The main functions performed by the blind area

Its main purpose is to prevent the soil around the building from getting wet, which, when wet, negatively affects the foundation of the house.

In addition, a wisely made blind area will be part of the landscape design and will give the house a finished look.

Why do you need a blind area?

If you want the foundation of your house to be strong and durable, it is necessary to provide effective protection of the foundation from water, which is the main cause of destruction of all types of concrete foundations.

Expert advice! Complete protection of the concrete base from moisture is possible only if three types of drainage systems are used simultaneously - drainage, storm drainage and blind area.

Fig. 1.1 : Blind area made of paving slabs

Drainage drainage is represented by pipes located in the ground along the perimeter of the base, which protect the concrete base from groundwater. Deep drainage pipes must be laid during the construction of slab and strip foundations.

Storm drainage consists of pipes located around the perimeter of the roof of the house. This system is responsible for collecting and draining rainwater flowing from the roof of the house during precipitation.

Storm drainage will lose the lion's share of its usefulness if a blind area is not placed around the house. The functional purpose of the blind area is to drain surface water, the so-called overhead water, from the walls and foundation of the house to a distance of more than 1 meter.

The term “overwater” refers to water formed as a result of snow melting and rainwater that flows through storm drainage pipes onto the blind area. The blind area is made in the form of a tape about 1 meter thick, which follows all the contours of the building and encircles the perimeter of its walls.

Expert advice! The blind area can be monolithic - made by pouring concrete formwork, or a prefabricated structure - made of natural stone, paving stones or paving slabs.

The blind area around the house has not only a functional purpose - in addition to protecting the foundation and base of the house from surface water, it also plays an important decorative role.

The blind area, if it is made of high-quality, aesthetically attractive building materials - tiles or stone, significantly improves the visual perception of the house, giving its design completeness and richness.

Types of blind areas used in house construction

There are several types of blind areas, which may differ in the material used and manufacturing method. Each of them has its own advantages.

This article will help you choose the most suitable option for constructing a blind area around the house.

Stages of creating a blind area

In order for the design to be made with high quality, it is necessary to adhere to some rules, which are described below as recommendations.

The width of the blind area around the house should start from 300 mm than the eaves of the roof of the house. The minimum width of the blind area of 600 mm is used in practice as a path next to the house, the width of which can be about 100 cm. It should be remembered that the wider the girdle is made, the stronger the protection from harsh weather conditions will be for the foundation of the house.

The blind area around the house on a slope should be built towards the house. Builders recommend using a slope of the blind area of 1.5 or 10 degrees. At the same time, you should not tilt it too much, since the path will then be uncomfortable for walking along it.

The exception to creating a large slope of the blind area is precipitation in the spring and the formation of flood waters as a result. The angle at which the blind area is created should be 3 degrees around the entire perimeter. Then it will be able to protect the building from moisture.

Clay blind area for home

Probably the most ancient way to strengthen the foundation of a home. Clay used as the main material has a number of positive qualities, such as water resistance and plasticity, which allows it to be successfully used to this day.

The positive properties of such natural material include the impossibility of weeds growing on it due to its high density.

Concrete blind area around the house

It is the most common solution for this type of work. The positive qualities of this material are:

- excellent mechanical strength

- high waterproofing qualities

- long service life

- ease of manufacture

For all its advantages, the concrete blind area has a number of disadvantages:

- in the absence of reinforcing structures, there is a high probability of cracks appearing

- concrete structure is not a standard of beauty and requires additional decor

- repair work requires significant effort

Variety

There are different options for choosing a blind area. Each of them has its own properties and specifics, so it’s worth familiarizing yourself with each type in more detail.

Classic option. This is a concrete blind area. For this type, clay, sand and crushed stone are used. All components are mixed in appropriate proportions and poured with concrete mortar. This is not difficult to do, but such actions will significantly protect the foundation from exposure to water in the future.

Paving slabs. This type has a surface that is neatly laid with paving slabs. This material is laid on a layer of crushed stone and sand. Adjacent slabs are secured with sand.

If you want a more colorful look, then you can use different colors of slabs. Such an unusual ornament, or, for example, a laid out pattern, will decorate the surface and significantly change the appearance of the house.

Another option is pavers made from concrete or stone material. The main advantage of this choice is aesthetics, as well as long service life. Following the example of paving slabs, this option is made without the use of water or concrete material.

Its location is between sand and a layer of crushed stone. Individual elements may have small gaps; they are covered with sand.

It is possible to install a soft blind area near your home. This fill consists of crushed stone, or gravel. Regardless of what material you choose, it is covered with a special waterproofing material.

This type is distinguished by its accessibility, because it has a corresponding price, as well as its simplicity. You can easily do this type of blind area yourself without additional effort.

- Design of the porch of a private house - ideas for beautiful design in 2021 (131 photos)

Metal tile Monterrey - A beautiful and inexpensive option for arrangement (60 photos)

Form for filling garden paths - original zoning of the site with paths (119 photos)

Note! Do not use ceramic magnetic materials for coating. Due to such inappropriate use, you risk getting a top layer that is of poor quality or has tears.

Asphalt blind areas to protect the foundation

Despite its rather simple appearance, asphalt pavement does an excellent job of its main function - protecting the foundation.

Blind area of the house using paving stones

This option serves mainly a decorative function. As a rule, paving stones are laid on a soft base, which will lead to moisture getting into the foundation of the house.

Laying in this way requires additional drainage systems or a concrete base.

Soft blind area around the house

It is the most labor-intensive of all the above methods. It consists of several layers, the top layer has a decorative function, the bottom one is waterproofing.

The presence of waterproofing in the lower layer presupposes the presence of a drainage system. This method of constructing a blind area around the house requires sufficient experience of the craftsman and financial costs.

Why do you need a blind area

The blind area consists of several layers. The first one is the bottom one. It is made from a mound of gravel and sand. The reinforcing mesh supports the frame of the edging, maintaining its shape. The litter must be placed directly on the ground, which has been leveled beforehand. The top layer is needed to waterproof the foundation from excess moisture. It also acts as decoration. If you choose the right materials and style, the blind area will help you decorate your summer cottage. This function is no less important than protective. The aesthetic pleasure of a beautiful yard complements your vacation and makes it more effective. The waterproofing must be tightly adjacent to the building so that moisture does not seep into the foundation.

Attention! To allow water to drain, the edging around the cottage is slanted towards the outside.

The blind area of a country house is needed for:

- protecting the building from cracks due to temperature changes in winter;

- insulation of the basement part of the building from excess moisture;

- maintaining the shape and integrity of the house;

- preventing foundation creep;

- prevents roots from destroying the foundation of the cottage;

- reduces the rate of foundation wear;

- reduces the need to repair the base of the house;

- complements the style of the garden plot;

- retains heat and prevents sudden temperature changes;

- makes it easier to move around the house;

- creates moisture removal during rains and snow melting.

The process of making a blind area with your own hands

There are several basic requirements for the manufacture of concrete blind areas. Construction work is carried out in summer, in dry weather.

Marking for future work requires compliance with the following dimensions:

- the width of the blind area is calculated from the edge of the cornice and exceeds it by 0.3 m

- the minimum thickness of the structure is 7 cm

- The tilt angle is set within 3-5 degrees

The step-by-step instructions described below will help you avoid gross mistakes during installation and can reduce the cost of pouring the blind area.

DIY construction technology

When constructing a blind area around the house, the emphasis, first of all, should be placed on its functional component - beauty is good, but at the same time, the foundation of the house must be reliably protected from the penetration of surface water.

Monolithic blind areas made of concrete or asphalt are considered the most reliable and durable. These types of blind areas, in most cases, are built by public utilities around multi-story buildings, while in private construction, owners of private houses prefer blind areas made of paving slabs as the most aesthetically attractive and at the same time completely reliable option.

Preparing the base for concrete work

Along the perimeter of the building, soil is removed to a depth of at least 0.3 m. The main requirement is the absence of a fertile layer with the presence of roots.

At the same time, an angle of inclination is created in the direction from the base of the house. It is advisable to use clay as the first layer, followed by compaction.

Technology for creating a soft path

A flexible blind area around the house can be installed on your own in the shortest possible time. But in order for the protection to be reliable and the appearance attractive, it is necessary to strictly follow the installation technology.

Necessary tools and raw materials

To work you will need the following set of tools:

- shovel for digging a ditch and filling materials;

- pegs for setting the level and measuring the evenness of the installation;

- a cord that will be pulled from the pegs;

- gloves to protect the skin of the hands.

It is also important to ensure the availability of auxiliary protective materials:

- for waterproofing: roofing felt, water-repellent membranes;

- geotextiles to prevent drainage contamination.

It is important to choose the right clay for the base layer; the blind area should be filled exclusively with material without impurities.

Materials for creating a soft blind area

Each element of the soft blind area performs a specific function, so if one of them is of poor quality, the quality characteristics of the entire structure will deteriorate. For waterproofing, special roll materials will be required.

There is a large assortment on the modern market: traditional roofing felt, innovative PVC films and polyethylene membranes. One of the well-known manufacturers of protective membranes is the TECHNONICOL company, whose products are of high quality and reasonable cost.

Drainage is laid in a separate layer. Sand and crushed stone are used as it, but it is also possible to use gravel, pebbles or expanded clay.

An important element is geotextile, which prevents siltation and helps to properly distribute the load. The material should be selected depending on the type of soil:

- for rocky ones - thermally bonded;

- for clayey ones – needle-punched;

- woven geotextiles are rarely used due to the low quality of waterproofing.

Thermal insulation material may also be required. It will eliminate the harmful effects of low temperatures. Insulation is not mandatory, but it is advisable to carry it out if there is a basement.

Marking and ground work

Initially, preparatory work is carried out.

A trench is dug according to certain dimensions, and pegs are driven into the corners. A cord is stretched between them.

Then a trench is dug from the wall to the stretched cord, the bottom of which is lined with clay. It should be compacted, and it should be backfilled at a slope. To prevent cracks from appearing, it must be moistened with water and wait until it dries completely. Only after this can you begin further work.

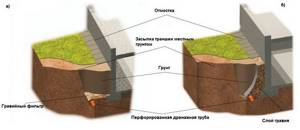

Laying the drainage system

The drainage system is arranged in such a way that the drainage is carried out into the drainage, and not into the soil, since erosion of the soil can lead to subsidence, which minimizes the useful functions of the soft blind area.

Drainage systems

To drain water, special pipes are installed, which are pre-wrapped in geotextiles.

Do-it-yourself soft blind area: laying layers

Next, the layers are laid out in the following sequence:

- a layer of waterproofing is laid on top of the clay;

- a layer of crushed stone is poured;

- then - sand, which is wetted with water;

- geotextile fabric;

- a mixture of sand and gravel with geotextiles;

- outer covering.

When constructing a soft blind area with insulation, the heat-insulating material is laid on a waterproofing membrane and covered with another layer of waterproofing material.

Options

Installation of formwork around the perimeter of the house

Along the outer edge of the prepared trench, formwork is mounted from prepared boards, which are fastened to pre-installed stakes.

The inside of the formwork is covered with a special material separating the layers, which should completely cover the entire internal volume of the formwork.

Preparatory work before pouring concrete

Coarse sand is poured onto the laid material, followed by compaction. After completion of the compaction work, the drainage system is installed, if one was planned.

If there is no insulation of the basement of the house, this work can be carried out at the stage of installing the blind area - insulation boards are laid on a compacted surface, followed by sealing the joints.

Reinforcement is mounted on the insulation layer to impart rigidity to the structure. The distance between the insulation layer and the reinforcement should not be less than 4 cm.

The beacons necessary to obtain a flat surface of the blind area are mounted from boards or laminated plywood. They will also serve as expansion joints, a properly made blind area.

Manufacturing of concrete blind area

To make such foundation insulation, no special knowledge is required. The materials can be purchased at any hardware store. The concrete blind area will be durable if you mix sand, cement and water in the correct proportions. It is also recommended to add a plasticizer to the mixture. It reduces porosity, increasing the strength of the material. You can make a beautiful blind area around the house with your own hands in a few steps:

Might be interesting House layout 6 by 6: features, projects with photos Assembling a greenhouse with your own hands How to build a fence from corrugated sheets with your own hands: step-by-step instructions with photos

- Dig a pit around the perimeter of the entire building. The thickness must be at least 1 m. Depth is acceptable from 50 cm.

- Compact the hole so that all edges are even. The outer sides can be made at a slight slope: this way the earth will not crumble inward.

- For houses located in areas with high rainfall, experienced builders recommend making an additional layer of clay formwork. It reduces the insulation capacity.

- Lay geotextiles over the entire area of the pit. Level it up. There should be no gaps between the sheets, so they are laid overlapping. You can also use bitumen mastic or tar as drainage. Less commonly, waterproofing is made from waterproofing compounds and roofing felt. Geotextiles, unlike these materials, retain the shape of the blind area longer, preventing it from deforming.

- Place crushed granite stone on top of the geotextile and level it. The material fraction should be 5*20 mm or 20*40 mm. The layer thickness should be from 5 cm to 10 cm. You can compact the crushed stone with a special slab or with your feet.

- Place geotextiles on the resulting layer.

- Add sand. If the material was not covered and got wet in the rain, you need to wait for it to dry completely. You cannot use soil from the site: the sand should not contain any admixtures of clay and stones. Lay out a new layer of at least 20 cm.

- Wet the sand and compact it. When the material is dry, repeat this step.

- In the finished layer, dig holes for plastic pipes, rainwater inlets and drainage systems. Moisture will flow through them into the drainage. Stormwater inlets need to be concreted. The pipe itself is made at an angle equal to the angle of the top layer.

- Make formwork over the entire area of the future waterproofing of the foundation. Boards should be placed along the outer edge of the entire structure and 2-3 transverse ones. They will connect the formwork to the main building. Wooden frames are used only for concrete structures.

- Next, the entire formwork needs to be reinforced. A mesh with a cross section of 6 to 10 mm is suitable for this. The material must be laid evenly.

- Fill the mesh with coarse crushed stone. The resulting layer should not exceed 10 cm.

- For additional protection of the base and to prevent its deformation, make an expansion joint. A small offset of 150 mm is sufficient. The material used is foamed polyethylene. The bundle of it should be slightly larger than the indentation. When compressed, the material will become even harder, compacting the blind area. Instead of polyethylene, you can use sealants or limit yourself to sand and crushed stone.

- Now you can pour the concrete.

To make a beautiful blind area around the house with your own hands, you need to use high-quality materials. In order for such foundation insulation to serve for a long time, only cement of a higher grade than M200 can be added to the mixture. You cannot do without a plasticizer: when the concrete hardens, bubbles appear, which later form pores. This increases the ability of the coating to pass water and the duration of its operation. The amount of plasticizer required per 1 kg of cement differs for all brands, so the method of use must be looked at on the packaging. Basic materials are mixed in proportions:

- 1 part cement;

- 2.8 volumes of sand;

- 4.8 parts crushed stone.

Attention!

To prevent concrete from cracking, it must be of a uniform consistency when pouring. It is almost impossible to achieve this by hand kneading: there will be small lumps in the material that you will not be able to see.

You cannot mix all the concrete at once. You also need to follow standard rules to ensure the material is durable. First, put only cement in the concrete mixer and fill it with water. Mix it for about 20 minutes, then add sand. You need to add it in small portions, waiting about 2-3 minutes between each addition. Do the same procedure with crushed stone. Leave the fully loaded concrete mixer running for 10 minutes, then you can pour part of the blind area.

Each portion of material must be additionally compacted so that there are no empty spaces left between the previously loaded crushed stone and the reinforcement. You can use a spatula for this. To speed up the process you will need an electric vibrator. When the concrete is completely compacted, it needs to be leveled. To do this, take a long straight board that would cover the entire width of the blind area. To ensure that the entire coating is without humps, you can attach a level to a homemade leveler. Use this tool slowly to give the concrete the desired shape.

Drying time depends on the thickness of the layer and the outside temperature. On average, you will have to wait at least 5 days before stepping on the blind area for the first time. Such conditions are relevant if the outside temperature is not lower than 24°, and the thickness of the concrete does not exceed 10 cm. Since the cement should not be exposed to moisture, it must be covered with polyethylene or other material that does not allow water to pass through while it is drying. Dig pegs along the edges of the blind area. The film must be attached to them and to the base using construction tape.

The finished blind area can be decorated with a thin border. This will allow the structure to retain its shape longer. Some summer residents decorate concrete with tiles. You can use ceramic or cement products. The first type is less relevant if you plan to walk on the blind area. Ceramics slip a lot after rain and snow. If In this case, you can cover the insulation with a layer of lawn.

Pouring concrete formwork around the perimeter of the house

To prepare a concrete solution, cement grades M200, M300 are used. It is not recommended to use less quality cement. To increase the strength properties of concrete, it is advisable to use plasticizers.

After pouring the concrete solution, backfilling and even distribution of cement onto the finished surface is carried out; this serves as a good way to relieve stress when the concrete dries.

To obtain a high-quality surface, the upper plane of the blind area is moistened with water daily for two weeks.

The formwork is dismantled a month after the pouring of the blind area is completed.

Finishing the finished blind area around the house

The finished concrete blind area has a rather modest appearance. You can make it quite attractive by laying paving stones or paving slabs on its surface.

On the Internet you can find quite a lot of photos of blind areas around the house, and choose the most suitable finishing option.

Where to start building a blind area around the house?

The most common option from which the blind area is made is concrete. This choice is more practical in terms of its service life and budgetary in price. The first thing you should tackle is marking the blind area. It is performed around the entire perimeter of the house.

To do this, pegs are driven into all corners according to the width of the girdle, onto which the rope is pulled, forming a kind of twine. The next step is the depth of the blind area around the house.

It is customary to dig the soil 250 mm deep along the entire perimeter around the house from the base to the string. The resulting bottom of the pit, if there are tree roots in it, is treated with a herbicide, which will avoid the destruction of the future blind area.

Then, formwork for the blind area is created in the resulting trench. The inner edges of the ditch are fixed using wooden formwork (it is removable). The bottom of this structure is lined with a base of 100 mm thick sand and then filled with water to allow shrinkage.

This manipulation allows the sand to be compacted in order to be densely filled with the foundation in subsequent stages. After compaction, it is backfilled with crushed stone, the thickness of which should be 50 - 80 mm.

This layer is covered on top with reinforcing mesh. This is done in such a way that the sections overlap each other with a margin of 150 mm.