It is known that meat or fish can be smoked either cold or hot. In the first case, the dish will remain dense and retain its original structure. Cold smoking is a lengthy process, but you shouldn’t rush into tasting it: it’s easy to get poisoned by half-finished food.

The deeper taste and unique aroma of smoke in hot smoked is due to the heat emanating from the coals, thanks to which they are cooked.

In this article, we will understand the operating principle of the device, and also describe step-by-step instructions on how to make a hot smoked smokehouse with your own hands.

Features of smoking and dishes

Nowadays, no one has problems with storing food, since what is left can always be frozen or canned. However, in ancient times, smoking was one of the main types of cooking, which was intended for long-term storage. This processing made it possible to store meat and fish for future use.

Nowadays, not only they are smoked: smoked cheeses, fruits, vegetables, and nuts have become very popular. Smoking is a method of processing food with smoke. During cooking, carefully monitor not only the temperature, but also the amount of smoke, uniformity of heating, and fumigation of food.

Pros of smoking

Smoking is popular for a reason; it allows you to:

- rid products of harmful microorganisms that can cause significant harm;

- due to the gentle temperature, preserve most of the “benefits” - vitamins, macro- and microelements;

- store supplies for a long time, but do not worry about their spoilage: smoke in this case becomes an ideal preservative.

The taste of such dishes is influenced by the wood used for smoking. Each wood, when burned, imparts its own unique taste to products. For example, sawdust manufacturers advise choosing certain types of trees in different situations. But more on that later.

Types of smoking and their differences

Processing can occur in different ways. There are two types of smoking - cold and hot.

- First, cold cooking takes longer because smoking occurs at a minimum temperature: most often it is 25-40°. The maximum limit is 45°. It is believed that products prepared in this way are more tasty. The downside is the length of the process: cooking can take several days. Plus - an impressive shelf life without loss of taste. It is 3-4 months. One of the reasons is the preliminary preparation of products. They are salted, pickled, etc.

- Hot smoking is a kind of express method. It requires higher temperatures - from 50° and above. This is the most convenient and fastest method, since it takes about 1-2 hours to prepare a meat dish, and about half an hour for fish, or a little more. In this case, the prepared food is served directly on the table: it can (should) be tasted immediately. Hot smoking has a drawback, but it is the only one. This is not a very impressive shelf life - only 3-4 days. Therefore, it will not be possible to make large reserves.

Despite the disadvantage of the latter option, hot smoking in nature does not lose popularity among vacationers, since the value of products that cook relatively quickly is the ability to eat them “here and now” and not send them somewhere for storage. Therefore, hot smoking is an activity very common among owners of dachas and country houses. They are attracted not only by the speed and excellent taste of the finished products, but also by the chance to turn the simplest items into a smokehouse.

Hot smoked smokehouse: device and principle of operation

Before looking for the answer to the question of how to make a hot smoked smokehouse, you need to get acquainted with the design itself. Such installations have different sizes, but slightly different devices work on the same principle.

How does it work?

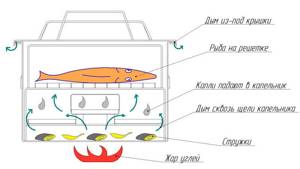

Unlike more complex structures designed for cold smoking, where the smoke needs a place to cool, in most smokehouses for hot processing of products, smoke formation occurs immediately, in the smoking cabinet:

- the smokehouse body is installed on a stand;

- sawdust of the selected wood is poured onto the bottom;

- install a tray for collecting fat a little higher;

- grates for food are attached to the side walls of the container.

After the preparations are completed, the products are placed on them or hung on hooks, then the smokehouse is closed with a lid. More serious designs have a side door. A fire is lit under the device, it heats the sawdust, which begins to smoke. The hot substance, rising, “gets to the victims.” To be able to control the process, a thermometer is installed near the products.

The process will be successful, and the result will be tasty, if you ensure that the sawdust smolderes slowly and not burns quickly. Using damp wood will make the finished products juicier. Thin dried branches, prepared in advance for the fire, will allow you to maintain the optimal temperature longer.

Types of smokehouse for home and materials for its manufacture

A home household smokehouse can be stationary or mobile.

The construction of the first is possible only on the site of a country house and they require the construction of a foundation, for which fire-resistant or fireclay bricks can be used.

Portable smokehouses, usually presented in compact designs, can be used not only in the country, but also in a city apartment, outdoors. Their important characteristic is the presence of side handles that make them easier to transport or carry.

As a rule, for their manufacture a metal sheet is used, from which a solid structure is welded. Although improvised materials are often used for manufacturing, for example, you can easily make a smokehouse from medical bix with your own hands, in which you only need to additionally install grates for food.

For a portable model, other finished metal products can be used, but if the smokehouse is made from scratch, then it is preferable to use stainless steel, although avid fishermen often use a bucket , which can be made even in field, or rather river, conditions.

It is important, when starting to manufacture a smokehouse, to pay attention to its dimensions, which determine the loading volume.

In a very small model, you will have to make several bookmarks, which is not very convenient, and a large container will be difficult to fill, especially taking into account the fact that the prepared products will have to be consumed within a fairly short time - no more than one week.

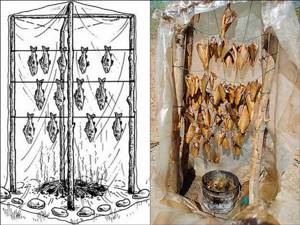

Lovers of outdoor excursions and fishermen can get a small portable model, but in such conditions a camp smokehouse , characterized by its simplicity of design, which can be assembled from scrap materials, is also quite justified.

For it, a small fire is lit, over which wood chips or even dry tree branches are placed on a grate or metal sheet, and the food is carefully hung on branches placed in a circle.

In order to ensure uniform heating and maintain the desired temperature, it is recommended to wrap the structure around the perimeter, for example, with plastic film, but be sure to ensure that it does not heat up intensely from the fire. Depending on the weather and the presence of wind, the top can be covered or left open.

Structural elements of the smokehouse and operating principle

Regardless of size, shape and other parameters, each homemade smokehouse must have the following elements:

- the actual container or compartment for smoking (in stationary models);

- grid(s) for storing products. Some models may also be equipped with hooks on which it is more convenient to hang whole medium-sized fish or chicken for smoking;

- a reflector, which is an ordinary tray, the purpose of which is to collect fat formed during the smoking process and prevent it from getting on smoldering chips or firewood. In mobile models, a design of 2 containers installed one inside the other is most often used - the outer one is the bottom of a sealed smokehouse, and the inner one is used to collect fat;

- Although a thermometer cannot be called an important functional element, without it it is difficult to control the smoking process, so it should be present in any smokehouse.

The principle of operation is based on the fact that products located on a grate or suspended on hooks are evenly fumigated with smoke, the generator of which is smoldering wood chips. During hot smoking, additional heat treatment is carried out, since the smoke temperature is high and reaches an average of 100 °C.

When fumigated with smoke, fish, meat, chicken, etc. are actively saturated with its components, which gives the finished product a characteristic taste.

Before smoking fish in a hot smoker or any other product, you should follow some rules, thanks to which the end result will fully meet your expectations:

- the product must be treated with smoke evenly;

- using only light haze, the content of harmful components in which, unlike dark haze, is negligible, and this is achieved by diluting it with oxygen;

- The intensity of smoke circulation in the smokehouse determines not only the cooking time, but also affects the quality of the final product, since this parameter determines the rate of absorption of its components released during the smoldering process of sawdust or wood chips.

What are the benefits of having your own smokehouse?

Firstly, because at any time you can make an original, tasty dish without any special expenses. But this is not the only reason to decide on the DIY Smokehouse operation. The advantages of creating such a device yourself include several other benefits.

- Saving. The price of purchased models can make you not only feel depressed, but also lose your appetite. Even the simplest smokehouse models will be quite expensive.

- Ease of operation. Such work, if all the materials and tools are at hand, in some cases takes no more than an hour. A day is the maximum that may be required to create a smokehouse.

- Ease of use and maintenance. Despite the simplicity of the designs, they do the job efficiently, so no additional actions are needed. They are also easy to care for.

The most attractive quality of homemade smokehouses is that they are free, if the owners already have everything they need in their “bins”. In addition, you can make not just one design, but several at once, for all occasions and for any company.

What to make a hot smoked smokehouse from?

There are quite a few options for homemade devices, but they all have both advantages and disadvantages.

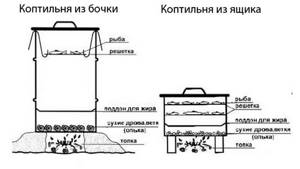

Bucket turned smokehouse

A waste steel bucket is the simplest, most common way to construct the desired device. Two grates are inserted inside the container. One of them is installed 100 mm from the bottom, the other a few centimeters higher.

The advantages of the elementary option are the speed of cooking and the mobility of the design, but the disadvantages are significant. This amount of food is unlikely to be enough even for an average family, so the owners will have to prepare food in portions. Another disadvantage is the unattractiveness of an improvised smokehouse. Therefore, it is logical to use such a “device” only under force majeure circumstances. For example, as an additional device if a large army of guests suddenly “raided” the site.

An old refrigerator is almost ideal

In this case, we are not talking about modern partings, but about reliable, strong Soviet units, which, through the efforts of the owners, are transformed into various useful “devices.” First, all the insides of such a refrigerator are removed and a hole is drilled to remove smoke.

In the upper part there are grates for food, under them there is a tray for leaking fat. A “baking tray” with sawdust is secured even lower. To ensure their heating, the structure is placed on a small electric stove.

The main condition for turning a refrigerator into an effective smokehouse is its tightness. The door of the device simply must close tightly. The need for an additional electrical appliance (tiles) can be considered a relative disadvantage of the method.

Stainless steel sheets

This is a more “civilized” solution. This smokehouse is a metal box with a lid. Inside it, corners/pins are welded on the walls for installing gratings. Such designs are unpretentious; they do not require any knowledge or any special care. The minimum thickness of the sheets from which these “ovens” are made is 4 mm. However, welding equipment is necessary.

A simple stainless steel smokehouse can last for decades. This option has only one significant drawback. This is the inability to control temperature. However, on a hike or at a picnic, it is quite easy to determine the readiness of a dish by the ruddy appearance of the food. Therefore, a reliable metal box can be considered a worthy contender for the role of a mobile smokehouse.

Brick building

Such a stationary brick structure, unlike portable devices, will require a foundation. In this case, fire-resistant brick is used as a building material. This work can no longer be called elementary, since only someone who is familiar with brickwork, not only in theory, can make a hot smoked smokehouse.

On the other hand, the small size of the brick structure gives beginners with no experience a chance to cope with the work. The main qualities for a future builder are attentiveness, accuracy, and slowness. Precise execution of all stages is mandatory even for creating such brick “miniatures”.

Help barrels

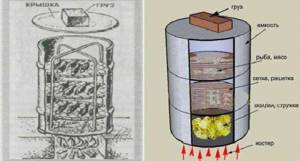

If the owners of the site have such “emergency” reserves, then you can create a structure that will be much more attractive than an ordinary bucket. There are two possible options: a simple device consisting of one barrel and a smokehouse made of two containers.

Transforming one “vessel” into a device for preparing smoked meats is not too radically different from “modernizing” a bucket. If the owners of the site decide to make a permanent structure, then they will have to arrange two barrels in the letter “T”. The lower part will be a full-fledged firebox, the upper part will be a smoking compartment.

How to make a hot smoked smokehouse?

Since not all options can be considered attractive to absolutely everyone, it is better to consider those structures that are easiest to build with your own hands.

The simplest device from a bucket

A bucket is the simplest container that does not involve any serious work, therefore, in the absence of an alternative, this method of creating a mobile structure has a right to exist. In this case, the author will not need any serious tools or special equipment, but he will need to find a bucket that has its own lid.

- After determining a suitable location, the found area is covered with a small metal sheet, which will act as a base for the firebox.

- Stacks of bricks are placed on both sides of it so that a bucket or a replacement for it (for example, a pan, a small metal box) can be installed on them.

- Metal gratings are installed inside the container on several “floors”. Coasters for hot dishes are ideal for this. Or homemade grid circles.

- At the bottom of the bucket there is a circle-pallet made of metal. An unnecessary pan lid of a suitable diameter will perform this role “brilliantly”.

That's it, the improvised smokehouse is ready. The owners will only have to put the firewood on the sheet, distribute sawdust on the bottom and arrange the food. The loaded smokehouse is closed with its “original” lid. The same electric stove can replace firewood.

If you have a barbecue, but no smokehouse

When the owners of the site already have a stove, but are suddenly drawn to smoked food, it is quite easy to find a way out. The grill will not have to be remodeled, since it will be enough to install a mini-smokehouse on top. To make it, you will need a maximum of an hour of time, a piece of large diameter pipe, or a not too “prominent” metal barrel.

What is found is laid across the grill. Then a grate (a piece of metal mesh) of a suitable size is installed inside. Sawdust is poured onto the bottom and wall of the pipe, then food is placed in a lying container, and its ends are closed. The best option is metal circles. A possible replacement is elements carved from wood and equipped with a handle.

Large barrel smokehouse

In addition to the bucket and pipe “superstructure,” you need to consider another, more “complex simple” option. Barrels are items that are easy to spot in almost any area, making them the first big contenders for a smokehouse. A mobile barrel does not require a reliable base; you can get by with simple tools, but as a result you will get a convenient, functional device.

Materials, tools

In order to make a hot smoked smokehouse from a barrel, the master will need simple materials and tools:

- a metal barrel in which neither petroleum products nor other harmful chemicals were stored, maximum volume - 200 liters;

- chimney pipe (metal, asbestos cement): diameter 100 mm, length - about a meter;

- metal sheet for the hot smoking chamber, thickness - 4-5 mm;

- mesh, reinforcing bars, minimum cross-section - 6 mm;

- wooden boards for making a lid;

- steel wire to create a lattice;

- small pieces of metal corner;

- latch, hinges, door handle;

- coupling with internal thread;

- grinder, disc for metal;

- welding machine;

- roulette.

If there is no “eco-friendly” container on the farm, then a smokehouse is made from what is available. In this case, the barrel is first washed, dried, and then burned with a blowtorch. After this treatment, the “vessel” is filled with water and left alone for several days. Then the barrel is thoroughly washed again.

Making a smokehouse

First of all, cut off the top lid of the sealed container. However, they do not throw it away: this part will be useful in making a tray for collecting fat. The prepared barrel is placed on a convenient stand.

- In the lower part, where the combustion chamber will be organized, a rectangular hole is cut out for loading firewood, its approximate dimensions are 200-300 mm. A door is made from a cut out rectangle: hinges are welded to it, a handle and a latch are attached.

- A round hole for the chimney is cut in the opposite side; its diameter is the same as that of the pipe. A coupling is welded into it. An external thread is cut on the pipe, then it is screwed into the fitting.

- Narrow longitudinal holes are cut in the bottom of the barrel, intended for blowing. They will ensure trouble-free combustion and allow the firebox to get rid of ash on its own.

- At a short distance from the firebox, install a cut off lid, which will become a baking tray for collecting fat. To make it removable, metal corners are welded to the walls of the barrel.

- A circle is cut out of a metal sheet; its diameter is equal to the internal diameter of the barrel; it will be the bottom of the “barrel-shaped” smoking chamber. The distance from it to the top of the barrel is one third of the height of the container.

- A stand for a smokehouse barrel is made from a sheet of metal. The height of its legs is 200-300 mm. Another option is rows of bricks; they can temporarily replace more reliable supports.

The penultimate stage of work is the installation of gratings, rods, and the manufacture of hooks. The recommended distance between levels is about 150 mm. To avoid the impossibility of removing the grease tray, you need to make sure that the grate supports do not interfere with this.

The last operation is making a lid from boards (hardwood). In this case, the gaps remaining between the elements will only help. They will give a chance to rid the smokehouse of excess moisture.

Other types of stationary smokehouses

If you don’t want to engage in labor-intensive construction, then a smokehouse made from a 200-liter hot-smoked barrel can become the basis for a future design. If desired, you can use containers of smaller or larger volume, taking into account the needs of the family.

1. First you will need to get rid of the layer of paint, which can be removed mechanically, but the fastest way to do this is with fire - to do this, just put the barrel in a lighted fire (or make a fire right inside) for about 1-2 hours.

2. Next, you should drill holes for attaching the gratings and install a so-called glass made of a sheet of metal, which is fixed in the lower part into specially prepared grooves on the bottom.

3. Afterwards, a lid is made, the size of which must match the diameter of the barrel, and a chimney is arranged with it. For a tight fit, it is recommended to use various weighting agents. The material for the cover can be steel, but even plywood can be used.

If the smokehouse is made in a wooden barrel, then the algorithm of actions will be the same, with the exception that fire-resistant material should be laid between the metal glass and the walls - most often asbestos sheets are used for this.

After this work, you can install grates, lay wood chips on the bottom and load food. The smoldering process is ensured by heating organized from below using an open fire from a fire or, for example, a gas burner.

, a home smokehouse for a gas stove can be made from a small container , which can be used both in the country and in a city apartment.

It is somewhat more difficult to convert a strictly gas cylinder into a smokehouse: first, the remaining gas must be removed from it and washed, then the door must be cut out, for which you will have to use a welding machine.

The next step is to install the grates and tray inside the container. In this case, it is best to organize smoke access from the outside, and to do this you need to cut off part of the bottom, but not more than half of its area. And the fire is lit directly in the firebox, which is made of metal and welded from below, under the bottom.

You can also use an old refrigerator for the smokehouse, but before doing this you should get rid of all plastic parts and the freezer section. An electric stove can be used as a heating device, which will heat the sawdust placed in a tray at the bottom of such a smokehouse.

Such a home smokehouse for a country kitchen will allow you to diversify family lunches or dinners with delicacies.

How to cook smoked meats?

If the owners are interested in how to make a hot smoked smokehouse, then most likely they do not yet know exactly how to cook food so that it is tasty and does not have strange odors and tastes. The first point to study is sawdust and wood chips. It is prohibited to use pine shavings: they not only greatly affect the taste of food (it becomes bitter), such fumigation makes delicacies harmful to health.

The best smokehouse “helpers”

The best candidates are deciduous, fruit-bearing tree species. Some sawdust are suitable for all products, others have their own preferences. The ideals include:

- cherries (vegetables, nuts, berries);

- pear;

- oak (chicken, red meat, pork ribs);

- willow (meat of elk, deer, bear);

- maple (red meat, fish, cheese);

- alder;

- hazel (venison or other “wild” red meat, poultry, fish);

- aspen;

- rowan;

- plum;

- apple tree (poultry, pork);

- ash (poultry, fish).

It’s not for nothing that juniper berries are added to some dishes: a small amount of such sawdust or twigs with berries will give the finished products an unusual, piquant taste.

If we talk about what kind of wood is best to use, then both dry and slightly damp raw materials have admirers. The first option guarantees a golden crust and a delicate taste of the prepared dishes. The second allows you to get a more tart smell and rich color. Since each family may have its own food preferences, determining the most suitable type of shavings can only be done experimentally.

How are the products prepared?

This process, unlike cold smoking, is quite simple. First, the selected chips are evenly distributed at the bottom of the smoking chamber. A tray is installed above to drain fat. In the upper part, products are placed on racks or hooks, pre-tied with string or twine. Then the barrel is closed with a lid. Firewood is placed in the firebox and set on fire.

How long does food usually take to prepare? Processing time depends on the type and size of future smoked meats. To cook medium-sized fish, half an hour is enough; a chicken “in its prime” will reach its condition in 40-60 minutes. The meat will take an hour or more. Here, not only its variety plays a role, but also the size of the portions.

How to care for the structure?

Caring for a barrel smokehouse involves cleaning it regularly. It includes removing fat from the pan, cleaning residual fat and scale from the walls. If you ignore this operation for a long time, the accumulated contaminants will cause a change in the taste of food. Of course, not for the better.

A homemade design is a simple method that gives you a chance to greatly diversify the menu, since it is not difficult to make a hot smoked smokehouse from simple available material. In this case, there is reason to hope that the food you prepare yourself does not contain suspicious substances, which means that it will not have a negative impact on the health of all household members.

You can find out the prices for smokehouses here:

Many skilled owners talk about how to make a hot smoked smokehouse. You can see this with your own eyes if you take the time to watch the following video, which has been rated by thousands:

Brick smokehouse for a country house

You can make such a design only if you are the owner of a country property, and the main advantage of its operation is:

- obtaining a high-quality product in compliance with the entire technological cycle;

- high demand for operation;

- the possibility of creating an additional rest or relaxation area, especially if the smokehouse is structurally combined, for example, with a wood-burning stove or barbecue.

But when choosing a stationary smokehouse for hot smoking, you need to be prepared for a significant amount of upcoming work.

1. Once the site for construction has been determined, you should begin constructing a foundation, for which you can use either brick or concrete blocks or even make it monolithic. When choosing a location, it is advisable to take into account the location of the house and the direction of the wind to prevent smoke from entering the room.

2. To build the smokehouse itself, refractory bricks are used, and fireclay material can be used for the internal part, in which smoking will take place.

3. Considering that such a home mini-smokehouse becomes an active element of the landscape, it is necessary to take care of its external decoration. You can use both finishing bricks, clinker is especially attractive in this case, and other materials, the selection of which should be approached in terms of their fire safety and fire resistance.

4. To reduce heat loss and increase the efficiency of the smokehouse, it is recommended to install a thermal insulation layer between the lining and the structure itself, for which the only suitable material is mineral wool.

5. The next stage is the installation of a door and a chimney, which serves to remove excess smoke. And then, depending on the size, a one- or two-tier smokehouse can be made with a tray for draining fat, installed directly above the combustion chamber in which the wood chips smolder.

For ease of use, you can take care to install and connect a flashlight, the presence of which will allow you to do what you love even in the dark.