What to build a bathhouse from

It all depends on preferences and capabilities. A country bathhouse, for example, is light and cheap, but it can only be used during the season, so it is not suitable for a permanent home. I considered three options for a bathhouse for my home:

- From wooden beams

- From a log frame

- From foam blocks

A log house was immediately ruled out, given the complexity and high cost of construction.

Building a bathhouse from a foam block will cost less than from a wooden beam, but I had serious arguments in favor of wood. I will give them briefly:

- The house itself is wooden, so a foam block bathhouse would look inharmonious next to it.

- Ecologically, a bathhouse made of timber is much preferable to a stone one.

- In our area there are no problems with natural wood (pine) for construction, and its price is quite reasonable.

Having estimated the cost of construction, I was convinced that I could financially handle a bathhouse made of timber.

Examples of country baths

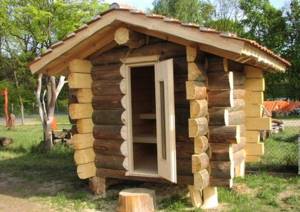

In photo No. 1 we see a simple bathhouse, reminiscent of Diogenes’ barrel. You can only take a steam bath in it. You won't be able to wash yourself here because there is no sewage system in the building. However, if desired, it is not difficult to do. To do this, you need to install a standard shower tray in the corner of the bathhouse and lead the drain pipe into the septic tank.

Photo No. 1 Build such a “barrel sauna” at your dacha and steam to your heart’s content

An important advantage of this design is its low weight, allowing it to be placed on a plank terrace.

The construction of the simplest bathhouse from the container category is shown in photo No. 2.

Photo No. 2 Option for a container country bath

It consists of one steam room. For washing, the owner needs to attach a canopy with a summer shower or add a sewerage system to the room, and the stove - a tank for heating water.

Photo No. 3

Improvising on the theme of a barrel-shaped bath, let's turn our attention to cellular polycarbonate. You can quickly and easily assemble an original design from it. In order for it to retain heat well, you will need two large sheets of this material and a frame made of metal or wooden blocks. A mineral wool insulation 10 cm thick is laid between them.

Photo No. 4

The ends of the building can be made from boards, stuffed onto an insulated wooden frame. Place such a bathhouse anywhere: at your dacha, on a polar ice floe or on the top of Everest and you will always be comfortable in its steam room (photo No. 5).

Photo No. 5 Simple barrel-shaped bathhouse

A small Russian bathhouse, made from scraps of timber, can be installed on oak posts. We see an example of such a structure in photograph No. 6.

Photo No. 6 Oak posts are an excellent support for a small wooden bathhouse

Larger structures require their own foundation. There are three possible options here:

- Rubble concrete tape.

- Brick columns.

- Piles made of asbestos cement pipes.

Do not forget that the type of foundation affects the choice of material and wall design. Pile and columnar foundations are used to install a wooden frame, as well as for bathhouses made of timber or logs (photos No. 7 and No. 8).

Photo No. 7 Bathhouse made of SIP panels on screw piles

Photo No. 8 Brick columns - the best option for timber, log and frame structures

The “tape” of rubble concrete is suitable for any walls (made of gas silicate blocks, logs and frames).

Photo No. 9

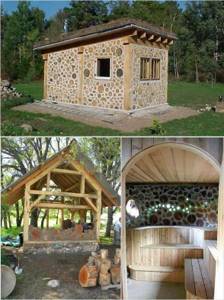

A cheap, reliable and simple version of a bathhouse is obtained using a technology called “clay mortar”. For such a structure you will need little: a truck of firewood, a cart of straw and a dump truck of clay (photo No. 10).

Photo No. 10

The best shape for a wood burning structure is round. It eliminates the need to reinforce masonry corners and looks aesthetically pleasing and original.

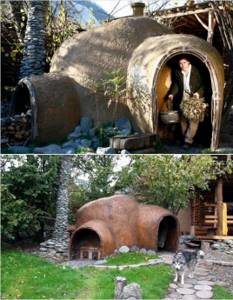

By borrowing from birds the technology of building nests from branches and clay, you can build such a simple and warm bathhouse (photo No. 11).

Photo No. 11 Wicker frame coated with clay - “know-how” of an inexpensive bathhouse design

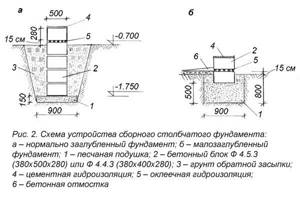

Which foundation for a bathhouse is better?

I considered the following types of foundations for a bathhouse:

- Columnar

- Pile

- Block tape

- Filling tape

Brief characteristics and prices of each type

- Columnar foundations are the cheapest. Cement blocks 20x20x40 cm (4 blocks for each support, 48 blocks in total) with a pitch of 2.0 m along the perimeter of the future structure will cost only 2,500 rubles. Taking into account an additional 1.5 tons of sand and cement, we get a total amount of about 5,000 rubles. This is where the advantages of such a foundation end. For its construction and reliable operation, stable sandy soils without winter swelling of the soil are required. Only in this case will the foundation be stable, and the bathhouse will not “move” in the spring. We also do not forget about the need for additional floor insulation, because... The bathhouse hangs on foundation pillars. Waterproofing the floor insulation is also necessary, since there is a lot of water in the bathhouse. Additional costs, as we see, cannot be avoided.

- Pile foundations are used in places with complex relief and geological conditions. Swampy soils, slopes, unstable soils - these are the reasons for constructing such foundations. Their cost is quite comparable with tape ones, which will be discussed further. Given the calm construction conditions, I did not consider this type of foundation.

- Block strip foundation is used, perhaps, most often. Its use is explained by its relative cheapness (for a 4x4 m bathhouse, the cost of installing a block foundation will be only 8,000–9,000 rubles). In this case, it will no longer be necessary to insulate the floors, i.e. an important expense item is eliminated. Perhaps the only difficulty in construction is that such foundations are not easy to build alone - you need at least two people.

- My option is a poured strip foundation. It is most convenient for building a bathhouse. The advantages are obvious: such a foundation is quite strong and durable, inexpensive, and quickly and easily constructed without special tools and equipment. Formwork and reinforcing mesh are installed in the dug trench, which is filled with monolithic concrete. The cross-section of the reinforced monolithic foundation in formwork is 40×60 cm, the length is along the perimeter of the building. The cost of a foundation for a 4x4 m bathhouse is about 8,000 rubles.

Options for mini-baths for a summer residence

If there is not a lot of space on the territory of your summer cottage for the construction of a massive bathhouse, there is no need to despair.

Horizontal barrel

Initially, such structures were assembled independently, but now you can buy a ready-made barrel sauna. Advantages:

- construction without building a foundation;

- small dimensions;

- quick heating of the steam room to the required temperature;

- mobility.

More often, the internal space is divided into two rooms - a steam room and a locker room. An electric heater is installed inside the steam room. For ablution, a summer shower is installed outside.

Vertical barrel

It is a steam room containing a stove (wood or electric) and shelves. There is no separate room for a changing room or shower.

Vertical barrel sauna (Source: pinterest.ru)

Caravan

Previously, people independently converted construction trailers into bathhouses. Now such designs can be bought ready-made. The internal space in the finished baths is divided into three rooms - a steam room, a washing room, and a dressing room. The steam room is equipped with an electric or wood-burning stove. Advantages:

- compactness;

- Possibility of use for simultaneous visits by 2–3 people;

- lack of foundation;

- mobility.

To begin bathing procedures, it is enough to install the trailer on concrete blocks, connect the electricity, and the water supply to the shower.

Polycarbonate construction

If the construction of a full-fledged bathhouse is delayed, and there are not enough bathing procedures, you can assemble a temporary bathhouse from polycarbonate. Externally, the steam room resembles a semicircular greenhouse. Such structures cannot be used for a long time, since polycarbonate is deformed at high temperatures.

Anyone can build a bathhouse in their country house. There are different options for constructing such buildings. The most important thing is that the building is located in accordance with the law. Otherwise, the owner may be fined.

How to build a cheap sauna at your dacha with your own hands

I simplified the construction of the bathhouse as much as possible using project-marked beams. If you are planning to build a bathhouse yourself, then nothing could be simpler than assembling such a “constructor”.

The construction process looks like this

1. Laying the first crown is carried out strictly horizontally - don’t be too lazy to check this with a level. The beam of the first crown should have a maximum cross-section (for structures with self-made beams, this is usually 20x20 cm, the next 15x15 cm).

2. The crowns are laid strictly in order and fastened together with wooden dowels or metal pins. There are different options for fastenings in timber bathhouse projects, and all of them are quite reliable. The main thing is not to allow amateur activities here.

3. Inter-crown insulation of walls is made with moss, tow or jute. It is preferable to use jute, since after laying it, the gaps between the beams will not have to be caulked with tow.

4. Installation of a gable roof (my case) - the next stage of construction, which includes the installation of a truss structure and a deck with sheathing and a layer of waterproofing. Shed roofs are used, as a rule, in cases where the bathhouse is adjacent to the house. Complex roofs with multiple kinks of more than two slopes are usually not used in the construction of baths. The under-roof attic space can be used for storing things, etc. The roof structure is supported by wooden ceiling beams, which are placed in special notches in the upper crowns. The size of the cutting should ensure that the beam fits tightly into the crown beam.

5. The construction of window and door openings is carried out after a six-month shrinkage of the bathhouse, which necessarily includes the winter period. Openings for windows and doors are cut with a chainsaw.

6. Internal finishing work is also done after natural shrinkage.

7. The final stage of construction is a blind area around the perimeter, the main purpose of which is to protect the lower beams from dampness.

Construction of a small frame economy bathhouse at the dacha

Let's start with the base of the bathhouse - the foundation. Since the bathhouse will be small and relatively light, there will be no need to pour a monolithic slab or make a buried reinforced tape. For a one-story bathhouse, a columnar foundation made of blocks or asbestos pipes with concrete poured into them is sufficient.

Stage 1. Marking

This stage is required for any type of construction. We choose a place on the site where the bathhouse will be located.

Take 4 pegs and a plumb line. We drive the first stake into the soil strictly vertically, that is, we mark the first corner of the house. From this point we set aside the length of one of the walls and drive in a second stake. We tie both pegs with a cord.

We place the third and fourth stakes in the same way. We check the equality of the marking diagonals and, if necessary, adjust the stakes and cord.

We also use a cord to mark the places where the interior partitions will be located.

We arm ourselves with a shovel and remove the top layer of soil along with the grass inside the cast-off. We level the bottom of the resulting base horizontally and compact it.

Video - Marking the foundation

Stage 2. Foundation

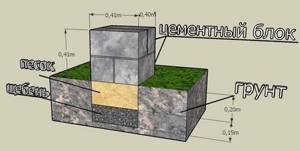

Let's consider the option of arranging a columnar foundation made of concrete blocks measuring 20*20*40 cm. Their price ranges from 45 to 60 rubles per 1 piece. You can use ordinary bricks (13-16 rubles per piece), including used ones.

Columnar foundation made of concrete blocks

We take a drill or a shovel and start digging holes measuring 50x50 cm for blocks or 35x35 cm for bricks. The distance between the holes is no more than 2 m, the depth of each is approximately half a meter. The holes should be located in the corners of the house, under load-bearing walls and interior partitions.

To install foundation pillars, dig holes of the required depth with slopes

We tamp the bottom of each hole, fill it with a layer of sand and crushed stone (each layer up to 10 cm) and repeat the compaction process again.

Fill the crushed stone with liquid cement laitance. We stick one steel rod strictly vertically into the center of each hole.

We lay out bricks or blocks around the rod, 2 pieces at a time. in every row.

The posts should rise 20-30 cm above the soil. We check the horizontalness of the entire base by pulling the rope and using a bubble level. If necessary, we compensate for unevenness with a layer of cement mortar.

Columnar block foundation

We cover each column with a piece of roofing felt.

Stage 3. Economy bath frame

For the frame, you can use timber 100*100 cm or 150*150 cm. There is no need to skimp on load-bearing elements. It is also advisable to impregnate the wood with a fire-retardant composition.

The lower harness consists of 4 beams.

Columnar foundation with bottom frame

Columnar foundation with bottom trim, diagram and explanations

Connecting corners using the “claw” or “half-tree” method.

We cut threads on the reinforcing bars protruding from the corner posts (the pins on the intermediate posts can be cut off). We drill holes at the ends of the beams for these pins. We cut out the ends of the beams according to the diagram shown.

We assemble the lower harness by putting the bars on the pins. Tighten the nuts and locknuts from above.

Next, we assemble the wall frame. Using perforated fasteners (angles), we fix the vertical beams to the bottom frame.

Between the vertical beams we nail or fasten with self-tapping screws horizontal jumpers from a 50x50 mm bar. We strengthen the corner posts with jibs made of 50x100 mm boards.

All that remains is to make the top trim. To do this, we use a 50 mm thick board, which we screw to the ends of the vertical beams with long wood screws.

This is how the corners of the frame bath were designed

The bars of the top trim are joined exactly above the wall stud. In the photo the frame is already insulated with foam plastic

Prices for wooden beams

Stage 4. Gender

Let's look at an example of arranging a leak-proof floor in a bathhouse. In order not to waste time cutting lumber, we take fastening perforated corners, self-tapping screws and assemble the floor joists. We place boards 50x100 cm between the beams of the lower frame on the edge, maintaining a distance between the logs of 40-45 cm.

Assembling the floor from the board in the “on edge” position for greater rigidity

Installation of subfloor

The floor joists can be covered with OSB-3 sheets (approximately 480-550 rubles per sheet 1250x2500 mm and 9 mm thick) or use the same wooden boards from which the joists are made. A hole must be provided in the subfloor for installing a drain from a washing room or steam room.

Installation of subfloor

Be sure to stretch Izospan or other vapor barrier film under the wooden subfloor.

To insulate the floor, we again attach logs on top of the subfloor, between which we lay expanded clay, sawdust or red moss, cover the entire “pie” with waterproofing film and assemble the finished floor from boards or moisture-resistant plywood (from 260 rubles for a sheet of 4 grades measuring 1525x1525 mm and 4 mm thick). The use of polystyrene foam as insulation, including packaging, is possible only in the dressing room.

An example of floor insulation with packaging foam

Prices for Izospan

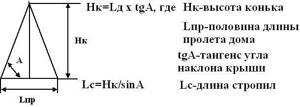

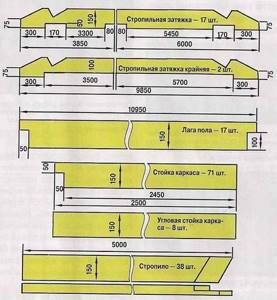

Stage 5. Roof

Before making the roof, we assemble the top floor (ceiling). We use the same fasteners and boards that were used when installing the floor joists.

It is better to make a gable roof for a frame economy bath. It will make the bathhouse more attractive in appearance, and the space under the roof can easily be converted into a sleeping area or a storage area for brooms. On the other hand, a lean-to structure will require less materials.

Example of roof slope calculation

Templates for cutting rafters, racks, floor joists

Table. Types of roofs, diagrams

| Roof type illustration | Advantages | Description |

| Flat or single slope Rafter system of a pitched roof Slope angle of a pitched roof Scheme of the rafter system of a pitched roof | Saving of materials, ease of assembly, ability to use the roof. | For baths up to 6 meters wide, it is permissible to arrange flat roofs with a slope of 10-25 degrees and sloping rafters. The ceiling is made from coniferous bars from 100x100 to 150x200 mm. The laying step is from 40 cm to 1 m. On top of the beams, a continuous, gap-free lathing is assembled from edged boards or OSB, then a lathing for insulation is installed - expanded clay with a layer of 10 cm, mineral wool or polystyrene foam. Several layers of roofing material or other moisture-proof material are laid on top of the insulation. The roof itself can be made from corrugated sheets, antiseptic-treated boards, etc. |

| Gable. Suitable for baths with an area >12 sq.m. Gable roof design Gable roof units | Possibility of using the attic for household purposes or for overnight accommodation. The roof is stable and durable | The roof angle is selected from 30 to 45 degrees depending on the type of terrain. To install such a roof, the top trim and the Mauerlat must be made of timber. Rafter trusses are isosceles triangles with a jumper between the ribs (crossbar). The rafters rest on the Mauerlat and can hang a maximum of half a meter. The rafters are cut according to a template and assembled into trusses using metal fasteners and long self-tapping screws. The outer trusses on the gables are attached first, followed by the remaining rafters at intervals of up to one and a half meters. A sheathing of slats or boards is placed on top of the rafters, a vapor barrier is stretched, after which the roofing material, for example, corrugated sheets, is secured. |

Video – Roof construction

Stage 6. Interior and exterior decoration

Table. Brief description of the stages of insulation, insulation and finishing of an economy bath

Attaching the insulation from the outside

| Work order | Scheme | Description |

| Attaching the insulation from the outside | Polystyrene foam will provide the walls of the bathhouse with additional rigidity and retain heat. For installation we use polyurethane foam and PSB-S-15. We cut out pieces of foam plastic according to the distance between the frame posts, insert foam plastic between them, and foam the cracks. It is recommended to cut out the foam 0.5-1 cm larger in size than the existing openings to avoid gaps. | |

| Lathing for insulation inside | Lathing for insulation inside | We use 2x5 cm slats. We fasten them horizontally. Fixation is carried out using wood screws. We take the distance between the slats equal to the width of the insulation. |

| Insulation of a bathhouse from the inside | Insulation of a bathhouse from the inside | We lay mineral wool slabs between the lathing slats. We stretch a polypropylene cord over the mats and secure it with small nails or a stapler. |

| Bathhouse cladding outside | Bathhouse cladding outside | The outside of the bathhouse can be covered with OSB-3 sheets, which can then be plastered or painted. Finishing with unedged boards or siding would also be an acceptable option. |

| Vapor barrier and wind protection | Vapor barrier and wind protection | On the outside of the bath, under the layer of finishing material, we attach an overlapping windproof film (you can use glassine). On the inside of the walls and ceiling we stretch foil vapor barrier with a thickness of 80 microns. We fix the overlaps of the strips with metallized tape. |

| Internal lining | The traditional material for interior decoration is lining. Economy option - aspen. It is better not to use pine lining in a steam room. In the dressing room, the walls can be covered with PVC panels or moisture-resistant plasterboard , and then painted. | |

| External skin | Many interesting materials are used as external cladding, such as shingles or shingles. These are thin wooden planks that are fastened with nails to the walls, and the rows are fixed with a slight overlap (top to bottom). An environmentally friendly and economical solution. |

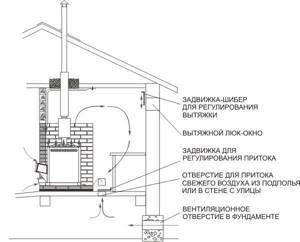

Stage 7. Ventilation

An economy bathhouse is probably a compact room, but this does not exclude the need for ventilation.

The hole for air flow is traditionally installed near the heater, closer to the floor, and the installation of the ventilation valve is carried out simultaneously with insulation and finishing of the walls. The air flow from the supply ventilation duct must reach the heating element of the oven. It is especially important to arrange effective ventilation if the firebox door does not open into the dressing room, but into the steam room.

The exhaust vent should be located closer to the ceiling. The hood must be equipped with a damper. The air is exhausted through a ventilation pipe to the roof; the head of the pipe is covered with an insect net.

Exhaust hood in the steam room

Natural ventilation can be organized through a small window located at a height of 185 cm above the floor level. Ventilation will occur with the windows and doors of the premises open.

Video - Ventilation in the bathhouse

Prices for bath fans

Stage 8. Equipping the bathhouse

Having assembled a bathhouse with your own hands, make a metal stove with a heat exchanger and an external water tank. The main thing is to lay asbestos cardboard on the floor and wall behind the stove during installation, and cover it with a steel sheet to prevent spontaneous combustion of wooden surfaces.

It is not necessary to calculate the load on the floor and rafters for a single metal stove; a floor structure made of 150x50 mm joists in increments of 45-50 cm and a 5 cm thick floorboard will perfectly withstand a heater.

Electrical wiring in the bathhouse is laid either before the finishing of the walls (hidden type) or after (external). Lamps and sockets are purchased and installed that are strictly moisture-proof, class higher than IP 54. Installation of a separate electrical panel and protection of all cables from moisture is required.

Prices for asbestos cardboard

How much does it cost to build a bathhouse?

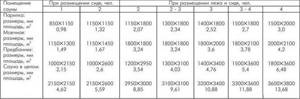

The cost of a bath will depend on many components. In the most general figures, I will give the cost per square meter of the baths discussed in the article. The prices shown can only serve as an indication of the approximate cost of various materials.

Log baths

A turnkey log bathhouse is the most expensive pleasure. The undoubted advantage of such baths is a huge selection of designs and ready-made structures for assembly. Specialized companies offer baths designed for different tastes and capabilities. Prices for a log bathhouse range from 11–17 thousand rubles per 1 sq. m. m area. The area of such baths is from 16 to 150 sq.m. Given the crisis, manufacturers often make serious discounts. When choosing such baths, I recommend that, in addition to prices, you pay attention to the installation team’s strict adherence to the standards and requirements during assembly.

Foam block baths

The main advantage of a foam block bathhouse over a log bathhouse is the ability to build it yourself. Of course, the price largely depends on the architecture, area, type of foundation, roofing, finishing, etc. The minimum prices for the construction of such turnkey baths start from 10 and reach 30-40 thousand rubles per sq. m. m. Building a bathhouse from foam blocks with your own hands will reduce the cost of such a bathhouse by at least half. Thus, the cost per square meter will be from 5–6 thousand rubles per square meter.

Baths made of timber

From my own experience in building a bathhouse from timber, I can draw the following conclusions about the cost. Construction of a turnkey bathhouse with the involvement of a team of installers will cost approximately 10–13 thousand rubles per sq.m. Self-construction will allow you to count on at least 6–7 thousand rubles.

Economy bath project

Having looked at the prices for materials, you will notice that it is more profitable to build a bathhouse from blocks or using Canadian technology. Moreover, the latter will be more profitable if some of the materials are used or low-grade (for example, instead of an edged board, you can use an unedged one, adding color to a country bathhouse). More accurate data on material consumption can be obtained after drawing up a project and estimate.

Before starting construction, it is extremely important to think through the design of the bathhouse, calculate the amount of materials, note all dimensions and at the same time plan not only the location of the premises, but also the furniture in them.

The main room in any, even the smallest bathhouse is the steam room. There must be two or three floors of shelves and a heater. Even if the dacha plot is small, and the bathhouse is planned to be very modest, the steam room cannot be made with an area of 3-4 square meters based on the simultaneous stay of two people (visitors should be comfortable steaming with brooms, sitting and lying on the shelves at full height). Such standards are determined by safety considerations (in a very cramped steam room it is easy to get burned on a hot stove or scald your skin with hot steam).

Also, if the entire stove is located entirely in the steam room and fuel is loaded from the same room, it is worth increasing the usable area of the room by another 1-2 meters to make it convenient to store and add firewood to the firebox. Directly in front of the stove, a pre-furnace sheet measuring 1x1 m must be laid, which is also noted on the plan diagram of the future bathhouse.

The bathhouse certainly includes water treatments, so you should think about a small shower located in a separate room or adjacent to the steam room. The second option, when the steam room and washing room are combined, allows you to save space and reduce the cost of installing sewer drains and interior partitions.

Bathroom layout

The last important room of the bathhouse is the dressing room or dressing room. There should be benches and hangers for visitors, a cabinet for bath accessories, and possibly a small table. It is also possible and preferable to have the heater located in the steam room, and the loading door opens into the dressing room, which allows you to save on heating.

The photo shows a small dressing room with a slatted wooden floor

In an economy bath you can do without:

But you won’t be able to do without electricity and sewerage, so it is advisable to order or build a septic tank/cesspool/drainage pit, as well as extend a power line to the site where the bathhouse is being built, because steaming by candlelight is very inconvenient.

Be sure to indicate on the plan diagram:

Below are several projects of small one-story country baths.

Video - Designing a bathhouse

Video - Bathhouse project. Compilation

What else you need to know before construction

Building a bathhouse on your own is quite possible, but it is not as simple as it may seem to an inexperienced developer. The special operating conditions of the bathhouse place increased demands on materials and quality of work. A timber, for example, must have ideal geometry and a smooth surface; it cannot have chips, deep cracks, or a large number of knots. The color of the material is natural, without “blue” indicating fungal damage.

Working with natural insulation materials requires special skills; roofing structures are quite complex to construct. If you do not have experience in self-construction, I recommend turning to professionals, of whom there is no shortage. Many companies and private owners offer turnkey construction of bathhouses. Before choosing a contractor, take an interest in his track record, take the time to look at the bathhouses he built, and talk to the owners.

If you are confident in your abilities and rely only on yourself, I wish you success! And enjoy your steam in the sauna you built with your own hands!

Advantages and disadvantages of frame baths

Frame steam rooms are of incredible interest due to their undoubted advantages over other structures:

- Construction time - building a frame bathhouse will take 3 times less time than a timber bathhouse (and even more so made of bricks), installation (along with insulation and finishing) will take from 20 to 40 days (it all depends on the complexity of the work) and can be at any time of the year.

- Cost-effective – the price per square meter is less due to low labor costs and the price of materials (starts at 5,000 rubles).

- Operation - the bathhouse can be used for its intended purpose immediately after construction is completed.

- Thermal insulation - a frame bath will quickly heat up and retains heat perfectly in any season.

- Reliability is the service life of a structure built without technological errors, which will be 10-20 years.

- Ecology - a bathhouse can maintain a pleasant microclimate, and it is also completely safe for human health.

Features of frame bath projects include:

The foundation is lightweight - the finished structure is light in weight, since it requires 1.5-2 times less wood than structures made of logs or timber, and this makes it possible to use a shallow or columnar foundation.- Insulation material - a well-chosen insulation will contribute to energy saving, and frame baths retain heat no worse than timber ones.

- Architecture - technological features make it possible to create a variety of façade and planning solutions (with an attic or veranda).

- Placement - such a bathhouse can be placed even in problem areas (with high groundwater levels, even in areas of flooding).

The negative ones include:

- Expenses on finishing and insulation - they make up a significant part of the price of the structure, but in no case should you save on them. Inexpensive mineral wool does not provide high-quality insulation, and polystyrene foam is a fire hazard.

- Shrinkage - this process can last up to 2 years (if wood with natural moisture was used during construction), and there is a high probability of damage to the finish (decorative panels or plaster). Wood with chamber drying has almost imperceptible shrinkage, but its use will be much more expensive.

Below is a frame bathhouse, and it is a modern interpretation of a conventional building.