Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

Tandoor (tanur - Farsi; tone - Georgian; tono - Turkic; tandoori - Hindi; tandoor - English) is currently a popular trend in dacha-stove fashion. However, it's not just about fashion. In a tandoor you can cook everything that you can cook on a grill or barbecue, and many other oriental dishes. And at the same time, making a good tandoor with your own hands is generally easier than any other country stove.

Another important advantage of the tandoor is that it can be made of clay, i.e. “truly oven-like”, without the slightest admixture of metal in the design, and at the same time mobile. At the end of the season, you can hide it indoors or take it with you when you move. Installation will require a minimum of work, and the tandoor as such does not need a foundation at all.

Finally, the tandoor is economical. It was born in places that were never abundant in fuel, and the design was perfected not for centuries but for millennia. The amount of fuel in the barbecue is barely enough for a heel of kebabs, in the tandoor it is enough for a dozen of them plus flatbreads, plus the tea will boil while the flatbreads are baking.

Many people who want to own a tandoor of their own making are put off by the complexity of pottery work. But they can be simplified, see below. And the tandoor is generally unpretentious in the choice of material - you can even build an Uzbek tandoor out of brick. Ancient nomads in the vastness of Turan, Taklamakan and Tsaidam generally made tandoors from whatever they found at their next stop, and the food was finger-licking good. A galaxy of Russian travelers in Central Asia in the 19th – early 20th centuries. confirms unanimously.

Make or buy?

Modern country tandoor

As for the tandoor for the country house or just for the household, you first need to decide whether to make it yourself or buy a ready-made one. There is no shortage of proposals, and the quality of the products, as a rule, does not require special praise, see fig. on right.

The fact is that it is difficult to make a real clay tandoor in mid-latitudes, and even impossible without special technological equipment. A special section will be devoted to this issue later, but for now we will only note that even during the initial firing, tandoors crack, even from selected fireclay clay, which requires at least 1,500 rubles for each attempt, not counting the work.

Ready-made insert for tandoor oven

Meanwhile, the price of purchased mobile tandoors, like the one shown in Fig. higher, ranges from 11,500 to 70,000 rubles. depending on size. The smallest one is the size of a large saucepan. It can be placed on a table, and can be carried without effort by one person. And the same person, if necessary, can climb into a large one, for 60-70 thousand rubles. It’s clear here that it’s better to buy: after all, the price includes a set of utensils, a lid with a hatch for the kettle and slots for skewers. Doing all this yourself will cost you more.

Homemade tandoor oven with ready-made insert

But if we are talking about a stationary tandoor oven, then the cheapest custom-made work of a tandoor master will cost no less than 100,000 rubles, and he will not take this money in vain. At the same time, the heart of such a stove, the tandoor itself (see the figure on the left above) of a proprietary manufacture, properly fired and with a guarantee, will cost from 5,000 to 30,000 rubles. depending on the size and method of delivery (to the place, pickup). And the actual stove that frames it (see the figure on the right) is quite capable of being built by any craftsman, even if before that he had only looked at bricks. The materials are also the most common ones, see below.

Video: basics of tandoor construction (1 channel)

About the correct kindling of a tandoor

To light a tandoor, the firewood must be dry and of medium size. You can also use compressed sawdust. The advantage is that the heat transfer when using such fuel is greater and after cooking it is easier to clean the tandoor from ash than from coals. It was about 30 degrees minus outside, we heated the tandoor with fuel in briquettes made of pressed sawdust. The ignition time was about 30 minutes. At the same time, we only went out into the street where the tandoor stood a couple of times for a couple of minutes. The rest of the time was spent indoors, because the tandoor does not need total control. It is enough to give it just a couple of minutes, the rest will happen naturally.

About electric tandoors

Civilization and electrification have not bypassed tandoors. In the end, you simply cannot heat with wood in a city apartment or restaurant. The obvious solution is to place an air heating element above the hearth, left pos. in Fig. below. The finished factory-made product looks elegant (middle position), and the price is not much higher than for wood-burning ones - from 14,500 to 80,000 rubles, again, depending on the size.

Electric tandoors

But an electric tandoor with an open heater is more of a prestigious gift than a culinary technique. The taste of dishes made from it will be distinguishable from the real thing even by an inexperienced gastronome. For the worse. The reason is that the heating element dries the air. Of course, it does not absorb moisture vapor, but as the temperature rises, the relative humidity of the air drops, the cakes dry out, and a burnt taste is clearly felt in meat, fish and poultry. If you burn with wood, then water, along with carbon dioxide, is one of the main combustion products. It penetrates into the microporous body of the tandoor during heating, and then is gradually released, maintaining the desired microclimate inside.

Trying to humidify the air by placing a bowl or tray with water on the grill is useless. It boils away, steam flies out, at the same time spoiling the food. There is also no point in trying to saturate the tandoor with moisture during heating: in order for its vapors to penetrate into the baked clay, their temperature must be at least 350 degrees, and not 100, as when boiling.

Therefore, a real electric tandoor is a device that looks like a kitchen stove (on the right in the figure), but is very complex inside and controlled by an on-board computer. The same clay tandoor is wrapped in an electric spiral, coated with an additional heat-resistant dielectric lining, lined with heat-reflecting screens, and moisture is introduced into the baking chamber in precise doses using inserts made of nanomaterials, like those used in mobile air conditioners, only heat-resistant. The price is appropriate. Replace the above rubles with US dollars, there will be no big mistake.

What and how to cook in a tandoor?

There are countless recipes for oriental dishes for tandoor. In addition, bread is baked in it and shish kebab is prepared. By removing the lid and placing a grate in the neck, the tandoor can be used as a barbecue. And by placing a teapot with a teapot neck there, or a cast iron pot, we’ll get tea no worse than the best samovar or a day’s worth of cabbage soup without a Russian stove.

To describe at least the basics of tandoor cooking, you need not even a separate article, but a voluminous monograph. Therefore, we will limit ourselves to the most general instructions.

First, if you cook any meat, especially lamb, you need to place a grate over the coals, and on it - a bowl into which the juice will flow. Without it, shurpa or tandoor-shurva will not turn out properly.

Kebab and shish kebab in tandoor

Secondly, if shashlik or kebab is cooked in an Uzbek tandoor, the skewers are either simply inserted into its mouth (on the left in the figure), or first inserted into the slots of the lid, then the meat is threaded, and the tandoor is closed with a lid. The second method is more economical (literally a handful of coals is enough) and guarantees uniform baking of pieces of any size.

If the kebab is cooked in an Armenian tandoor - tonir - then the skewers are hung vertically on a hanger (right position). Not every cook can cook kebab in a tonir, but in any case there is no need to turn the skewers.

Butter flatbreads on an Uzbek tandoor

Third, flatbreads can be baked in an Uzbek tandoor both inside and outside, see fig. on right. Which one depends on the recipe. In general, dinner bread is baked inside and baked goods outside.

Fourth, by hanging a grate at the mouth of the tandoor on hooks of adjustable length, you can cook everything the same as in a Russian oven. At the mouth cut, the temperature will be approximately the same as in the fire, and directly above the coals - as at the back wall of the furnace immediately after burning. An additional plus is that you don’t have to cook in cast iron; it works just as well in regular pans.

Fifth, dishes in a tandoor cook much faster than similar ones in other ovens:

- Beef - no more than half an hour.

- Pork, lamb – 15-20 min.

- Fish, poultry – 7-10 min.

- Vegetables – 3-5 min.

Sixth – a little culinary secret. After cooking, when the tandoor has not yet completely cooled down (you can put your hand inside, but it burns), we put a pan inside filled with pieces of old, impossibly stringy beef. Close the lid tightly and wait until the morning. Now you can cook anything from this meat, and it will melt in your mouth.

Stationary

This stove has a large weight and volume. Its weight can reach 1000 kg, so the structure is assembled directly at the installation site on a specially prepared foundation. The undoubted advantage of a stationary tandoor is the length of time it retains heat. Thick clay walls simply do not let out heat, so you need to preheat the oven less.

As for dishes, the high heating temperature allows you to cook anything, including meat that requires long simmering and stewing. Food is heated evenly and cooking occurs faster. Even old meat cooked in such an oven does not differ in taste from fresh meat. This design is suitable for a country house where people live permanently and therefore often cook.

About firewood and firebox

Tandoor is fuel critical. In its homeland, Central and Central Asia, it is heated mainly with saxaul. Occasionally - elm or plane tree (sycamore). Of these, in the southern regions we only have the plane tree, but here it is a valuable ornamental tree and is not allowed for firewood.

Saxaul and ready-made saxaul firewood

In our area, tandoors are heated with wood, the same as barbecues. Charcoal and pellets are not suitable - they produce too much heat, an expensive tandoor can crack and cannot be repaired. Coal is absolutely no good: the tandoor will become saturated with coke gases and will forever become smelly and poisonous.

The amount of fuel in the tandoor is small, about 1/5-1/6 of its height. It is specifically determined by the experience of use so that there is enough coal for cooking. In general, barbecue requires two to three times less fuel. Cooking begins when the fuel burns down to coals. A prerequisite is that the soot and soot on the walls must also burn out. With good quality fuel, this is always observed.

In tandoors with a built-in firebox, the vent is not closed after heating, so that the coals smolder without burning. And in order not to create excessive draft, the mouth of the tandoor is not completely covered with a lid, if it is solid. In mobile Uzbek tandoors (see below), the lid is made double; At the end of the fire, the smaller one is removed. Its nest in a properly made tandoor is made jagged, then you can place a kettle on it without disturbing the draft.

Types of tandoor

Since the appearance of the first tandoor, it has not undergone any significant changes. bricks are also used to create it . It is these materials that are necessary for the construction of a real Central Asian tandoor. However, there is a division of the furnace into types based on the location of its installation.

Tandoor with thermometer

Vegetables cooked in tandoor

The ground tandoor is installed in the yard, on a clay platform. For bread, samsa, shashlik, tandoor is installed vertically, horizontal installation is applicable only for baking bread.

Ground tandoor lined with brick

DIY tandoor from a clay pot, tiled

A pit or earthen tandoor is placed in a hole dug in the ground. Clay and fireclay are used in its construction. In ancient times, this type was often used for heating rooms.

Yamny tandoor

Cooking in a pit tandoor

A portable tandoor is a modern type of stove that has iron handles for carrying. Small in size, in the shape of a barrel with a lid, it successfully replaces the grill .

Modern portable tandoor

Homemade portable tandoor

History and evolution

So how can you build such a wonderful culinary unit yourself? In order to approach construction with knowledge of the matter, let’s dwell a little on its origin.

Initially, a tandoor is the same hearth, a fire in a fence or recess so that the wind does not blow away the flame. However, the heart of Asia, where the map is entirely mountains, is, oddly enough, poor not only in fuel, but also in stones. The reason is severe wind erosion in a sharply continental climate. N. M. Przhevalsky described how in the Gobi, right before our eyes, granite boulders were worn into dust. The author of the article had the opportunity to be in those places, to see something for himself in the summer, not in the winter, and he does not have the slightest doubt about the veracity of the great researcher.

But the same terrible winds, combined with daily (!) temperature changes from +45 to –30 degrees, abundantly supply the Asian plains with loess - the smallest stone dust. She very quickly buries what the wind carrying her did not have time to wear away. Loess layers on the Asian plains reach hundreds of meters in thickness. To see any pebble, you need to climb quite high into the mountains.

Actually, dust is not loess. Loess is obtained when dust is knocked into a dense conglomerate by the wind, carrying stones the size of a fist, periodically baked by the Sun during the day and frozen in dry air at night. Loess has incredible properties. It is exceptionally fertile, producing stable wheat yields of 40 kg/ha in monoculture and without any agricultural technology.

But it’s more important for us to know something else: loess is heat-resistant, like fireclay clay. When dry, it is as strong as cement, but is completely permeated with microscopic pores, i.e. breathable and quite easy to process. And if you soak it a little, you can sculpt it like plasticine. True, if it rains heavily, the loess gets soaked into mud, in which the tank gets stuck up to its turret. But heavy rains where there is loess occur once every 10 years, and not every decade.

It is clear that in such conditions it is useless to simply fence the fire with stones: they will simply be blown away along with the fire and food. But the same wind also provides a solution to the problem - loess. The ancient Asians sculpted their hearths from it 6000 years ago, and in some places they still sculpt them, see fig.

Ancient loess tandoor

The evolutionary tree of European ovens, from barbecue to Swedish and Russian, is entirely made of stone. The Asians, settling beyond the loess plains, looked everywhere for a replacement for such wonderful material. They had three more allies - the hot Sun of low latitudes, the eternally cloudless sky and very dry air. As a result, tandoors of various types appeared, and culinary subtleties were added to them during development.

Zemlyanoy

The simplest tandoor is a hole in loess soil with a diameter of about 0.5 m and a depth of about 35 cm, to the bottom of which an inclined passage is dug from the side - an air duct. Loess tandoors are still in use; connoisseurs claim that only they produce real tandoor delicacies.

Where there is no loess, the pit is lined with bricks to dry it (see figure), and pipes made of fireproof materials are used to supply air. However, the same experts claim that such a tandoor is no longer a tandoor.

Earth tandoor

You can dig a pitcher-shaped hole in the loess without the danger of it collapsing. This made it possible to significantly save fuel: due to the reflection of IR, the heat was concentrated in the center of the chamber. In areas without loess (in Fergana, for example), you cannot build an earthen tandoor, but there are also many deposits of high-quality clay, and pottery has been developed since time immemorial. It was there that the Uzbek tandoor was born.

Uzbek

Scheme of the Uzbek tandoor

The diagram of the Uzbek tandoor is shown in Fig. The fireplace underneath is ordinary, made of masonry with slots for air access. But the main secret of the Uzbek tandoor is the clay top placed on the fireplace. It, as can be seen from the figure, is two-layer.

The first, inner layer, was made from high-quality clay with a small (1:1 or 1.5:1) admixture of sand and the addition of chopped wool; The wall thickness is half a span. The solution was made very thick, the consistency of plasticine. To achieve complete homogeneity, we kneaded the solution with our feet.

Then natural conditions came into force. In the center of the Asian continent, the air is constantly saturated with fine dust; The sun in a completely clear sky appears as if in a haze. Meteorologists call this phenomenon a danger. You can quite understand the degree of dustiness in the air there when you see a phenomenon common in those places - dry rain. Drops of water collect dust particles as they fly. Due to the extreme heat and dryness, the water evaporates and dry pellets fall to the ground.

Dust completely absorbs ultraviolet radiation, even at an absolute altitude of 1800 m there is almost no ultraviolet radiation in daylight. Caucasian Asians come to the sea in the summer with the same “brown cheese” tan as northerners from Olenegorsk, Naryan-Mar or Norilsk. But dust re-radiates all absorbed radiation (UV and upper visible spectrum to blue-green) in the IR range - the air is oversaturated with thermal rays. Asians seem to live in an annealing furnace.

Having sculpted the blank, it was exposed to the Sun. The unbearably hot light, combined with very dry air, literally drove the water out of the workpiece within an hour or two in the morning, but drying (in fact, low-temperature firing; at noon the workpiece was heated to the temperature of sand in the desert, 70-80 degrees) lasted two weeks. The workpiece turned out to be microporous. The famous Bukhara sweating jugs were prepared for firing in the same way, keeping the water poured into them cool in any heat.

It is precisely due to the inability to organize such a natural technological process in cooler and/or humid places that homemade Uzbek tandoors fail. During drying, a crust forms on the workpiece, which does not release water from the solution. Gradually it still evaporates, but the workpiece goes into firing with residual stresses, which is why it cracks during firing. In middle latitudes, the maximum wall thickness of pottery is about 13 mm; for a tandoor this is clearly not enough, and it is impossible to build up and dry in layers due to the same residual stresses.

Uzbek tandoors

But the tandoor cannot sweat, and the heat capacity of a vessel with a wall thickness of 40-50 mm is not enough for proper fuel economy. He must return the water obtained during heating. Therefore, the first layer after drying was lined with a solution of ordinary white or gray clay without fibrous additives. After 2-5 days of drying, the product was fired. The top layer often cracked, see Fig. higher, but this did not deteriorate the quality of the tandoor: the outer layer is simply additional thermal insulation.

Over time, small portable single-layer tandoors appeared, with their own firebox and grate. They were no longer suitable for baking baked goods, but meat cooked perfectly in them. These were more commonly used by the nobility and were richly decorated. Most of the modern tandoors available for sale (see next figure) are from the “Bai” branch.

“Bai” tandoors

How to install a tandoor and how to use a tandoor

How to install and use Tandoor

After purchasing a Tandoor, you want to immediately try it out and prepare all sorts of delicacies from meat, fish or vegetables, as well as bake bread or samsa.

But before you start preparing dishes in the tandoor, the question arises: how to install the tandoor correctly?

A ceramic wood-burning tandoor is placed in an open area. If the Tandoor is placed on the veranda, then there must be an exhaust duct above the Tandoor, since an open fire comes out of a wood-burning Tandoor when heated and the height of the flame can reach 1.5 meters.

The electric Tandoor does not have such a limitation, since the heating of the electric Tandoor occurs with the help of an electric coil, which is attached to the inner wall of the vessel.

It is better not to allow children near the Tandoor to avoid injuries and burns.

Medium and large tandoors include a stand for the tank .

The stand allows you to raise the bottom of the vessel above the soil. Thanks to the stand, the ceramic stove warms up better and cools down longer than models buried in the ground.

Installing a Tandoor is not a complicated process, and first of all, you need to meet the conditions - place the Tandoor vertically on a flat, hard platform. You can make this platform yourself by laying horizontal paving slabs or just bricks. Then the Tandoor will be stable while cooking. After heating the Tandoor, it is difficult to move it, since the Tandoor heats up to a high temperature.

How to prepare a new Tandoor for use (how to light a tandoor)

During the production process, all Tandoors are fired at a temperature of about 1100°C, but after purchasing a Tandoor, it is very important to properly ignite the Tandoor for the first time.

The initial lighting of the Tandoor is done gradually, starting with a small amount of firewood in the Tandoor. Coal is not suitable for heating the Tandoor, as it quickly burns out and does not have time to warm up the Tandoor. During the kindling process, wood is gradually added to increase the flame in the Tandoor. You can immediately lay a large amount of firewood, but then you need to regulate the flame using the position of the bottom plug - open it gradually to change the amount of draft in the flame.

During the initial lighting of the Tandoor, its walls become covered with many tiny cracks. This allows the ceramic to expand thermally. The characteristic cracking and clicking sounds produced by the expanding wall are considered normal.

Tandoor - Instructions for use

- Place the portable ceramic tandoor on a flat, hard surface. To connect an electric tandoor, you will need a carrying extension cord.

- In a wood-burning Tandoor, install the grate that comes with the Tandoor on the bottom and load the pre-prepared firewood into the Tandoor. It is better to use firewood from hard wood. Pine firewood is not suitable for lighting a tandoor, as it can release resin. It is not recommended to use lighter fluid, as an unpleasant odor will remain in the closed container, which will be transferred to the food.

Connect the electric tandoor to a carrying extension cord.

- Open the blower hole, which is located at the bottom of the vessel.

- Light a small fire in a wood-burning Tandoor and add small pieces of wood a little at a time so as to maintain a low burn for 30-40 minutes.

The electric tandoor will warm up gradually, since the required spiral is already installed in it, which will gradually warm up the vessel.

- When the outer walls of the wood-burning Tandoor become noticeably warm, only after this can you begin to increase the heating of the Tandoor by adding thicker firewood and logs inside to 1/3 of the volume of the vessel. It is during this process of rapid heating of the Tandoor that you can hear the cracking of a ceramic vessel and the appearance of cracks on the Tandoor.

- When the loaded firewood burns out and the strong flame disappears, the Tandoor vessel must be closed with a large lid, leaving the small hole of the lid open so that the smoke from the burning wood comes out. Burn until hot coals form.

- Add a second portion of firewood to the vessel by 1/3 of the volume and repeat the process.

The readiness of the tandoor to add food for cooking is determined only visually. As the wood burns and the Tandoor heats up, the walls of the vessel become covered with black soot. As the tandoor warms up and the wood burns, the soot burns out.

When the inner walls of the tandoor become light, the temperature in the tandoor will reach an operating level in the range of 250-300°C. The hot coals remaining from the firewood are partially (or completely) removed through the blower and after that the blower is closed with a ceramic stopper that comes with the Tandoor.

- Next, you can load pre-prepared products into the Tandoor to prepare barbecue or other culinary dishes.

A heated medium and large Tandoor holds the temperature necessary for preparing all sorts of delicacies for 2.5-3.5 hours. So, you have plenty of time to cook a lot of meat and vegetables.

- After preparing food in the Tandoor, allow the vessel to cool naturally, and under no circumstances use water for cooling , otherwise the vessel may burst.

- Once the tandoor has cooled, clean it of coals and put it indoors or cover it with a cover to protect it from precipitation and dust.

To measure the internal temperature in the Tandoor, some models have a built-in thermometer,

but it is best to measure the temperature using an infrared hand-held thermometer, which is useful not only for Tandoor on the farm.

This infrared thermometer comes as a gift when purchasing a Tandoor from us

The tandoor can also be used for cooking in winter, but heating (the first time) of the tandoor must be done in the summer to prevent the vessel from cracking; otherwise, using the tandoor in winter is no different from using it in the warm season.

Contact by phone

8(800)505-96-84

or

(the call is free for you)

Together with you, Online Store “Russian Smekalka”

Uzbek tandoor oven

There is also a class of tandoor consumers in Central Asia, from whom a very high heat capacity is required at a reasonable price. These are the dukhan-keepers (tavern-keepers) and the tea-khan-keepers. The stationary tandoor had to provide continuous preparation of food for visitors within 3-4 hours from one heating. Asians are a patient people when they have to tighten their sash, but if they have several tangas in their belts for pilaf or beshbarmak, they become very active. And firewood is expensive.

Tandoor hoods for sale

For catering tandoors of old times, craftsmen began to produce ready-made fired inserts, many of which are still exhibited in Central Asian bazaars, see fig. Most of them are in the form of a cap, they are cheaper, and the stove is also cheaper: the brick is ordinary, the thermal insulation is self-leveling from unfired clay. A diagram of the design of such a furnace will be given below.

Tandoor-non

In areas especially poor in fuel, starting from the 18th century. Stoves with an insert in the form of a jug became widespread. The chamber was made relatively small (see figure on the left), lined with a thick layer of fireclay bricks. The blower air duct was made long to heat the air from the furnace body. An elbow-length bundle of saxaul, which could be wrapped around the fingers of two hands, was enough to bake a dozen flat cakes and boil kumgan water for five; The kumgan was installed in the neck of the tandoor instead of a lid. This tandoor oven is called tandoor-nan or tandoor-non.

Video: Uzbek traditions of tandoor construction

What is cooked in tandoor

A lot of things are cooked in the tandoor - from meat to bread, and even today in Central Asia - this device is not so rare in the courtyards of private houses. The taste of these dishes is surprising, it is original and recognizable. There is something akin to dishes cooked in a real Russian oven. In Russia, everything is built at dachas and individual plots - barbecues, Pompeian pizza ovens, barbecue complexes, and tandoors too. All of these ovens can be multifunctional. In addition, these national stoves, with all their color, are quite democratic; they are for people all over the world.

Toner

The second trunk of the tandoor evolution tree came from Transcaucasia. It's hot here too; in Shamakhi it is perhaps hotter than in Fergana. And the air is also dry, but clean and transparent. This alone was enough to prevent pottery tandoors from being made here.

But the Transcaucasian Highlands is perhaps the first region on Earth where people discovered deposits of fireclay clay and learned to work with it. Armenians are considered jacks of all trades and the best artisans among the Caucasian peoples.

Toner lining

The Armenian tandoor, or tonir, is laid out from fireclay bricks on a clay stove mortar; in terms of properties, its body is equivalent to an Uzbek clay body with walls half as thick as brick. The outside of the tonir is lined, like the Uzbek one, with clay, see fig. The purpose of the lining is the same - additional thermal insulation. It could be made of brick, but it would be difficult and expensive.

On Uzbek tandoors, the decorations are mostly molded and glazed: such a large “pot” without reinforcement is not very strong and may not withstand additional load. Toner is like a brick structure, much stronger. Therefore, the external decoration of tints is much more varied and richer: from simple coating with decorative colored clay with polishing and cladding with wild stone to the most complex tiled compositions, see fig.

Armenian tandoors - tonirs

It is much more difficult to build a brick vessel with a complex curvilinear configuration than to fashion it from hand-thick clay sausages, pressing and pinching them. Therefore, toners are most often made in the form of a cylinder topped with a truncated cone, or even in the form of a straight pipe. In this case, IR can more freely escape outside without any use. The high heat capacity of fireclay, combined with its negligible thermal conductivity, compensates for this disadvantage to some extent, but still, a toner of the same capacity per unit of finished product consumes 15-20% more fuel than an Uzbek tandoor, not to mention a Nana stove .

Another (however, like the first, not significant) disadvantage of toner is due to its “brick” strength: it also gives “brick” weight. If mobile toners are made, they are made on a stand with wheels. And horizontal tints, embedded in the wall, are found as an exception. Almost a third of the “Uzbeks” go to walling up.

Earth toner

There is also a difference in the soils: in Central Asia they are more alluvial, alluvial, i.e. weak, and in Transcaucasia - volcanic, strong, waterproof. Therefore, earth toner has been revived in Armenia (more for the sake of saving space and space). It is made in the form of a well (see figure), and in terms of product quality it is not inferior to an earthen tandoor in loess. But trying to build one in the black soil or loam of the middle zone is a waste of time, soil moisture will get inside through any lining and ruin the entire gastronomy.

The tandoor of my dreams - I wanted it, I thought it up, I made it happen

An invariable attribute of country life is the preparation of barbecue and other meat dishes. Of course, to carry out this action, you can get by with an iron grill, or even just a hole with bricks for skewers. But real connoisseurs are disgusted by such minimalism, and they acquire more advanced and versatile designs. For example, a member of the FORUMHOUSE portal Mcgoga dreamed of a tandoor, and successfully realized his dreams. And he shares the results with all like-minded people.

Dreams Come True

Originally, tandoors were common in Asian countries, where they were used both for heating and for cooking - mainly for baking dough products directly on the inner walls. In our country, they are popular among lovers of country holidays as universal outdoor stoves.

It is believed that meat cooked in a tandoor is tastier than in a grill or barbecue.

In addition, there is no need to watch over the skewers or grill.

Andrey PavlovetsFORUMHOUSE user

Firstly, the taste is really different from simple grilled cooking. And secondly - you don’t have to constantly stand and twist the skewers and at the same time either inflate or fill the coals - I hung it up and went to talk to the guests.

Whether these or other reasons became decisive, Mcgoga wanted a tandoor and began to make his desires come true.

McgogaFORUMHOUSE user

For a whole year I dreamed, planned and prepared to make myself a tandoor in the spring. I read everything about them on this forum and in others, and decided to do everything my own way.

There was enough time for theory, and the approach to the matter was serious: a solid foundation, appropriate materials, a decorative, and not just a functional form. Implementation - with your own hands.

The foundation is a monolithic slab with metal profile reinforcement. Marking along the string on pegs, removing the fertile layer, tamping, driving the profile in the corners and in the center, backfilling the base with large crushed stone. In order for the slab to protrude above the ground - formwork around the entire perimeter and filling with mortar.

Initially, it was planned to lay the base with self-made cement tiles, but something didn’t work out, and the process was somewhat simplified. Another layer of tinted mortar, a centimeter thick, and cut with a mold into individual tiles.

Masonry - although traditionally tandoors are made of solid clay, you can also use brick. Mcgoga settled on the fireclay variety ShB-8. As a masonry mortar - a special oven mixture designed for heating above a thousand degrees. The shape of the stove I chose was jug-shaped - on a round “leg”; it is more difficult to manufacture, but also looks more interesting than a square or cylinder. In order not to make mistakes when laying, the brick, sawn to the desired shape, was first laid out dry and numbered. To strengthen the tandoor, grooves were cut out in the upper and lower parts of the brick, and each vertical row was reinforced with metal tape. The first row after the “leg” was laid out with an outward slope, and there was an air vent in it.

The next two kept this expansion, and the final ones already sloped inwards, forming a narrowed neck. Although the diamond blade cut fireclay without any problems, the work was painstaking. Both the cutting itself and further “trying on” took a lot of time and effort.

In addition, during the laying process, Mcgoga also took care of the beauty of the seams, since he did not plan to veneer the tandoor. Ten days were allotted for drying, after which it was brought into proper shape and launched for the first time.

Use - the first firing showed excellent traction and operability of the structure; a small number of small cracks along the seams did not affect the integrity. The first cooked dish (kupaty) turned out to be very lumpy, but it was decided to improve the oven by installing a thermometer to control the heating. The bimetallic mechanism mounted in the body of the tandoor did an excellent job of achieving this goal.

McgogaFORUMHOUSE user

The length of the rod is 100 mm, the diameter of the dial seems to be also 100 mm, I chose it from stainless steel, the range is from 0 to 450 ⁰C. The thermometer has a 1/2-inch male installation thread - I bought a 1/2-inch coupling with a female thread, approximately 3 cm long, at a regular plumbing store. I installed it in the brick, on the mortar. To close the hole while the tandoor is being lit, I bought a half-inch plug from the same plumbing store.

The next step was the manufacture of a “device” for vertical fastening of the skewers - a rim with a cross. A DSP board cut to the shape of the neck was used as a temporary cover.

Tightness - due to a non-flammable seal placed along the rim. The second “pancake”, in the form of a kebab, turned out juicy, tasty, no burnt edges, but the “lump” was due to dryness - it was overcooked a little. But the game that followed turned out to be almost perfect.

As for the temperature regime, everything is within the expected range:

- Fast heating up to 420⁰С.

- Slow cooling to 200⁰C in an hour and a half (this is especially important, since the plan is to roast the pig for two hours, which is quite doable if you do not open the lid).

Based on the cooking results, it was decided to leave the tandoor without insulation and finishing, as it was unnecessary - it holds the temperature and looks quite decorative.

Other owners of tandoors also joined the discussion, and a heated conversation ensued on the topic of cooking recipes, the intricacies of the firebox and design features.

For example, a user with the nickname Hafis uses his tandoor mainly for baking samsa and flatbreads, which is what it was originally intended for.

Hafis FORUMHOUSE user

When I started cooking samsa, I gave up on all experiments with meat. I realized at that moment that baking samsa is the pinnacle of tandoor cooking.

Alex 0576 did not bother with curved lines - his tandoor is in the form of a cylinder. But during use, some problems emerged:

- Without a layer of waterproofing, the bottom row absorbs moisture from the foundation, and in the off-season the tandoor becomes damp even under the protective cover.

- Refractory stove mortar is hygroscopic and is washed out of the masonry during precipitation, so lining is necessary.

- The DSP lid is thin, and with constant heating it quickly failed.

To avoid the solution being washed out, Mcgoga decided to treat the seams with a sealant that is resistant to the external environment; he really didn’t want to cover the clear lines drawn with such difficulty. For those who are inclined towards finishing with insulation, another member of the portal, Andrey Pavlovets, who “ate the dog” not only on tandoors, but also on Pompeii, recommends the following “pie”:

- Wire strapping

- Basalt insulation

- Net

- Finishing plaster (cladding)

Using this “recipe” Alex 0576 insulated his tandoor.

One of the most important parameters of a tandoor is its tightness, thanks to which the oven maintains the temperature for as long as possible.

Therefore, the lid should not just be a plate thrown over the neck that comes to hand, but a special one, designed for operating conditions and completely blocking the outflow of heat. The best option is a “sandwich” made of fire-resistant insulating material and the same DSP as a base. And to prevent direct contact of the insulation with the flame and food, you can use food foil. Mcgoga successfully used a bare slab temporary hut several times, but at one absolutely unfortunate moment, the lid practically exploded. By a lucky coincidence, the fragments did not harm anyone, although they scattered throughout the yard.

So safety should come first, and the manufacture of the lid should be approached no less responsibly than the oven itself.

The NikO74 has cast-iron brake drums from a heavy truck, lined with solid brick, adapted for the tandoor. Of course, you can’t cook samsa and flatbreads in it, but for meat it’s a completely workable option. The metal lid with longitudinal slots is of interest - they are designed to fix the skewers in the desired position and thus adjust the degree of frying.

NikO74FORUMHOUSE user

I make shish kebab in large pieces, cook for 15-17 minutes, chicken 1.8 kg - 40 minutes. I recently bought a 4.5 liter cast iron pot with a lid, I want to try making a roast. Now I almost never use a barbecue; with a tandoor it’s safer, easier and tastier.

The theme of Mcgoga and Orfo74 inspired him to get a tandoor, and now he regularly pampers his household.

The fact that dreaming is not harmful, but even useful and productive, is proven time after time by the craftsmen of our portal. They generously share their experience and are always ready to give practical advice. Join, dream, make your dreams come true, and FORUMHOUSE will help you with this.

All the details, interesting recipes, photographs and videos are in the Mcgoga topic “Tandir of my dreams”. Other popular types of outdoor ovens and entire complexes are in the section on barbecues, barbecues and smokehouses. How to build a gazebo into which a tandoor will fit perfectly is in the article about the original dome structure. And in our video - just a review of the outdoor stove complex.

About the cauldron

A tandoor-cauldron is made quite simply: a boiler with water is placed at the mouth or on it, depending on the size of the tandoor/boiler. If baking or cooking is being done and the skewers do not stick out, the water heater can be combined with cooking: the hot air above the mouth is exhaust, and the body will not give off more infrared than it can emit, so the product will not spoil. You just need to place pieces of something durable and non-flammable under the bottom of the boiler to create a gap for air to escape.

Step-by-step guide to building a brick tandoor

There are three types of homemade stoves: pit, portable and above ground. Now we will consider the option of building a ground tandoor from fireclay bricks. This is due to the fact that a pit tandoor is usually used to heat rooms, while a portable one is a type of barbecue.

You will agree with the statement that any serious project must begin with comprehensive preparation. On the one hand, there is nothing difficult in building a brick tandoor, and any professional builder will tell you this. But on the other hand, you need to be properly prepared to create a durable and comfortable object.

About the form and mouth

The shape of the tandoor slightly affects its fuel consumption, but does not significantly affect the quality of the finished dishes. The tandoor can be made spherical, oval, ogive-shaped (jug), in the form of an inverted cardioid, a barrel, cylindrical-conical or in the form of a straight pipe. The usual diameter of the mouth of Uzbek tandoors is 0.35-0.7 of the internal diameter of its lower back, and for tonirs it is 0.5-1.0 of the same.

Domed with a wide mouth, cylindrical-conical and cylindrical tandoors are better for baking: lumps of dough are stuck more conveniently and in larger quantities onto the inner surface of a large area. Other tandoors are mainly meat and fish, but in general the specialization of tandoors is relative. When using a skilled cook, it simply comes down to the dosage of fuel.

How to store a tandoor outdoors?

Such difficulties in operating a stove indoors are easily explained - the stove is not intended for this, it is for outdoor use. How to store a tandoor outdoors? There is no difficulty in this. To protect against dust, dirt and moisture, a waterproof cover in the form of a bag with drawstrings at the bottom is purchased or sewn. The oven is covered with it after use - naturally, the tandoor is allowed to cool (only on its own), the coals and ash and accessories are removed from it. But there is no need to worry about fat - it burns out the next time the stove is lit.

Do I need to remove the coals from the tandoor while cooking? If you do not use a special cutter, then most of the coals are removed, leaving very little to form a crust on meat or fish. But if you use a splitter, then the coals remain, continuing to heat the walls of the oven, and without affecting the food being cooked.

Making tandoor

From the above it is clear that making a tandoor yourself comes down to two options: a tonir made of brick or something like an “Uzbek” made from it. There is, however, a way to make a clay tandoor even in Murmansk, we will also dwell on that.

A brick tandoor can be built by anyone whose hands have not grown into their pockets, who can distinguish their wife’s breasts from the back of her head by touch, who can pick up an office folder with papers and bring a cup of coffee to their mouth without spilling it the morning after yesterday. The sequence of work is basically clear from the figure; we will only give some explanations.

Construction of a brick tandoor

Materials - fireclay bricks (300-1500 pieces depending on size), ready-made dry kiln masonry mixture, which is diluted with water to the desired consistency, and ordinary construction sand. There is no need for a foundation: we dig a pit two times the diameter of the base of the tandoor and as deep as the bayonet of a shovel. We fill it halfway with sand and fill it up to ground level with liquid, creamy, oven mortar. We stick an even pole or rod exactly into the middle and set it vertically along a plumb line. We secure it from the wind with temporary guy ropes on pegs. We also protect from rain with a temporary canopy made of slate or galvanized steel. Film or fabric cannot be stretched for reasons that will be clear from what is described below.

While the clay dries (this takes 1-3 weeks), we prepare the main working equipment: a rotary template according to the shape of the inner surface. In order to avoid undercuts of bricks when laying, we coordinate its shape with the size of the brick and the permissible thickness of the seams - 3-13 mm.

When the fill dries, lay out the first row of bricks on a dry surface. We carry out the masonry with butts (bricks across the masonry line; if along the bricks, they are called spoon bricks, or spoons; emphasis is on the penultimate syllable) standing up. Having laid out, adjusted the width of the seams and aligned them by turning the template a full turn, take out the bricks one at a time, dip them in clean water for a second, apply the masonry (dough-like) mortar, and insert them into place. At the end of the row, we turn the template again and level it. We work slowly, the clay solution takes a long time to harden.

In the first row we leave an opening of two bricks, this will be the vent. The same brick will go onto the beam above it, see middle pos. in Fig. We lay out the arc of the row above it from halves of brick. We put it and the subsequent rows, like the first one: first on a dry basis, and double-checking it with a template. If the template is calculated correctly, then by changing the width of the seams it will be possible to lay out all the rows with solid (solid) bricks, changing only their number in the row.

The third and all other rows will be continuous. But already from the second row, you need to try to maintain the dressing of the seams between the rows: install the first brick of each subsequent row in the middle on the seam between the bricks of the previous one, as highlighted in the right pose. Here, at the stage of calculating the template, you also need to follow the rule: the protrusion of the row inward is no more than 1/4 of the width of the brick. The second option, but less durable, is to lay the bricks with the bricks tilted in a vertical plane; then no internal lining is required.

Complete dressing will not work, because... The diameter of the rows changes smoothly. Therefore, we begin the laying of each subsequent row not from the same place as the previous one, but shifting by 1/5-1/3 around the circumference; It’s convenient to navigate around the ash pit. This technique is called dressing through rows. So we bring the masonry to the top.

Video: example of building a simple brick tandoor

Video: tandoor based on a finished insert

Tandoor - at the dacha

“Tandir flatbread,” you read in the supermarket and remember with nostalgia the rosy and delicious Armenian bread. And, breaking off a piece from a store-bought one, which only looks like the real one, you think: shouldn’t you put a tandoor in your dacha?

Surely, such a thought occurred to more than one forum member when he looked at the apparent ease with which samsa and flatbreads are baked in an Armenian oven, meat is fried and even tea is brewed. However, building a tandoor at your dacha yourself is not so easy. To find the best option, forum users started a discussion.

Tandoor according to the rules

To make tandoor, craftsmen use special light yellow kaolin clay. Sheep or camel wool is added to it, kneaded and left to mature like dough. T.N. “living” clay is mined near Akhangaran, in Uzbekistan. The material is used without processing.

A week later, they make a tandoor: make “sausages” 30-40 cm long and 5-7 cm in diameter, roll them into a thick ribbon. Pieces are cut off from it, rolled up and laid on top of each other in the form of a cylinder with a narrowed neck. The oven should dry in the shade for about a month. The usual dimensions of a tandoor are: height - one to one and a half meters, diameter in the middle part - up to 1 m, neck (also known as the chimney and incendiary hole) - 0.5 m.

The structure is assembled directly on the foundation. To create a thermal jacket, a “jug” is coated with clay, a brick wall is placed on the front side, clay or sand is tamped into the resulting gaps. A hole is left in the bottom part on the side to blow air into the working chamber or a pipe with a diameter of 10-12 cm is placed. after fuel burns out. To improve traction, a cone-shaped tin pipe is placed above the neck. When the tandoor is first fired, the inside is coated with cotton oil (so that the clay does not stick to the cakes) and fired for 24 hours, gradually increasing the temperature so that the clay does not crack.

The Bukhara, Samarkand and Kashkadarya regions of Uzbekistan are characterized by a vertical placement of the tandoor; in the Fergana Valley and Tashkent region, the stove is placed horizontally, placing the base near the wall. The top and sides of the working chamber are lined with bricks and coated with clay mixed with wheat straw and salt. They also make underground tandoor.

Before each baking, dry brushwood and small firewood are burned in the working chamber. Fuel is added until the chamber is red hot. The coals are raked towards the middle, the walls of the chamber and the cakes are sprinkled with salt water so that the bread can easily come off the walls.

Brick tandoor

A member of the “Home and Dacha” forum, Billy, who had no experience in laying stoves, decided to make a tandoor out of brick, combining it with a garden stove under a cauldron. Having calculated that it is more difficult to work with clay, and the result is difficult to predict, the owner opted for fireclay bricks.

Tandoors made of cement or brick take longer to warm up, and cooking in them is more difficult than in clay ones.

The task was complicated by the fact that the tandoor was supposed to be installed in a summer kitchen, for which the structure had to have a slanted facade, because of which it was necessary to frequently cut the brick, and the order was constantly confused.

Billy laid out all the rows “dry” and adjusted them. Red bricks were placed on clay-sand mortar, fireclay bricks were placed on a special masonry mixture. The forum member filled the voids between the fireclay bricks with clay mortar, and laid basalt wool between the working chamber and the cladding for thermal insulation.

The owner covered the arch of the furnace tunnel with two fireclay bricks, lying on the 45th corner and cut to the shape of the firebox. The corners of fireclay left over from the cuts were placed in the voids; expanded clay was poured into the voids in the last facing rows.

Error: Billy poured liquid cement mortar on top of the expanded clay and added cement to the sand-clay mixture. It turned out that it was in vain: after the first fire, the cement burst and split the top two rows of masonry. As a result, they had to be redone.

To obtain a smooth surface of the firebox, the seams between the bricks were rubbed down as much as possible. At the end, Billy inserted the door and scalded the entire top of the oven with metal corners. Two days later, the owner made the first fire: he put the firewood and left, after an hour and a half to two hours he returned and made a shish kebab in a hot oven.

In modern tandoors, not only coals are used as fuel, but also gas or electricity: a gas burner is installed on the bottom or an electric coil is placed.

RESULT: after 25 minutes the meat was ready, and it turned out much juicier than on the grill. The intense heat in the chamber remained for about five hours, so the cakes were also baked successfully. Billy believes that the big advantage of a tandoor, compared to a barbecue, is that you don’t need to stand near it: wait for the coals to burn out, turn the skewers. Even if you overcook the kebab, it will not burn, but will only become less juicy.

Based on materials from participants of the “House and Dacha” forum

Commissioning

If the tandoor is also intended for baking, then after the masonry has dried (2-4 weeks under a canopy), we line it from the inside with the same masonry mortar, but with plasticine viscosity. Before lining the tandoor, thoroughly spray it from the inside with a spray bottle.

After another 1-2 weeks we begin pre-firing. First - paper, cardboard or shavings. We set fire to a handful and throw a handful at a time through the mouth until the outer wall becomes slightly warm. Then cover with a lid and let cool completely, this will take about a day. We gradually increase the heating dose over the course of 2 weeks until the water dripped onto the outer surface begins to boil, shooting out and splashing. You can’t pour too much, half a liter can ruin a tandoor that hasn’t been fully annealed!

Now it’s time for the final firing. We fill the tandoor a quarter full with standard fuel and let it burn down to coals. Add fuel in the same portions until the tandoor is at least half filled with smoldering coals. It is better to take firewood that burns out quickly, but smolders slowly (cherry, apple) so that the level of the coals approaches the mouth. Let it cool, still under cover. In this case, you need to be careful and follow fire safety rules: the hot stream of air from the tandoor will hit with reactive force. Once it has cooled down, unload the ash, the tandoor is ready for use.

Gazebo with tandoor: construction features - Our Gazebo

Gazebo, tandoor with your own hands

A trip to a country estate or to a dacha is so attractive to us not only as a relaxation in the fresh air. Most vacationers associate it with the opportunity to pamper themselves with tasty and healthy food that smells of smoke. Today it is no longer possible to surprise anyone with an ordinary shish kebab fried on a grill. Tandoor in a gazebo - this is exotic!

What is this oriental stove, how to build it and implement it in a summer kitchen? You will learn about this by watching the video in this article.

Advantages of tandoor

According to its configuration, the tandoor has the shape of a large jug, and this is clearly visible in the photo above. A portable version is presented here, but such an oven can also be stationary. In general, the tandoor has been used since ancient times by nomadic tribes in Asia, and naturally, it was portable. Basically, bread cakes were baked in it, but sometimes vegetables and meat were cooked.

So:

- As nomadic peoples became sedentary, the kiln became stationary, turning into a more massive structure. Moreover, they began to place the tandoor in the ground, which made it possible to better retain heat in it. It takes very little time to cook dishes in this oven, and they turn out incredibly tasty and juicy. Shish kebab cooked in a tandoor cannot even be compared with shish kebab fried on a grill (see Grill oven for a gazebo: how to make it).

Shish kebab in tandoor

- Thanks to the sealed cavity, a constant temperature is maintained in the oven. Skewers with meat are hung on a special hanger in the form of a ring, and at the appointed time the finished product is taken out.

They don’t need to be fanned, like on a barbecue, constantly turned, and the flames doused by sprinkling water on the coals. So, the advantage in the process of preparing shish kebab in a tandoor is obvious. And their main advantage is the minimum amount of firewood required for combustion.

Modern interpretations

Today they build both stationary tandoors and portable ones. Both options can be done independently, and if you have such a desire, you can watch the video in this article.

Those who don’t have such a desire can simply buy a tandoor - and there are not only wood-burning stoves on sale, but also electric models.

- The centuries-old technology for creating this furnace has not undergone any significant changes - except that modern materials began to be used: fireclay bricks, steel wire and mesh, fire-resistant masonry mixtures. If the tandoor is intended only for baking lavash, it may have a horizontal axis.

Stationary brick tandoor

- But for universal use, only the vertical version is suitable. Earthen tandoors are probably used today only in Asia, but in our country mobile ovens have become very popular. After all, a tandoor is not only delicious food, its external design can become the main “highlight” of the interior of a summer kitchen.

Note! A factory-made portable tandoor may have an unusual shape and an interesting lid, forged rims and handles, a glazed coating, and a beautiful relief on the surface. It comes with skewers and a three-tier mesh for cooking vegetables or fish. This stove looks beautiful and is very convenient to use.

Mobile tandoor

So, a gazebo with a tandoor with your own hands is quite realistic for each of us. Next, you will be given instructions for building this stove, and all the nuances that need to be considered in order to place it inside the building will be discussed.

Brick tandoor for gazebo

If you want to build a stationary brick tandoor, first of all, you need to take care of a strong and reliable foundation. Since our article is about how to place a tandoor in a gazebo, we would like to draw your attention to the fact that when building it, you need to take into account the weight of the stove. Naturally, it depends on the size of the structure.

So:

- Let’s say it takes 57 bricks (3 rows of 19 pieces) to build a small tandoor with an internal diameter of 40 cm, if they are laid on a spoon, as shown in the picture below. By weight, it will be about two hundred kilograms, plus the weight of the supporting part and the solution. This is less than the weight of, for example, a barbecue oven, but still requires a certain strength of the base.

The base for the tandoor, and the first row of bricks with an opening for the blower

- All this must be provided for during the construction of the gazebo itself. If a monolithic slab foundation is being built under it, then there is nothing to worry about at all. In the place where the tandoor will be located, you can simply make a small podium out of brick, which will also serve as the bottom of the tandoor. Otherwise, you need to pour a low foundation, or lay it out of concrete blocks.

- Some customers prefer to bury the tandoor a little deeper into the ground. This is not difficult to do, you just need to provide for the depth of the depth in the process of arranging the floor of the gazebo. The brick for the foundation of the furnace can be ceramic or silicate, and for the construction of the walls - only fire-resistant (fireclay). The brick received this valuable property from fireclay clay, which is the main raw ingredient in its production.

Dry mixture for laying stoves

- Accordingly, this component is also present in masonry mixtures intended for the construction of furnaces. A solution of fireclay clay is also used to coat the walls of the tandoor. With masonry mortar, we think there is no need to “fence the garden”; one or two bags of a factory-prepared dry balanced mixture can be bought. The price for a bag weighing 25 kg varies between 200-250 rubles.

In this case, to make the solution you will not need to look for clean river sand, cement of the required brand, or check the clay for fat content. Before starting work on the construction of the furnace, it is necessary to prepare a steel grate for the bottom (grid bars), a door for the blower, and a rim for the neck. The manufacture of the lid can be done after the construction of the furnace.

Bottom structure and wall laying

In order for a tandoor to function normally, it, like any other oven, must have draft. This is provided by the ash pan, and the ash is removed through it. Therefore, after the foundation of the furnace is laid out, all attention must be paid to the correct arrangement of the bottom.

So:

- Before performing any actions, you need to draw a circle on the base along which the brick will be laid. You also need to mark the location of the blower channel. Then, the first row of bricks is laid out - it is not solid, but has an opening in the place where the blower door will be mounted. If the tandoor is large, then an opening can be made in the second row.

Laying tandoor walls according to a template

Advice! To build brick tandoor walls, it is best to use a template. It is not difficult to make, you just need to calculate the dimensions correctly. With its help, it will be easier for you to maintain the smooth shape of the stove body.

- A grate is mounted above the blower section - its diameter must correspond to the size of the furnace. In any case, as the work progresses, you must immediately coat the inside of each row of masonry with fireclay clay, and tie them around the outer perimeter with steel wire. Despite the fact that the bricks are laid at the ends, one should not forget about bandaging the seams.

- Considering that the tandoor has a rounded shape, tapering towards the neck, the bricks in each row will have to be cut in thickness, giving it a trapezoid shape. To understand how much to trim, the difference in diameters from below and above is divided by the number of rows of bricks, and also in half, since the narrowing occurs on both sides. If the brick is not trimmed, the stove will end up with a cylindrical rather than a round shape.

Laying the top row of the furnace

- Since the cut brick will be in an inclined position and rest on the template, each time you will have to wait until the mortar sets. Only after this can the template be moved further around the circle. The more the masonry narrows, the thicker the seams between the bricks are.

After all the rows are laid and tied with wire, they are covered for strength with a fine-mesh plaster mesh, which is welded to the metal neck. But if the construction was carried out according to a template, and the brick was cut correctly, such measures need not be taken. The outside of the tandoor can be immediately plastered with the same masonry mortar and lightly heated to dry the masonry. After this, the very next day you can cook in it.

Tandoor ovens

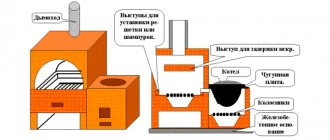

The best tandoor oven is made from a ready-made, purchased tandoor-hood in a brick shell with thermal insulation, which is also an additional heat accumulator. Its installation diagram is shown in Fig. The foundation is two rows of tongue-and-groove blocks (GGB) on a cement-sand mortar and a cushion of sand or crushed stone. Thermal insulation is the same crushed stone or vermiculite chips (more expensive, but better), mixed with clay oven mortar - “sour cream”. The masonry is made of ceramic bricks on cement-sand mortar (walls) and clay oven (under and at the foot).

And here’s another exotic option: tandoor-barbecue oven. True, only the name is derived from the tandoor: the authors of the design honestly warn that it is unsuitable for baking. However, this product has an undoubted advantage: a chimney, and it is suitable for installation not only outside, but also indoors. Therefore, it would make sense to lay out the firebox not in a cone, but like the brick tandoor described above.

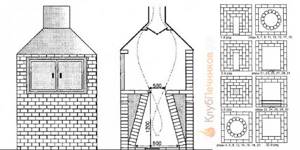

The drawing and order of the “tandoor-combi” are shown on the next page. rice. It requires a full-fledged stove foundation, so this work is not for beginners. The 31st row is reinforced with a sixty steel corner. Smoke collector - made of steel from 2 mm. Chimney diameter – from 250 mm.

Drawing and arrangement of tandoor-barbecue

And yet – clay!

Now we’ll tell you how to make a tandoor from clay yourself. They say that this method was invented by specialists from military chemical and bacteriological enterprises of the USSR. This extremely dangerous production was concentrated in Central Asia - away from the center, closer to the then potential enemies with a dense population and poor medicine.

Already in the 70s, the production of this nasty thing was completely stopped, enterprises were repurposed for agricultural chemicals, insecticides, and plant protection products. Specialists who served for 8 years (a year there was 2.5) received severance pay, which allowed them to immediately buy a cooperative apartment in a regional city and, if they wanted, to retire. Of course, they immediately pulled away from the terrible climate, deadly poison and plague at hand. But they missed tandoor dishes in new places.

The solution was found very simply: an ordinary cucumber or cabbage barrel. A very competent engineering solution: since the issue is uneven drying across the thickness of the material, it needs to be made uniform. Don't have an industrial drying chamber? We will ensure uniformity from the opposite: not by heating, but by moisture. Will the process take longer? For myself, it’s not scary.

The technology is as follows: wash the barrel and fill it with water. Let stand for 2 weeks until the wood swells completely. Then pour out the water and thoroughly coat the inside of the keg with vegetable oil. Flaxseed is best, but refined sunflower or corn will also work.

Next, we wrap the barrel tightly with rope, but so that it does not catch the hoops. We protect the coils from slipping with nails. Now we cut the hoops and remove them. We cut a hole in the bottom to the diameter of the mouth of the tandoor.

At this point, firstly, a temporary cushion must be ready, at least from bricks laid directly on the ground on dry ground. The oven solution, described above, with the consistency of plasticine, must also be prepared. Nowadays, there is no need to trample clay with your feet until exhaustion: a 1.5-2 kW hammer drill with a mixing attachment at low speeds will bring the solution to the desired homogeneity in an hour and a half.

Instead of wool, 25% by volume of fluffed asbestos was added to the solution for strength. You need to work with fibrous asbestos in the open air with full protection of the respiratory organs, eyes, face and body, but those men on demobilization also took gas masks with them with them, just in case.

The barrel was placed on a pillow, and the inside was coated with clay with a layer of 60-70 mm. Then they turned it upside down and placed it on 4-6 bricks so that there was a gap at the bottom. After 2 weeks, the harness was removed and they waited until the rivets began to fall off on their own. The last one fell off - it was dry enough to burn. The work began when the weather began to warm up in the spring: drying lasted for months.

Firing was carried out as the initial one described above. Upon completion, it was lined with clay without filler, like an Uzbek tandoor, dried again and finally fired. This method does not provide a 100% guarantee, but with some ingenuity and observation, 7-8 out of 10 pieces can be fired without problems.

Everything ingenious is simple. Making a gazebo with a tandoor with your own hands

Outdoor recreation and food cooked over a fire are practically synonymous. A good weekend at the dacha is when kebabs are grilled on the grill, and your closest people are sitting nearby. Of course, not everyone has a real brick barbecue at their dacha. People often use old iron structures as a barbecue, and place the cauldron on ordinary bricks. Of course, the food turns out to be edible. But not as tasty as if it was prepared using a tandoor.

There is an opinion that making a tandoor with your own hands is an unaffordable and too expensive luxury. The article will convince you otherwise. He will also tell you how to build a brick tandoor without the help of specialists. The result is that a real oriental oven will appear in your garden plot. In it you can prepare many delicious dishes.

Tandoor. Construction Features

The classic version of tandoor was invented in Central Asia. Fireproof clay is used as the main material. It is dried in the sun, after which it is fired on special saxaul firewood. It is not difficult to create such a regime in the Asian climate - the hot sun quickly evaporates moisture, the clay heats up to 60 degrees and above. Airborne dust becomes a reliable filter of UV rays. That is why in Asia a stationary tandoor dries quickly and without cracks. Even after annealing, the thick walls remain unharmed.

In mid-latitudes it is almost impossible to make clay tandyriz at a decent level. We don’t have the right humidity, we don’t have the ability to create the necessary light spectrum. When dried under normal conditions, the clay becomes covered with a crust, but remains permanently inside. Any attempts to burn her end in failure. Moisture comes to the surface, which leads to the formation of cracks. So, even with excellent fireclay clay, a gazebo with a tandoor “like in Asia” is an almost impossible task in our country.

This is one of the reasons why craftsmen prefer the closest relative of the tandoor - the Armenian tonir. In its design and characteristics, it resembles a classic oriental stove. But for construction it is not clay that is used, but fireclay brick. Thanks to the fairly thick walls, the heat is retained much longer. Setting up a tandoor in a gazebo is a much simpler, completely doable task. Masonry is not difficult, and all materials are available.

What materials will be needed?

Since we are not interested in a gazebo with a barbecue, but in a structure with a tandoor, we will need a variety of materials.

- The walls are made of refractory bricks. How many pieces should I take? It all depends on the wall of the tandoor and its thickness. Usually the quantity varies from 400 to 1200 pcs.

- Mortar - prepared from clay, pre-sifted sand. However, you can do it easier - purchase a heat-resistant composition.

- Coating - the outside of the finished stationary tandoor is coated with a solution; mosaic is used as an additional finishing material. If you plan to use a tandoor with a chimney to bake flatbreads, it is recommended to coat the inner surface with heat-resistant clay.

- What should the foundation be made of? Step one is to prepare a concrete solution, step two is to stock up on reinforced rods.

- Blower - as in the case of a barbecue, a gazebo with a tandoor should be equipped with a blower. It can be built from a pipe.

- The tandoor project is impossible without a wooden block, as well as boards for the template. Why can't you do without a template? Laying is usually done on it. And if there is no template, it is impossible to make a perfectly even circle, the upper vault.

Foundation for tandoor with photo. How to do it right?

It takes 3-4 weeks to build a tandoor. Why so long? It will take 10 to 14 days just for the foundation to harden. We recommend starting construction in early summer. Warm and sunny weather is optimal for work.

It is impossible to imagine building a tandoor without a reliable foundation. The need for laying is explained by soil movements. A strong foundation will help prevent the destruction of the masonry. Some people make it from a concrete slab, but it is best to pour concrete mortar into the ground according to the size of the stove.

Step-by-step guide to pouring a foundation

- Mark the rounded contours of the eastern stove.

- Remove the grass from the area in a circle. Some homeowners have sandy soil. In this case, it is enough to simply level it. When the soil is clayey or loamy, it is necessary to remove another 15 centimeters, and fill the resulting depression with sand, water it, and compact it.

- When areas are not damp and the ground resembles dry dust, it is possible to arrange the foundation flush with the ground.

To avoid stagnation of water, the foundation is raised by 10-15 centimeters, after which wooden formwork is made along the contour. - Lay reinforcement with a diameter of no more than 12 mm. The distance of one rod from another is 15-20 centimeters. It is best to lay them out in the form of a lattice and tie them with annealed wire.

- Pour concrete and then level the surface with a level and board. The top of the fill is sprinkled with cement, which makes it more water-resistant.

- Make a depression in the center.

- Cover with film and leave to dry.

Periodically moisten the top layer if it is too hot outside. - A mobile tandoor can be erected in about 2 weeks.

How to prepare a template for a gazebo with a tandoor?

While the foundation dries, work on the template. This is a kind of “skeleton” that will serve as a guide for your masonry and help you maintain the radius.

The most important condition is maintaining the distance between levels. It should be the same as the row height. The first brick is placed on the short edge to achieve a height of 26 cm. The first 2 rows will have a height of 52 centimeters, after which the narrowing of the arch can begin. The easiest way is to make a template from plywood or boards.

Tandoor laying step by step

The template is something that needs to be taken into account when creating a gazebo with an oriental stove or a tandoor separately. You can lay out the structure in Saturday-Sunday if you stock up on tools and materials in advance. You definitely won't be able to do without a grinder and a stone circle - you'll need it for trimming some bricks. Of course, you will need a trowel, a rubber hammer, 2 containers - for water, clay solution. You will find out why water is needed a little later.

- Mix a solution containing clay, sand, water, salt (1 tbsp per bucket). The consistency should be such that the solution rolls into a ball, and when dropped from 35-40 centimeters, it flattens, but does not crumble. However, you can simplify this process by purchasing a heat-resistant mixture.

- Place the first row on a narrow edge. Creating curves is easy. Make the inner radius with a minimum gap, and the outer radius wider.

- Each exposed brick is dipped in water, and the solution is applied from below, on the sides. Then they place it again and check it according to the template.

- To ensure that the process of preparing shashlik in a tandoor results in a cracked wall, the finished row is checked again and, if necessary, leveled. The clay solution dries for a long time - you have time to do everything smoothly and as efficiently as possible. On the outside, the seams are filled with mortar and embroidered.

- Laying the 2nd row is no different from the first. But to increase the strength of the structure, you can make a dressing by moving the bricks halfway. To create a blower, 2 bricks are sawn in half and a hole is left. You will need to install a pipe in it and secure it with a solution.

- The third row is one of the most responsible. In order for the tandoor at the dacha, a photo of which you can see on the website, to serve you for many years, it is important to make the structure as stable and reliable as possible. Since we are making a stationary and not a portable tandoor, the masonry of the walls is especially important. To give the structure a slope, all bricks are sawed at the bottom with a grinder.

- Since the diameter of the structure begins to decrease, the dressing will be incomplete. The shift relative to the previous row will be 1/3 of a brick.

- The final stage of masonry is drying the oven. But if it’s too hot outside, the masonry is moistened from time to time to prevent sudden drying out.

Furnace finishing, firing: key features

A self-built gazebo with a tandoor and barbecue will delight the owner and his guests. But there is one nuance that should also be remembered. The design has good thermal capacity, but you can improve it significantly. To do this, the tandoor is coated with a solution inside and out. Classic masonry mortar is used as a finishing material. It is kneaded to a “plasticine” consistency.

After heating, you can fire it. Hardwood wood is used as fuel. When they burn out, there will be a lot of coals left. Apple and cherry are especially good. They smolder for a long time, and after burning they do not crumble into ash.

After placing the first batch of firewood on 1/4 of the stove, you need to set it on fire and wait for coals to form. Then you can stack the next batch of firewood. The procedure is repeated until the tandoor is filled with coals to 2/3 of its volume. Then cover it with a lid and let it cool completely.

conclusions

A brick tandoor built at your dacha will replace your barbecue, barbecue, or even baking oven. Shish kebab cooked in a tandoor turns out extremely tasty. What can we say about fish, vegetables, and other dishes - cooking food in such a stove is a pleasure. The article considered the option of building a stationary-type eastern furnace. If you plan to build in a closed gazebo, you will need a tandoor hood. It is made according to the same principle as a hood for any other oven or barbecue.

Finally, I want to share a video that shows in detail the process of finishing a tandoor:

Source: https://probesedki.ru/besedki-dlya-dachi/stroim-besedke-s-tandirom.html