Territory for chicken coop

If you are a novice poultry farmer and decide to build a chicken coop yourself from scrap materials in the country, you need to first study the drawings and features of arranging a poultry house. First of all, you need to choose the appropriate type of structure and determine its location.

When choosing a place for a bird house, consider 4 criteria:

- distance. Chickens are very shy and do not like noise. Frequent stress negatively affects the ability of chickens to lay eggs and gain weight. Therefore, the chicken coop is located away from a residential building and barns with noisy animals;

- elevation. This prevents the accumulation of moisture and flooding of the walking area during rains and when snow melts. If the area is flat, create the landscape yourself, using a mound of earth or gravel. As a last resort, dig a ditch to drain moisture;

- orientation to the cardinal points. A hen's ability to lay eggs depends on the length of daylight hours. It is preferable to place windows and doors so that the sun's rays illuminate the room for as long as possible. The rectangular building is located along its length from east to west. The ideal placement of the poultry house would be when its windows face south and the door faces east. Windows should let in as much light as possible during the day;

- square. Decide on the number of birds. The area required for the chicken coop will depend on this. Will it be a mini chicken coop for 5 chickens, or a large full-fledged poultry house. To calculate the area, use the ratio: for 1-2 chickens there should be at least 1 m2 of internal space in the chicken coop, and at least 3-4 m2 in the walking area. When planning a winter poultry house, it is additionally necessary to provide space for a warm vestibule. It protects chickens from frosty air from the street.

How to build a chicken coop

First you need to prepare the base. It is necessary even for a summer chicken coop made from scrap materials. The foundation keeps the floor dry and prevents rodents and other pests from entering the structure.

For a chicken coop, a columnar base can be recommended. In this case, there will be a distance between the floor and the ground, thus providing additional ventilation. Columnar foundations are made of brick or concrete blocks.

- First you need to level the site for the future building. The site is marked with rope and pegs so that the posts are level.

- Under the pillars, holes are dug approximately 0.4-0.5 wide at a distance of 1 m.

- Next, brick pillars are laid in the pits. To hold them together, you will need cement mortar. The height of the posts should be approximately 20 cm above the soil surface. Levelness is checked using a level. Ruberoid is laid in two layers on the finished posts.

- It takes 4-5 days for the solution to harden and the pillars to shrink. The posts are treated with bitumen, and the rest of the holes are filled with sand or gravel.

The next stage is the construction of the floor. To better protect the chicken coop from moisture, the floors are made of two layers. Insulation can be laid between the layers.

- A subfloor is laid on the foundation; any material is suitable for it.

- A frame is made of thick, even boards around the perimeter and attached to the foundation.

- For the finished floor, use smooth, good quality boards. They are attached to the frame with self-tapping screws.

The easiest way is to make a frame chicken coop from scrap materials. Wooden beams are used for the frame, and it can be sheathed with plywood or boards. For windows, openings are left in which a metal mesh is stretched. For a small chicken coop, it is enough to install bars in the corners, which are connected at the top by horizontal jumpers. For a large structure, additional vertical posts at a distance of 0.5 m will be required.

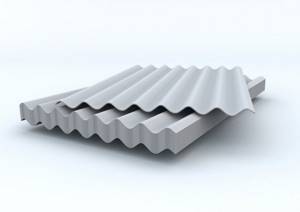

The roof of the chicken coop is usually made of a gable roof, which allows rainwater to flow better from it. For such a roof, the rafters are first installed, then the sheathing is made (boards are laid across the rafters). One of the inexpensive roofing materials is roofing felt. You can use corrugated sheet or any other suitable material.

The chicken coop is ready, now we need to equip it from the inside. Sawdust is poured on the floor or straw is laid. Place feeders, drinkers, nests or cages for chickens, install perches, preferably in the form of a ladder, so that it is convenient for chickens to climb them.

You can also make nests in the form of shelves, arranging them in rows or in a checkerboard pattern. Drinkers and feeders in the chicken coop are installed on a hill.

Choosing a chicken coop

Summer and winter

Based on seasonality, poultry houses are divided into summer and winter. Birds are kept in winter homes all year round; in summer there is no such need; birds spend a lot of time outside.

The simplest summer barn is used to protect chickens from the elements from spring to autumn. The structure is constructed quickly from boards, mesh and available materials. Suitable for those who do not plan to keep the bird for longer than 8-9 months.

A winter poultry house is a more permanent structure with a vestibule and windows. The room must be insulated to protect against severe frosts with thermal insulation materials. Additional artificial lighting is mandatory.

Stationary and portable

A stationary chicken coop is a permanent structure designed for a large number of chickens. The size of the room allows you to simultaneously keep broilers, quails, turkey ducks and other birds in it. Each species is kept in separate cages and walked in different fenced areas (walks).

The bird house can be one or two stories high. Increasing the number of floors allows you to accommodate more birds in a small area.

Advantages of this type:

- year-round keeping of chickens;

- protecting birds from predators;

- storage of equipment and birdseed indoors;

- using chicken coop litter as fertilizer.

Disadvantages: location-specific, speed and complexity of production. Before building a permanent chicken coop, you need to make a foundation.

A portable chicken coop is an easy option for a small number of birds (usually no more than 10 chickens). Portable chicken coops come in different types: arched, box, and even a poultry house on wheels in the form of a trailer or wheelbarrow.

The most popular type is arched. Thanks to its semicircular shape, it is lightweight and highly mobile.

When building a poultry house on wheels, do not skimp on the diameter. This way you will increase the permeability of the structure.

Thanks to easy movement to a new location, mobile poultry houses have the following advantages:

- renewal of grazing forage by transferring it to another territory;

- ease of cleaning when approaching a water source;

- the absence of a foundation speeds up and simplifies construction.

A portable winter chicken coop is insulated with lightweight material. Such a room can be heated with an infrared heater. This is enough for the birds to continue their normal life activities in warm winter conditions. But if winters are too cold in your area, choose a permanent poultry house.

Distance from the chicken coop to the border of the neighboring plot

Determining the distance from the chicken coop to the fence of a residential building in articles written by incompetent authors is easily and simply determined to be 4 meters, as well as to the border of the neighbors’ property. SNiP, adopted in 1997, indeed indicates such a distance as the minimum possible.

Pig sty on SNT land

The building code can be changed by local or regional authorities, by decision of the general meeting of a non-profit garden partnership or dacha cooperative. One thing is certain: in small areas there is no official ban on keeping birds and animals, the only question is the permitted quantity. You can keep a couple of chickens, a goat or ducks, but not all at the same time.

In rural areas, there are plots where housekeeping is an indispensable condition for staying on the land, but if a person intends to breed livestock in industrial quantities, in order to build a large barn or poultry house, he will have to obtain the appropriate permit, register as a farmer and pay taxes on his activities. Accordingly, the distances intended for a potential environmental threat will be completely different, because this is required by law.

Pigsty on private housing construction land

Fencing land property with a fence is a way not only to determine the boundaries of one’s own territory, but also a criterion for measuring the corresponding distances. For outbuildings, standards are observed not only up to the fence between plots, but also up to the owner’s residential house, as well as other structures on the land plot and the neighbor’s house.

If you place a chicken coop or pigsty at a distance from the fence, but directly opposite the neighbor’s windows or a well on the other side of the fence, this can also cause his legitimate indignation, although it seems to have been carried out in compliance with the standards.

Watch the experts' opinion in the video.

Manufacturing materials

When choosing materials for building a chicken coop, pay attention to their durability and thermal conductivity. To reduce costs, use what you find on the farm, after making sure of the quality.

Wooden chicken coops

Wood is the easiest to work with; it does not require expensive tools for processing, is a natural, breathable material, and is inexpensive. The only drawback is the fragility of the material. The problem is solved by protecting against moisture and treating the walls with substances that prevent rot and mold.

For the construction of walls made of wooden materials use:

- Beam. A chicken coop made of timber is the most affordable. But, if there is insufficient dryness, the timber dries out and becomes deformed, forming cracks.

- Shields. A wooden beam is used for the frame, to which OSB sheets or boards are nailed. This design is built quickly and is highly reliable.

- Logs. It will not be possible to quickly build a chicken coop from a log house with your own hands; special technology and experience are required. After the walls are erected, the building is left to shrink for several months.

- Railway sleepers. This material is treated with impregnation that prevents rotting. Thanks to this, speed of construction and reliability of the structure are achieved.

Block chicken coops

The blocks are stronger than wood, but cool quickly in winter. Most often used:

- Brick. Building a brick chicken coop takes a long time, since the bricks are small in size and the masonry is done by hand. It is not recommended to build a wall to its full height in one go.

- Cinder block. Due to the larger size of one element, the construction of cinder block walls is faster.

- Gas blocks. It has good thermal conductivity and hygroscopicity. To increase strength, the perimeter of the chicken coop is fastened with steel reinforcement.

- Foam blocks. The material is safe for chickens as it is non-toxic. The thickness of the walls is chosen based on climatic conditions: if the winter is cold, double masonry is made from foam blocks.

What can you build a chicken coop from?

A chicken coop can be built from a variety of available materials. It can be:

- boards,

- cinder blocks

- sandwich panels,

- beam,

- plywood,

- plastic.

You will also need concrete, mesh, and insulating materials. You can use boards that were left after dismantling another building, and any available materials, especially if this is a summer chicken coop for a summer residence.

Important features of a chicken coop

When building a chicken coop, it is important to correctly determine its size. It depends on the number of birds and their breed. 3 meat chickens or 4 laying hens are placed per 1 m2 of usable area. Separate rooms should be made for chickens at the rate of 15 pieces per 1 m2.

A chicken coop for laying hens should have nests and perches for roosting, places for the hens to eat, bathe and walk.

To allow chickens to go out on their own, you need to make a hole in the wall (hole) raised above the ground. There must be a ladder or ladder leading up to it. The same ladder should be suitable for the perches.

The door leading to the chicken coop should open inward to prevent the chickens from running out when opened. Make a latch to prevent wild animals from getting into the coop.

Make an ash bath for chickens near the poultry house. By wallowing in it, the birds get rid of insects. There should be a small canopy over the walking area to protect the birds from rain and sun.

Foundation

In order for the chicken coop to last for a single year, it is important to make a strong foundation. The choice of type of foundation depends on the soil. For a poultry house, one of 3 types of foundations is made: columnar, strip or pile.

A columnar foundation is suitable for a winter frame chicken coop. It should be borne in mind that the chickens will make tunnels, reducing the stability of the poultry house. Advantages of this type of base:

- is constructed simply and quickly;

- it is inexpensive (you can use old brick or stone);

- protects (rodents will not be able to get into the house, and ventilation under the floor will prevent rotting of the wood).

A strip foundation is suitable for a chicken coop with block walls, with the load evenly distributed around the perimeter of the building. The advantages of this foundation:

- ease of construction;

- high reliability.

The foundation for a chicken coop on stilts is the most difficult. It is built with low bearing capacity of the soil. For strictly vertical driving of piles, equipment is rented and a grillage is used.

Roof

The roof is constructed with 1 or 2 slopes. If the chicken barn is small, one is enough. In this case, the angle of inclination should be up to 30 degrees, for a roof with 2 slopes - up to 40.

Advantages of a single-pitch design: ease of coverage; savings on building materials; ease of installation of the ebb.

The gable provides additional space under the roof, which can be used to store garden tools, building materials or birdseed.

The roof of the chicken coop is made of slate, corrugated sheets, tiles or roofing felt. Although it is not recommended to use a metal roof (metal tiles and corrugated sheeting) for a chicken coop, because chickens do not like noise. During rain or hail, they may become frightened, which will negatively affect their ability to lay eggs.

Insulation of walls and ceilings

To make a warm chicken coop for the winter, mineral wool or polystyrene foam is usually used. These materials attach quickly and easily.

To insulate the walls of a chicken coop with mineral wool, you must first make a frame of beams, which will ensure a tight fit and eliminate cracks. If cracks do form, they are filled with polyurethane foam. Before laying the insulation, it is necessary to make a vapor barrier layer of polyethylene film.

Polystyrene foam is often used for external wall insulation. It is lightweight and holds heat very well. But it must be protected from chickens and rodents with plaster and façade mesh. The joints are covered with polyurethane foam. Mineral wool is placed between boards and slabs. External insulation prevents cold air from entering deep into the walls.

To prevent warm air from escaping through the window in winter, you must use double or triple glazing.

If the poultry house is located in a cold region, a layer of insulation is also laid under the ceiling to insulate the roof. To do this, floor beams are additionally secured to the slings. Plywood is fixed on the attic side. Mineral wool is placed in the space between the beams. Additionally, a vapor barrier film is secured. Then the ceiling is sheathed with plywood, plasterboard or wooden paneling.

The wooden floor is laid in 3 layers: untreated boards, vapor barrier material, treated boards. The top is covered with deep (hay, straw or chopped stems) or shallow (sawdust, shavings or chopped straw) litter. The cracks in the walls and floors are covered with flax and jute fiber.

Do-it-yourself chicken coop on two floors

At first I tried to adapt ready-made premises for keeping chickens - an old garage, a former cowshed. But in the end I came to the understanding that serious poultry farming requires the capital construction of a new poultry house, initially adapted for birds. Of course, deep reconstruction is also suitable, but sometimes it is impossible or so expensive that it is better to take on the construction of a new room.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

I built a 6x5m chicken coop for my laying hens.

The walls were made of AGS (gas silicate foam) 40 cm thick. This thickness is justified by the fact that I never heat the poultry house in the winter, it is expensive. In a barn with a floor area of 30 sq. m you can keep from 120 to 150 chickens (the standard allows 4-6 adult birds to be placed per 1 sq. m). But I started 250 chickens, having equipped an improvised second floor: I placed wide wooden racks along all the walls of the barn, on which I placed additional perches. In total, I made enough perches so that all the chickens could sit on them (20-30 cm long per bird), and made them two- and three-row.

A prerequisite for high egg production of chickens is compliance with the lighting regime. Ideally, the bird is exposed to light for at least 15-17 hours every day. In summer, such conditions can be easily achieved through large windows (their area should be close to 1/5 of the floor area). But when installing windows, it is important to remember that in winter, due to heat loss, they can do more harm than good.

So I nailed honeycomb polycarbonate to the frames on both sides. In the summer, the interior upholstery is removed and returned to its place by winter. I foam the cracks that inevitably appear in the window frame with polyurethane foam. Another small, but also important point is the extension of illumination during short winter days. Personally, every day I turn on the lights in the barn at 7 o’clock and turn them off at 21 o’clock. To do this, I hung several fluorescent lamps in the chicken coop. In order not to go broke paying for electricity, I use modern energy-saving lamps.

Sawdust is best suited for bedding birds. They easily absorb moisture and allow you to keep the chicken coop in an aesthetically pleasing appearance. I sprinkle them regularly, twice a week, but I clean them as the layer accumulates. I get sawdust for free from a local farmer, who is also grateful to me for cleaning the sawmill. I go for them once every two weeks, collect them in bags, which I store under a shed near the chicken coop.

poultry house///two-story chicken coop///comfortable room for keeping poultry

We also recommend reading: Do-it-yourself chicken coop from A to Z

Conditions for birds

Laying hens require nests in which the hens will rest and hatch their eggs. Straw or sawdust is placed inside for softness. A tray is brought to each nest, along which the egg rolls. This way the eggs can be collected without disturbing the hens.

The number of nests is calculated from the proportion - 1 nest per 4 laying hens. Nests are located in dark, quiet corners. The bird should easily get into the nest. The boxes must be stable.

You also need to build wooden perches (perches) on which the chickens spend most of their time. To save space, the perches are secured with a ladder, but with a horizontal indentation so that the chickens do not defecate on their neighbors. Birds should not interfere with each other.

To make cleaning easier, a litter tray is made under the perch, and the ladder leading to the perch or to the nests is removable.

The feeder can be stationary or retractable. Feed is poured into the retractable box without entering the poultry house, which significantly saves time. A feeder made of plastic pipes with one end leading out is easy to use. The food is added for future use without disturbing the birds.

The Importance of Temperature, Ventilation and Sanctification

Maintaining temperature conditions is an important condition for normal reproduction of chickens. The indoor temperature should be between +12 and +24 degrees. Therefore, for the northern regions, in addition to insulating the chicken coop, heating is carried out. At temperatures above +24 degrees, the number of eggs laid is halved, and if the thermometer shows more than +30 degrees, the chickens stop laying eggs.

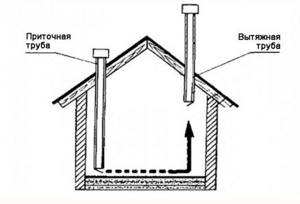

Ventilation removes harmful substances and odors from the room, regulates temperature and humidity, and protects walls from rotting. Types of ventilation:

- Forced (mechanical): using a fan.

- Natural: an open window or exhaust pipe for air inflow and outflow.

If the chicken coop is small, limit yourself to forced ventilation. For large rooms, forced ventilation is recommended, which will cover the entire space.

For summer poultry houses, ventilation is not needed; just leave the window or door open. In winter, it is necessary to regulate the flow of fresh air so that the chickens do not freeze and there are no drafts.

The optimal daylight hours for birds are 12–15 hours.

In winter, it is necessary to install lamps that diffuse warm yellow light. Chickens do not see well in the dark, so they turn off the lamps completely when all the birds have taken their places on the roost. Chickens need constant bright light; as the birds grow older, the brightness of the lighting is reduced.

Walking area

There are 2 types of chicken run: open and closed. With an open range, birds have direct access to the street. The area is fenced off with a net. At the same time, the chickens walk in a large area and feed on fresh grass, but they heavily pollute the area.

Closed type - a system of a chicken coop and an aviary, which are connected through a vestibule. Pros: cleanliness of the area, preservation of lawns and flower beds, round-the-clock protection of birds from predators.

The walk is located in partial shade, under trees or under a canopy. There should be enough space for the birds to move freely. There should be at least 1 m2 per 3 birds.

The poultry house is fenced with a chain-link mesh or fence. The size of the mesh is selected in such a way that chickens cannot escape, and rodents and pests cannot enter the chicken coop. A gate is made in the run for easy cleaning and filling the bird's water bowls with water.

What is a smart chicken coop

Even the simplest mechanization of some functions makes the life of the chicken coop owner easier. Automatic drinkers allow you to change water once a day by simply filling the main container. Turning the lights off and on eliminates the need to walk around the yard late at night and early in the morning in winter.

An autonomous chicken coop combines automation, remote control and independence from external conditions. This option can exist unattended for 2 weeks and provide birds with warmth, drink, food and light.

The advantages of an autonomous system over a mechanical model are significant.

- Automatic heating – heating is adjusted to maintain a temperature comfortable for the bird. Heaters operate in economical mode. The required difference in daily temperature is taken into account. In addition, the control panel allows you to set different heating levels in different areas. The chick compartment needs to be heated more intensely. An area with nests for laying hens does not need good heating.

- Short daylight hours affect egg production, so electric lighting is used in autumn and winter. Automation allows you to set the lighting to turn on and off at the appointed time.

- The drinking bowl system can be connected to the water supply and the smart home. At the same time, the supply of clean water becomes automated.

- It is possible to automate the preparation of feed and its supply to birds, as well as the removal of excess.

- You can also take control of ventilation, which is important in the hot season.

- An automatic egg collector prevents chickens from pecking eggs. And you can’t pick them up every day.

- A smart automatic chicken coop for a private home ensures the protection of birds. The poultry house can be equipped with an alarm system.

- Work data can be transferred to the owner’s phone or laptop. At the same time, the owner of the dacha can control the system from a distance and change the settings.

The only drawback is the need for electricity.

The water supply, ventilation, and heating systems can be synchronized with the smart home system. To do this, you will need to equip your chicken farm with special sensors. The most commonly used hardware and equipment is the Arduino complex. The poultry house is equipped with Wi-Fi and controlled using gadgets connected to the Smart Home system.

Manufacturing

Before construction, it is necessary to make a drawing of the room indicating the exact dimensions. In this case, it is necessary to take into account the number and breed of chickens. Laying hens require more space than meat chickens. They must move freely. Cages are not used in such poultry houses. While for meat breeds it is necessary to limit the space so that they gain weight faster.

There are many schemes available on the Internet, adapted for a certain number of birds. For 5 chickens, a small chicken coop without heating and ventilation system with 1 nest and water bowl is sufficient. It can be portable. Housing for 10 or more individuals requires large expenses and equipment.

After choosing the territory and marking it out, it is worth thinking about the building materials that will be used for the poultry house.

Necessary materials

Each part of the bird house (fencing, foundation, walls, ceiling and roof) will need different materials. They were discussed in more detail above. The choice is made based on the price and merits of certain types. It is also worth considering fittings (nails, screws, screws, etc.), windows and the front door.

The construction sequence is indicated in the work plan.

Work algorithm

Main stages of construction:

- Chicken coop design (for this you need to accurately determine the dimensions and location of the main premises, and make a drawing of the chicken coop).

- Making the foundation.

- Construction of walls and partitions.

- Roof construction.

- Installation of windows and doors.

- Organization of flooring.

- Making amenities for birds.

- Insulation and heating.

- Lighting.

- Fencing the territory.

Construction stages

The construction of a brick chicken coop is carried out using traditional technologies, and if you decide to do the work yourself, it is important to know all the stages. An approximate construction sequence diagram looks like this:

- excavation work for pouring the foundation;

- foundation installation;

- walling;

- roofing;

- windows and doors;

- insulation, lighting and interior decoration;

- external works.

Choosing a foundation

A solid foundation must be laid under brick walls:

- strip is poured from concrete or stacked from ready-made blocks around the perimeter of the building;

- monolithic - a solid concrete slab with mandatory reinforcement;

- columnar is made in the form of columns over the entire area of the building.

A monolithic plinth is suitable for a spacious building, and if we are talking about housing for 5 laying hens, then a strip or columnar plinth will be just right. When choosing a chicken coop design that is raised above the ground, you need to take care of the safety of the birds. To do this, a metal mesh or solid sheets are buried 30-40 cm into the ground, covering the perimeter of the building. Using a moisture-proof material laid between the building and the foundation, dampness in the chicken coop from below is eliminated.

Floor installation in a brick chicken coop

It is best to leave the floor in the poultry house earthen, but other options are possible:

- concrete screed;

- wooden boards or timber;

- clay.

For any type of covering, bulk material is used on top of the floor: sawdust, hay or straw. Coniferous sawdust is often preferred because it has antiseptic properties and absorbs moisture better than straw and hay. The bedding is designed for comfortable movement of birds and ensuring dryness indoors. This layer is removed as it gets dirty and new, clean material is added.

Walling

Brickwork is done in the traditional way: bricks are held together with mortar. The most reliable and durable type is cement. In addition to the main component, it contains sand and water. The bricks are laid in a row, making sure that the vertical seams of the previous row do not coincide with the next layer. During work, you will need the following tools: a container for mixing the solution or a mixer, a shovel, buckets, a trowel, a level and a plumb line. The walls of the chicken coop are erected taking into account the openings of windows and doors, otherwise it will be problematic to make these elements in the future.

Brick is a reliable material, but it has high thermal conductivity, so a brick poultry house needs insulation.

What roof?

The shape of the barn roof can be:

- single slope;

- gable;

- broken.

Materials for covering the poultry house: slate, tiles, corrugated sheets, metal sheets. Regardless of the type of roofing material and type, the roof is carefully insulated. This technique allows you to keep cool in summer and warm in winter. The insulation is chosen at your discretion: polystyrene foam, mineral wool, glass wool, sawdust. The roof is preferable to light shades, since in summer the sun will heat the surface of the poultry house, which will make staying inside unbearable.

Poultry house arrangement

The internal filling of the structure includes the following mandatory elements: perches, nests, feeders and drinking bowls. The structures are positioned in such a way as to provide a comfortable place for the birds to live and help the owner maintain them. The nests are located in secluded corners of the poultry house, the exit from them is oriented from the front door. This creates a calm atmosphere during egg laying. Feeders and drinkers are placed on the floor or attached to the walls, near the entrance, so as not to disturb the bird every time. In addition, the number of nests, perches and feeders is calculated based on the size of the livestock.

Communications

Air exchange methods

Fresh air is necessary for chickens, and in the chicken coop, droppings create the release of harmful substances. Therefore, the arrangement of ventilation is a mandatory measure. There are 2 types: natural and forced. The forced one consists of a through hole into which a fan is mounted. Such a system is energy dependent, which should be taken into account when designing. Natural ventilation works by moving air between pipes located at different levels. One pipe is mounted at ceiling level and rises above the roof, and the second is 10-20 cm from the floor. Ventilate the room by opening the windows, which helps to refresh the air inside the room in the summer.

Cost of building a chicken coop

The amount spent on making a chicken coop depends on the following factors: the expected number of chickens, the type of coop (summer or winter), the area of the chicken coop and the height of the room, materials for production.

The price is also affected by additional costs associated with heating, ventilation, lighting and other amenities.

The minimum amount that will be needed to set up a small household facility (up to 5 chickens) is approximately 20 thousand rubles. A modern capital chicken coop for 15–40 chickens will cost approximately 40 to 200 thousand rubles.

Whether this investment will pay off depends on the conditions of detention, the chosen breed and your diligence.