- brickwork,

- frame assembly.

Project of a wooden extension made from timber Source remoo.ru

Bathroom or kitchen

Before installing the foundation, utilities are brought to the construction site. Sometimes you have to install separate plumbing.

If you decide to add a bathroom, do not forget about the water supply and sewerage

In addition, it is necessary to pay attention to the insulation of absolutely all parts of the building and think through a thorough waterproofing of the floor in advance.

Construction of a frame extension to a house

Any construction requires careful planning. Adding an extension to a brick house is hard work that requires experience and skill. The same can be said about the implementation of a specific project for wooden structures. It doesn’t matter which type was chosen, the construction principle is the same. The entire construction cycle can be divided into several stages:

- Construction of the foundation.

- Walling.

- Installation of subfloor.

- Installation of roof and ceiling.

Foundation arrangement

The basis of any building is the foundation, which means it must be made of high-quality materials. If unsuitable raw materials with low performance indicators are used, the extension to the frame house will be damaged. If the foundation begins to collapse, you may have to dismantle the walls and roof, which can result in serious financial costs. In addition to purchasing high-quality materials, it is necessary to strictly follow the technological process.

Foundation for an extension Source nl.decorexpro.com

Construction of extension walls

After the foundation is ready, they begin to arrange the walls - 3 walls, because the 4th is already there, the one to which the room is attached. However, there are also options when 2 walls are enough, it all depends on the design of the building. Adding an extension to a wooden house is usually not difficult at all. Metal plates and other specialized parts are used as fastenings.

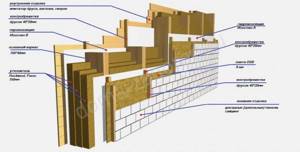

The wall pie of a frame house is not much different from the wall of an extension, if it is a living room

If the additional area is made of timber, then you need to take into account that the size of the material should not be less than 200 by 200 millimeters, in the case where permanent residence is planned. You need to know that timber is a rather heavy material, and subsequently it shrinks. Only at the end of this process can the new building be properly and firmly fixed to the house itself.

Regarding the time required for shrinkage, it is about a year, or a little more. The duration of this period is influenced by the area of the extension, the quality of the material, as well as the condition of the structure to which the extension was made. The main rule in this matter is to take your time.

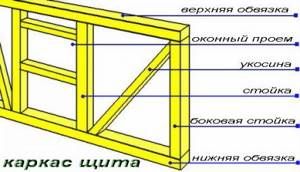

The shield frame is slightly susceptible to shrinkage if the timber used has been dried to the required level

Upon completion of shrinkage, the originally supplied fastening materials are removed and fixed in a new location. During the period of precipitation, the structure should be insulated using felt, cotton wool, or some other material.

Construction work can be carried out all year round; in winter, prices for building materials and work are several times cheaper

To improve the quality of thermal insulation and give a good appearance to the joints, a special wooden element is used. At the moment of shrinkage, it may move slightly, so there is a need to remove and strengthen it again.

Don’t forget about the roof of the extension; it can be made a continuation of the roof of the house, flush with the wall or with an overhang - everything is at the discretion of the owner or designer

When the size of the house increases, the issue of roofing arises. Everything happens in the usual way using standard technology. The approximate order of roofing is as follows:

- First of all, the rafter system is equipped. Do not forget to comply with all load characteristics.

- Upon completion of the installation of the rafters, they proceed to creating the sheathing, using bars and slats. Instead of this design, sometimes a solid type of flooring is used - boards or plywood are suitable as building materials.

- Facing of gables.

- Hemming of cornices.

- Installation of wind elements.

- Direct installation of the roof. The material is chosen independently, based on the personal taste of the owner of the house.

Next - the floor, ceiling and other interior finishing work. Installing openings is not particularly difficult. If the extension to a wooden house is made of the same material, then other parts are best made using lumber.

How to insulate an extension?

The extension is thermally insulated based on what type of walls is chosen. Wood is usually not wrapped. It is warm, looks aesthetically pleasing, and retains heat perfectly inside. As for insulation, thermal insulation materials are mainly used for bricks and foam blocks. It is not recommended to insulate both options inside. It is necessary to do this from the outside, leaving a small ventilation gap of 1-2 cm thickness.

As for the frame model, here the insulation comes from the inside. The climatic zone of residence is taken into account, on which the thickness of the heat insulator depends. The building is sheathed with sheets outside and inside. This option is considered the most effective, since the extension is protected from wind blowing inside and outside by means of cladding. This is a proper extension to the house .

The insulation of brick and foam block walls should be either cotton wool or polystyrene foam. The outside will have to be finished, because otherwise it will be destroyed by sunlight and bad weather. A special windproof film is used for this work. As for finishing issues, both plastic and siding, brick, metal and other varieties can be used here.

Building a home extension with your own hands is not difficult, so don’t be afraid to try. Everything will work out, the house will become larger, because this is a usable area, since its construction is approached consciously. Do everything wisely and do not buy the cheapest raw materials. Regardless of what you add, this is where you will live or spend time. Therefore, everything should be cozy, warm and protected from the wind. Make the junction of the roof structure to the main wall waterproof, use sealants and film.

Buy only insulation that has been tested and that everyone uses, according to reviews. Otherwise, your eyes will water and problems with the respiratory organs will begin. For residential premises, lay it in several rows, with overlapping joints, since this is a potential cold bridge, where it will blow even with brick walls. Cover it with cladding, since even the best option will be destroyed by the sun and rain.

What is a “cold extension”?

All premises attached to a residential building are divided into two types:

- Heated. The annex is heated from the house, or less often, its own heating system is installed. The presence of heating allows you to use the veranda or covered terrace all year round. But at the same time, the costs of heating the entire structure increase.

- Not heated. The room is used for its intended purpose only in the warm season, and in winter it is not used at all or serves as a warehouse in which various belongings and home preservation are stored. This type of extension is called cold.

The materials from which the walls of the attached part are erected are subject to less stringent requirements than the materials from which the main structure is erected. Therefore, the list of materials for the construction of a veranda, terrace or summer kitchen is very diverse, but, as a rule, home owners prefer to use the same material from which the load-bearing walls are built to build an extension.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

This allows you to ergonomically fit the extension, making it not “built on the side”, but a logical continuation of the residential building. Most often, the attached parts of the building are constructed from the following materials:

Foundation for extension

The foundation is an important element in construction. It is necessary to transfer the weight of the structure to the ground. The type of foundation depends on the type of soil, as well as the weight of the structure and is determined at the design stage.

To build a porch and light structures such as pergolas, you do not need a solid foundation. Heavier extensions require a permanent foundation. Of course, it is better to immediately lay the foundation along with the foundation of a wooden house during its construction. But if the plans did not initially include an extension, then when making a foundation for the building, it must be well connected with the main one.

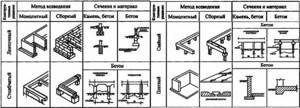

If an extension is being built after the house, depending on the type of extension, you can lay a strip or slab foundation, and also build it on pillars or piles. To lay the strip foundation, a trench is dug along the perimeter of the base of the future extension. Next, foundation blocks are placed in the trench on a prepared bed of sand or crushed stone and filled with mortar.

Foundation options for an extension

Before pouring a monolithic strip foundation, a reinforcement frame is welded in the trench and formwork is installed. For a slab foundation, the frame is also welded over the entire base area of the future veranda or terrace and filled with concrete. The advantage of such a foundation is that it can serve as a floor.

The capital foundation of the extension must be well secured to the base of the main building. To do this, we drill holes along the entire frontal length of the house foundation every 20–30 cm and insert cut pieces of reinforcement of a suitable diameter. We weld the ends to the reinforced frame of the base of the extension. After the foundation of the extension is laid, it must be given time to settle.

Designing a new premises

The goals of professional design of an extension to an old house:

- achieving external harmony of the main building and the attached premises. The architectural style of the house and the extension should be the same. The same or similar construction and finishing materials are used;

- obtaining a functional building in accordance with its purpose. Open terraces and verandas are equipped areas for leisure activities. In a residential building for year-round use, it is necessary to provide locations for heating and lighting devices. These features are reflected in the drawings and plans.

A kitchen or bathroom requires installation of engineering systems (sewage, water supply). For the winter garden, the project determines the types of window and door units with a large glazing area to ensure full natural light at any time of the year.

In order for the building to serve for many years, at the stage of developing the project for extensions to the house, calculations are made to ensure the strength of all components of the structure. Factors such as:

- soil type;

- groundwater level;

- the presence of elevation differences on the construction site;

- type of construction;

- weight of selected construction and finishing materials.

Base design

The design process begins with specialists visiting the site and conducting a study of the foundation under the main building. For permanent buildings, the same type of foundation is usually chosen as that laid under the old house.

On moving soils, with high groundwater levels, and if there are significant elevation differences in the area, a pile foundation is installed. For it, metal piles are screwed in or monolithic pillars are erected from reinforcement and concrete mortar. Such a foundation can easily withstand one-story light-weight buildings built on a frame filled with sandwich panels or constructed of wood.

For brick buildings, a more powerful foundation is needed - a strip foundation with a large depth or a monolithic one, capable of supporting a heavy brick structure.

If the extension is planned to be used only in the warm season, as a place to relax, then the project provides for a base on low columns of blocks or bricks, which does not require significant digging into the soil.

To prevent the floor on the veranda or terrace from deteriorating from excess moisture, waterproofing is carried out on the foundation side. For flooring, it is recommended to select boards impregnated with special protective compounds that increase resistance to moisture.

In projects for extensions to a house, the junction of the foundation of the main building and the completed structure is indicated. It is recommended to fasten the lower rim using the “tongue and groove” principle. This creates conditions for slight mobility of the lower rims of the structure, which avoids deformation of the structure during the period of shrinkage and seasonal temperature fluctuations.