In the practice of building a thatched house, there are 2 main approaches.

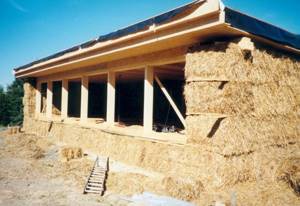

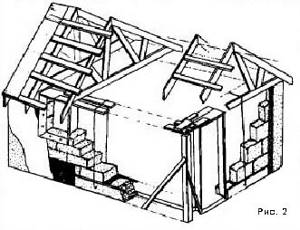

Frame construction

The method involves the use of an additional supporting frame, as for a panel house. The frame is constructed from wooden beams, after which it is filled with blocks of straw. There is another variation of this method. When the frame is not filled with blocks, but covered. In this case, before covering the frame with blocks, you should cover the frame with a metal mesh for further plastering of the internal walls. You need to start laying blocks from the corners. Before laying, waterproofing (roofing felt, polyethylene) is laid on the foundation. To join the frame with the blocks, a special gap must be left in the block; this can be done with a chainsaw.

Load-bearing walls made of straw blocks

Building walls using straw blocks is no different in principle from building walls using bricks. The straw blocks are placed in the dressing so that the seams do not match.

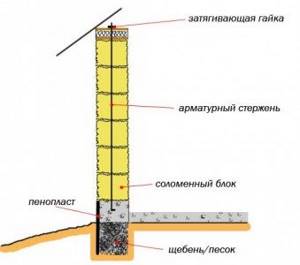

To give the structure additional rigidity, many techniques are used. Basically, the blocks are held together with vertically driven wooden stakes. It is also possible to use metal rods. In this case, the rods are embedded in the foundation of the house so that the length of the rod is enough to connect two straw blocks. The distance between the rods should be about one meter. Afterwards, the first two rows are put on the rods. In subsequent ones, rods are driven in in the same way.

There is a technology in which the rods are increased as the blocks are laid. As a result, after the construction of the wall is completed, a pin is obtained that passes through the wall along its entire height. The lower part is also walled into the foundation, the upper part rests on the mauerlat (support for the rafters) and has a thread onto which a nut is screwed. This creates a screed. The distance between the pins is one meter.

Straw blocks (in places with a more humid climate) are also held together with clay or cement mortar.

The history of thatched houses

The first settlers of North America also used this cheap and readily available building material to build temporary and permanent homes. To do this, the straw was packed into bales. In the 19th century in France, straw began to be laid in dense straw blocks, and the construction of thatched houses received its next revival. The blocks consisted of straw stalks cleared of grains and then laid on a clay foundation.

Also, the use of this material was widespread in Australia, and in the Soviet Union less than 50 years ago, thatched houses could be found quite often. The foundation was based on a mixture of clay and straw, which was also used to insulate and cover the roof. Currently, the direction of building environmentally friendly houses has gained popularity. Once again, the use of this material has become widespread and in demand.

Straw blocks, their advantages and disadvantages

Straw refers to the remaining stems after the harvest of grain crops. In addition to construction, it is used for feeding cattle, after additional processing. Therefore, it does not have any particular economic value and often after harvesting, unnecessary straw is simply burned. Considering the scale of our country and the widespread use of land for planting cereals and grain crops, straw reserves can be said to be practically inexhaustible. Indeed, to build one private house with a total area of 60 to 70 square meters, it is enough to use the remaining waste after harvesting from 3 or 4 hectares.

The construction of a house from straw is carried out according to the principle of laying bales, which have dimensions of 500 * 400 * 500-1200 millimeters. Many potential developers are somewhat frightened by the high fire hazard of this building material. However, in blocks the stems are pressed so tightly together that due to lack of oxygen, the ability to ignite is noticeably reduced. The principle is similar to a sheet of paper and a thick thick bundle of papers, where the sheet suddenly ignites and burns out completely without a trace, and the bundle of paper only becomes charred at the edges. For additional safety, straw blocks are plastered, and therefore the fire hazard of such material is an order of magnitude lower than that of wood.

For your information. In addition, the advantages of a straw house definitely include the low cost of the raw material. A set of building blocks is made from a variety of cereals: wheat, rice, rye. The cost of such a block will be approximately 1/10 of the cost of a similar amount of brick. In addition, a house built from straw provides its owner with excellent thermal insulation.

Building a house from straw means living in a warm place, because such a house is several times warmer than a wooden house and retains heat almost ten times better than a brick house. Therefore, the use of straw as a main component for building your own home should be considered seriously, because building materials, as well as prices for the provision of heating services and electrical energy consumption, are in continuous growth.

A significant factor in the preference of straw over other materials is the speed of construction of a residential building. It is quite simple to build a house from clay and straw with your own hands; you only need to understand the process and technology of constructing such buildings. A fully finished straw bale house can be erected without special equipment or complex machinery. The main condition is the installation of a light foundation and, if possible, edging with a wooden frame, but frameless construction is also acceptable. Therefore, it will take only a few weeks (depending on the number of people and intensity of work) from the creation of the project to the delivery of a completely finished residential building.

Important! The disadvantages of using such material, of course, include the susceptibility to rotting and the presence of small rodents.

Although this problem has now been solved, it is enough just to create a pressure in the blocks of 300 kilograms per cubic meter with a press, then the walls are plastered, and such a structure is not subject to the destructive effects of water or the activity of small rodents. But the high pressure created in the blocks is a result of the large weight of the blocks and the consumption of more materials, so rodent control requires the use of slaked lime as a powder between layers and an additive to the plaster.

Do-it-yourself block production

You can make wall panels from pressed straw with a wooden frame for building a house yourself, but first you will have to make an appropriate press , because you will need to compress the material.

To create such a press, it is best to use hydraulic cylinders with a large piston stroke from various equipment and a hydraulic pump feeding them.

Moreover, the module with hydraulic cylinders must move freely along the entire structure so that it can be moved as each section of the panel is filled.

The panel manufacturing process is as follows:

- Longitudinal (guide) bars are made from boards 25–40 mm thick and 100–200 mm wide;

- Transverse panels (frames) are made from boards 30–50 mm thick and 50–100 mm wide;

- the outer frame is attached to the guides using sufficiently long screws or self-tapping screws, then reinforced with braces;

- this structure is installed on a press and filled with straw bales;

- an intermediate shield is inserted, to which a compression device based on hydraulic cylinders is connected;

- hydraulic cylinders compress the section until the required straw density is achieved;

- The intermediate shield is fixed with self-tapping screws or self-tapping screws;

- repeat the operations until the entire panel is filled, after which the end shield is installed and secured.

The process of making adobe blocks is similar to that described above, the only difference is that the straw is first crushed using a straw cutter, then the finished mixture is not placed in wall formwork , but in special forms, which are removed after a few hours. Then the finished blocks are dried for 1–2 weeks, after which they can be used to construct or insulate a wall.

If you add lime to the solution, you cannot knead it with your bare feet, as this will lead to severe burns and subsequent inflammation.

After adding lime, you can knead the solution either using a concrete mixer or wearing high rubber boots on your feet.

construction costs can only be estimated conditionally, and by dividing all costs, that is :

- acquisition and delivery of materials;

- creating conditions for its storage;

- foundation installation;

- construction speed;

- the ability for an unfinished structure to survive the winter without destruction;

- remuneration of workers and equipment involved in installation.

Delivery and purchase of material are cheaper than wood, and even more so brick or any other massive, including monolithic, construction. After all, compressed straw bales are very cheap, panels and blocks are more expensive, but the price is still lower than even for a wooden house kit, not to mention more traditional materials.

In addition, straw panels or adobe blocks can be made directly on the site of the house construction, then the costs of purchase and delivery will be sharply reduced , although you will have to pay for the labor of several workers and the purchase or manufacture of equipment for such production.

If you buy ready-made panels, then their cost is 1.5–3 thousand rubles per 1 m2, which is noticeably less than the cost of even a wooden house kit with the same heat loss value without additional insulation.

For storage, compressed briquettes are carefully stacked in a large pile, then covered with a vapor-permeable waterproofing material (sometimes tarpaulin or polyethylene is used, but there is a high risk of rotting under them), providing open areas on the sides for ventilation.

The requirements for the foundation depend on the type of material for the walls - if it is panels, then even a non-buried strip foundation will do, but if it is any form of clay-straw mixture, then a powerful buried foundation is required.

The speed of construction, and therefore the cost of it, directly depends on the type of material:

- the panels are installed very quickly, comparable in speed to a frame frame or a log house from a house kit;

- frame with filling the walls with briquettes takes a little longer, but is also comparable to a conventional frame;

- a frame house with walls filled with a mixture of clay and straw is comparable in time to monolithic construction;

- adobe blocks require the most time and the construction of such a house is comparable in terms of time to the construction of a conventional building made of cinder blocks.

Unlike a brick house, which requires a large team to quickly erect , a box made of straw panels can be raised by three or four people in a few days, so the cost of paying for their labor will also be minimal. In this case, the bare minimum of equipment will be required, and when constructing one-story structures, you can do without it.

Main stages of construction and choice of material

A house made of straw is built with your own hands in stages:

- Determination and selection of building materials;

- Creating a support;

- Selection of design type;

- The process of laying blocks.

Material selection

Before purchasing straw bales, you should carefully inspect them for quality, because they will form the basis for your home! For tying bales, the most reasonable solution would be to use polypropylene, because, unlike metal wire, it does not corrode, and rope made from natural materials is susceptible to rotting. In rare cases, straw is sold in rolls, which is undesirable for construction, because most of the stems will be broken, and this will negatively affect the thermal insulation properties of the home. It is preferable to use rice and rye stalks.

The quality of the bale production and the straw itself can be indirectly determined by weight. A bale in which the stems reach a meter in length and a density of 100 to 140 kilograms per cubic meter reaches an average weight of 20 kilograms. In order to avoid buying low-quality goods and defects in the form of dampness, it is worth touching the entire bale from the outside and as far as possible from the inside; also, wet or rotten straw emits a special smell that is quite easy to detect. It is necessary to check the stems for flexibility; with slight bends they should not break, otherwise the straw is old and should not be purchased under any circumstances!

For your information. A thatched house, like any other, needs support. To do this, you need to make a foundation, the type of which is determined taking into account the analysis of the soil at the construction site. It is necessary to lay the foundation in such a way that the lower straw blocks are slightly higher than the floor. This will ensure the safety of the walls from contact with water in the event of a possible pipe break.

Building a house

After erecting the foundation, you must decide on the structural type of the house: frame or frameless. A frameless thatched house can only have one floor, the length of the wall is no more than 8 meters and the area of all windows and doors should not exceed half of the total area of the walls. This is due to the fact that the entire load-bearing load falls directly on the straw blocks, so in this case it is recommended to use blocks with a higher density. In addition, in a frameless thatched house, it is advisable to build a light roof without wide eaves, since this structure is fixed to the straw blocks using wooden mauerlats.

History of thatched houses

The first thatched houses began to be built in America in the middle of the 19th century. Very often, the wood that was used in the construction of structures was not enough, but there was an abundance of straw in the fields. The first officially registered house made of straw is considered to be a school building in Nebraska at the end of the 19th century, the walls of which were completely eaten by cows a few years later. This is probably why compressed straw blocks began to be supplemented with a strong frame made of logs in the very near future.

A little later, the construction of houses made of straw for a wide variety of purposes began in full swing, the area of which reached 70 square meters. m. These were schools, shops, residential buildings, barns, cowsheds, vegetable stores and even small luxury estates.

However, already in the middle of the twentieth century, straw house construction, as a result of the advent of more modern construction technologies, began to gradually lose its position. Despite this, the idea of building inexpensive and yet reliable structures did not leave people's minds. At the end of the last millennium, these ideas grew into a whole movement to build economical and environmentally friendly houses.

The interest of architects was of greatest importance for the popularization of straw houses, thanks to which buildings with the most unusual architectural and planning solutions began to be erected in America. The resurgence of straw bale construction was supported by television and print media, including the New York Times and National Geographic magazine.

Gradually, houses began to be built in a variety of climatic zones and countries: Australia, Chile, Canada, Mexico, France and, naturally, in the USA. In Russia, the very first straw bale house was built in the village of Mayak (near Chelyabinsk) in 1994. Houses made of straw bales with various fillers (clay, sand, slurry) were known in Rus' as adobe houses. In warm regions, such construction is still popular to this day.

Reviews

Moreover, some of them are either specialists in the construction of such houses or their owners.

Another source of information is YouTube, where owners and builders post video reports about such houses.

You can also find reviews on the websites of companies that sell straw press panels or offer turnkey construction of houses from them. Therefore, we have selected links to the most authoritative forums, as well as the most interesting reviews and video reports.

These are the links:

How to build a straw house with your own hands

Blocks of pressed straw measuring 35*45*90 cm are used as a building material. They are tied with nylon cord or wire. When making blocks, flax, rye or wheat straw is used; in addition, you can use hay. It is worth noting separately that the straw in blocks is usually pressed so tightly that it is impossible to burn through the bale even with a blowtorch. Thanks to this, straw houses are not exposed to moisture. Raindrops can penetrate the treated walls and roof no deeper than 5 cm.

Blocks for construction are usually made in a rectangular shape. Their size depends on the length of the stem: the longer it is, the larger the block and, accordingly, the more reliable. During construction, you can use not only dry straw blocks, but also those soaked in clay mortar. Before starting installation work, the compressed bale is dipped in a clay solution, and then thoroughly dried for a certain time. Thanks to these actions, it is possible to achieve precise wall geometry, as well as high fire safety and strength.

But here it is worth noting a number of some disadvantages: such walls retain heat less well, take too long to dry, and can become moldy. This technology is called “light adobe”, since the amount of clay in such a compressed block does not exceed 10% of the total weight.

Once the foundation is prepared and the necessary supply of straw bales is available, the installation of doorways and walls can begin. The standard height of a straw bale wall is, on average, 5-6 rows. Building houses from such blocks does not present any difficulties, since only a crane is required to lay them. Straw is a very convenient material that allows you to erect buildings of almost any architectural complexity.

Laying straw bales

Straw blocks can be used as load-bearing walls, but to more reliably strengthen the structure, strong frames should be used. The frameless option involves laying load-bearing walls directly from the straw blocks themselves, fastened to each other using a special mortar or vertical stakes. If desired, instead of wooden stakes, you can use plastic or metal rods, the lower end of which is attached to the foundation, and a tie nut is attached to the upper end.

Scheme for constructing a straw wall

The main advantages of this type of construction are the ease of construction and low cost of the house. Keep in mind that when installing a heavy and architecturally complex roof, the construction of frames will be a prerequisite, even despite the high density of the blocks.

Frame houses made of straw involve building, first of all, a wooden supporting frame, between the beams of which straw blocks are carefully laid. The structure of the frame is exactly the same as in the construction of simple frame houses. The blocks should either be tightly packed into the frame, or additionally reinforced with a special solution, rods or stakes. If desired, you can build a double frame, which will make the load-bearing capacity even higher. Double frames can support even the heaviest metal or wood roofs.

Drawing of a frame house made of straw blocks

After the window openings and walls are completely prepared, you can begin tightening the house along the frame with plastic tapes. Due to this, the straw will shrink, which will make the plastering process more convenient. If all these conditions are carefully met, the house will not settle for several years. Keep in mind that straw blocks must be laid at a slight elevation above the floor, which will protect them from moisture. When creating unusual architectural designs, straw blocks must be carefully trimmed with a chainsaw.

Before finishing the internal and external walls, the gaps between the blocks are eliminated using small bundles of straw, which are first dipped in liquid clay. A polymer or metal mesh is attached on top of the stacked straw blocks, followed by a layer of plaster about 75 mm thick.

Plaster is a reliable protection against the effects of rodents, fire, moisture and other troubles. On top of it you can apply any decorative finishing you like, for example, covering the walls with plasterboard.

Advantages of straw as a building material

The main advantage of thatched buildings is the extremely low level of heat loss .

With the same wall thickness, they surpass in this parameter not only stone or brick, but even wooden structures.

In the villages you can still find straw huts built before the revolution, while the houses, if they have been looked after, are in good condition and can last for many more decades.

The same situation applies to adobe houses, that is, made from a mixture of clay, straw and other components. Those who have lived in such houses note that they are cool in summer and warm in winter , which is caused by the low thermal conductivity of the wall material. And the unsightly appearance and low load-bearing capacity are fully compensated by either external brick finishing or internal load-bearing brick walls.

Pros and cons of compressed straw houses

Advantages

- Economical. Average prices per 1 sq. m of finished housing is no more than 5 thousand rubles.

- Thermal and sound insulation is 4 times higher than that of a wooden house. In the winter season, such houses are very warm, and in the summer – cool.

- The average lifespan of one house is about 50-100 years. Rye straw, which is used in construction, is not damaged by rodents, and in case of dampness it rots little. Speed of construction and availability of materials required for construction. It is also worth noting the versatility of the options - from the cheapest and simplest to quite high-quality and original designs.

- Possibility of easy and quick redevelopment, and, if necessary, reconstruction of the entire building. Straw blocks allow you to build structures of almost any complexity. Blocks can be made in advance in the most unusual shapes, or during the construction of housing they can be given the required shape using electric saws.

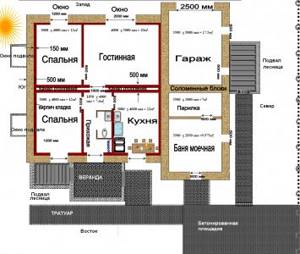

An example of the layout of a straw bale house, which can always be easily changed at the request of the owners

- Low weight and pressure on the ground, which is very important in cases where the structure is being built on a slope. If you want to save money, you can give preference to a pile foundation, which can easily support the structure of a thatched house. Further shrinkage of the house is considered an extremely rare occurrence.

- High fire safety indicators, since compressed straw does not burn, but simply smolders slowly, which allows you to smell and smoke very quickly. High-quality plastered buildings are non-flammable.

- Thick walls easily create a feeling of warmth and comfort. It is also very easy to create a project for some unusual fairy-tale house.

Installation of windows and doors

Installing windows and doors in thatched houses is a simple process. Installation is carried out in the same way as in wooden and brick houses. The main requirement is moisture resistance. Windows and doors are fixed to frame elements. If the walls of the house are built exclusively from straw blocks without using a frame, then in this case, wooden stakes are used to secure the door and window frames, which are hammered into the walls of the house. Also, in order to improve moisture resistance, the mesh should cover several centimeters of door and window frames.

Straw block characteristics:

The parameters of a straw block may vary, on average its dimensions are:

- Length - 90 cm

- Width – 45 cm

- Height – 35 cm

- Weight 20-25 kg

Fire safety of straw block

In order to test the straw block for fire resistance, the following experiment was carried out:

A straw block plastered on all sides with clay plaster was subjected to intense heating for 4 hours. During this time, the temperature of the straw block rose to 43 °C only twice. Not only did the block not catch fire, there was also no appearance of smoke. This meets all fire safety requirements. The plaster, after being exposed to a temperature of 100 °C for 2 hours, retained its appearance, without cracks or chips.

A straw block is an interesting material that, in its thermophysical parameters, surpasses all known materials (brick, wood). Its thermal conductivity is 8 times lower than that of brick, and 4 times lower than that of wood. To avoid heat loss, it is very important to take care of the thermal protection of the house, from the base to the roof.

The most significant proof of the reliability of straw blocks is that buildings that are about 100 years old are still preserved. People still live in them.

As a result of tests carried out in Canada, a wall 2.5 meters high and 3.6 long, covered with a layer of plaster, withstood a vertical pressure of 8,000 kg/m2 and a lateral pressure of 325 kg/m2.

Is it possible to build standard thatched houses?

Every year in Russia about 800 million tons of wheat and rye straw are produced, the bulk of which is burned. Half of this straw is enough to build 2.6 million houses with an area of 150 square meters. m (that is, 390 sq. m. of housing per year). Straw belongs to the category of a rapidly renewable natural resource that is obtained almost free of charge. The cost of straw required for the construction of a medium-sized cottage (about 150-200 sq. m.) will be approximately 30 thousand rubles. Considering that straw is a very light material, prices and costs for building a foundation will be insignificant.

At the moment, the cost of constructing a straw house is at the level of wooden cottages, since in our country there is no infrastructure capable of ensuring the continuous production of straw blocks for housing construction. The straw must be thoroughly dried, and in our climate this is very problematic. Despite this, adherents of environmentally friendly construction are confident that the future lies with thatched houses.

One of the little-known housing options in our area is a straw house. Meanwhile, this is an excellent alternative to a brick or wooden house for certain climatic zones. Such housing is built from environmentally friendly materials and has been successfully used in the West for a long time. For example, Americans have been building similar houses for about 80 years. In Ukraine, you can also find such successful projects of your own housing in eco-villages.

Pros of a straw house

Let's look at the main advantages of building such a house.

Straw house in Ukraine

Durability of the house

Many people associate straw with a fragile, unreliable, dry and short-lived material. How can one, it would seem, build a house out of it for many years of use? But surprisingly, such housing can last a very long time. For example, in America, some straw houses have served faithfully for more than 100 years. If construction technology is followed correctly, the house will last a very long time.

Cost-effectiveness of an eco-house

Building a thatched house is much cheaper than using any other popular material today (wood, stone, brick, etc.). In addition, during construction you will be able to save on the foundation (it will be much less massive due to the light weight of the straw frame and the absence of shrinkage of the straw house), on transportation (straw blocks are large, but very light, they are easy to transport and move independently using small-capacity vehicles) .

Eco-friendly home

Straw is a natural material, so the environmental friendliness of such housing will be at the level. Bales of rye straw don’t even need to be soaked with anything - rodents don’t feed on such straw. To protect the straw from external natural destructive influences (rain, humidity), it is advisable to treat the straw block on all sides, for example, with a clay solution.

Thermal conductivity

Straw retains heat very well, even better than traditional wood. It will be necessary to spend much less resources on heating such housing. In the summer, such houses will perfectly accumulate heat from the environment.

Fire hazard

At first glance, it may seem that straw housing has one very serious drawback - excessively high flammability. However, test tests have shown that the flammability of properly compressed straw is extremely low: when the fire flame is directed from the burner to a straw wall, combustion occurs even at a higher temperature than wood.

Straw house video

Speed of construction of an eco-house

A thatched house can be built in just a few weeks. The first step is to erect a wooden frame, after which the walls and ceilings are filled with blocks of compressed straw. Next, all that remains is to make the roof and do the finishing work.

Disadvantages of a straw house

However, you still can’t do without a fly in the ointment. Despite such bright prospects, eco-houses made of straw cannot be built everywhere. Straw is very susceptible to rotting and deteriorates quite quickly when placed in damp areas. That is, building an eco-house from straw in an area with long rainy seasons and high humidity is not recommended. Such housing is designed for warm, dry southern cities or countries.

And yet there is no doubt that such buildings have a good chance of being popularized in the future due to their unpretentiousness, low cost, and speed of construction.

Useful video

For a better understanding of how straw houses are built, it is recommended to watch a video that clearly shows the whole process.

A straw house is an excellent solution for those who want to surround themselves and their loved ones only with high-quality and natural materials. The raw materials used for construction are not only environmentally friendly, but also inexpensive. Considering the variety of technologies used to build straw houses, it is possible to choose one that will satisfy all the criteria of the future owners of an eco-house made of straw.