Fence on a slope: preparation for installation

The fence installation process is carried out in several stages:

- First, the site is inspected and marked, a diagram is drawn up, and an installation option is selected.

- If, as a result of inspecting the site, it is decided to install a fence based on the foundation, then the second stage will be pouring it. This process is not necessary for all cases, but in this article we will look at an example of installing a fence with a foundation.

- Then the support pillars and connecting logs are installed.

- Next, if necessary, a drainage system is installed.

- The process is completed by covering the frame with corrugated sheeting.

Each location has its own characteristics that should be considered before installing fencing. Let's look at each of the stages in more detail.

Design options - photos and diagrams

With all the variety of designs, patterns, shapes and decorative elements, forged fences are usually made according to the most common patterns. Such limitations are explained by the production method and metal processing technology.

A wide variety of wrought iron fence patterns allows you to choose the most suitable option for your site

The combination of stone, forging and wood looks original

Forged fences, photo diagrams of which can be viewed before ordering, are made in the following form:

- Separate spans. Decorated with brick or natural stone. The supports can be made according to a foundationless scheme or connected by a plinth with a height of 15 to 100 cm.

- Solid fabric. The fence is installed on steel tubular supports. The diameter of the pillars is small, so the entire fabric of the forged fence looks like one continuous span.

- Steel sections with screen. Most often, screening is used to protect or shade the local area. Basically, thin sheet metal or cellular polycarbonate is used to install the screen. Corrugated sheeting is also suitable. The closer the fence is to the house, the larger the shielding surface should be.

A forged fence, complemented with profile sheets, will hide the yard from prying eyes

When planning sketches, it should be taken into account that the production field has its own established forms, style and design ideas. A radical deviation can spoil the aesthetic appearance of the product.

There are countless design options for forged sections, here are just a few of the most common designs:

Inspection, site marking, drawing up a diagram

Half the success of the work done lies in the precise marking of the area where the fence will be installed. This will allow you to calculate the amount of consumables and design the architecture of the fence. Geodetic reconnaissance to study the soil, its structure, type of soil, depth of the fertile layer, etc. will not be superfluous. All these nuances will help you navigate when:

- choice of material;

- foundation construction;

- choosing structural supports (brick, concrete, iron pillars);

- span size;

- height of the fence.

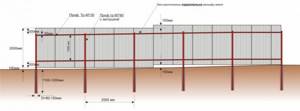

After marking and calculating the area of the site, the amount of material is calculated. Then an installation diagram is drawn up, containing:

- landscape contour, ground level, slope;

- size of the depth of the trench under the foundation;

- height of the concrete base;

- fence height, span width;

- height of support pillars;

- number of logs, distance between them;

- difference in span height, etc.

Examples of schemes:

The pitch of the drop depends on the magnitude of the slope. The greater its degree, the smaller the span width. The installation option for fencing also largely depends on it.

What type of wrought iron fence should I choose?

Forged fences, sketches of which you can make yourself or purchase from specialized companies, are distinguished by a variety of styles, shapes and sizes.

Products are divided into the following categories:

- Functional. The main task of such structures is their protective function. The fences are distinguished by their simple structure and minimalism. In most cases, lattice structures with inexpensive screens made of polycarbonate or corrugated sheets are used.

- Artistic. Made by hand from many complex pieces. They are distinguished by their effectiveness and high cost.

- Combined. They combine stamped and hand-forged parts. They combine beauty and practicality.

A wrought iron fence should not be overloaded with complex and flashy patterns. The key to beauty lies in simplicity and elegance.

Schemes and sketches for fences and enclosures

When choosing a fencing style, you should not rely only on the recommendations of professional designers. It is necessary to take into account the subjective factor: specialists can propose a project that they see as beautiful and fashionable, but does not coincide with the tastes of the owners of the site. It is recommended to study catalogs of diagrams and sketches, look at the structures that friends and neighbors have installed in order to compare theory with practice. You should choose the style that best fits into the design of the site.

When deciding what a fence with forging elements will look like, you need to draw up drawings of the following parts of the structure:

- The foundation is strip, columnar or pile.

- Pattern – lattice, arrow or artistic. Plain or with gilded elements. Black, patina or painted.

- The screen is solid, solid or translucent. Durable or decorative.

- The base is concrete or stone, buried or surface.

- Pillars - concrete, steel, stone or brick.

The classic option is a composition of black steel sections, a stone base, brick pillars and a bronze polycarbonate screen.

How to make a fence on a slope: installation options

There are two options for installing a fence on a slope:

- Repetition of the site's topography.

- "Steps".

The connecting beams between the pillars in this case run parallel to the ground. The height will be the same, uniform along the entire length of the fence. Most often, such fencing is installed on extensive slopes. This option is ideal for areas with an uneven slope. A more suitable material is a metal picket fence or chain-link mesh. In the case of profiled iron or a 3D fence, more effort will be required to ensure that the structure secures the soil and looks harmonious. The best option for a uniform slope is a fence set up in “steps”. The spans between the pillars are installed in this way - each subsequent profiled sheet is attached lower than the previous one, going down the slope in steps. It is not recommended to install such a fence on an area that is too uneven due to sudden changes in height. There will be a risk of large gaps forming between the bottom of the structure and the ground surface.

When choosing any of the installation options, you need to understand the importance of firmly attaching the vertical posts. Failure to follow the fastening rules will lead to deformation of the fence, sagging or bulging of posts.

Advantages and operating features

Of course, the artistic component, as well as the opportunity to non-verbally declare to the world their social status, are the main motives for owners who decide to install an iron fence made by forging on their property.

But these products also have important performance characteristics, which must also be taken into account when choosing. They differ:

- long service life - at least 70 years;

- excellent anti-corrosion properties due to the absence of welds;

- high resistance to deformation and mechanical stress;

- simple and easy care;

- ability to withstand natural factors;

- security - the presence of a metal fence 2-3 m high or more can become a reliable barrier for intruders, or at least a structure that can force them to abandon their bad intentions.

But, when planning to install a wrought iron fence on a site, the owner should know that such a structure is unable to protect against dust flying from the street, as well as noise.

And, of course, it is not an obstacle to the prying eyes of passersby. You also need to be prepared for the fact that the price of forged products is much higher in comparison with metal structures made by welding.

This is due to the fact that most products are made to order.

And, preferably, experienced craftsmen, the cost of whose services cannot be low.

You can reduce the cost of the design by choosing combined products, characterized in that they are based on structures made by welding, onto which forged decorative elements are then attached.

Laying the foundation and installing pillars

Depending on the slope angle, the formation of the foundation may vary. There are three options:

- With a slight, uniform slope, the surface is maximally leveled. The upper and lower boundaries of the fence run smoothly along the entire length thanks to embankments of soil. This option eliminates joining of sections of different heights, which greatly simplifies the work. But still, builders rarely resort to this option because of its labor intensity. Another disadvantage is the violation of the fertile soil layer due to the embankment of soil.

- When the slope angle exceeds 30 degrees, the foundation is laid in the form of a ladder, where each section is located lower than the previous one. Two pillars are attached to one span. The section width is standard - 2.5 m. If the slope is steeper, then the span step is reduced to 2 m.

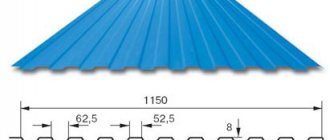

- The orientation of the fastening of each span is along the top of the fence - it is located horizontally even along the entire length of the fence. The lower part is adjusted to the contour of the landscape. This option is chosen when installing a fence made of corrugated sheets. Profiled iron is easy to adjust; it can be freely adjusted to any fence size.

Whatever option is chosen, construction begins with the foundation. It will become a powerful support for the fence and strengthen the soil from erosion.

They start digging a trench from the top point of the site. Its depth is constant throughout the entire distance. The exception is in places where the fertile soil layer lies deeper than the lower level of the trench. In this case, the trench should be deepened until the fertile layer is completely removed.

The formula will help you calculate the depth at the top point of the perimeter:

It = Ipv + Ip.

The depth of the trench (It) depends on the sum of the height difference (Ipv) and the thickness of the vegetation layer (Ip).

If you ignore the vegetation cover, which may hide large differences in height, this will negatively affect the level of the plinth relative to the top and bottom of the fence line. For example, in the upper part it will protrude more above the ground, in the lower part it will protrude less. The pillars are installed in holes and reinforced with broken bricks, gravel and concrete. Pouring concrete will prevent the pillars from sagging or protruding. The diameter of the pit should be 15-20 cm wider than the pillar. The length of the supports varies depending on the degree of slope. The distance between them should not be slightly less than the width of the profiled sheets. This will make it easier to fit and sew them on top of each other.

If the fence on a site with a slope is installed on clay soil, the formwork does not need to be placed inside the trench. The walls will cope with its role. The main condition is to maintain a strict horizontal position along the entire length of the trench. A sand “pillow” will help here, which needs to be carefully compacted and leveled. If a stepped foundation option is chosen, then the cushion should repeat each “step” of the slope. Roofing felt is laid on top of the sand layer.

Types of fences with forging elements

Often, in order to make the fence blank, the production of fences from forged elements is combined with the use of different sheet materials.

1. The simplest and most affordable option is to use corrugated sheets or sheet metal.

However, despite the fact that corrugated sheeting, although it has excellent performance characteristics, is still a rough material in combination with forging.

2. Structures in combination with sheet metal look more elegant, but the latter should be carefully treated with anti-corrosion compounds, painted and constantly maintained in proper, well-maintained condition.

Such fences are more durable and have a very beautiful appearance, mainly due to the fact that the forging pattern stands out better against a contrasting background.

3. You can combine forged fence elements with polycarbonate, a material characterized by sufficient strength and light weight. Such fences look more airy, but are reliable.

In addition, they are able to hide the private space of the site from prying eyes, although they allow one to guess the silhouettes of people and some objects located behind the fence.

4. But, probably, the combination of forging with wood can be considered the most successful due to the characteristics of the materials and their excellent compatibility.

In this case, the production of structures can be done in two ways.

The first option involves making a forged fence and installing it together with the rear wooden part (following the example of combining it with polycarbonate or metal).

The second option involves a complete combination of elements of different materials in one product. The base of the fence can be either a metal structure with wood inserts, or vice versa.

But the frame is always made of metal. Often such fences are a structure filled with boards, between which forged elements are installed, forming an ornament or some kind of design.

Installation of formwork

When installing formwork, the following criteria must be taken into account:

- creating smooth corners;

- no deflections;

- ease of dismantling;

- optimal thickness of building material;

- strength and stability of the structure.

The formwork system is installed after marking. Installation process:

- Wooden bars are driven into the ground to a depth of at least 50 cm, the ground part - at least 40 cm. The distance between them along the length of the fence does not exceed 120 cm. Width - 60 cm.

- Next, the side and top parts of the formwork are attached. On the sides, for greater resistance to pressure, they are fixed with strips with emphasis on the ground. Additionally, you can tighten the structure with screws and strengthen it with nails.

- After the work has been done, it is necessary to inspect the formwork for evenness and measure it with a building level. If there are no comments, concrete mixture is poured inside. Subsequent installation begins after the concrete has completely set after 4-5 days.

When choosing a wooden material for formwork, all parts of the structure should be impregnated with a waterproofing solution. This will prevent moisture from being absorbed from the concrete mixture. Otherwise, the concrete will crack as it dries, which will negatively affect the strength of the foundation.

Drainage system

A drainage system is needed for the stability and durability of the foundation. Installation of drainage in clay and loamy soil is required. It normalizes the outflow of water and prevents soil erosion. To ensure a drainage system, holes are left in the foundation for perforated pipes. They play the role of a drainage channel.

Gravel is an excellent drainage system. It is wrapped in geotextiles and laid under the foundation.

To ensure the outflow of water into the collector pit, a sewer pipe with holes drilled in it is laid in the ground. To better absorb moisture from the soil, it can be partially filled with gravel.

Installation of a corrugated fence on a slope: the final stage

Logs are attached to the support pillars. If the pillars are iron, they are welded or bolted together. In the case of concrete, brick, stone, the logs are fixed with fasteners. The upper and lower logs should be located horizontally parallel to each other, regardless of the type of foundation and slope.

Profiled sheets are fastened with rivets, screws or bolts. Each leaf overwhelms the other. When installing a stepped fence, the step size and the difference in span height are taken into account. When calculating the number of fastening points, the ventilation of the landscape is taken into account. The structure must stand firmly and withstand strong winds.

The material is adjusted close to the foundation. The upper part can be decorated with a fence strip. This will give the structure a finished and aesthetic appearance.

Having figured out the question of how to install a fence on a site with a slope, you can begin installing it. If you doubt that you can cope with this time-consuming task yourself, then leave a request on our website. Applications are processed instantly. A specialist will respond within 1-2 hours. We will not only advise, but also help you build a fence of any complexity, regardless of the type of terrain. We have already received hundreds of grateful reviews about the installation, and we are sure that yours will be one of them.

Types of metal structures

It should be noted that a metal fence as a fence is deservedly popular not only among private developers - they are also installed to enclose other objects and are also permanent attributes of the urban environment.

It is important to consider that this type of product is represented by both welded and forged structures, and, despite the fact that the same metal (metal) is used for their production, they differ in the manufacturing method.

In the first case, ready-made elements are used for fences, which, when heated during the welding process, receive their shape.

Forged products are made differently: first, the master blacksmith heats the workpiece, and then, using a special forging tool, gives it the desired look and shape.

Due to the fact that hot metal has high ductility, it can be used to make products of any shape and design, even creating elegant openwork designs with various twisted elements.

Next, depending on the task, the blacksmith combines the resulting elements into a single structure in accordance with a previously prepared sketch, and connects the finished sections to each other, for example, using support posts.

An important feature is that the connection of elements and entire sections also occurs by forging, although sometimes the use of a welding machine is allowed.

But it is forging that ensures the reliability of connections, the seams of which are almost impossible to notice.

And this not only gives the structure a more aesthetic appearance, but also provides them with better performance, reliability and durability.

It should be noted that welded fences can also differ in the presence of elements of different shapes and “curls”.

But in this case, the result is achieved through the use of special devices, with the help of which the metal heated by the “cold forging” method becomes elastic for such operations.

Thus, there are no fundamental differences between the products, but this is if you do not take into account the artistic component, which provides value and justifies the high price.