It is impossible to imagine simple country life without benches or simple furniture for sitting and relaxing. You can, of course, bring plastic or wooden furniture, but such furniture is enough for a couple of summer seasons at most. It is well known that garden benches need to be made of metal, especially since a simple bench from a profile pipe can be built with your own hands in a few hours with a budget of 800-900 rubles.

A budget option made from a profile and water pipe will cost several hundred rubles, no more

Metal profile pipes as a material - advantages and disadvantages

Metal profiles are widely used for making benches. The material is made of carbon steel and has a number of positive characteristics:

- easy to process;

- resistant to loads;

- welds well;

- has an affordable price;

- has a small mass.

Despite many advantages, profiled pipe has some disadvantages:

- to give the pipe blanks a curved shape, special equipment should be used;

- It is necessary to install plugs at the ends to seal the internal cavities of the pipe in order to prevent corrosion.

Photo gallery: benches and benches made of metal profiles

The color can be chosen according to the taste of the owners

Bench in a simple classic style

Budget solution for a garden bench

Good solution for the park

A product with a strict design

Forged elements give the bench lightness

The combination of bright colors pleases the eye

Original decor transforms the bench

Classic garden bench

Original garden bench design

Bench of strict geometric shape

Warm sunny color improves mood

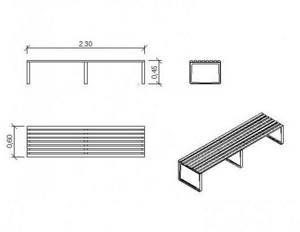

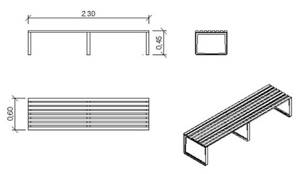

DIY drawings and dimensions of a metal bench

Product design features depend on individual requirements and are determined at the design stage. Profiled pipe is quite often used for the manufacture of metal shop structures. The back and seat of the bench are covered with wood slats.

At the design stage, it is necessary to consider the features of fastening wooden planks and the cutting scheme for profile pipe blanks. Depending on the relative position of the elements, the ends of the workpieces can be cut at different angles.

Before you start producing a bench, you need to decide on the dimensions of the product and develop a sketch or drawing. This will allow you to accurately calculate the need for materials in the future and facilitate the manufacturing process.

When developing a sketch, follow these guidelines:

- the width of the supporting part of the bench should be in the range of 40–60 cm;

- a backrest height of 50 cm above the seat level will provide sufficient area for support;

- the distance from the bottom of the bench to the seat support bars should be 40–50 cm.

You can make a bench with a back.

The drawing contains all the necessary dimensions

It is more labor-intensive to manufacture. However, sitting down on such a bench, you can relax and enjoy your vacation as much as possible.

It is possible to make a small bench yourself. The product has a traditional design. The construction of the support frame requires a minimum amount of materials and is simple.

The product has a simple design

There are no strict requirements for the geometric dimensions of the bench. Individual considerations should be made based on convenience and functionality.

Options for benches made of profile pipes

The choice of a specific furniture scheme directly depends on its purpose. Benches made of metal pipes have a similar structure in many respects, but there are slight differences in the design and assembly of the frame. You have to take into account the design features and method of its use. For example, if this is a place to relax under the canopy of trees, then it is best to make a bench on the street with your own hands from a massive corrugated pipe, with a cross-sectional edge of at least 50 mm. Often such furniture serves not only for relaxation, but also replaces a stepladder when harvesting fruit. But many people simply like the design in the Loft style.

Despite their unsightly appearance, garden benches made of reinforced profiled pipe are popular among summer residents

Most summer residents prefer making a bench with their own hands from a profile pipe in one of the most popular options:

- A classic version of a long-length country bench without a back;

- Garden bench on a metal frame;

- Bench for relaxing on the veranda or terrace;

- A simple bench with a backrest.

A classic country bench is assembled on a profile frame with a long and narrow seat. To prevent the board from sagging, a beam is sewn onto the frame at the bottom, acting as a stiffener. This bench is used primarily for gazebos or canopies, complementing a large dining table under a canopy with a summer kitchen.

For an open terrace or veranda, people traditionally look for options for a beautiful bench made from a profile pipe. Such designs use elegant curved side rails and racks with a curved back.

Bench for veranda

For gatherings in the backyard of a dacha around a lit fire or at a table, corner benches are often used. The L-shape is considered the most convenient and practical.

It is not necessary to try to make a frame from a square profile; it is difficult to bend, and not everyone likes square shapes. You can make an elegant bent bench with a canopy; it looks more interesting and at the same time safer for children’s games.

A tall frame made of profile pipe will need to be attached to the ground base

In addition to design and purpose, you have to take into account that a bench from a profile pipe for a dacha is made with your own hands, taking into account the covering on which the furniture will be located. For example, if a bench made from a profile pipe in the garden will stand on soft ground, then it will have to be made with “ski” or solid supports.

Otherwise, the bench will constantly sag and sink in soft soil. For compacted soil areas, you can use ordinary metal “spots”.

Advice! If there are no specific preferences, then the best solution would be to make an ordinary homemade bench with a back from a profile pipe. Simple and reliable.

Bench model with correct seat angle and front edge hemming

Recommendations for choosing material

When purchasing a metal pipe with a profile section to build a future bench, pay attention to its profile, wall thickness, and the presence of a welding seam.

Pipes have different cross-sectional configurations

According to the cross-sectional profile, the cross-section of the pipe can have the following shape:

- square;

- rectangle;

- oval of traditional shape;

- oval with flat sides.

An important parameter is the wall thickness of the profile pipe. For example, a rectangular pipe measuring 40x20 mm can have a wall thickness of 1.2 to 3 mm. The wall size affects the cost of the material, the weight of the finished product and corrosion resistance. In addition, welding thin-walled pipes requires certain qualifications to perform welding work.

The use of a profile pipe with a cross-section of 40x20 and a thickness of 2 mm will ensure high strength and long service life of the bench.

Such a product can be used outdoors painlessly for more than 10–15 years.

Profiled pipes are produced using a seamless or electric welding method. Manufacturing is carried out by hot or cold deformation. The technology for manufacturing profile pipes is not important when choosing a material for making a bench.

Bench without backrest

Making this product yourself involves welding three steel rectangles and connecting them with two guides. Instead of wooden slats, you can use rectangular pipes. Then the task is simplified even more; they are attached to the frame by welding, after which the entire product is covered with anti-corrosion paint. To make a garden bench look more aesthetically pleasing, it can be placed in a metal frame that hides sharp corners.

- If duralumin pipes are selected, connect them with bolts.

- When deciding on the mounting bolts, pay attention to their heads. For the seat, it is permissible to use bolts only with a rounded and flattened head. Otherwise, the clothes of everyone who wished to rest on the bench would be at risk.

- The bolts can be sunk into the wood (if you chose a seat made of wooden fabric), however, the wood at the fastening site will become more vulnerable.

- Longer sections of the bench supports are placed horizontally, and shorter sections, respectively, vertically.

- The corners of the supports are welded at an angle of 90°.

- All dimensions of the bench that the drawing shows can be changed. However, when lengthening the product, do not forget about the need to increase the number of supports.

- Don't forget to clean and prime all seams after welding.

- When the supports are connected into a frame, holes are drilled symmetrically on them for attaching each wooden block.

Product details:

- Profile pipe (section 30 by 30 or 25 by 25);

- 2 pieces of 2.3 meters each (long parts of the seat, fastening the supports);

- 6 sections of 0.6 meters each (long parts of rectangular supports);

- 6 sections of 0.45 meters each (short parts of rectangular supports).

A total of 10.9 meters of pipe will be required, from which blanks are cut. If a metal frame is being made, add another 1.2 m of pipe. Rectangular bars (8 pieces) 6 cm wide are made from wood. Connecting them to the frame will require 24 bolts and nuts.

Please note: wooden blocks are varnished or stained in advance, and their fastening to the frame is done last.