Mills

In the production of cement, lime, gypsum, ceramic products, etc.

materials are crushed to particles less than tenths of a millimeter in size. Size of the source material entering the mills: 25 mm for limestone and marls; 15 mm for cement clinker; 30 mm for soft limestone, gypsum and coal; 10 mm for solid active additives and inert additives when grinding clinker. The finished grinding product is characterized by grinding fineness, or specific surface area, which is:

- for raw materials 2800…3000 cm2/g;

- for cement clinker 2800...4500 cm2/g and more.

The grinding process is characterized by high energy intensity and cost.

Rice. 1. Schemes of mills : a - rotating drum with grinding media; b - drum vibration; c - rotating drum with self-comminutement of particles and grinding against the drum lining; g - roller-pendulum; d - hammer; e - jet

Based on their design, mills are divided into mechanical (drum, ball, ring, roller, mid-speed, impact and vibration) and aerodynamic (air, steam jet, etc.).

Mechanical mills are the most widespread.

In Fig. 1 shows diagrams of drum mills.

Types of mills

Spice grinders are divided into three groups: disposable, manual and electric.

Disposable mills

These are transparent glass or plastic flasks already filled with one seasoning or a ready-made spice mixture. To add salt or pepper to the finished dish, simply twist the lid over the plate.

Pros. There is no need to mix spices - the manufacturer took care of this. Other advantages are compactness and low price. Advanced models even allow you to adjust the degree of grinding.

Minuses. Lack of choice - you may not find the combination of spices you need on the store shelf. In addition, a certain set, as a rule, is suitable only for one type of dish, so instead of one mill you will have to purchase several. And most importantly: a disposable device will not last long, and buying a new one is an additional expense.

Manual (mechanical) mills

They consist of a flask, millstones and a container for prepared spices. To grind the seasoning, you need to twist the handle or lid.

Pros. Mechanical devices also do not last forever, but they will last much longer than disposable ones. By grinding spices by hand, you can precisely measure portions of the product and mix spices the way a recipe or inspiration suggests. Hand mills are made from a variety of materials: wood, ceramics, acrylic, stainless steel, cast iron. The design is also varied, so among the mechanical devices you can find one that will perfectly match the style of your kitchen.

Minuses. This kitchen utensil is not entirely universal - salt crystals are difficult to grind by hand.

Electric mills

Automatic mills operate on batteries or batteries through a motor that drives the grinding wheels inside the structure. To grind spices, just one press of a button or sensor is enough.

Pros. Simplicity and versatility, different grinding modes: such devices save time and effort and easily cope with any content - even hard sea salt. Another advantage is high productivity: with an electric grinder you can grind much more seasonings than by hand.

Minuses. High price.

Designs of drum (pipe) mills

In drum mills, the material is crushed inside a hollow rotating drum, during the rotation of which the grinding bodies (balls, rods) and the ground material (called the charge) first move along a circular path along with the drum (Fig. 2), and then fall along a parabola.

Rice. 2. Scheme of the movement of balls in a drum mill

The part of the load located closer to the axis of rotation rolls down along the underlying layers. The material is crushed as a result of abrasion during the relative movement of grinding bodies and material particles, as well as due to impact.

Drum (pipe) mills are classified:

- according to the operating mode - periodic (Fig. 3, a) and continuous (Fig. 3, b-e) action;

- by grinding method - dry and wet;

- by the nature of the work - open and closed cycle;

- according to the shape of the grinding media - ball, rod and self-grinding (without grinding media);

- by unloading method - mechanical, hydraulic and pneumatic;

- according to the design of the loading and unloading device - with loading and unloading through the hatch (Fig. 3, a), with loading and unloading through hollow pins (Fig. 3, b, d, e, f), with peripheral unloading (Fig. 3, V);

- according to the drive design - with a central (Fig. 3, g) and peripheral (Fig. 3, f) drive.

Depending on the diameter D and length L of the mills, which are included in the designation, a distinction is made between tube mills (L/D > 3) and drum mills (L/D < 3).

Rice. 3. Basic schemes of drum mills : a - periodic action; b - continuous action with a cylindrical drum; c - with peripheral unloading; g - with unloading through the end grille; d - with a conical drum; e, g - with peripheral and central drive

Drum mills are relatively simple in design and easy to operate. However, they have significant disadvantages: low speeds of impact of grinding media on the material, only a part of the grinding media is involved in the work, the working volume of the drum is used by 35...45%, energy consumption is 35...40 kW h/t.

In the building materials industry, continuous mills, dry and wet grinding, operating in an open or closed cycle are predominantly used. From wet mills, the material comes out somewhat under-ground and is separated in separators or hydroclassifiers into the finished product and a coarse fraction, which is re-ground in the mill. With this operating scheme, grinding efficiency and productivity increase due to the continuous removal of fine material from the mill.

Batch mills are used for fine grinding of clays and glazes in the production of fine ceramics. Mills with a relatively short drum are called ball mills, and mills with a length exceeding 4...5 times the diameter are called tube mills.

Technical characteristics of drum mills are given in table. 1.

Table 1

Technical characteristics of drum mills

| Index | Mill | ||

| ball | pipe | autogenous grinding | |

| Drum diameter, m | 0,9…1,5 | 2…4,2 | 5…9 |

| Drum length, m | 1,8…3,0 | 10,5…13,5 | 2,2…3,0 |

| Productivity, t/h | 5,4…18 | 18…130 | 240…400 |

| Drum rotation speed, rpm | 25…39 | 16,2…18,7 | 12…15,5 |

| Main engine power, kW | 22…100 | 1000…3200 | 630…3930 |

| Weight (without electrical equipment and grinding media), t | 5…21 | 254…486 | 194…500 |

| Mass of grinding media, t | 2,3…10,5 | 80…226 | — |

Ball mills 0.9×1.8 and 1.5×1.6 m (diameter and length of the drum), designed for grinding materials of medium hardness, are available in two versions: for dry and wet grinding methods. They differ from each other in the design of loading and unloading devices.

The 1.5x5.6 m mill is designed for dry grinding of ores and building materials. Tube mills 2×10.5 and 2.6×13 m are used for open-circuit grinding of clinker and raw materials that require fine grinding in both dry and wet grinding. The 3.2×8.5 mill is used for grinding soft raw materials using a wet method in an open and closed cycle and for grinding raw materials with drying in a closed cycle. The 3.2×15 m tube mill is available for wet grinding of raw materials and for grinding clinker in an open or closed circuit. The 4x13.5 m mill is designed for wet grinding of clinker with additives and raw materials. A 4.2×10 m mill is used for grinding raw materials with simultaneous drying when working in a closed cycle.

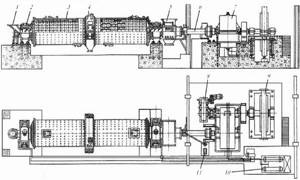

The structure and design of the main components of drum mills of different parameters are largely similar. In Fig. Figure 4 shows a typical two-chamber pipe mill 3.2×15 m. The drum 3, installed in bearings 2, is driven by a motor 9 through a gearbox 7 and an intermediate shaft 6. The material is fed into the drum through the loading device 1, and the finished product

Rice. 4 . Diagram of a two-chamber pipe mill 3.2×15 m

is removed using an unloading device 5. In the middle part of the drum there is an unloading-loading interchamber section 4. The mill is equipped with a centralized lubrication system 10 for servicing the gearbox and drum bearings. For repair work, the mill has an auxiliary drive 8. To lower the temperature and remove static electricity that occurs in the second chamber during abrasion of clinker with additives, water is introduced into the mill from installation 11, consisting of a pump, distribution system, pipelines and nozzles.

Burr mills: features and advantages

In the article we will talk about the main types of mills, we will understand how commercial and household millstones differ, and how the grinding fraction is regulated. And let's talk a little about the most important thing for which these mills were invented - millstone flour and its benefits.

There are many questions that arise in the process of choosing a grain mill. Which mill is better - burr mill, impact cam mill or roller mill? How important is grinding speed? What does the type of grain grinding mechanism mean? There are quite a lot of options on the market now. We hope that our article will outline an understanding of how grain is ground, what a particular grinding mechanism can do, and will also help you narrow your search to the options that best suit your requirements.

Main types of mills

The only function of a grain mill is the ability to produce flour of the desired grinding fraction from whole grains. The heart of this device is the grinding mechanism. There are 3 main types of mechanisms: millstone, roller and hammer.

The hammer mechanism is the most common in large flour production plants. A commercial model of such a mill can process up to 5-6 tons of grain per hour. The main working element is an electric motor connected to the rotor. The jackhammers are mounted on a shaft driven by a motor. After turning on the device and feeding the raw material, the rotor rotates at a very high speed and creates an air flow that draws in and forces the grain and cereal to rotate. Moving freely through the mass of grain, the hammers strike the grain with their working edges and crush it. The grinding fraction in such a mill is the smallest, but grain processed in this way loses a significant amount of nutrients.

Preparation of flour in mills with a hammer mechanism

The roller mechanism consists of two horizontally located cylindrical metal shafts with a grooved or rough surface, which rotate towards each other at different speeds. The grain falling between the rollers is flattened and ground. This method is more gentle, but still not as good as a millstone.

Roller mill for grain

The millstone method of grinding flour, which humanity has used since ancient times, allows the structure and all components of the grain to be preserved. The resulting flour contains bran and germ, in which all vitamins and minerals are “stored”, and is considered the most useful for making bread.

Millstones have been used for grinding grain since ancient times.

Commercial and domestic burr mills - what's the difference?

Flour is prepared using stone millstones using the same method that was used many centuries ago. Early models were made of two smooth stone surfaces rubbed against each other to crush and grind grains and seeds into flour or grits.

Modern burr mills operate on a similar principle and are used both in domestic and commercial settings (depending on the required volume of preparation).

Sana household burr mill

In household mills, millstones with a diameter of 85 mm and a power of 360-600 W are mainly used. Using such a mill you can prepare about 5-6 kg of flour per hour, which is enough to prepare homemade baked goods in a bread machine.

Commercial versions use large burrs and a powerful motor. For example, the Haussler HM30P mill uses millstones with a diameter of 30 cm and a powerful 1.1 kW motor. This allows you to cook up to 40 kg of medium-ground whole grain flour per hour.

It is possible to adjust the size of the gap for feeding grain, which changes the speed of feeding grain to the millstones. A special magnet is placed on the grain feeding funnel, which prevents metal objects (screws, nuts, nails) from falling onto the millstones.

Commercial burr mill

Grinding fraction of burr mills

In both domestic and commercial mills, it is possible to adjust the grinding fraction. The gap between the millstones can be adjusted so that the output is flour with a fraction from 0.6 mm to 3 mm. Using the rotating neck mechanism, you can increase or decrease the gap between the stones, thereby selecting the desired grinding fraction and even preparing cereal. The peculiarity of burr mills is that it is not possible to obtain 100% flour of the required fraction, for example 0.6 mm. Therefore, for example, the commercial mill Haussler HM30P in one of the options is supplied together with an automatic flour sifter.

Millstones mill Haussler HM30P with automatic sifter

Inside the device there are several sieves of different fractions (0.6 mm, 0.8 mm, 1.3 mm) and several containers for flour and bran. If you take 100 kg of wheat for grinding, you will be able to get 20 kg of flour with a grinding size of 0.6 mm, 25 kg - 0.8 mm, 35 kg - 1.3 mm and about 20 kg of bran. If you grind the bran again, you will get about 20% more flour of the corresponding fraction.

Similar sifting can be done in a household mill if you purchase a hand sieve or a special sifter.

Flour sifter for Sana household mill

Features of millstone flour

The main difference between millstone flour and regular flour is that the normal process of preparing flour removes all the germ, bran and other useful particles, while flour prepared with a stone mill contains all the elements of the grain. Baked baked goods containing wheat germ and bran are healthier, tastier and more filling due to the heavier nature of millstone flour. You can read more about the features of millstone flour in the article “Millstone flour retains all the benefits of grain.”

Millstone flour is considered the healthiest for baking

There are many other advantages of grinding grain using the millstone method:

- raw materials for flour (grain) are always cheaper than finished flour;

- whole grains are stored many times longer than flour;

- homemade millstone flour is fresher, healthier and more nutritious because it contains all parts of the grain - germ, bran and endosperm;

- freshly prepared flour has a sweeter and “lively” aroma that store-bought flour cannot compare with;

- Home milling gives you complete control over what goes into your flour, without any unwanted additives;

- Like growing your own vegetables, making your own millstone flour is a fun and enjoyable experience.

The Sana by KoMo mill is presented by Sana®, which is the official representative and specializes in the field of home mills and healthy eating equipment since 2009.

Visit the website to learn more about the technical features of this model, which may be useful when purchasing mills. The Haussler HM30P Combi mill is presented by Sana® and is intended for daily commercial use. Made from natural materials in Germany. It is reliable in operation. Visit the site to learn more about the technical features of the model that may be useful when purchasing mills.

Schemes of grinding plants

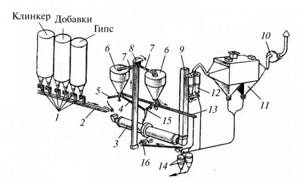

In Fig. Figure 6 shows a diagram of a dry grinding installation operating in a closed cycle with a separator. The material from bins 1 is fed through dispensers by conveyor 2 into mill 3. The material crushed in the first chamber is fed through the unloading device via air chutes 16 into the elevator 8, from which it flows through chutes 7 into separators 6. Large particles from the separators are fed through air chutes 4, 5 and 15 for regrinding in the mill. Small fractions from the separators through the air chute 13 enter the pneumatic supercharger 14, which transports them to the warehouse. The smoke exhauster 10 removes air through the mill, the aspiration shaft 9, the cyclones 12 and the electric precipitator 11. From the cyclones and filters, the product is sent to the pneumatic blower 14. When the mill operates in an open cycle, the product, having passed the first and second chambers, goes directly to the pneumatic pump 14 and beyond to the warehouse.

Rice. 6. Installation diagram for dry grinding

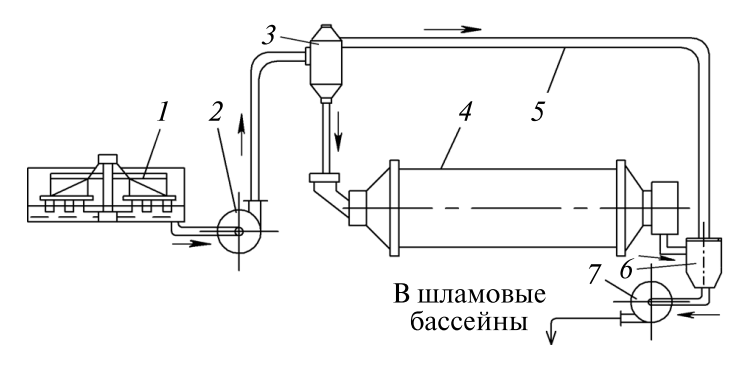

In Fig. Figure 7 shows a wet grinding installation. The sludge, pre-prepared by the mud grinder 1, is fed by pump 2 into the hydrocyclone 3, in which a fine fraction that does not require grinding is separated and sent through pipeline 5 to receiver 6. The large fraction from the hydrocyclone enters mill 4 and, after grinding by pump 7, is sent to sludge pools.

Rice. 7. Installation diagram for wet grinding

Basics of automation of grinding processes

Automation systems must provide remote control of plant units, monitor the technical parameters of the grinding process and regulate the operating modes of the devices to achieve maximum productivity with high product quality. The intensity of the grinding process and the quality of the product in drum mills depend on the level of its loading and the properties of the ground material.

The operating mode of the mill can be judged by the level and frequency of noise that occurs during its operation, since there is a certain relationship between the level of material loading and the noise level. This ratio is chosen such that a stable grinding fineness at the exit from the mill is ensured.

For the successful operation of automatic control systems, strict compliance with the following conditions is necessary:

- loading the mill with grinding media must ensure the specified grinding fineness on the most difficult to grind materials, and it is necessary to replace the grinding media or replenish them in strict accordance with the requirements of technical operation;

- the sizes of pieces of raw material supplied to the mill should not exceed those specified for a given mill and technological process;

- power supply to the mills must be continuous and uniform, and the feeders must have one and a half to two times a reserve capacity in relation to the nominal productivity of the mill;

- The humidity and temperature of the raw material components must be within specified limits, since their deviation from the norm leads to sound distortion and disruption of the accuracy of recording this signal by microphone sensors.

Type of design

There is a division by type of ball mills depending on the installed drum - tube, cylindrical-conical and cylindrical installations.

In practice, small sizes are predominantly used for grinding ore raw materials. The essence of the cylindrical-conical system is the presence of two cones and a small cylindrical part - this is the body of the unit. The force exerted is proportional to the useful resistance. The peripheral speed decreases in the direction from the cylindrical section towards the unloading section.

For pipe ball mills, the operating principle is based on the use of a central shaft, which is attached to a coupling. The main feature is that axial displacement is not transmitted to the engine or gearbox. The crushed rock is unloaded through the wall or end of the ram.

The performance of ball mills and the quality of the final material are greatly influenced by the size of the installation, its length and diameter. Another important factor is the number of cameras. For example, tube and long drum mills have two chambers, while short and long drum mills have only one. Single chamber equipment is most often used in processing plants. Characteristics should be selected based on the company's industry, the type of ore being processed and the desired end result.

Mills with increased speed of movement of working bodies

With increasing grinding fineness, the energy intensity of the grinding process increases sharply. As the particle size decreases, their relative strength increases, since the number of areas with a pre-fractured structure decreases. Microcracks that appear during the first loading cycles can close under the influence of molecular forces. This effect can be neutralized by the use of surfactants (films of liquid) that adsorb on the particles and penetrate into the cracks. These films shield molecular forces that tend to close cracks. The effect of “self-healing” of particles can be reduced by increasing the speed of application of loads and the frequency of exposure to force pulses, as a result of which the intensity of destruction due to fatigue phenomena increases.

The considered process of destruction of materials served as a theoretical basis for improving grinding equipment and, in particular, for creating machines operating at increased speeds of movement of grinding media. Such machines include medium-speed ball, roller and roller-pendulum mills.

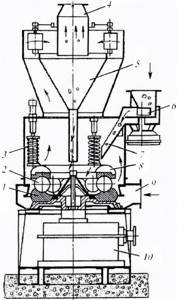

Ball Ring Mills

In ball ring mills (Fig. 8), used for grinding, for example, lime, gypsum, dry clay, the material is crushed as a result of crushing and abrasion with the relative movement of balls 2 and rings 1 and 8. The material is fed by feeder 6 through chute 7 to the lower ring 1, driven into rotation through gearbox 10, and under the action of centrifugal forces enters a chute with balls with a diameter of 195...275 mm placed inside it. The balls are pressed against the lower ring by springs 3 through the upper ring 8.

The crushed material is poured through the outer edge of the lower ring and carried away by an air flow supplied through pipe 9 at a speed of 20...30 m/s into separator 5, where it is separated by size. The finished material is carried out through pipe 4, and the material that requires further grinding enters the mill again.

The diameter of the balls should be 10...12 times the size of the largest piece of the starting material.

Rice. 8. Scheme of a ball ring mill

The productivity of the mill depends on the grinding fineness and the properties of the material being ground. It is determined empirically.

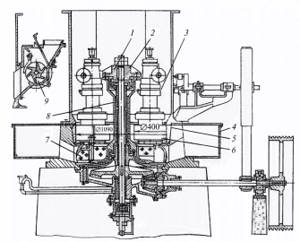

Roller mills

In roller mills (Fig. 9), the material is crushed between plate 2, driven by an electric motor through gearbox 1, and rollers 4. The rollers are mounted on axles mounted on levers 5, which are tightened by springs 6, due to which the rollers are pressed against the plate.

This type of mill usually has two rollers. When the plate rotates, due to frictional forces, the rollers also begin to rotate and, rolling over the plate, crush the material by crushing and abrasion. The crushed material is carried away by the air stream

spirit supplied through channel 3 into the separator. Roller mills are manufactured with a plate diameter of 0.6...1.7 m. The rotation speed of the plate is no more than 3 m/s.

Rice. 9. Roller mill diagram

The angular velocity of the plate, rad/s, is calculated from the condition under which particles should not be ejected from the plate by centrifugal force.

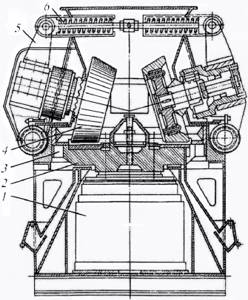

Roller pendulum mills

They are used for grinding soft, weak and medium-strength rocks (clay, gypsum, chalk, graphite). In them (Fig. 10), the material is crushed between a fixed ring 5 and rollers 6, which roll along the ring when the crosspiece 1 rotates, mounted on a vertical shaft 2. The rollers are mounted on pendulums 3, hinged to the crosspiece. When the cross rotates, the rollers are pressed against the stationary ring under the action of centrifugal forces. The material is fed into the mill by feeder 9 and, using plow blades 7 attached to a quill 8 rotating with the shaft, is lifted and directed to ring 5 in front of the roller. The crushed material is carried into the separator by a gas flow supplied through manifold 4. Roller pendulum mills are produced with a grinding ring diameter of 600...1800 mm and a roller diameter of 300...700 mm.

The angular velocity of the cross must be such that when the rollers rotate, inertial forces are created that provide a force for pressing the roller to the ring (1...2)·105 N per 1 m of roller width.

The motor power of roller mills is calculated as the power of roller mill motors. The sliding speed can be taken equal to 0.1 of the roller peripheral speed.

Rice. 10. Roller pendulum mill

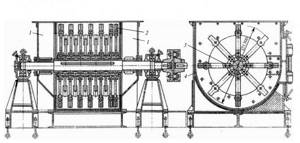

Impact Mills

In impact mills, the material is crushed under the influence of rotating beaters at a speed of 30...80 m/s, repeated collisions of particles with reflective elements and with each other. Such mills are used for coarse grinding of soft rocks (gypsum, asbestos, coal, clay, etc.). Here, grinding wet materials can be combined with their simultaneous drying. The maximum initial temperature of the drying agent can reach 350°, and the temperature of the air mixture can be 50...70 °C.

In the building materials industry, mills with beaters rigidly attached to the rotor and hinged hammer-beaters are used.

The main parameter of impact mills is the diameter of the circle described by the beaters.

Rice. 11. Mill with hinged hammers

Impact mills are slightly modified impact crushers. In Fig. 11 shows a mill with hinged hammers 2 suspended on the rods of a rotating rotor 3. The material is crushed by hammer blows, repeated impacts of particles on armor plates 4 and abrasion between hammers and grates in the lower zone of the chamber. When the rotor rotates, a vacuum is created in the chamber, which ensures air suction through channels 1.

Mills for extra fine grinding

The fineness of grinding materials is of great importance for the intensification of various technological processes. For example, increasing the fineness of cement grinding by 60...70% allows you to almost double the grade and reduce the hardening time, which provides significant savings in the manufacture of cement-based products. For ultrafine grinding, it is more rational to use machines in which grinding media act on the material with high frequency, for example, vibrating mills. High frequencies of particle collisions at high absolute velocities are achieved when they move in turbulent gas flows, for example, in jet mills. Jet mills have no moving parts, which allows them to use wear-resistant but fragile materials (ceramics, stone casting, etc.). Their use is especially effective when contamination of the material with metal wear particles from grinding media is unacceptable.

Vibratory Mills

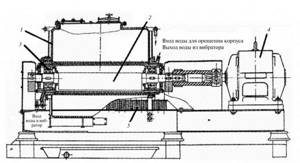

Vibratory mills are either inertial or gyratory. The inertial mill (Fig. 12) consists of a housing 1, in which an unbalance shaft 2 is installed on bearings 3, driven by a motor 4.

Rice. 12. Inertial vibration mill

The mill body rests on springs 5. When the shaft rotates, the mill body with loaded grinding media and material vibrates at high frequency. As a result, the grinding media intensively acts on the material and crushes it. During mill operation, the load slowly rotates in the direction opposite to the direction of rotation of the unbalance shaft.

The drum of the gyratory mill is driven into a circular oscillatory motion by the eccentric shaft on which it is installed. The eccentric shaft of the mill receives rotation from the engine through a coupling and an intermediate shaft.

When a vibrating mill operates, a lot of heat is generated, as a result of which the housing and material can heat up to 300 °C. As the grinding fineness increases, the heating of the mill increases significantly, and productivity decreases sharply.

The power, kW, of the vibrator drive motor is spent on transmitting vibrations to the system and overcoming the friction forces Ntr in the bearings.