- Pallets: raw material or material?

- What can be made from pallets?

- Ideas for crafts and furniture made from pallets, video

- In the garden and at the dacha

- About tilting the backrest from the pallet

- DIY sofa made from pallets, video

- Kitchen furniture made from pallets

- To the house and apartment

- Video: bed made of pallets in loft style

- What types of pallets are there?

- How to make furniture from pallets?

- Disassembly

- Toning

- Grinding

- putty

- Assembling modules

- Tables

- What not to do

- Is it just furniture?

- Video: garage made of pallets

- Video: pool made of pallets

Furniture made from pallets : photos, videos, diagrams, drawings. Furniture made from pallets today has moved from objects of amateur hobby and design delights to the category of industrial products. But many home craftsmen and individual entrepreneurs continue to do it: it’s cheap, profitable and useful to everyone. Furniture, and not only furniture, made from cargo pallets (pallets) is a rare example these days of a heavily promoted trend, in which fashion trends are organically combined with practicality and benefit.

Why is pallet furniture so popular? Freight pallets are produced in the millions and are used mainly for transporting construction materials and piece goods. This is justified both economically and environmentally: without pallets, compensation for waste for waste, damage to packaging, etc. would require costs of raw materials, production capacity and funds many times greater than for pallets. The materials (mainly wood, see below) used for cargo pallets are of high quality, but the service life of the pallets is limited: for example. when loaded with working bricks at the full rate of 1 t/sq. m – only 1 transportation cycle; although in reality pallets go up to 3-5 cycles.

What to do with used cargo pallets?

As a result, wholesalers accumulate mountains of pallets (see figure) awaiting inspection or sending for processing, and in many self-built buildings or small contractors, excellent seasoned wood, the manufacture of useful things from which is available at home and virtually free, goes to the landfill. Pallets, conditionally still suitable for their intended purpose, but not trimmed, can be purchased at a price 2-3 times lower than the same cubic capacity of industrial pine. Wholesalers will be happy to sell pallets waiting in line for disposal for pick-up. As for small contractors, the typical answer to a request is that there are no pallets? - like: “Pallets? Come on, take everything to...! Just everything at once! Isn’t it necessary to break bricks and tiles?” Such generosity is quite understandable: used pallets are a flammable material, littering the area near buildings of any kind is prohibited, and warehouses/dumps for cargo pallets must be located and equipped in accordance with all fire safety rules. The fire inspectorate, as you know, if they notice a violation, they won’t blame you.

As a result, tinkerers can get excellent material literally for free and in any required quantity.

Pallets: raw material or material?

To make furniture from pallets with your own hands, you do not need any special skills or complex tools: each pallet itself is a ready-made, durable assembly unit of convenient sizes for everyday life (see below).

But, unfortunately, many examples of homemade products from pallets serve as clear examples of how good, strong structural modules turn into not very strong, or even downright bad, things. The fact is that a cargo pallet is not just a set of pieces of wood, but a material in itself with certain properties that requires some specific technological techniques. They are not known not only by “paper experts” who write something like: “Pallets stacked on top of each other (of course, secured with screws) with a soft mattress can serve as a bed.” But what and how to do with pallets is not described in the manuals on carpentry and wood processing. There is no such officially recognized craft material as a used cargo pallet; there is also recycled wood raw material. Therefore, a significant part of this publication is devoted to rational methods of working with pallets, described randomly in various sources and tested in practice by experienced furniture specialists and, in part, by the author of this article personally.

Financial calculations

Before starting to manufacture a product, it is necessary to calculate what costs will be incurred and how quickly the investment will pay off. The big plus of the idea is that at the first stage, expenses can be minimized.

Start-up capital

| № | Name | Price, rub.) |

| 1 | Organizational expenses (enterprise registration, payment of state fees, website creation, etc.) | 5000 |

| 2 | Rent of production and warehouse premises | 25 000 |

| 3 | Purchase of necessary equipment and tools | 30 000 |

| 4 | Salary for 3 employees based on the minimum wage is 9,489 rubles. | 28 467 |

| 5 | Purchase of pallets, consumables and accessories | 10 000 |

| Total | 98 467 |

Thus, at the initial stage, you will need about 100,000 rubles to start production and 65,000-70,000 rubles to cover the expenses of the second month. From the third month, the business should already reach self-sufficiency.

Monthly expenses

Monthly expenses will consist of:

- rent;

- utility bills;

- salary expenses;

- purchase of pallets and materials;

- advertising and promotion costs.

Total about 65,000-70,000 rubles.

How much can you earn

Earnings depend on what kind of furniture you plan to make, and how soon customers will become interested in the offer. In the first months, the profit will be low, since part of it will be spent on additional advertising and repayment of investments. Then earnings increase. Approximate amounts of earnings on types of furniture can be seen in the table.

| Type of furniture | Earnings (per unit of goods) |

| Small items (chairs, coffee tables, coasters) | 2000-4000 rubles |

| Tables | 5000-10000 rubles |

| Beds, wardrobes | 10000-20000 rubles |

Payback period

Start-up costs should be recouped within 3-4 months. The period can increase to almost six months if you purchase all the necessary equipment at once. It rarely exceeds 6 months, especially if you don’t forget about investing in promotion and finding buyers.

What can be made from pallets?

There are so many ideas for furniture made from pallets on the RuNet that just listing them would require more space than is allowed for this article. Some of them are shown in the photo; eg home bicycle parking made from pallets is simply simple, convenient and not so trivial.

Useful things from pallets

For more on crafts made from pallets, we suggest watching the following video, and we will then move on to things the creation of which from pallets requires a more thoughtful technical approach.

Ideas for crafts and furniture made from pallets, video

Financial calculations

The financial section of the business plan contains specific numbers and calculations, based on which it is easy to determine the profitability and payback period of investments. Let's analyze the data using the example of a small workshop located in a rented garage, where 1 carpenter, the owner of the business, works.

Investments in the project

At the start you will have to spend money on:

- individual entrepreneur registration – 800;

- purchase of tools and consumables – 30,000;

- purchase of pallets – 5,000;

- advertising – 20,000.

Total: 55,800 rubles.

Current expenses

Every month the entrepreneur will spend funds to support the project and its promotion. This includes expenses for:

- garage rental – 5,000;

- utility bills – 1,000;

- advertising – 10,000;

- tax deductions – 6% of income;

- purchase of pallets – 30,000 (working capital).

Total: 46,000 plus tax.

Income and profit calculation

It is quite difficult to calculate the average bill when it comes to selling various furniture. For example, income from one chair can be 2,000, from a table – 3,000–4,000, and from a bed – 8,000–10,000 rubles. At full load (200–250 products per month), the entrepreneur will receive revenue in the range of 100,000–120,000 rubles.

Let's make calculations to find out how profitable it is to produce furniture from pallets:

- 120,000 x 0.06 = 7200 – tax deductions;

- 120,000 – 7200 – 46,000 (current expenses) = 66,800 rubles – the entrepreneur’s net profit for the month.

Business profitability

To calculate profitability, you need to compare the company’s net profit and dirty income:

66,800/120,000 x 100 = 55.6%.

The business of producing furniture from wooden pallets is highly profitable. However, it will not be possible to reach such indicators immediately; first, you will have to work hard in search of distribution channels. The average payback period for investments is 3–4 months.

The idea of starting your own production of furniture made from pallets is economically feasible and attractive. The main criteria for success are the ability to think creatively and produce high-quality products. Having earned a good name, the entrepreneur will begin to receive a large number of orders within a few months, so he will have to think about expanding production.

In the garden and at the dacha

Most often, garden furniture is made from pallets: wood, even painted wood, harmonizes well with living greenery. Pallets are made from rot-resistant wood; After biocidal and hydrophobic impregnation and painting/varnishing, such furniture can serve outdoors for years. A cheap biocide and at the same time a water repellent for street furniture made from pallets is used motor oil. Oil-based, alkyd and nitro varnishes and paints adhere firmly to treated wood. If the product will be painted/varnished with acrylic compounds, then the wood must be impregnated with a water-polymer emulsion. It will cost a little more, but health care and ecology are ideal.

Country and garden furniture made from pallets

You can get a useful hanger-rack for your dacha by simply hanging a sanded painted pallet on the wall, pos. 1 in Fig. By the way, you also need to be able to sand “hairy” pallets, see below in the technological sections. If you add 2-3 100 mm card loops, a couple of hooks in the wall, 2 pieces of rope or chain and a window latch as a lock to the same solid pallet, you will get a folding work table instead of a tool hanger. It is very convenient to tinker with seedlings, soil mixtures and potted crops on this: the spilled material falls down and does not clog the work surface.

Another option is to also place the solid pallet upside down and secure it with L-shaped pins. The pallets are designed to carry weights of many hundreds of kg, and the 3-4 concrete blocks that make up the tabletop, left over from paving the path, are not a load for them. But we have a compact work table that can, without modification, turn into a bar counter on the street, pos. 2. Well, sometimes, out of the blue...

Country furniture made from pallets for gazebos and verandas, pos. 3 and 4, most likely, will require dismantling the pallets (see below) to obtain moldings: long materials - boards, beams, baseboards, moldings. Tables, chairs, stools are made quite like carpentry, because... furniture made from solid pallets or parts thereof is quite bulky. However, it’s not difficult to make a table or stool with your own hands, as long as the material is good, and you can get plenty of it from pallets. Something that is more technologically complex (a sofa, a bench) made using traditional methods is also cumbersome; in this case, pallets will allow an inexperienced beginner to obtain a high-quality product, similar to garden furniture.

A relaxation corner in the garden is the perfect place for furniture made from pallets. Its dimensions and weight are not as important here as the endurance of the pallet. It is technologically possible to make furniture from pallets for the garden in different ways (items 5-8), but in any case the problem of tilting the back arises, which is discussed further in a separate section. If the back is straight, then comfort is achieved with pillows that need to be taken out/brought in and saved from the rain.

Note! Pay attention to pos. 5, not everything is so simple there. Namely, the armrests of the sofa. Finding a vessel with a drink in such a niche is no more difficult than on the armrest, but accidentally knocking it down is almost impossible.

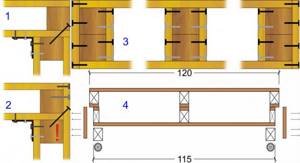

Finally, it’s worth taking the trouble to completely disassemble 2-3 pallets in order to make a picnic set: a table with benches. It can be located in a gazebo, pergola or outdoors. You can move the picnic corner together or even alone: the weight of the finished structure will not exceed 25-30 kg. What a 4-seater picnic table with benches looks like is shown on the left in the figure; drawings of its supporting frames are given there on the right. The length of the tabletop and benches is standard for Euro pallets, 120 cm. By connecting a pair of pallets for the tabletop, as described below, it can be increased to 240 cm, and the capacity of the product up to 8 people, without adding support frames. Connections between legs and cross beams are made with M8 through bolts.

Appearance and drawings of a picnic table or gazebo made of pallets

About tilting the backrest from the pallet

The backs of furniture made from pallets, such as those left and center in the top row in the figure, turn out to be fragile. In the first case, the steel screws in the fastening units work in shear and gradually tear the wood. In the second, this happens even faster, because The ratio of the lever arms when reclining is large. The same circumstance applies if the backrest angle is obtained by sawing off part of the seat tray with excess (orange arrow at the top right). The fastening unit (yellow arrow there) now works in tension, but the turning lever is still long and the screws are gradually creeping back.

The backrest design shown below on the left is quite reliable. Here 2 thick trees (pieces of timber) rest against each other and work for compression, which the wood holds well. Using the same method (compression work), you can strengthen products that are more openwork (in the center at the bottom) or more loaded (at the bottom right) by placing spacers or support posts. For a chaise lounge made from pallets, it is better to make them adjustable by making the nodes shown by blue arrows, hinged on bolts and cutting holes in the lower supporting frame for the heels of the rotating posts.

Important! However, the required overall strength of furniture made from pallets can also be achieved using tensile stiffeners. See eg. Below is a master class on making a sofa from pallets. In this case, these are armrests.

Kitchen furniture made from pallets

One varnished tray in the kitchen can serve only or mainly as a decorative element (see figure on the right), because natural wood fits perfectly into almost any kitchen interior. However, most often kitchen furniture made from pallets is made fully functional, here again the strength and durability of the material plays a role.

Technologically, the simplest are various kinds of hangers, shelves and minibars, pos. 1-4, 6 and 7 in Fig. below. Not much more complicated, but much more beautiful and suitable for zoning a living space, a bar counter made of pallets, pos. 5. The main thing here is how to tint the boards of the tabletop; we’ll figure this out later.

Kitchen furniture made from pallets

A rack made of pallets (item.)

The situation is interesting with tables made of pallets, dining and cutting tables, pos. 10 and 11. Usually in tables the tabletop is heavily loaded, which places special demands on the quality of its manufacture. But a strong supporting structure made of pallets provides a reliable basis for any countertop (glass, stone, etc.) or stacked tabletop. The latter can be assembled with your own hands from boards and beams from disassembled pallets, see below.

To the house and apartment

Furniture made from pallets has a unique appearance, so when designed for a home, it must match the style of the interior design, which is not always possible. For example, a bed made of pallets will fit perfectly into the now fashionable loft style, but with rustic styles there will most likely be an aesthetic inconsistency, even though the bed is wooden.

Video: bed made of pallets in loft style

However, aesthetically universal options for making furniture made from pallets are possible if the product is relatively small, does not dominate the setting compositionally, and is equipped with some details that create visual transitions from the visually rough “core” of pallets to the overall decor. As an example, we can cite a work table that fits into an apartment of almost any design, except for frankly pretentious styles (empire, baroque, shabby chic, etc.), see figure:

Desk made from pallets

The connecting links in this case are the legs of a geometrically correct shape, but painted in a contrasting color to the tabletop and the surrounding color. The utilitarian advantage of this table is the spacious niches in the tabletop, where you can stuff all the necessary rubbish. This table is also well suited for the kitchen: the dimensions of its tabletop (from 60x80 to 100x120 cm) are optimal for a table in a small kitchen.

The legs in this product are ready-made, a set for kitchen tables with a postforming tabletop, but they are not attached in the standard way. The standard fastening of metal detachable legs for tables is 3 pairs of screw-threaded socket for each. However, threaded sockets for such legs fit firmly only in laminated chipboard or dense fine-grained wood, and are easily broken out of soft coniferous wood. Therefore, the frames of the legs of this table are fastened with 6x80 self-tapping screws at the attachment points located on the timber and through M6x (40-45) bolts to the boards. Washers with a diameter of 30 mm or more are placed under the nuts of the bolts. Standard fastening pairs will be useful to a craftsman for something else.

Advertising and Marketing

No matter how trivial it may sound, in the business of selling furniture from pallets, the main task is to find a client. Since furniture is made according to individual projects, and the demand for it has not been formed, this will be much more difficult to do than for ordinary furniture. Although the launch is much cheaper. It is also necessary to take into account the fact that the visual part of pallet furniture is specific, so owners of private houses and dachas will buy it more often than residents of apartments.

The following tools will be used in the work:

- Creating groups on social networks and creating a small online store based on them.

- Placing advertisements on sites such as Avito.

- Installing a sign over the garage.

- Distributing leaflets in public places.

- Posting advertisements in the private sector and at dachas.

We will spend about 20 thousand rubles on all this in the first month and then we will spend 10 thousand rubles every month to maintain advertising activity.

What types of pallets are there?

Let's first get acquainted with the types, structure and sizes of cargo pallets. This will be needed, firstly, to calculate the quantity required for this work. Secondly, to competently develop your own design from pallets. Among the latter (see also at the end) there are those that allow you to achieve 30-40 times savings in money (!) and a 3-7 times reduction in labor costs compared to standard analogues.

Types of cargo pallets

A single-deck, 2-way cargo pallet (items 1 and 6 in the figure) is the same age as the Egyptian pyramids. At least its first images are known from the time of their construction. Modern Euro pallets (items 2 and 7a) are made single-deck, 4-way. See below for more details, because... These are the ones you will most likely have to deal with.

Note! “two-way” and “four-way” in this case means the number of ways to supply slings under the pallet deck during rigging work.

2-layer, 2- and 4-way pallets (pos. 7b and 7c) are produced in limited quantities for heavy concentrated or especially critical loads and are rarely available, as well as reusable plastic (pos. 3 and 4) or metal pallets (pos. 5). Worn-out plastic pallets make a good “green” driveway to the garage (lawn road), which costs 2-4 times less than the same one made from a special mesh, and metal pallets, if you happen to have them, are best sold as scrap metal - they are mainly made made of aluminum.

Sides for Euro pallets for valuable piece goods, pos. 8, they are made from good plywood. But don't try to rip the corner pieces out of them; they are driven into place with a machine like a large, powerful furniture stapler. The whiskers of the bindings sit dead on the plywood, so it is better to simply saw off the strips with the bindings.

Drawings and standard sizes of Euro pallets

Euro pallets differ from traditional freight pallets by having a deck made of boards of different widths. This simple technique made it possible to increase the turnover rate to 3-7 cycles under full load, subject to periodic revision. There are several standard sizes of Euro pallets (on the right in the figure), in contrast to the statements in most popular sources. You will most likely come across the most popular pallets 1200x800. Drawings of such a pallet are given on the left in the figure; from them you can calculate how many boards and pieces of timber will come out of one pallet.

Note! As a source of ornamental moldings, wood craftsmen are most suitable for Euro-sized pallets and domestic designs, see fig. on right. Their advantage in this quality is boards of the same section 100x25 and all pieces of timber measuring 100x100x80. It is much more convenient to work with these than with different-sized ones.

Stylish shelf for the garden, home or office from one product

From pallets you can make stylish and easy-to-use racks or shelves for shoes, flowers, etc. with your own hands.

To do this you will need to select materials. make a competent drawing, collect the necessary tools and begin the work process.

Materials and tools

The following materials will be required in the work process:

- prepared pallet;

- brushes and rollers;

- self-tapping screws, nails, screws;

- paints and varnishes.

Tools that will be useful:

- wood hacksaw;

- nail puller;

- hammer;

- sanding machine (if you don’t have one, you can use sandpaper of varying degrees of grit);

- screwdriver;

- level;

- tape measure and a simple pencil.

Drawing

Before you start making a practical shelving for your home or office, you need to prepare in advance a diagram of its assembly and manufacturing of parts . The drawing indicates the exact dimensions of all parts, options for connecting them to each other and other useful information.

The drawing of the shelving can be drawn by hand on a piece of paper, or the easiest way is to find a ready-made version on the Internet.

When drawing up the drawing you will need to take into account:

- The dimensions of the room , which will determine the size of the shelf.

- General interior of the room. It is worth noting that pallet racks fit perfectly into the following styles:

- loft;

- country;

- Provence

- Load capacity of the structure .

Here it is thought out in advance what will be placed on the shelves. If these are figurines, photo frames or other decorative items, then it can be made small. If books and various educational supplies are stored on the rack, the shelves will have to be additionally reinforced with corners.

The standard dimensions of pallet racks are:

- shelf thickness is at least 25 cm;

- length from 90 to 150 cm;

- depth – 50 cm;

- height between shelves – 55 cm.

You can make the simplest rack from one pallet as follows:

- We remove the crossbar from the pallet.

- We build in from 2 to 4 boards (shelves) at the same distance from each other.

- We polish the product.

- We process with paints and varnishes.

- We attach the finished product to the wall. To do this, we make markings on the surface, checking the accuracy of the work with a building level. The structure is hung on hinges and screwed with self-tapping screws.

How to make furniture from pallets?

Making furniture from pallets is almost never enough just by sawing the pallet into pieces. Already in the simplest kitchen shelf you need to attach boards to the bottom that form the actual shelves. There are enough boards on the same or the next pallet, but they need to be removed from there. Further, used pallets are not smoothly planed; they need to be refined externally, then firmly connected as needed and the finished item finished. In general, making furniture from pallets comes down to the following operations:

- Complete (for working material) or partial (for it and assembly modules) dismantling of pallets, including sawing. As for sawing, there is only one piece of advice: lay a film on the floor and carefully collect the sawdust. They will later make an excellent putty, see below;

- Upon request and design - tinting of blanks, including emphasizing the texture of the wood.

- Sanding (sanding) and rough putty.

- Assembling blanks into a product and final putty.

- Finishing – painting, varnishing. We will not dwell on it, because... it is no different from that for all other wooden products.

Disassembly

If you have already worked with wood, then it is better for you to consider pallets as a source of molded materials: from the same number of pallets, in this way you can get much more and more valuable things. Inquire at online auctions or special resources for prices for stacked countertops, collars or boards (serving, chessboard, etc.) made from boards or end cuts, see fig. Find out the prices yourself, because... a person familiar with carpentry and wood processing does not take their word for it.

Stacked countertops and chessboard made from pallets

However, first the pallets need to be disassembled, which is not easy: they are knocked together very tightly and the nails are most often corrugated. The caps are recessed into the wood, and just picking at it with a nail puller will ruin more boards and kill you than you will get the material. That's right, quite easily and quickly, disassembling cargo pallets is done using a carpenter's ax and a 1.5-2 kg sledgehammer:

- The ax blade is slipped slightly under the board being removed from the end, under the timber - perpendicular to the wood fibers;

- Once or twice, not very hard, but sharply, hit the ax butt with a sledgehammer so that its blade goes under the board/beam at least 1/4 of its height;

- Press down on the ax handle with your hand so that the part being removed rises by at least 8-10 mm;

- Press down the part to be removed with the butt of an ax (do not hit too hard so that the wood does not wrinkle!);

- If necessary, operations 1-3 are repeated until the nail heads come out enough to pry them off with a nail puller.

Foreign-made pallets are sometimes found fastened with self-tapping screws. It is not possible to unscrew them with a regular screwdriver; it is weak for this. The way out of the situation is simple: a bit suitable for this type of hardware (cross, hexagon, etc.) is inserted into a drill from 250 W and unscrewed, turning the tool on in reverse rotation. You cannot use a drill instead of a screwdriver to tighten hardware: the impact at the end may break the gearbox or chuck jaws (screwdrivers use collet chucks with elastic petals). But when turning, shock loads are excluded and there is nothing to fear for the tool.

Toning

Wood tinting (tinting), as is known, is done with special compounds - stains. Staining wood is a rather complicated process and requires precautions: working solutions and their components are toxic. However, straight-layer porous wood of pallets can be tinted with colored varnishes, diluted two or three times. Nitro varnishes are best; the appropriate thinner for them must be taken, for example. 646 or 647. Tones of almost the same quality are produced by water-based acrylic varnishes; they are diluted with distilled (required!) water. Oil, bitumen and oil-resin varnishes are not suitable for tinting wood. Toning wood with varnishes is carried out step by step as follows:

- Initial operations are carried out on “hairy” wood, before sanding;

- You need to work in the shade or in a shaded room at a moderate (up to 25 degrees) temperature;

- If it is necessary to emphasize the fibrous texture of wood, then before impregnation the part is passed along the fibers with a steel brush;

- The diluted varnish is applied in 1-5 layers, each subsequent one after 5-10 minutes after the previous one has been completely absorbed. The brightness and saturation of the tone depends on the amount of impregnation;

- The part is dried for at least 3-5 times until the varnish is completely dry, indicated on its packaging, so that the varnish dries in the surface layer of the solid wood;

- The part is rough sanded with sandpaper No. 120-140 manually or with a grinder in one pass to remove splinters, burrs and rough irregularities;

- Continue sanding with sandpaper No. 240-260 or finer. After each pass, the sawdust is blown off, removed with a barely damp rag, and the resulting texture and tone are evaluated. When the desired surface type is achieved, grinding is stopped.

Grinding

Before sanding, especially with a grinder, you need to additionally recess the nail heads. In addition, in order for the putty (see below) to hold firmly, the holes above the fastener heads should be no smaller than 4-5 mm. The caps are recessed using a special tool - a hammer, see fig. on right. It can be made using sandpaper from a steel rod with a diameter of 8 mm or more or by grinding off the tip of a bench punch. The diameter of the hammer pad should be slightly smaller than the diameter of the nail head.

putty

Furniture made from pallets is rarely puttied, but in vain. In Fig. it is clear that rough, but well-plastered furniture made from pallets looks great both on the street and in the apartment, left and center. But the holes and holes in the top of the table on the right, which clearly took a lot of work, are also clearly useless. Maybe this was the designer's intention, but it definitely failed here. If only because design art is purely functional, and dirt readily and happily collects in the holes and crevices of the countertop.

Shackled and unputted furniture from pallets

Homemade wood putty is made from sawdust mixed with PVA or acrylic glue. Proportion – 1-3 volumes of sawdust per 1 volume of binder. Thick putty (sawdust: glue = 3: 1) is putty roughly a day or two before sanding. Without rough putty, the surface of the part will go into waves after sanding due to the same holes and cracks. Liquid putty is rubbed until the surface of the assembled product is even before final finishing.

Assembling modules

Pallets and their parts are usually assembled into furniture on straight steel plates, see fig. below. But this is only due to ignorance of the basics of mechanics and strength of materials: mechanical stress flows to solid and rigid, virtually point-like fastening points on a less durable basis, and the table or bed soon becomes loose, although nothing of the sort seems to have happened on them.

Assembling furniture from pallets on steel plates

Schemes for the correct assembly of furniture connecting parts from pallets are given on the following. rice. Pos. 1 – vertical angle, e.g. in a bar counter or lawn chair. The base is a steel corner 50x50x2 or 60x60x2 with a width of 60-70 mm for diagonal pairs of nails or self-tapping screws with a diameter of 4-6 mm; from its edges to the edges of the beam there should be 15-20 mm. An important role is also played by pairs of hardware, driven obliquely, with a distance of 30 mm from the edges of the beam: it is they who “take” the focus of mechanical stress to the strongest place - to the center of the piece of timber (the connecting boss of the pallet).

Connecting furniture assemblies from pallets

At pos. 2 shows the connection of pallets in a horizontal angle, for example. for the table; The bottom boards (of which there are 3 in pallets) of the pallet-sidewalls are shortened to the thickness of the pallet-tabletop. It works on the same principle, which makes it clear that it is impossible to remove the upper bosses of the sidewalls (marked in red!), as is often done, they need to be rearranged.

The load-bearing base of the bed from pallets (item 3) is assembled using linings cut from the removed underside boards. In addition to high strength and rigidity (the bed base of 8 pallets measuring 240x200 cm does not require additional reinforcement), this creates voluminous niches for linen boxes. Using the same principle, the base of the coffee table is made from a pair of pallets (item 4), but for the sake of beauty, the bottom pallet is cut around the perimeter to the thickness of the board (25 mm). The remains of the lower bosses with a thickness of 75 mm are sufficient to ensure overall strength with a large margin.

Tables

The middle of the underframe of a large table is always highly stressed and under its own weight, so the supporting structures described above are not suitable in this case. The underframe of a large, 200x120 cm dining table from pallets is assembled according to the principle of a spinal frame (diagram on the right in the figure), and such a table in real life does not look heavy at all, on the left there. If niches for drawers are not required, but much greater strength is needed (banquet table made from pallets), then the side linings can be made the same length as the middle ones and secured in the same way. It won’t be possible to make it even longer and stronger, covering the entire length of the underframe; there are no such long boards in the pallets.

Arranging a table base from pallets