Brick fences are popular among country property owners. These are simple and reliable designs that guarantee reliable protection, have a pleasant appearance and a service life of several decades. Wrought iron fences with brick pillars can easily withstand the effects of temperature changes. Homeowners use wooden spans filled with picket fences. The brick fence is complemented with forged elements. This adds stability and decorative features.

What is the most important factor for you when choosing a fence?

BeautyProtectionAll together

Advantages and disadvantages

To understand the advantages of brick fences with inserts made of forged parts, they are compared with other fences. Among them are traditional ones, which are assembled from forged elements, and those made from corrugated sheets.

The obvious advantages of fences that are built of brick and forging include:

- Strength of the structure and individual components. The fence can withstand serious mechanical loads created by wind or snow.

- In buildings of this type, different materials are used.

- Brick and forging visually combine with each other.

- The fence is used in a lighting device.

However, this type of fence has the following disadvantages:

- The construction requires only high-quality bricks.

- The structure is massive, so it is installed with the obligatory fulfillment of technological requirements.

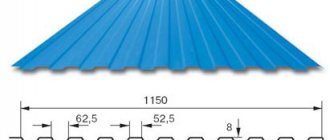

When comparing brick fences with structures made from corrugated sheets, the advantages of the former are noted:

- durability and resistance to loads;

- builders can perform original brickwork;

- beautiful design appearance.

What will you choose?

BrickProfile sheet

Comparing these fences, we identify the disadvantages that are inherent in brick fences:

- cost of materials: bricks and forgings;

- not all fences with brickwork with inserts made of forged products guarantee protection of the house from noise and prying eyes;

- limited color palette.

Useful How to make and install a fence with your own hands using forging elements

If you need to protect yourself and your home and plot not only from physically possible attacks from the outside, but also simply, from prying eyes, and at the same time, do it powerfully, thoroughly, and, at the same time, airy and beautiful, in a special way, then a brick fence with forging is the best solution!

Content

- Brick fence: types

- DIY brick fence video video

- Fence made of brick and forging

- Fences with forging elements photo

Brick fence: types

Since ancient times, people have sought to build a fence around their home from available materials: wood, stone, and a little later - brick - an affordable, durable, simple, but beautiful material.

At first, it was necessary to protect yourself and your property.

But, at present, a brick fence is an indicator of the status, wealth and taste of its owner, a way to create your own cozy and special world, far from prying eyes.

It is not for nothing that we mentioned brick as the main material for the construction of fences. Its availability, strength, the possibility of variations in color and masonry methods, as well as the ability to combine it with all available, both traditional and modern materials, have made it simply indispensable in the construction of beautiful permanent fences for homes and gardens.

All brick fences can be divided into:

- Combined brick fences: the posts and possibly the base of the fence are made of brick, and the rest is made of wood, forging, corrugated board and other materials. Such fences may or may not be solid.

- Brick fences with elements, most often forged. As a rule, these are solid fences that serve to protect a house, more than 1.7 meters high, with elements of forged structures located on pillars or on the top of the brick wall-spans of the fence. It is these fences that we will look at in more detail.

DIY brick fence

The construction of any brick fence begins with a correct assessment of your financial capabilities: because... Despite all its accessibility, this pleasure is not cheap. You need to draw up a project, calculate all the dimensions: depth (depending on the characteristics of the soil and the mass of the fence structure, in the final version) and width, which depends on the planned height of the fence and, to some extent, personal preferences.

The required stages of work when building a brick fence will be:

- construction of the foundation: cleaning, marking the territory, digging a trench of given dimensions, constructing formwork and pouring the strip foundation itself and the foundation for support pillars with the obligatory use of reinforcement.

- laying waterproofing on the entire surface of the foundation.

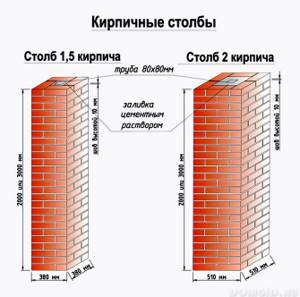

- installing reinforcement and/or metal pipes inside the brickwork of support pillars and then filling it with concrete.

- bricklaying: for the construction of fence posts or spans, it is carried out with the installation of beacons for the seams. A brick fence is also a decorative structure, which means it must be neat, aesthetically pleasing, with the same thickness of seams.

Fence made of brick and forging

A fence made of brick and forging is a high-status structure that goes well with other design elements of any house made of any material, be it wood or stone, brick.

And if you use only forging elements, then it’s also a blind one, designed, first of all, to protect your home from the prying eyes of your neighbors.

Indeed, in this case, artistic forging of fences acts only as a decoration (balusters, inserts, decorative stripes, caps, rings, tops, overlays, endings, etc.),

designed to decorate and give the brick, which is, in principle, quite typical in the method of construction, fence, lightness, delicacy and, most importantly, individuality.

Forged elements are installed after the main work on the construction of a brick fence, from above, because perform only a decorative and protective (for the fence itself, in the case of installing forged canopies and caps on support posts) function, therefore, they do not require additional thinking over fastening methods at the stage of erecting support posts, but can be mounted in fact using a hammer drill.

But, unfortunately, forging fences, especially on an individual order, is not a cheap pleasure, and it takes a lot of time to create an individual masterpiece.

And independent production of forged elements requires special skills and abilities, a blacksmith’s tool, and is not accessible to everyone.

Knowing this, many construction companies specialize in the manufacture and sale of ready-made forged elements for fences of the most popular patterns and shapes.

They, of course, are somewhat different from their truly artistic counterparts, but, nevertheless, they allow you to show imagination and creative thinking and create an original brick fence with forging elements, with much less financial and time costs.

Fences with forging elements photo

So what can come out of a brick fence if you decorate it with forged elements... It's worth a look!

Author: Sergey and Svetlana Khudentsov

10

What you need to know to order

In order for a brick fence with inserts made of forging elements to last as long as possible, it is important to observe the following nuances:

- correctly draw up technical specifications;

- select appropriate materials, including brick;

- perform installation in accordance with the requirements of the working documentation.

Brick used

The following types of bricks are used to construct a fence:

- Ceramic resists temperature, has strength parameters and a smooth surface.

- Fireclay is made from clay of the same name using firing technology. This brick has high performance parameters, including resistance to weathering. For installation you will need a special masonry mortar.

- Silicate is made from a cement-lime mixture using firing, which guarantees frost resistance and long service life. Sand-lime brick is inexpensive.

- Clinker is made from clay using firing; this brick is distinguished by high performance parameters and strength. The appearance is preserved even under the influence of ultraviolet radiation. Such bricks are expensive and weigh a lot.

Useful Modern wrought iron fences for a summer house and a private house: beautiful views and features

Recommended sizes

When choosing the size of a future structure, it is necessary to be guided by the wishes of the client and his finances.

It is recommended to consider the following parameters:

- The width of the base and support posts ranges from one to three bricks.

- The height of the fence is in the range of 0.5-3.5 m. Low-height buildings are laid out in one brick, high walls are laid out in two or three.

- The typical span width between pillars is 3 m, but in practice other sizes are also found.

Foundation

A wrought iron fence of this type weighs hundreds of kilograms, so when installing it, a lot of attention is paid to creating the foundation. A good option for a brick fence would be a strip structure laid on a gravel bed.

A good option for a brick fence would be a strip structure laid on a gravel bed.

For a strip foundation, a trench is dug 0.5-1 m deep. The width of the trench depends on the width of the future masonry and is on average 0.3 m. A sand and gravel cushion is installed at the bottom, the height of which is in the range of 100-250 mm. After installation, the pillow is compacted.

At the next stage, a frame is erected; periodic reinforcement with a diameter of 12-14 mm is used to create it.

After installing the frame, they proceed to the manufacture of formwork for the basement of the fence. Concrete is poured only after the formwork is assembled.

Expert opinion

Vladimir Ulyanov

I have been involved in fences for over 10 years, answering questions and helping people cope with the installation task on their own.

Ask a question to an expert

The solution is poured in layers, the layer height is 150 - 200 mm. After pouring the next level of concrete mixture, it is compacted. The work is performed with a mechanical vibrator or manually using a bayonet shovel or metal rods.

After the filling is completed, a technological break occurs for a period of one month. During this time, the concrete will reach its design hardness.

Using ready-made elements

Fence elements made using cold forging technology and installed in a composition lead to lower costs and faster assembly of the structure. But such details lead to the loss of originality of the forged product.

Useful Modern wrought iron fences for a summer house and a private house: beautiful views and features

Here we can only rely on a craftsman who is able to make a forged structure from standard elements. Typical components include:

- Vine - repeats the silhouette of a living plant.

- Plugs – installed on the ends of the supports.

- Peaks are placed on top of a brick wall, which creates an additional obstacle for uninvited guests.

How to calculate the cost

The construction of a brick fence begins with drawing up a project, which includes working documentation, estimates and specifications of materials.

To draw up an estimate, determine the number of required consumables. Knowing the geometric parameters of the structure, builders calculate the required amount of brick. In addition, you need to know how much rolled metal will be required for the construction of supports.

Of course, they perform calculations to obtain the cost of the foundation.

The cost of a practical fence will be the sum of the costs of purchasing materials and the wages of workers invited to build the fence.

How to position gates and wickets

At the planning stage, the location of the gates and wickets is determined. The following installation methods are used:

- buildings are located nearby;

- the gate and the gate are placed at some distance from each other;

- the gate is combined with the gate leaf.

How the price is formed

The final cost of the project is discussed during the process of coordinating the design and selecting materials. The final cost is affected by:

- the type, quality and thickness of the metal used in the work;

- design features of the structure - complexity, the presence of decorative forged elements that are difficult to perform and their quantity;

- the scale of the project and the timing of its implementation - we accept urgent orders, but the cost may vary;

- type of paint coating - additional protection against corrosion, brand of paint, product consumption.

We invite you to discuss the details and cost of your order with the manager by phone or during a personal meeting in the office.

How to make a forged fence with your own hands

Making a wrought iron fence on brick pillars requires professional skills. The builder must be able to operate cold forging machines. Such skills are acquired after completing special courses, so forged products are ordered from companies that specialize in such products.

Previous

Forged How to make and install a fence with your own hands with forging elements

Next

Wrought ironModern wrought iron fences for cottages and private houses: beautiful views and features

Advantages of brick fences

Until recently, the construction of brick fences was an unaffordable luxury, since the cost of this building material is considered expensive. However, the safety of life and housing has become of paramount importance, so brick fences have confidently won the sympathy of buyers. They are durable, resistant to mechanical stress and destructive environmental factors.

In addition, brick fences have a neat appearance, which can also have a decorative value, with the use of various brick laying options in construction. A popular way to make these fences attractive is combined construction, because brick combines perfectly with many materials - wood, stone, metal (forging). Fences with brick pillars and strip foundations are common, which serve as a support for the installation of forged fences, corrugated sheets and other materials.

Fences with forging elements

Many country property owners prefer to install solid fences, but at the same time want to somehow improve them and give them a special look. The best way to do this is to supplement the fence with forged elements.

In fact, there are countless options for wrought iron fences. Since forging is done by hand, it is impossible to find two completely identical fences. And if you take into account the huge number of design solutions, then you can make a wide variety of fences, ranging from laconic and strict fences to luxurious expensive structures, from mono fences to combined fencing structures made of different materials. Thanks to this, everyone will be able to choose the option that best meets their aesthetic and financial requirements. But we can definitely say that wrought iron fences meet all modern trends.