Accommodation

What are the criteria for choosing a location for a future well?

- Distance from home. A reasonable minimum is about five meters: in this case, you do not risk the foundation subsidence while digging. The large distance is limited only by the size of the plot.

But: if the well is intended to be used not only for irrigation, but also as a source of constant water supply, it will be necessary to lay an inlet from it - a plastic or metal pipe. It is buried below the freezing level of the soil. It is clear that a greater distance from the house indicates a greater amount of excavation work.

- Removal from sources of groundwater pollution - landfills, leaking cesspools, filter wells of local sewage systems and without that . In accordance with the current rules and sanitary standards (SanPiN), the minimum distance from them to a weakly protected water intake (and the well falls into this category) is 50 meters.

- In areas with difficult terrain, a well is dug in one of the lowlands . The instructions are due to the fact that there the distance to the aquifer is minimal.

Depth

In most cases, the depth of a well that is dug with your own hands, without the use of equipment, rarely exceeds 8 - 10 meters. How exactly do you find out the distance to the aquifer?

A simple method is to ask your neighbors. It’s as if some of them already use a well or water well. Obviously, the depth of the aquifer can vary, but in adjacent areas the difference in most cases is no more than a couple of meters.

There are also indirect indicators of the proximity of water: abundant greenery, a cluster of birch, spruce and aspen trees, and sedge thickets.

Finally, a simple way to check how water flows over a long distance is to cover a small area of soil with polyethylene overnight. Abundant dew on its lower surface indicates the proximity of the aquifer; if it is at a great distance, the film will remain dry.

Safety at work

It is recommended to build a concrete or wooden well with your own hands, taking into account safety standards:

- Digging a hole in the ground is carried out in special protective clothing for construction work, a standard set of mittens, a helmet, a protective bandage, shoes made of thick rubber, etc.

- For work we use tools of proven brands without cracks or malfunctions.

- When using a winch or tripod, the reliability of the devices is checked.

- When installing water supply to wells, it is recommended to be careful not to increase the pace of work to prevent violations.

- Carabiners are used to secure the bucket to the rope; it is not recommended to tie the rope into knots.

- Children are not allowed at the work site.

- During digging, it is necessary to take into account the possibility of removing dangerous gases from the soil. If dizziness occurs, it is recommended to pause work and get up.

- For a large volume of excavation work, it is recommended to dig the pit in shifts.

- The soil that is lifted is laid out no closer than 3 m from the depression under the water source.

excavation and material selection

What and how to make a well at the dacha? More correctly, its walls?

Brickwork

If the depth is small, the well is often made of simple brick.

What does construction look like?

- The well shaft is dug approximately half a meter wider than its expected dimensions.

- In the middle of the shaft, a pit is opened into which a drainage pump is placed. It will ensure the bottom is drained during construction.

- The bottom is covered with crushed stone. It will perform the function of drainage, and at the same time it will serve as a backfill under the cement pad for the wall.

- After this, the cement pad itself is poured: M200 concrete is laid out on compacted crushed stone around the perimeter of the shaft.

- The walls are made of red solid bricks with horizon control using a level. The thickness of the masonry is half a brick or brick. A simple cement-sand mortar is used in a ratio of 1:3.

Please note: the advice to use red brick was not given for the sake of words. Silicate, in contrast, quickly collapses when interacting with water.

- The gap between the soil and the walls of the well is filled with excavated soil or, better yet, compacted clay. Water must enter the well only from below, after filtration through the ground has finished.

The brickwork, however, is evidenced by a succession of technical difficulties during the construction phase.

- With a huge flow rate (water flow), the drainage pump may not be able to pump it out.

- Earthen walls dug to their full depth will inevitably crumble and erode in the aquifer.

- Finally, construction will take a long time.

The second option does not have these shortcomings.

Rings

Ready-made concrete rings allow you to speed up the construction of a well. But - here's the problem! - they are very heavy and in most cases are mounted into the mine using a crane. But the need for invention is clever: the author had to install the rings manually, without the involvement of technology.

How is this work done?

- A small dig is made under the ring lying on the ground.

- A small log, a brick, or any durable object is placed next to it as a stop for the lever.

- The ring is lifted by a lever of sufficient length - a log, beam or pipe. A pair of rounded logs are rolled under the slightly raised edge, which will serve as rollers when moving the concrete product.

- The operation is repeated otherwise the rings. The total number of rollers that should be under the ring must be at least four.

- The ring is transported to its permanent location. Rollers are placed under it as it moves. In order to place the ring on the ground, we use the already familiar maneuver with a stop and a lever for it.

- The pit breaks off into rings and under its walls. As the soil deepens, it slowly settles.

- At the time when its upper edge is equal to the ground level, the next ring is transported and installed on top using the method outlined above - and without that to victory.

Tip: the water surface should be at least one and a half meters above the bottom. This way we will protect ourselves from seasonal drops in water levels. In addition, a pump suspended at a certain distance from the bottom will suck in less other suspended matter and sludge.

Digging technique

Several digging methods can be used to build a well:

- closed;

- mine;

- tubular;

- open.

Open

The space for the construction of a well from concrete rings can be prepared in the ground using an open method. It is necessary to take measurements and remove the soil to the required depth with a shovel. The diameter of the recess in the ground should be 20 mm larger than the diameter of the reinforced concrete ring for the shaft frame. After placing and strengthening the concrete elements, the joints are sealed with a fastening compound. The recess between the walls of the mine and the mass of land must be filled with soil.

Closed

A well for a summer cottage can be made using a closed method. First, a depression of up to 2 m is prepared in the soil. A reinforced concrete ring is placed in the hole. The structure will gradually sink down. The following rings are gradually attached from above, the last block should rise above the soil. The joints must be sealed using special building materials.

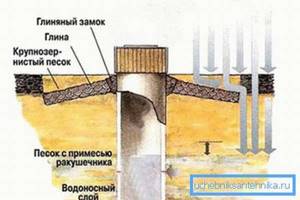

Shakhtny

The shaft well consists of the following elements:

- gates;

- pile;

- drainage ditch;

- log house;

- gravel layer;

- clay castle;

- board covering of the head.

The mine needs to be strengthened to prevent the soil from collapsing. The shaft of the shaft is secured with wooden planks or reinforced concrete round rings to protect it from sewage and other contaminants.

Tubular

Tubular technology is used for shallow groundwater flow. To implement the technology, you need to order or purchase specialized equipment. The work is carried out by specialists.

Alternate installation of rings

Installation of a well made of reinforced concrete rings is carried out using successive steps:

- a concrete ring is placed on the planned site;

- the soil is gradually removed from under the ring;

- the symmetry of the location of the element is checked to prevent distortions of the structural components;

- after the ring is immersed in the ground, the next one is mounted on top and digging of the pit continues;

- As the structure is successively deepened, the soil is removed using a bucket along a rope;

- Rubber seals are fixed at the joints.

Installation of rings after reaching the aquifer

Installation of rings is possible using another technology:

- First, a shaft is dug, it is necessary to control the integrity of the walls and prevent the soil from falling off;

- after finding the aquifer, it is necessary to place rings using a crane step by step and strengthen the walls of the structure;

- to deepen the level, you can remove more earth from the bottom of the shaft;

- during work it is necessary to control the verticality of the elements;

- earth is added between the rings and the ground.

Advantages of the technology:

- the diameter of the shaft is increased, the digging process is simplified;

- you can create greater depth of the structure;

- It is possible to manufacture external waterproofing.

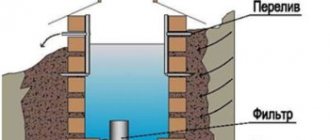

Bottom filter

How to make a well in a country house if the requirements for water purity are high?

It is equipped with a so-called bottom filter, which will limit the entry of suspended matter into the water.

- The bottom is leveled and cleared of dirt. Obviously, this requires digging a surface pit and pumping out all the water.

- After this, the well is filled with coarse sand to a depth of 20-30 centimeters. In fact, its layer will provide effective filtration.

- The next layer is small crushed stone (approximately 20 centimeters).

- Finally, the surface of the bottom filter is formed from small boulders. They will not only prevent you from accidentally scooping up the filter sand, but will also reduce siltation of the bottom: the silt will settle on the stones.

When putting the filter into operation, the well is completely pumped out two or three times. In this way, we will wash not only the filter sand, but also the aquifer: the enormous speed of water movement in it will remove part of the accumulated suspended matter.

Open digging method

In this case, we dig wells to the full depth, right down to penetration into the aquifer, and only after that we begin the installation of casing rings. This technological method is characterized by the danger of collapsing the walls of the mine with all the ensuing consequences for humans. Therefore, open technology should be used exclusively on dense soils - clayey or compressed gravel-sand.

After installing the casing elements, the seams should be sealed to prevent the entry of contaminated water from the upper layers of the soil - “upper water”.

The advantage of the open digging method is that there is no need to constantly keep lifting and mounting equipment at the work site to install the rings. The crane is ordered only at the final stage of work, for the simultaneous installation of all concrete rings into the shaft.

Trim and Pump

By what indicators should you choose a pump for a well? Will I need to purchase any additional equipment?

It all depends on your goals.

Watering

If the only purpose of constructing a well is to water the beds, it is completely possible to get by with a submersible drainage pump. The price of devices with a capacity of approximately 120 liters per 60 seconds is 2.5 - 3 thousand rubles. The pump is capable of lifting water with a large number of suspensions and generates an output pressure of 10-20 meters, which is quite enough for a small area.

Please note: the presence of a float switch is a definite plus. Shutting off when the water level is low will protect the pump from overheating: the electric motor is cooled by the pumped liquid.

In this case, the only additional equipment required is a reinforced clamp and a watering hose, with which this hose will be pressed onto the pump nozzle.

Constant water supply

But with a constant water supply, the requirements for the pump and its piping are completely different.

- The pump must be designed to operate for a long time without repair and, if possible, without maintenance.

- The water supply system requires enormous excess pressure. It is needed for valves and normal operation of toilet tank faucets: rare fittings are capable of operating at a pressure of one to two meters.

- The pump piping must provide it with the ability to periodically stop without loss of pressure in the water supply.

How are our tasks solved?

The optimal choice of pump depends on the amount of impurities in the water. If there are few of them (no more than 30 grams per cubic meter), it is possible to give preference to relatively inexpensive vortex devices. Their characteristic feature is the minimal gap between the housing and the impeller, due to which, with compact dimensions, decent performance and pressure are fully ensured.

For water with a huge amount of suspended matter, centrifugal pumps are much better suited. The increased gap is compensated by the presence of several stages, each of which consists of a diffuser and an impeller. The more steps, the higher the pressure at the outlet pipe.

Useful: if the well depth is no more than 7 meters, you should pay attention to surface pumps. If the distance from the surface to the water surface is greater, alas, such a product simply will not raise the water column.

What productivity and pressure should you focus on?

The pressure must be approximately 30 meters greater than the depth of the well. Quite often, another 10 percent is added to the result taken for unaccounted losses.

When assessing the required performance, it is worth starting from 50 liters per 60 seconds for a family of three. As the number of consumers increases, the need for water also increases proportionally.

What's with the harness?

It must include:

- Check valve. It is installed at the end of the pump outlet and prevents water from draining back when the engine stops.

- A crude filter and several shut-off valves. Sand in a water supply system from a well is a guarantee of a small and unhappy fate for any faucet with a ceramic cartridge or faucet axle.

- Hydraulic accumulator or storage tank. The first device is mounted at any point in the water supply system and maintains a constant pressure in it, when it drops, the sensor gives the command to turn on the power to the pump to a special relay. The tank is equipped with a float level sensor; the pressure in the water supply system is ensured by placing the tank at the top point of the building.

Debris protection and decoration

How to improve a well in a country house and protect it from debris?

A simple protection that is easy to make with your own hands - a simple cover. It is a shield made of boards, impregnated with an antiseptic to protect against decay. If you have the opportunity to choose the type of wood for the lid, it is better to choose larch, which is very rot-resistant.

An advanced option that will require a huge investment of time and material is an unusual house that can protect the well not only from trash and dust, but also from freezing in the winter. In most cases, boards and timber are used as materials for it; for waterproofing the surface, classic roofing materials are used - from roofing felt to metal tiles.

What and how to paint a well at the dacha?

- Wooden elements are best treated with drying oil. As an option, they can be coated with polyurethane yacht varnish, which is very resistant to mechanical wear and moisture.

- How to paint a well in a country house if only cement and metal elements of its structure are located above the ground level? The concrete is primed with any penetrating primer, after which the entire structure is painted with PF-115 enamel or its imported alkyd-based analogues.