Standard sizes of cargo containers

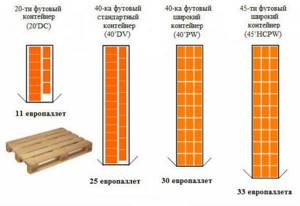

For the construction of country houses from all existing types of container containers, universal large-capacity containers are usually used:

- 20-foot (dry freight);

- 40-foot (dry freight or high cube);

- 45-foot (dry freight or high cube).

Standard high cube containers differ from conventional dry freight modules in their increased height and greater capacity. To make the ceilings in the house higher, it is better to purchase containers of this type.

It should be noted that the width of all types of containers is the same and is 2350 mm. The length of the 20-foot module is 5898 mm, and the 40-foot module is 12032 mm. The height of both containers is 2393 mm. For the High Cube container, this parameter is 300 mm larger. The dimensions of the 45-foot module are several millimeters larger than the dimensions of the 40-foot module.

We also recommend that you read the article “Requirements for the distance from the fence to buildings”:

An interesting project for a two-story country house, built from several containers, with an open terrace on one of the modules

Characteristics of sea containers

Containers for maritime transport are standardized according to the international ISO classification and have code 8301981. Initially, containers were produced according to US standards, but later amendments were adopted and containers adopted approved dimensions. This is due to the need to comply with European road transport regulations.

There are two main modifications of containers: 20 and 40 feet. Their mass is 2.3 and 3.9 tons, respectively.

Another container option that has become widespread in recent years is the 45-foot design. The main advantages of such a container are its size, which provides more working space, and the ability to be transported on standard-sized trailers. The advent of 45-foot containers has led to increased competition between cargo carriers, as the standard semi-trailer has become less popular.

The material from which the container is made is a durable steel alloy. High-quality design makes it possible to install containers in several rows, the number of which reaches thirteen or more. The containers are secured with twistlocks.

Options for standard sizes of sea containers are not limited to the indicated 20, 40 and 45 feet. Depending on the characteristics of the cargo being transported, specialized containers can be used. These include refrigerated containers, tanks for liquids and gases, containers for transporting animals.

Sea container sizes 20ft, 40ft, 45ft

| Length, mm | Width, mm | Height, mm | Volume, cubic m | |

| Container 20 feet Standard | 5898 | 2352 | 2393 | 33,1 |

| Container 40 feet Hight Cube | 12036 | 2350 | 2697 | 76,3 |

| Container 45 feet Hight Cube | 13556 | 2352 | 2698 | 86,0 |

Design features of large-capacity containers

A country house built from a container will not be accessible to lovers of other people's property who constantly visit the territory of garden societies. After all, the design of the container is not only simple, but also reliable.

Rigid frame

It is based on a durable frame welded from steel beams. The lower base of the frame are longitudinal and transverse beams, to which side ribs are welded at the corners. The upper plane, forming the roof of the container, is also defined by transverse and longitudinal load-bearing beams.

Steel plating

The lining of the cargo modules is made of anti-corrosion steel sheets with corrugated profiles, made of high-quality alloy steel COR-TEN steel.

The thickness of the galvanized walls of the container varies from 1.5 to 2.0 mm, so the structure is strong and quite rigid. A high-quality paint and varnish coating applied to the walls of the container along the entire perimeter reliably protects the metal from the negative effects of the environment and corrosive processes.

Plywood floor finishing

Pressed plywood, the thickness of which reaches 40 mm, is most often used as a floor in large-capacity containers. This material is additionally impregnated with a special composition that prevents the development of fungi and mold.

The use of plywood and other types of lumber for flooring provides:

- resistance of the wooden base to mechanical damage;

- good elasticity of the material;

- maintainability and easy replacement of flooring;

- high coefficient of friction when transporting goods.

When finishing the floor in a container adapted for a country house, a thin concrete screed is often poured over the existing base, into which the electric heating system is hidden.

Swing doors

Standard containers are equipped with swing doors, which are hung on strong hinges. The doors are opened using special handles that activate the locking mechanisms. To seal the doorway around the entire perimeter, a rubber seal is used.

The hinged doors of the containers are welded shut, while the entrance to the house is provided through glass sliding doors built into the panoramic glazing of the wall

Construction safety requirements

The container is unloaded and installed in the design position using mechanization means. Rail cranes are used, and vehicle-based lifting devices are also used for small blocks, if lifting capacity allows. Certified cables are used for lifting, and the slings are hooked onto all 4 grips; carrying on two loops is not allowed. Sometimes the crane’s lifting capacity allows you to lift 2 containers at once, but this is absolutely forbidden. They work with the next module after installing the previous one.

Construction precautions:

- slinging and unslinging is carried out by specially trained specialists with a certificate;

- people climb to the roof of the module and descend back only using ladders; they cannot climb using stiffening ribs and other protruding parts of the container block;

- when moving by air, there should be no people in the container;

- You must not be under the boom of a tower or truck crane while carrying a container.

In the evening and at night, the work site must be illuminated. Lamps are placed on the sides of the working site on stable stationary supports and along the access road. I also mount lamps on the crane boom so that people can determine the boundaries of the danger zone.

Requirements for foundation construction

Despite their large overall dimensions, the containers weigh very little. The weight of a 20-foot module is 2200 kg, and that of a 45-foot module is 4590 kg. Therefore, under such a lightweight structure there is no need to build a powerful strip foundation with strapping.

It is enough to place the container house on piles, the length of which depends on the type of soil, the depth of groundwater, the complexity of the terrain, the likelihood of flooding during the spring flood and other factors characteristic of the region. The foundation can be:

- regular blocks;

- reinforced concrete support pillars;

- screw piles;

- TISE piles with an extension at the bottom in the form of a sole;

- rubble concrete pillars poured into formwork;

- large diameter pipes, etc.

A steel support pad must be welded to the reinforcement frame of each foundation column. This platform is needed in order to firmly weld the container itself to it. This will protect the country house from thieves who could steal the entire structure for the purpose of its further use or resale.

Installation of a used container on a pile foundation using special lifting equipment is carried out with extreme care

Rusty shipping containers

It is possible that the planned cutouts for doors, windows and rooms for your container will coincide with damaged areas. This is a great situation where you can save money on a low quality container.

The roof is made of corrugated metal, which is slightly different from the walls. The best way to test this is to climb onto the container.

First, inspect the general condition, including previous areas, signs of standing water (usually coinciding with dents in the roof), etc. A hammer can be used here to distinguish between surface rust and deeper structural rust.

The end doors and associated hardware are the only mechanical parts of the entire shipping container. Anything that moves has a high chance of being exposed to dirt, rust and other corrosion.

Try moving all four striker bars and see how easily they rotate, how well the cams and holders lock, and how easily both doors open on their hinges. Also take a look at the rubber gasket around the doors. Any missing pieces or particularly dry/cracked areas likely signal a need for replacement.

Country house made from a standard six-meter frame

The budget option for building a house from one standard 20-foot (six-meter) container implies the presence of:

- one pivoting window made of single-chamber PVC with double-glazed windows;

- external door;

- individual heating;

- thermal insulation;

- internal cladding made of PVC panels (ceiling) and MDF boards (walls);

- household linoleum used as flooring.

- Artificial lighting is provided by two fluorescent lamps.

- There is one outlet and one switch.

It will cost a little more to convert a standard container into a country house if you cover not only the ceiling, but also the walls with PVC panels. Replace household linoleum with semi-commercial one. Install plumbing: toilet, washbasin and shower, as well as a 200-liter boiler for heating water for household needs.

Recent Entries

5 working ways to use tar in the garden 7 indoor plants that help you get married even in adulthood Indoor plants that can bloom in trouble

One of the options for arranging the interior space of a container house. The usable area of the room is increased by removing the walls of adjacent containers

You will have to spend even more if you design two windows in a container, replace the trim from PVC panels with laminated chipboard panels of the color you like, organize heating with an electric heater equipped with a thermostat, install hidden electrical wiring using Euro sockets and Euro switches. Tile the floor and order special furniture that fits into the narrow and long space of the container.

A more exclusive design involves the presence of panoramic windows, sliding doors that allow you to expand the internal space due to the adjoining terrace, external decoration, and the construction of a roof.

You can learn more about how to build a terrace at your dacha from the material:

Useful tips for home improvement

Based on personal experience, the owners of such buildings give several recommendations for converting cargo containers into living quarters:

- A vestibule should be installed at the entrance to prevent cold from the street from penetrating into the building.

- Metal-plastic windows are equipped with adjustable valves for ventilation.

- Decorative and protective roller shutters are installed on the windows outside.

- Before installing the sea box, the concrete foundation should be covered with waterproofing material.

- You need to install a hygrometer inside and connect the ventilation system controller to it. It will automatically adjust performance to maintain humidity at the optimal level.

Design ideas

A container house designed in a loft, modern or high-tech style looks most organic. Minimalism, transparent or shiny (chrome) objects are welcome. Rooms with shelves and sliding glass doors and large windows look impressive.

A country house can be decorated in a country style by covering the inside and outside with wooden siding or a block house.

Big house.

Thermal insulation: inside or outside?

You can only insulate a metal container from the outside if you plan to operate your country house all year round. In this case, the container will not freeze, which means that condensation will not form on the internal walls of the house. If you want to use your country house mainly in the summer, and visit it occasionally in winter, then you need to insulate it from the inside.

In what order should the work be performed? And like this:

- First, cut out all window and door openings in accordance with the container modernization project, as well as openings for ventilation and chimney pipes.

- Weld spot-weld square pipes on both sides of each cut opening to the sheathing, which will run from floor to ceiling. Weld horizontal pipes to them with a continuous seam, running above and below the opening. This way you will restore the structural strength of the container wall, weakened by breaking the continuity of the stiffeners.

- Weld the hinged doors of the container and clean its surface from traces of rust, if any.

- Make a vertical sheathing from wooden blocks 5-10 cm thick, which will serve as a beacon when spraying polystyrene foam or polyurethane foam, which fills the profiles in the walls of the container well.

- Spray the insulation and cut off its excess along the exposed beacon bars.

- Insulate the ceiling in the same way.

- Then tighten the walls and ceiling of the container with a vapor barrier membrane, targeting it to the sheathing bars with a construction stapler.

- Carry out the final finishing using lining, gypsum board, particle boards, PVC panels and other materials.

- Insulate the floor using the same spraying or polystyrene foam boards. It is not forbidden to pour screeds made of lightweight concrete. It is undesirable to use mineral wool as floor insulation, which, when exposed to water, retains moisture for a long time, which can cause rusting of the bottom of the container, as well as the formation of mold and mildew.

It should also be noted that when installing a fireplace, stove, or chimneys, it is necessary to use 5-10 centimeter basalt wool to insulate areas of possible contact with hot surfaces.

The material on arranging a summer kitchen in a dacha with your own hands will also be useful:

Spraying of insulation onto the walls and ceiling of the container is carried out wearing a protective mask and special disposable work clothes

Reviews of container houses

of the container house are positive . Most people who have built such housing for themselves are satisfied with it.

We found out on the Internet about houses made from containers and decided to buy the same country house. Installation costs were significantly lower compared to building a conventional house. If desired, the cottage from the container can be easily transported to another place.

Marina, Tula

I'm thinking of building a house, I liked the idea of using containers for this. Fast and relatively cheap. The main thing is to properly insulate and finish; the modules can be customized to your liking. It will be necessary to study in more detail the different projects and prices of houses, and then start construction.

Elena, Ryazan

I have been building private houses for a long time.

I have studied the projects of container houses quite well and I think that in our conditions they can be just as in demand as in other countries of Europe and America. The advantage of such houses is quick installation. I built myself a country house from two containers, the conditions there turned out to be quite comfortable. Andrey, Kaluga

Stage two: foundation

A monolithic foundation is certainly not suitable in our case. It will quickly crack and be squeezed out of the ground (the latter, in turn, will begin to sag). For this reason, the foundation should be minimalistic, just like our future home.

If our house starts to sink, we can always simply lift the container.

We make a regular “pillow” from any inert material, for example, gravel. Next, we install piles on the gravel (with delivery they will cost 9,000 rubles) - in parallel, at a distance of 6 meters from each other. As a result, we should get a perfect square.

Stage three: installation of containers

We cannot install the containers on our own, although they weigh relatively little - about 5-6 tons. To do this, we resort to the services of special equipment. After installation, we securely weld the containers together using a gas generator and a welding machine.

It is better to entrust this work to an experienced welder, who would weld the joint between the containers “in a circle.”

Approximate cost

Used containers are sold at the following prices:

- 20 feet - 70-80 thousand rubles;

- 40 feet - 110-125 thousand rubles.

Other expenses may significantly exceed their cost. Thus, in some cases, for delivery alone it was necessary to pay an amount commensurate with the price of a container for sea transportation of goods.

Finished residential premises

The following examples will help you roughly estimate the cost of a house made from decommissioned sea containers on a turnkey basis:

- A building consisting of 1 sea box (20 feet) on screw piles, with a window and a door, insulated with mineral wool, with finishing and lighting - 560 thousand rubles.

- The same from a sea cargo container 40 feet long, with 2 windows - 1.2 million rubles.

Construction estimate

If you build it yourself, the cost items will be as follows (example):

- 2 boxes 20 feet long with increased height - 2 x 70 = 140 thousand rubles.

- Columnar foundation with sand and gravel cushion and porch - 19.6 thousand rubles.

- External wall cladding made of timber, lining and mineral wool (thermal insulator) - 22 thousand rubles.

- Internal lining with clapboard on the frame - 13.3 thousand rubles.

- Wooden insulated ceiling (lining + mineral wool) - 10.2 thousand rubles.

- Insulated plank floor - 13 thousand rubles.

- Doors (entrance and 2 interior) and windows (3 pcs.) - 38 thousand rubles.

- Solid fuel boiler with hob - 22 thousand rubles.

The total costs are 281 thousand rubles.

Utilities should be included in the estimate. Their cost largely depends on the preferences of the owner.