Such structures are considered to be fundamental and reliable. That is why many owners of private houses, cottages, and summer cottages prefer brick fences, or fences using fundamental structures. During the manufacture of such a modification of the fence structure, the support pillars are prepared from brickwork, and the space between them is filled with other materials, depending on the wishes of the customer and the required operating conditions of the fence.

Such designs look fundamental and reliable. In addition, building a base and supplementing it with other materials is much more economical than making a complete one. Such work is not cheap due to the relative simplicity of its execution. Of course, the work is very painstaking and technologically advanced, but you need to follow the technological processes; the frames are made independently.

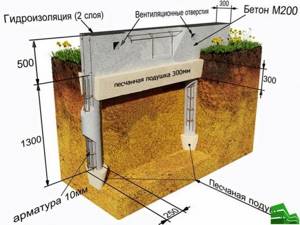

First you need to organize the foundation. The process determines a number of circumstances that influence the construction of the fence. For example, soil plays a very important role. If you make driven piles, then a pile foundation is needed for each individual column. You need to dig a hole to the depth prescribed by GOSTs and bury a pile. There are different types of soils, groundwater fills at different heights.

So, for clay or loam containing high water, twenty centimeters below the freezing level is enough; inside sandy loams and sands, a pile literally eighty centimeters deep is buried. Due to good moisture permeability, it passes through the soil, accumulates minimally, is retained inside, the excessive depth of the stable structure. This concept saves time and money for the customer. What the foundation will be like is additionally influenced by the expected total load of the structure, because all materials weigh differently: corrugated sheets are light, forging is heavy.

The standard technology for manufacturing a pile foundation is determined by compliance with the following parameters:

- The well must have a diameter of more than 30 cm, due to the considerable cross-sectional diameter of the future pillar. The wider it is supposed to be, the stronger the support itself.

- After assessing the nature of the soil, a well was drilled to the required depth, and finely ground crushed stone was poured down as a reinforcement layer.

- The crushed stone is trampled, compacted, and the hole is made with smoother edges.

- Next, a pipe is inserted into the recess, around which the main building material will be laid. An important point in the process is that the pipe must be strictly vertical. Sometimes special spacers are made, additional “shoots” are welded to the main pipe, which fix a stable position in the pit. Some soils require the creation of additional frames, for example, heaving soils after winter. This is one of the most “floating” types of soil, so it is important to fix the base well, otherwise it will “float” in a couple of seasons.

- The top of the structure is additionally filled with concrete. It is important to understand: these works require M300 grade concrete, because cracking and peeling are unacceptable. It is unnecessary to pour concrete around the edges; it is enough to fill the hole to the edges and leave until completely dry. Only after the concrete has “set up” do construction work continue.

A strong frame must be supported by appropriate pipes, which will add rigidity to it. In addition to thickness and cross-section, length parameters are important. It is simply calculated, because it consists of a length that is buried in the ground, filled with concrete, remaining superficial, and holds the entire brick structure. The upper section does not have to reach the top; a height of 50 cm shorter is sufficient. The ratio of the height of the fence with the subsequent hanging of a gate or even a gate is important; the stronger the post, the higher the column should be made. Installation using a strip foundation is also possible. Most typical are regions with difficult soil for construction, strong winds, or if the fence is planned to be made entirely of brick, the load increases than when using other materials. During the manufacture of a strip foundation, the bottom of the pit is laid with a special metal strip that looks like a lattice, only with thinner rods. It kind of holds back the soil and strengthens the foundation. The depth is different, if the structure is installed as strong as possible, 1.5 meters will be more than enough, the strip foundation of the house is buried at an almost identical depth. Next, everything is done according to technology, the pipe is inserted, filled with concrete, also until completely dry.

Technique for building brick fence posts

The solution is made from sand, a loaf, the proportion is 5:1. It is better to mix fine-grained sand, high-quality cement, for example, M300, M400, preferably higher. A little secret for builders is adding dishwashing liquid and liquid soap. This way the solution will be more plastic and viscous. One bucket - you will need about 30 grams.

Visibility is an important characteristic of the required consistency. The aggregate that is too dry will crack, the piles in it will not last long, and the quality of the foundation is very low. Too liquid is also not good, in addition, it is more difficult for them to work. Before starting work, builders check the mortar liquid: spread a little on a flat surface, draw a cross, if it is stable, then the quality is good. Liquid compositions take longer to harden and, due to the excessive water content, also have low strength.

If the pillars are made of white brick, builders sometimes add construction soot to the cement solution; it is sold in bags in stores. This color will be black and is used as an additional decorative element, because gray fills look ordinary. Similar options are often used with white pillars and black wrought-iron gates, so as not to disturb the color integrity of the composition; it looks very impressive and replaces subsequent painting.

Bricks use any, different sizes, markings. There is a concept - freezing and defrosting cycles. The more of them, the better, but in principle any will do. The important point is size. The average discrepancy is 2-3 millimeters, but materials of different sizes are found. When building a house, it doesn’t matter, one way or another they are cut, the work is less precious. The distance between the rows is small; you need to choose the same sizes, or at least very similar ones. This will greatly simplify the work; there is no need to additionally saw off the length with a grinder. Therefore, a very important principle is the minimum discrepancy between acceptable dimensions.

Preparatory work

Like any work, installation of fence posts requires preparation, that is, you need to prepare the components for making masonry mortar, and tools, in particular, a trowel, a level, and a tape measure. To obtain the mixture, a steel sheet and shovels are required.

Before starting installation, you need to prepare a solution. That is, on a steel sheet it is necessary to mix 1 part of M400 cement and 5-6 parts of sand. Water is added during mixing. Some craftsmen add a certain amount of washing liquid to the resulting mass; this additive adds plasticity to it. Mixing is carried out until the desired consistency is obtained.

Expert opinion

Vladimir Ulyanov

I have been involved in fences for over 10 years, answering questions and helping people cope with the installation task on their own.

Ask a question to an expert

To give the masonry a pleasant appearance, coloring pigments are added to the solution; they are purchased at a hardware store.

Brick selection

The main task that builders have to solve when building a fence is to choose the right brick for the posts. It must be durable, reliable and consistent with the aesthetics of the building.

On the construction market you can choose from the following types of bricks:

- red;

- facing;

- silicate;

- fireclay;

- clinker.

The classics include silicate and ceramic. To make the first, quartz sand is used, for the second, clay, pressed and annealed under given parameters. Among the main properties of bricks is the number of periods of defrosting - freezing. Clay brick is inferior in this to silicate brick, which can withstand up to 60 periods.

Useful Construction of a fence for a private house and cottage from sand-lime and facing bricks: step-by-step instructions

Calculations

Before starting work on building a fence, you need to calculate the exact amount of material used. Most often, the row is laid out so that four bricks are needed per layer.

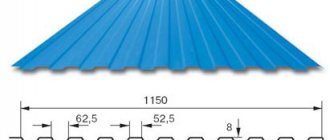

The typical cross-sectional size of a fence post is 120*250 mm. With the chosen type of installation, the side size is 120 + 250 + 10 = 380 mm, where 10 is the thickness of the cement. Taking into account the thickness of the cement salt between the laying layers, for the construction of racks 2 meters high, 108 pieces will be required.

When performing the calculation, it is necessary to take into account that the bottom 3-4 rows are made of solid stones. This is required so that the support has greater mass and durability.

Did you manage to complete the calculation?

Not really

Preparation of solution: proportions

To obtain the mixture, sifted sand and cement are used, preferably grade m - 400. The solution recipe includes 1 part cement and 5 parts sand.

In the process, sand and cement are mixed in a dry state and after that, water is added to the resulting mixture. The resulting mixture should not spread over a flat surface, but should not be excessively dry. After its preparation, the construction of the fence with pillars begins.

Pouring the foundation

To build a fence with brick pillars, several foundation options are used, for example, columnar or strip. To construct the latter, you need to prepare a trench and formwork

The foundation for the fence is poured in layers, the thickness of one layer is 150-200 mm. Pouring the next layer is permissible only after the bottom layer of the mixture has been laid and compacted. To seal, it is permissible to use a mechanical seal or use an entrenching tool.

Laying a fence with brick columns

The usual fence masonry is made of one and a half to two bricks with a cross section of 380*380 or 510*510, respectively. The height is less than three meters. The standard seam is placed up to ten millimeters. The technology is often carried out with an offset, the so-called dressing, when it is overlapped, that is, the seam of the lower row is covered by the body of the upper one, the row is repeated from bottom to top. This rincis is the most durable, reliable, simple.

First, the foundation is prepared. Cut-off waterproofing material is laid on top. There are different options; it is much better to lay roofing felt in two layers at once, of greater density. Waterproofing with bitumen mastic is best suited; the brick will be securely fixed. Moisture will not penetrate inside, it will last much longer, and will be fixed better. In the summer, when groundwater approaches, especially in flood-prone regions, which are not properly waterproofed, they collect moisture inside themselves. They are located at a decent depth, even if the moisture dries out, it does not dry out completely, so the brick will remain wet. In winter it is frozen. After several cycles it will lose its strength, break and crumble. Therefore, it is necessary to waterproof the foundation.

A good replacement for rolled waterproofing is bitumen mastic, which is used to coat the base several times. It is better to immediately waterproof foundations located in damp soil with mastic or waterproofing tape.

A solution approximately 1 centimeter thick is applied on top of the waterproofing, and bricks are laid directly on top. They need to be well aligned, from the side, from above. It is advisable to do this by tapping with a special rubber hammer. Excess cement is removed to avoid cement smudges and bulging places, otherwise the effect of excess will appear, as if the mortar is falling out of the bricks. The masonry is initially not only smooth and durable, but also beautiful and neatly made. Otherwise, a beautiful fence, for example, made of forging, will look ridiculous despite the high cost of the structure.

Bricks are completely different in composition and absorb moisture in different ways. Ceramic absorbs all the moisture around, they need to work as quickly as possible, otherwise it will be very difficult to locate it in the right place. The mortar also tends to dry out, so the process is carried out as quickly as possible: the brick is dipped in water for just a few seconds, after which it is placed on top of the mortar, which retains its elasticity better during such manipulation, then the excess cement base is immediately wiped off from above the surfaces; a dry rag is quite suitable.

Next, the rows are laid one by one in the same way as the first: first, a layer is leveled over the surface, then the bricks so that the seam overlaps, that is, overlapping, they are leveled on the sides, the excess is removed, the residue is wiped with a dry cloth (if this is done later, the cement will then be difficult to wipe off). Be sure to periodically check the evenness of the dimensions with a tape measure; it is important to initially eliminate all displacements, even the smallest of a few millimeters; if displacement begins, then the whole structure will go crooked. The rows are tapped with a hammer so that they are closer to each other. The rows are laid similarly to the previous ones, evenly, firmly, without excess, maintaining distances. This type of masonry is suitable for more experienced builders; it will be difficult for beginners to maintain evenness, parameters, and dimensions.

The frame pipe is thinner than the masonry itself, so a void is sure to form inside. You cannot leave it, you will have to fill it out. There are two main filling options.

- A small cavity is filled with cement-concrete mortar, which is used to make the masonry itself. The filling is very durable, but it will not be cheap.

- If the void is large enough, it is better to reduce the cost of filling: pour coarse crushed stone, fill it with concrete-sand mortar, liquid enough to seep between the stones to the very bottom.

Sectional fence posts

The laying of a post for a sectional fence is carried out after installing a metal support from a profile or round pipe. Essentially, the pipe is lined with brick. Typically, the masonry is done in one and a half bricks (including the seam, the thickness is 380 mm) with each subsequent row offset by half a brick to bandage the seams. The resulting space, in the center of which there is a metal pipe, is filled with concrete. As it is erected, metal plates are welded to the pipe at the level of installation of the logs, which are embedded parts for the subsequent installation of sections.

The upper part of the column can be made with fluff. To do this, when laying the last 2-4 rows, the bricks are laid offset outward from the center, and a part of the brick cut to size, taking into account the seams, is placed in the resulting gaps in the center on each side of the column.

It is necessary to take into account the laying of electrical cables in a timely manner if the installation of lights, a surveillance camera, a bell, an intercom or a gate drive is provided on the poles. The cable is inserted into a metal pipe before laying, otherwise it will be impossible to do this later and the wires will have to be run outside the supports.

Pillars made of red ceramic bricks KR

KR masonry brick of standard format 1 NF 250x120x65 mm is usually used for laying the walls of a house and in the recent past has been widely used for the construction of enclosing structures and pillars in particular. Today, such pillars are a thing of the past, since their appearance is greatly affected by stains, efflorescence and unevenness of this brick. Moreover, this is the cheapest material, and its laying is done using a simple sand-cement mortar, which is also inexpensive.

Nevertheless, the structure made of simple masonry bricks has not outlived its usefulness, but, on the contrary, with the use of cladding it has acquired high attractiveness. For cladding, sandstone, clinker tiles and other materials are used that increase the aesthetically attractive appearance of the structure. Based on the fact that the masonry will ultimately be hidden, it can be done in any way that will ensure reliable dressing of the seams. You also won’t have to fill out the seams, and all unevenness will be smoothed out with an adhesive solution during cladding.

Sand-lime brick pillars

Sand-lime brick is characterized by increased strength and a smooth surface of the dowels and dowels, so structures made of this brick without cladding have a fairly neat appearance and remain relevant. In addition, the material is produced both white and colored (decorative), which allows you to create a mosaic pattern. Masonry mortar is also used, the most common one made from a mixed cement-sand mixture in a proportion of 1/3-1/5, depending on the brand of cement. The peculiarity of the masonry is special care, and the technology depends on the future jointing.

The jointing is carried out immediately before the solution has hardened. To achieve a contrasting highlight of the seams, you can use black or other special jointing solution for jointing. In this case, the masonry will have to be done using special markers so that the seam to a depth of 1 cm remains empty, and filling and jointing must be done after the masonry mortar has hardened.

Pillars made of facing CL or clinker bricks

Today these are the most popular fencing supports, which have already become the hallmark of luxury cottages. Fences with brick pillars are often combined with forging, and a wide choice of designs adds a touch of uniqueness and self-expression to the design.

Facing ceramic and clinker bricks are similar in operational and aesthetic parameters, and the masonry technology is the same. It is only worth noting that clinker is stronger and more durable, but more expensive. Decorative facing brick KL (with relief, torn) is often made by hand molding and in this case its strength is reduced.

Typically, the masonry is made of one and a half bricks - this is the minimum thickness when lining a metal pipe. If desired, you can build a support that is thicker, but for a sectional fencing structure this will create an unnecessary bulky effect and will negatively affect the aesthetics of the structure. In addition, the costs of materials and, accordingly, the cost will be significantly higher.

Laying brick pillars under rods

If the simple masonry described above works better with professional builders, or at least those who have already been involved in brick work can quickly navigate the actions, then beginners use the technology of masonry under the rod. I use a rod diameter of up to ten millimeters. Pieces up to fifteen centimeters larger than the size of the pillar itself are laid immediately after the first row, the area is filled with mortar, with a small excess at the edges, after laying the second layer of brick, the excess is removed by cleaning the rod. The rows are also leveled; the other edge is held back by a rod. They also level the side, removing excess mortar along the rod. After the level is level, press the seam from above with a trowel, and then pull out the rod. Lay out row by row. The technique is accessible even to beginners; it is easier to keep track of the seams and make the masonry more even. It is important to control each row, take your time, but try to do everything as quickly as possible.

Masonry technologies

In practice, two options for laying supports under fences are used - standard and under rods. Traditionally, 4 stones are laid in a row.

Standard

A layer of hydraulic insulation is laid on top of the foundation for the fence. It is required to prevent saturation of the base material with moisture coming from the ground. Hydraulic insulation is made using sheets of roofing felt, or mastic.

The first layer of brick is laid on a layer of mortar laid directly on the waterproofing. The layer thickness should be slightly more than 10 mm. The stones are laid out according to the masonry pattern. The installed bricks are aligned in space.

To make laying brick easier, it is dipped in a bucket of water. The presence of moisture on the surface allows the solution to retain its plasticity longer.

The second layer is laid according to the same scheme, on the surface of the first layer, a layer of mortar is applied and bricks are installed, but with dressing. That is, the seams of the lower layer overlap. After laying the row, use a tape measure to control its dimensions. The bricks are moved using blows with the back of a trowel.

A void is formed between the reinforcement installed in the rack and the masonry, which requires filling it with mortar, crushed stone and pouring the mixture.

Under the bar

The masonry of pillars described above has been used for many years, but those who do this work for the first time find it difficult to obtain a high-quality seam. To simplify, we came up with the following method. To implement it, you will need a steel rod with a square cross-section with a side size of 8-10 mm. Its length is 100-150 mm longer than the support.

Useful Features, types and advantages of concrete fences from sections for fencing a site

The sequence of operations is as follows:

- As soon as the first layer is ready, a rod is laid along the edges of the brick pillar. The resulting patch is filled with a cement mixture, and on the side of the central pipe the layer of the mixture is slightly thicker. After this, you can lay the stone. The installed rod will prevent it from falling down.

- Then, you need to install the rod in a vertical position, it is installed from the side of the butt, a solution is applied to the side surface of the brick and it is leveled. Of course, all manipulations are accompanied by control of the location of the stone in space, and with the help of a tape measure, it is necessary to constantly monitor the size of the support.

According to this scheme, all the stones are installed in a row. Using this method allows you to lay even rows of masonry with your own hands.

Which technology did you like best?

For rod Standard

Problems when laying brick fence posts

The main problem that arises is gradual twisting and changes in size. Occurs due to lack of control, non-compliance with dimensions, poor work with the level. So, for beginners, the top rows often turn out wider than the bottom ones; to avoid this, you need to control each row. Since the usual level is less than 80 centimeters long, the height and width of the rows are additionally controlled with a regular tape measure. Sometimes planks are specially made, for example from plywood, and applied to the rows, checking the evenness. Templates will also help to avoid twisting, when the corners of each row gradually twist around its axis from bottom to top. It may be less visually noticeable, but fastening a plank to an uneven post is a problem, it is almost impossible; all posts should be made even.

Filling the fence frame

Filling with metal and brick elements requires horizontal pillar fastening structures. This point needs to be thought through in advance. It is important what kind of fasteners there will be; they make lugs, corners, and strips. The types of fasteners determine how the fence will be filled. The main thing is the horizontal arrangement of the same distance, corresponding to the location of the fastening elements of the gate itself, the main condition is that they must be ready.

The final element of a brick pillar is a cap. It is necessary to prevent precipitation from getting inside the column. They are completely different, depending on the design of the gate: metal, concrete, sometimes they are laid out with their own hands from the remaining material, according to the customer’s decision.

Brick posts are the strongest frame, regardless of the type of gate filling. The main thing is to do the right masonry and organize a decent foundation. Gates of this design will last a long time.

How we build brick pillars

If you are a skilled mason, you can make your own brick fence posts. For everyone else, we recommend ordering their construction from a specialized company, because this requires precise engineering calculations and extensive installation experience. We build brick supports like this:

- Making the foundation Our installers arrive at the site at the agreed time. If you plan to make a fence with a strip foundation, first prepare a trench 380 mm wide and pour concrete M300 on top of the sand cushion. All details of the process can be found in the section “Reliable strip foundation for a fence.” If a monolithic base is not needed, workers immediately proceed to the second stage.

- We install metal supports. At equal distances, the builders drill holes 1.5 meters deep. This is done inside the trench under the strip foundation or simply by marking if the fence does not have a concrete base. Metal pipes with a cross section of 60x60 mm are installed in holes measuring 380x380 mm, which will become the basis for brick pillars. The pits are filled with concrete and compacted, the surface is carefully leveled.

- Laying the brick When the concrete has dried, the installers will weld the joists to the support pipes and make the cladding with brick of the shade and texture you need.

It is advisable to cover the tops of the posts with special galvanized caps to match the main color of the fence. They will protect the structure from damage due to precipitation. The supports are ready. All that remains is to sheathe the fence spans with the selected fabric, install the gate and wicket.